Tech Authority

advertisement

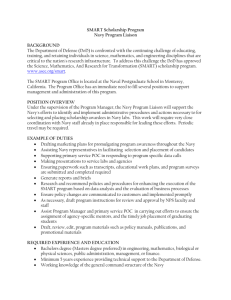

RDML McCoy (NAVSEA 05, Navy’s Chief Engineer) Presentation to Shipyard Engineers on Technical Authority (15 Sep 06) - - There are many challenges facing the Navy today, but he wanted to keep the brief upbeat. On balance, shipyard engineers are doing a very good job. You have to really love what you do to come to work every day in a naval shipyard. He has tremendous respect for what shipyard and NAVSEA engineers do. Technical authority is Job One for NAVSEA o He has been given $300 million by the CNO to improve and refine the state of technical authority across the Navy. Possibly some can be used for Virginia class. o He used to think that technical authority was having the right person making the decision, but it includes stewardship of people (since they are the ones making the decisions): education, skills, training, development and tools and processes as well. The average age of the Navy’s industrial and technical processes is fourteen years. There has not been the money or the time to doing much updating, but we are getting ready to build significantly different combatants (such as the all aluminum hull LCS). Are we ready? How much do we know about the processes and materials that will be needed to support them? There are twenty-seven or twenty-eight ship designs or studies going on right now, some of which include radical new technologies. Should our next generation amphibious ships or surface combatants be nuclear powered? The DDG 1000 will have integrated electric drive. o His job as NAVSEA Chief Engineer is to preside over and nurture the technical authority pyramid. The Navy has 162 officially designated technical warrant holders for ship systems. The warrant holders are formally designated and must pass a series of oral boards. NAVSEA has a process for assessing the health of each warrant (a dashboard that assesses the education of the holders, the capacity of the warrant, and demographics (age of those holding the warrant) among other factors). The process rolls up to a Red, Yellow, or Green assessment for each warrant. The desired outcome is no reds, obviously. For further reading, see: From the Top — Technical Authority, by Captain Larry Baun, Wavelengths Online, July 21, 2004 (in this document or on the web). Technical Authority—Making Sure the Right People Fit the Right Job, by Jack Templeton and William Palmer, Wavelengths Online, July 21, 2004 (in this document or on the web). Human Capital Digital Dashboard – NAVSEA’s Future Method of Measuring Community Health, by Matthew Tropiano Jr., Defense AT&L: November-December 2005 1 - Reserve Engineering Duty Officer Alignment with NAVSEA Technical Authority, by LCDR Mark McLean, NAVSEA DET 109, 14 February 2006. NASA/Navy Benchmarking Exchange (NNBE) Volume II, Progress Report, Naval Reactors Safety Assurance, July 15, 2003 This is partial documentation of the collaboration and comparison NASA and the Navy did started by Sean O’Keefe’s, NASA Administrator at the time and former Secretary of the Navy. Pages 23-24 document the theory behind the problem hierarchy triangle used by Naval Reactors. We need to give some thought to the NAVSEA 05 Red Lines o God bless Ronald Reagan for embarking on an expansion of the Navy in the 80s, but today we are at 282 ships and they are aging. We want to build enough ships to have 313 ships. This will require us to build 200 ships over the next twenty years. [At this point, he covered similar data to what he brought up in the talk to Engineering Duty Officers about shipbuilding budgets, DoD and Navy shares of the discretionary budget, and personnel costs.] o You are only as good an engineer as your last technical decision and we have made some poor technical decisions in the recent past. USS Dolphin (AGSS 555) Flooding and abandonment at sea. The Navy kept operating the ship with problems and should not have lived with so many. The ship was commissioned in 1968. It is home ported at the Naval Research and Development (NRaD) facility in San Diego, and is the Navy's only operational, dieselelectric, deep-diving, research and development submarine. On 21 May 2002, at about 1130 PDT, while operating approximately 100 miles off the coast of San Diego, California, Dolphin was cruising on the surface, recharging its batteries, when a torpedo shield door gasket failed, and the boat began to flood. Due to high winds and 10- to 11foot swells in the ocean, approximately 70 to 85 tons of seawater entered the ship, an amount perilously close to the boat's reserve buoyancy. The flooding shorted electrical panels and started fires. After 90 minutes, Commander Stephen Kelety, Dolphin's commanding officer, ordered the crew of 41 and two civilian Navy employees to abandon ship. The Oceanographic Research ship McGaw was operating in the vicinity and immediately responded. The fire and flooding was beyond the ability of the crew to control so they were evacuated by small boat to McGaw after the submarine hatches had