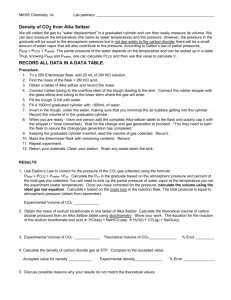

Handout

METALATION OF DIPHENYLMETHANE WITH N-BUTYLLITHIUM

I.

Background. Metalation is defined as replacing a group on a molecule (usually H) with a metal, in this case Li, generating an organometallic intermediate. The organometallic resulting from metalation can be viewed as an intermediate lithioanion, preferably a lithiocarbanion. This carbanion is usually pictured as either a salt or a very polar covalent bond.

R: Li R Li

The importance of this technique lies in the synthetic versatility of the carbanion intermediates that react with a variety of compounds called electrophiles (E

+

) in condensation (molecule enlarging) reactions.

R: Li + E

+ R E

+ Li

While the condensation reactions are varied and somewhat complex, the reaction to generate the intermediate carbanion (metalation) is nothing more than an acid/base reaction in the carbon system. The only requirement in theory is that the metalating agent, in this case n-butyllithium, be a sufficiently strong base to abstract a proton from the compound one wishes to metalate

(diphenylmethane).

In general, R-H must be a stronger acid than butane, C

4

H

10

, or n-butyl carbanion, CB

2

, must be a stronger base than R : in order for the equilibrium to lie in favor of the products. This criterion is often met since C

4

H

10

is one of the weakest of all acids. Consequently, n-C

4

H

9

Li is an excellent metalating agent.

R H or omitting the Li

+ CH

3

CH

2

CH

2

CH

2

Li R: Li + C

4

H

10

R H + CH

3

CH

2

CH

2

CH

2

CA

1

CB

2

The specific metalation or acid/base reaction of interest is:

R:

CB

1

+ C

4

H

10

CA

2

(C

6

H

5

)

2

CH

2

CA

1

+ nC

4

H

9

Li

CB

2

(C

6

H

5

)

2

CHLi

CB

1

+

C

4

H

10

CA

2

Metalation Page 1

Because of resonance with the 2 phenyl groups, the lithiodiphenylmethide, CB

1

, is a much weaker base than the N-butylcarbanion. Thus, equilibrium should lie far to the right. The other way to look at it is that the pKa of C

4

H

10

is 60 whereas the pKa of (C

6

H

5

)

2

CH

2

is only 33.

Therefore, C

4

H

10

is 27 orders of magnitude, or a 10 27 times weaker than (C

6

H

5

)

2

CH

2

. This large difference in acidity between the two carbon acids might be unexpected, however, resonance can have tremendous effects on both the acidity and basicity.

II.

Conditions. Metalation reactions are quite sensitive to side reactions with O

2

and H

2

O and are usually run under conditions that minimize these two common contaminants. Metalations are typically run in solution. This then requires an inert solvent that does not decompose the metalating agent before it can undergo the desired acid/base reaction. The most common solvents are ethers and hydrocarbons. Quite often even when there is a great difference in the pKa values of the conjugate acids involved, the metalation is not successful. If contamination and solvent decomposition can be excluded, then the most likely reaction is poor kinetics – the metalation reaction is much too slow. To avoid sluggish reactions, tertiary amine catalysts such as TMEDA are often used.

H

3

C

N CH

2

CH

2

N

CH

3 Tetramethylethylenediamine

(TMEDA)

H

3

C CH

3

In this experiment, the intermediate lithiodiphenylmethide will be trapped or condensed using

CO

2

as the electrophile. CO

2

is a classic electrophile reacting with many types of organometallics to form carboxylic acids with one more carbon (from the CO

2

) than contained in the intermediate organometallic. The acid group enables the product to be readily separated from other components in the reaction mixture by acid/base extraction procedures.

R M

+

+ CO

2

O

RCO M

+

III.

Procedure: Metalation of Diphenylmethane.

H

+

O

RCOH

Weigh 1.68g of diphenylmethane into a clean, dry 50 mL round bottom flask (note 1, 2). Add

15-20mL of dry tetrahydrofuran (THF) and a magnetic stir bar (note 3). At this point you should replace the stopper with a rubber septum (note 4). Clamp the septum-sealed round bottom flask over a magnetic stirrer. While stirring, cool the flask prior to adding the n-butyllithium (n-

C

4

H

9

Li) and during the metalation also.

Withdraw 4.0 mL of 2.5 M n-butyllithium in a syringe as directed by instructor (note 5).