been secured. All crewmembers were safely recovered with only a few minor injuries. Two crewmembers were recovered from the water 2 by United States Coast Guard helicopter during the transfer. McGaw transported the crew to San Diego. The last time an American submarine caught fire and was abandoned was in 1988, when the diesel sub Bonefish lost three sailors in a battery compartment fire. Dolphin underwent three and a half years of repairs and upgrades at a cost of $50 million, then completed sea-trials during the summer of 2005 and returned to her duties for one year. In mid-2006, the Navy decided to retire Dolphin, citing the $18 million her operations cost annually. She is scheduled to be inactivated on 22 September 2006 and decommissioned in January 2007. Curtailment of aviation capability for the USS John F. Kennedy (CV 67). NAVSEA had to condemn the arresting gear since the foundations of the equipment had deteriorated beyond their yield strength for a hard landing. We knew this problem was coming, but no one “threw the penalty flag.” Two FFGs in Mayport had uncontrolled flooding due to needle guns penetrating the hull. This was followed by having to take an FFG off deployment for the same problem. This was three ships in a row and no one got excited prior to this about the looming problem. We finally had to take 60 days to inspect the 31 remaining ships of the class. 23-24 had significant problems with their hull integrity. USS Leyte Gulf (CG 55) had to be taken off-line since its hull was deflecting so badly that some thought it might suffer from a fatigue failure. Inspections revealed that all hull structural support in the affected area had corroded away. There may be other examples of not taking the correct action in the midst of a deteriorating condition. We have to assume that NAVSEA is the last line of defense in these situations. No one else is going to backstop us. The USS Ohio (SSGN 726) was heading for an on time conversion delivery, but when it came time to certify the ship, Electric Boat “forgot” to do the hull Non-destructive tests. Everyone was so disappointed about the impact on delivery and so focused on cost and schedule that they requested to defer the inspections. o When a ship’s crew goes to sea, they should never have to worry about the hull. There are certain things that we are not going to tolerate in the program and missed hull weld NDTs are one of them. RDML McCoy does not “give up” hull structure or stability. There was no push back when he made the decision to do the hull weld NDTs on USS Ohio (just like the situation on JFK). The fleet 3 - may not like it, but they will respect us when we identify the red line. The people who made the above decisions are not bad people. We are all operating in a resource-constrained environment, but NAVSEA’s technical warrant holders have the authority, responsibility, and accountability for making the right decisions. Making risk informed technical decisions o NAVSEA 05 engineers have the responsibility and authority to provide risk-based options to the fleet, but need to do a better job than they are now of doing so. o Example 1: The fleet asked if the ten-year docking of the USS Mahan (DDG 72), based in Norfolk, could be extended to twelve years. Motivations for the request were the feeling that the ship repair contracting was going to charge too much for the work and there was a desire to incorporate some structural upgrades into the availability that would not be ready in time for this docking. Engineers looked at the data they had. Shafting became the limiting component and there was no data for shaft performance beyond eight to ten years so the engineers at NAVSEA said do, the docking could not be extended. RDML McCoy’s belief is that if all NAVSEA can do is look at the “book” and read it to people, the Navy does not need engineers at NAVSEA. Just hire someone to read the “book” to us. The real tasking was this: the fleet wanted to know what the requirements were and what the pros and cons were for extending the docking interval so RDML directed the engineers to take another look at the problem. If shafts are the limiting component and you do not repair/replace them at the desired periodicity, what is the worst that can happen? The shafts could break, but it seems unlikely that two would break at the same time and the ship is a dual shaft ship so it probably would not be stranded (Soule – although you might want to consider operational restrictions for heavy weather). The worst time for a shaft to fail might be maneuvering in port and an unexpected shaft repair at another inconvenient time might affect the ship’s deployment (either could not go on time or would have to curtail an ongoing one). Since it appear inconceivable that a shafting casualty would sink the ship (Soule – again, you may have to consider heavy weather operations) or kill someone, the impact to ship’s operations is more of a fleet commander decision than one for NAVSEA (Soule – the decision process gets a bit more complicated for nuclear powered ships given the high profile of anything that happens to them, that is why NAVSEA 08’s decision process will probably include different factors). 4 Once NAVSEA presents what is known and what its engineers believe the risks to be, we have to be willing to ask the fleet what risk level they are willing to accept. We cannot guarantee the assessment without more reliable data, but this appears to be worst case and what we think the risk is. o Example 2: The bow sonar dome boot of the new USS Virginia (SSN 774) was delaminating and starting to come off in November 2005. Post Shakedown Availability (PSA) was scheduled for Feb 06 and no drydock was available before then. The operators asked “What are the repair options? Can we defer the repair or do a temporary repair and operate the ship until PSA?” The technically acceptable risk-based approach would be to consider worst case. The worst case in this situation would be that the sonar dome falls off or the boot fails completely. In the former case, no one would die and the ship would not sink. In the latter case, it would add $3 million to the repairs in PSA. NAVSEA recommended a temporary repair (lag bolts for a sling/straps around the boot) with speed and depth operational limits. o Example 3: An LSD in San Diego wanted to defer its docking for four to five months to finish important training, but it had significant hull cracking in the bow structure. NAVSEA recommended a temporary repair, operational limits, and periodic monitoring in order to extend the drydocking date. o Example 4: The City of Corpus Christie has high solids paint delaminating from the torpedo tube impulse tank. Full blast and paint appears to be a schedule “buster” that will preclude finishing the ship before 22 Dec. NAVSEA’s technical answer is to full blast and paint the tank. This is why the fleet has the impression that NAVSEA “just does not get it.” The shipyard’s engineers (RDML McCoy made it clear at this point he was only talking to non-nuclear engineers at this point since he has no authority for nuclear engineering) have dealt with nuclear power and submarines their entire careers. He sees people struggle with making the right technical call every day. RDML McCoy noted that he has been what Engineering Duty Officers call a “pump kicker” (i.e., doing fleet maintenance in depot facilities) his entire career (having served in Charleston, Mare Island, Norfolk, Portsmouth, and Puget Sound) and he never imagined he would have cognizance over all manner of ship design issues to reduce costs. Every day engineers at NAVSEA are involved in taking things off ships that we have always had in order to reduce costs (such as taking fire insulation off CVN 78 for $15 million or allowing the LCS engineroom to be so noisy that the human stay time with even double hearing protection is only 60 minutes or no sound insulation on CVN 78 below the flight deck) or we will not be able to build and afford the 313 ship Navy. The money issue is 5 real and he sees it every day impacting decisions. He worries about what we are giving up after three to four hour design reviews that leave participants mentally exhausted at completion. o The message he wants non-nuclear engineers to receive is that everyone in NAVSEA has an obligation to look at what we do with regard to technical answers. There are three basic answers we should be giving to the fleet for technical issues: Make it like new and use the book answer (this is the blast and paint the impulse tanks on City of Corpus Christie answer) Identify the worst-case impact and assess that impact on operations (on City of Corpus Christie, that might look like blast or scrape the paint off, but do not repaint, replace the zincs, and put no paint back on until the next docking four years from now). Recommend a temporary repair with monitoring (on City of Corpus Christie, that might look like hand prep the surfaces, fair some touch up paint on the tank. This might result in additional paint flaking off in the future that may require more frequent replacement of the slide valves). o Bad things can happen in our business. Approximately 350 ships sink per year. 6 From the Top — Technical Authority, by Captain Larry Baun, Wavelengths Online, July 21, 2004. DIVISION—This month’s theme technical authority—where it should reside and how and when it should be delegated—is one of our top five management initiatives. This subject is important to you and the Division because it is understood by Navy leadership that technical authority brings military value to the warfare centers and NAVSEA. All of our work at the Division supports our ability to execute our role from the technical authority perspective. We must ensure that we understand and comply with our role in technical authority and support this aspect of NAVSEA’s mission. You have probably heard discussion on the report by the Columbia Commission on the subject of technical authority. Simply stated, the Columbia Accident Investigation Board concluded