Immediately syringe the n-butyllithium into the stirred, chilled contents of the 50 mL round

Metalation Page 2

bottom flask (note 6). An immediate color change should occur and be noted (note 7). Allow the mixture to stir in the ice bath for at least 30 minutes before quenching with the appropriate electrophile (note 8).

IV.

Procedure: Condensation with CO

2

and Work-up.

Just prior to the end of the metalation period, obtain a pellet of solid CO

2

in a plastic bag as prepared by your instructor (note 9, 10). Before using the CO

2

pellet, break it into smaller chunks. When ready to quench the metalation mixture, empty the crushed dry ice into a 400 mL beaker and add enough diethyl ether (~100 mL) to completely cover the CO

2

. Quickly remove the septum from the metalation mixture and pour the contents of the round bottom flask + magnetic stir bar into the beaker containing the dry ice-ether slurry (note 11). A white precipitate and another color change should be noted. Transfer the beaker back to the magnetic stirrer and agitate. Use a glass-stirring rod to break up any large chunks of the white precipitate.

Stir until all the excess CO

2

has been evolved, or when the solution stops ‘fizzing’ (note 13, 14).

Add 15 mL of saturated NaCl solution to the beaker while stirring. The white solid should dissolve (note 15). Any spattering on the sides of the beaker can be rinsed down with a water wash bottle (note 16).

Transfer the two layers into a 250 mL separatory funnel, shake, and allow the layers to separate.

Test a drop of the aqueous bottom layer with litmus paper to make sure it is strongly basic (note

17). Separate the lower layer dropwise back into a beaker (in an ice bath) containing 5.0 mL of concentrated HCl and 50 mL of ice. A white precipitate should form (note 18).

Collect the solid by vacuum filtration and recrystallize using a solution of ethanol-water. Allow the solid to dry thoroughly and determine the melting point and percent yield. According to literature, diphenylacetic acid is reported to melt at 148 o

C.

---NOTES---

1.

It is important to exclude moisture from the reaction. Obtain a flask from the oven.

2.

After removing the flask from the oven, it should be stoppered between manipulations with a rubber septum to prevent contact with any unnecessary moisture.

3.

THF is very hydroscopic, so when finished with the THF be sure to recap the bottle.

4.

Septum placement can be tricky. Practice on an empty flask – have your partner firmly hold the bottom of the round bottom flask in a cork ring on the lab bench.

5.

CAUTION: n-butyllithium is a very strong base and is rather caustic. Avoid contact with skin. If any of the reagent comes in contact with your skin rinse the area with water.

Your instructor will show you the best way to withdraw the n-butyllithium.

Metalation Page 3

6.

The addition of the n-butyllithium should just about fill the round bottom flask if you’ve followed directions correctly.

7.

The metalation (acid/base reaction) begins immediately to form a lithiodiphenylmethide, which because of considerable delocalization, is colored.

8.

This period is referred to as the metalation time and should be accurately determined and recorded in your notebook. It is not necessary to quench the metalation exactly 30 min after adding the n-butyllithium.

9.

The instructor will prepare the pellet for you.

10.

Avoid exposing the dry ice to the air more than necessary. The solid CO

2

is cold (-78 o

C) and readily condenses water vapor from the air onto its surface so that when the metalated intermediate is poured onto the CO

2

, side reactions with water may occur.

11.

Do not pour the mixture so rapidly that it foams over or splatters.

12.

The white precipitate is the lithio salt of the carboxylic acid products:

O

RCO Li

13.

A pellet of CO

2

weighs approximately 44g, so a healthy excess has been used.

14.

To avoid bumping and splattering while the CO

2

escapes, the stirring continues during this time. To speed up the evolution of CO

2

, the outside of the beaker can be rinsed with warm tap water to warm the solution.

15.

The lithio salt (shown in note 12) is water soluble.

16.

The NaCl is added in a procedure called “salting out” to make the aqueous solution more polar and thus reduce to a minimum the amount of THF dissolved in the aqueous phase.

THF has an appreciable solubility in water and can cause difficulties later on if not removed into the organic phase.

17.

If the aqueous layer tests only moderately basic or even neutral, add several mL of 10%

NaOH to the 2 phases and then re-extract.

18.

The white precipitate is product, diphenylacetic acid. Sometimes if there is considerable

THF left in the aqueous layer or if the metaltion did not proceed as well as it should have, the product initially oils out. Several minutes of stirring or scratching are usually effective in converting the oil to solid. Any stench noticeable at this point is due to the presence of valeric acid, a liquid arising from the carbonation of unreacted butyllithium.

Presence of valeric acid indicates that the metalation reaction did not go to completion.

O OH

O

OH

Metalation

Diphenylacetic acid Valeric acid

Page 4