that NASA’s dilution of technical authority by excessive delegation and reliance on outside support for making technical decisions ultimately contributed to an inability to make a technically pure decision that was “independent”—in other words, may have been adversely affected by business decisions. According to the literature, this lack of clear technical authority, sense of complacency, and lack of appropriate resources all contributed to decisions made which, at least indirectly, led to the Columbia disaster. During the subsequent investigation, the Navy—NAVSEA in particular—was cited as an example of appropriate use of technical authority—that is, it is an inherently governmental function that is separate from program management functions. Since the Columbia accident, NASA has taken steps to develop a technical authority structure similar to NAVSEA’s. The requirement for the Navy to maintain technical authority is based on law (CFR Title X, Chapter 503-5013) and regulated by Navy and NAVSEA instructions. This does not mean that private industry cannot support technical authority—we do this today—but it recognizes that funding, business, and operational concerns need to be separated from influence on technical decisions —the technical authority needs to be independent of outside influences. By “independent,” I don’t mean that business, funding, or operational concerns are ignored. We operate the Navy in this environment and call on our scientists, engineers, and managers to understand the environment and the risk involved. A correct technical decision or recommendation frequently considers the risk and outside factors but is governed by the technically correct answer. What does all this mean to you? For starters, you should know that there are formally designated technical warrant holders (TWHs) warranted by Commander, Naval Sea Systems Command. These warrants are signed by Vice Admiral Phillip Balisle (COMNAVSEA) and issued through Gregory Maxwell (NAVSEA 03, Human Systems Integration), Rear Admiral Paul Sullivan (NAVSEA 05, Ship Design Integration and Engineering), Rear Admiral Alan Hicks (NAVSEA 06, Warfare Systems Engineering), and Rear Admiral William Timme (NAVSEA 07, Undersea Warfare), SEA 00V, and 017 also administer certain warrants. There is a clear line of authority and accountability present. A “pyramid” of personnel supports each TWH (there are currently 168 within NAVSEA). The article on page 3 contains a detailed explanation of the pyramids. 7 In the past, this pyramid was understood to be the myriad of government engineers, scientists, and private industry and academia in the respective disciplines and specialties but was not always well defined or formal. We are in the process of formalizing and “populating” these pyramids, identifying by name those who support the TWHs and how they do it. Two levels are identified: “engineering managers,” who are in turn supported by “lead engineers.” Again, these positions may exist at NAVSEA Headquarters, within Warfare Center divisions, Fleet activities, or in private industry. What is important is that the positions are by name vice billet (although they may be synonymous), and they are based on technical competency. The Division has four technical warrant holders; check out the article on technical authority on page 3 for a list of Division warrant holders. Many of you are assigned to engineering manager or lead engineer positions within individual technical authority pyramids. It is important for those in these positions to clearly understand their role and where they stand within their pyramid; certainly TWHs should understand—in detail— the structure of the pyramid that supports them, who is in it, and the “health” of the pyramid (i.e., the age demographics, workload, etc.). If you are not assigned by name to a technical authority pyramid, that does not mean your skills are not valued or needed. It is understood, but not yet well defined, that the “pyramid” has a foundation of people, that consists of many of the employees in the warfare centers and is supported by the numerous taskings and jobs that we do. You should understand what technical authority pyramid your work supports ... it may be several. Our product area directors (PADs), while not directly responsible for technical pyramids, have a stewardship responsibility to ensure that the work within their product area supports the health of the pyramid. Division commanders share in this responsibility. Those who are not named specifically within a pyramid should understand what areas they work within; it is likely that they will support multiple pyramids. While I’ve provided some detail above, I think it is important to understand the approach the Navy and NAVSEA have taken to technical authority and how it applies to you. The Division’s lead for interface with NAVSEA in populating technical authority pyramids and all tech authority issues is Jack Templeton (24). Please take time to read the articles in this month’s Wavelengths for an overall understanding of your role—and don’t hesitate to discuss this with your supervisor if you have questions. www.dt.navy.mil/wavelengths/archives/000086.html (Return) 8 Technical Authority—Making Sure the Right People Fit the Right Job By Jack Templeton and William Palmer WEST BETHESDA—The concept of technical authority, which for decades has been the focal point of the Navy’s hull, mechanical, and electrical (HM&E) technology research and development for both surface and submarine platforms, has taken root at the Division. In recent years, with the transition of more acquisition and in-service engineering services from NAVSEA, the Division has become an acknowledged full spectrum engineering organization. To that end, the Division is a key member of an ongoing NAVSEA headquarters initiative intended to formalize a process that establishes and enforces technical standards and policies. The scope of this process is currently captured in NAVSEA Instruction 5400.97A, Engineering and Technical Authority Policy, dated February 3, 2003. This document states that COMNAVSEA is the technical authority for ships, weapons, systems, and infrastructure as defined in the document. COMNAVSEA in turn warrants SEA 03, SEA 05, SEA 06, SEA 07 and SEA 00V (and recently SEA 017) for technical authority in their respective areas. Jointly with COMNAVSEA, they warrant their respective technical authority warrant holders. The warrant holders in turn establish an infrastructure (or pyramid) of engineering assets to fulfill their duties. There are three basic components to the technical authority pyramid: at the top is the warrant holder; the midsection contains the engineering managers—effectively the supervisory element of the technical community under whom the engineering staff reside—and the pyramid’s base is comprised of those engineers who actually do the work. There are currently more than 150 warrant holders in NAVSEA, meaning that there are this many different areas of expertise represented by the associated warrant holder. Much of the detail associated with the makeup of these pyramids is captured in two additional complimentary NAVSEA instructions: NAVSEA Instruction 5400.61D, Systems Engineering and Technical Authority Policy, dated February 3, 2003; and NAVSEA Instruction 5400.57D, Engineering Agent Selection, Assignment, Responsibility, Tasking, and Appraisal, dated February 3, 2003. What is a warrant holder? Jack Templeton (24), himself a warrant holder, defines the position as “an individual who’s a recognized technical expert in a particular engineering area.” Warrant holders are the “go to” people when a decision is required, when design standards or practices are being deviated from, where safety of life at sea is at issue, or impact of mission effectiveness is of concern. Four warrant holders are resident within the Division: Templeton, in charge of surface ship arrangements; Paul DiTaranto (9612), heading the submarine sail systems warrant; Andy Paryzek (23) for the Egyptian fast missile craft; and Brooks Darden (23), leading the boats and crafts warrant. The remaining warrant holders work at NAVSEA headquarters or within other field activities, including Naval shipyards and other Warfare Center divisions. Templeton says the new organizational structure will benefit not only NAVSEA and the Division, but our sponsors and the operators in the Fleet as well. “One value added by 9 this pyramid process is that it’s hoped that it will allow engineering management across the enterprise to assess the health of our respective warrant areas and potentially support core equities health assessment. By having a relationship between the technical area expertise which is captured in these pyramids and the programs of record (which can number as many as 30 or more), we can assess if we have enough engineers to support not only the technology development but also support the interaction with the programs and make sure the designs are progressing as well. From a program manager’s or operator’s viewpoint, they can rest assured that the appropriate expertise is being brought to bear on design issues they face, and this expertise is accessible when needed.” Templeton also explains that the technical authority process should help headquarters managers better appreciate the relationship required with the field activities to better understand staffing requirements. “We’re always struggling with what the workload forecast is for upcoming programs.” How does technical authority fit in with the current warfare center/product area business structures? Templeton says flag-level Navy officials are currently looking at the answer to that very question. At the recent Engineering Leadership Conference held at the Washington Navy Yard May 11 through 13, C. Randy Reeves, Product Area Director (PAD) for Ships and Ship Systems, cited a number of key roles of the PAD. Specifically, he noted that the PAD will share a stewardship role with the various technical authority warrant holders to sustain the capabilities of the technical authority pyramids. He also noted that the PAD will concur with all engineering agents assigning documents to ensure technical alignment with Warfare Center capabilities. For further information on technical authority, please contact Jack Templeton at 301-2275572 or templetonjk@nswccd.navy.mil. http://www.dt.navy.mil/wavelengths/archives/000098.html (Return) 10 NASA/Navy Benchmarking Exchange (NNBE) Volume II Progress Report | July 15, 2003 Naval Reactors Safety Assurance www.nasa.gov/pdf/45608main_NNBE_Progress_Report2_7-15-03.pdf Event Assessment Process Problems are assessed using a variant of the classic Heinrich Pyramid3-approach with minor events at the base and major events at the top (see figure 3.6). During training of prospective commanding officers, one instructor teaches about megacuries of radioactivity and then a second presenter addresses picocuries (a difference of 1018). The picocurie pitch is very effective because it emphasizes how little problems left uncontrolled can quickly become unmanageable. The point is to worry about picocurie issues, which subsequently prevents megacurie problems. Radioactive skin contamination is treated as a significant event at NR. The nuclear powered fleet has had very few skin contaminations in the past five years, and the total is comparably orders of magnitude lower than in some civilian reactor programs. 3 H.W. Heinrich, Industrial Accident Prevention – A Scientific Approach, 1950. (see figure on next page) 11 The Triangle Theory Pinnacle Event – Reactor Accident (a similar event for NASA would be loss of the Space Shuttle S e v e r i t y Deficiencies The NNPP Triangle The NNPP Triangle Problems manage you 1st Order – Incidents 2nd Order – Near Misses You manage problems 3rd Order – Deficiencies NNPP Pyramidal Problem Representation The triangle and hierarchy of problems (number and severity) model the experience of accident investigators that most incidents and serious problems do not strike like a “bolt from the blue,” completely unexpected and hard to anticipate. 1st order – Incidents – least frequent type of problem, represents serious breaches of defense systems leading to major injury or equipment damage 12 2nd order - Near Misses - less frequent than deficiencies, more serious problems that are signs of deeper weakness and could lead to much bigger problems 3rd order – Deficiencies - small problems of low individual consequence and importance, most numerous category 1st order problems are typically preceded by a number of 2nd order problems and an even larger number of 3rd order problems that an organization has been tolerating for some time. In almost every case of an organizational accident like the loss of a Space Shuttle, the organization was tolerating and not correcting many 3rd order deficiencies. By focusing on reducing and aggressively investigating 3rd order deficiencies, organizations “put pressure” on the triangle and push more problems lower (or prevent them in the first place) and build a broad population of questioning attitudes and awareness of deficiencies that will ultimately reduce the likelihood of 1st order incidents. In this way, organizations can look closely at how they accomplish work and attempt to design processes to make second and first order problems exceedingly unlikely. In the Naval Nuclear Propulsion Program, any problem reaching 1st order requires that a report that goes directly to NAVSEA 08 (this is called an “incident”). Naturally, correspondence of this nature and the dialog between the senior staff of an organization and their counterparts at NR gets the senior leadership of an organization involved in very important details associated with problems. This is by design. This process seeks to inspire/encourage treatment of the lower level problems before they contribute to a more serious event. The local Naval Reactors Representative Office (NRRO) performs monitor watches to evaluate how well the organization is managing its 2nd and 3rd order deficiencies. By maintaining issues at 3rd order, they are usually more manageable. At level 3, organizations manage the problems, 1st and 2nd order problems manage the organization and bring additional scrutiny of regulators, reducing the flexibility and management discretion. Every corrective action follows a closed loop corrective action process that addresses the problem, assigns a corrective action, tracks application of the corrective action and subsequently evaluates the effectiveness of that action. A second order problem is considered a "Near Miss" and typically receives a formal management review. Ideally, the only difference between the way an organization treats a 1st order problem and a 2nd order one is the formal correspondence sent to NR HQ. Headquarters gets involved with all first-order and some second-order problems. The visibility of issues available to the Admiral allows him to choose the appropriate level of involvement with first, second, or sometimes third-order issues. (Return) 13