The Genetic Engineering of a Poly His Tag on the C

The Genetic Engineering of a Poly His Tag on the C-

Terminal End of the E.coli receptor for Glucose and

Galactose

Andrea Fischer, Chad Sydor, Dave Evans and Linda Luck

The glucose galactose binding protein (GGR) is a bacterial periplasmic receptor that has been used as a biosensor since it is very soluble and easily obtained through genetic engineering procedures.

The challenge in building a biosensor is the immobilization of the protein on the surface of the detecting device. We were interested in finding ways to immobilize the protein on the surface. One way to do this is to add of six histidines to the C-terminal end of the protein. Through the use of a cross linker the protein can be attached to the surface. The surface has been coated with a self-assembled monolayer

(SAM) of 3,3 Dithiobis(N-(5-amino-5-carboxypentyl propionamide)-N-N-diacetic acid) dihydrochloride

(Dithiobis(C

2

NTA)). This is a biological agent that serves as a cross linker between the His tag and the gold surface. In solution the molecules line up along the surface of the gold in a monolayer allowing the

His tag to attach to the other side therefore immobilizing the protein all along the surface.

Figrure 1. This shows the GGR protein attached to a gold surface.

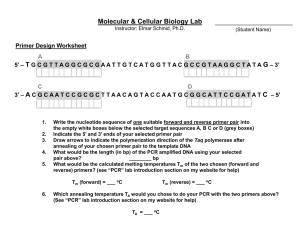

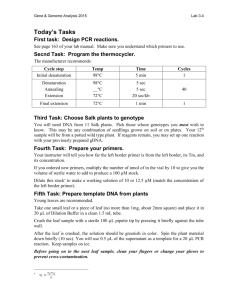

Initially we designed the basic primers to do the genetic engineering using polymerase chain reaction

(PCR). Since the addition was supposed to flank the stop codon the sequence both before and after the

Class of 2006 Department of Chemistry Clarkson University

stop codon was needed for the design process. The initial sequence was taken with the histidines added and a few amino acids on each side were considered for the first primer. The second primer is simply the compliment of the first. Sequencing primers are suppose to be able to anneal to the target DNA in a predictable location and must be capable of extension by Taq DNA polymerase. However, the addition of six amino acids translates into eighteen base pairs which in molecular biology is a rather large addition mutation. The original primers and specification are seen below. They were designed treating the insertion as a normal mutation.

Forward: 5' GAATTTAGAAAGAAA CATCATCACCACCACCAT TAAGACTGAGAGCTC 3'

Reverse: 5' GAGCTCTCAGTCTTAATGGTGGTGGTGATGATGTTTCTTTCTAAATTC 3'

Length: 48 bp

GC content: 39.58%

Melting temp: 83.7°C

Mol. weight (fwd): 11643.27 Da

Mo. weight (rev): 11744.26 Da

Mismatch: 0.00%

Ends in G or C: Yes

Tm = 81.5 + 0.41(%GC) - 675/N - %mismatch

where N = primer length in base pairs.

The mutagenic primers must contain the desired mutation, the bolded section in the primers shown above, and need to anneal to the same sequence on opposite strands of the plasmid. The mutation is in the middle with approximately an equal number of base pairs on each side. Optimally, the GC content should be 40% and both primers should terminate in one or more C or G bases. The above primer was the best candidate meeting all of the design criteria, however after more research it was discovered that the HIS tag was too large to treat as a mutation. This discovery was made very late in the stages of the research and the approach needed to be altered to facilitate the size of the insertion.

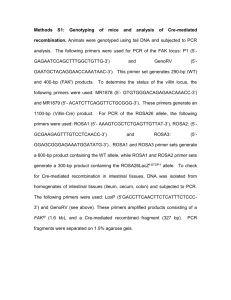

Instead the addition must be made using a series of PCR products utilizing restriction enzyme cut sites. The primers can be designed to PCR out the 3’ end of the pUC18/GGR and add the sequence for the HIS tag using the ApaL I and EcoR 1 restriction sites. A 3’ end PCR product can be generated that has the same restriction sites on both sides of the stop codon and has the HIS insert. The original pUC18/GGR is cut at ApaL 1 and EcoR 1 to remove the 3’ end. Once this is purified using a gel the HIS tag containing PCR product can be placed into the pUC18/GGR vector at the ApaL 1 and EcoR 1 restriction sites using a ligation kit. After the ligation is complete a transformation is performed on competent E.coli cells.

Class of 2006 Department of Chemistry Clarkson University

Figure 2. This is a block diagram of a transformation.

The bacterial pUC18 plasmid contains an antibiotic resistance gene to determine which colonies have taken up the vector successfully. Once positive bacterial colonies are formed the DNA can be sequenced to confirm that the HIS tag is present. One colony is taken from the antibiotic containing plate and placed in a starter culture via a flame sterilized wire loop. The starter culture is grown in LB media also containing an antibiotic, in our case ampilicin, and is placed in a shaker incubator overnight.

Contamination is an issue so a control tube is prepared containing the media and antibiotic but no colony.

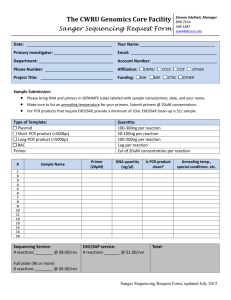

A miniprep DNA purification system can used to obtain the plasmid DNA and then it is sent out for the sequencing confirmation. Once the presence of the HIS tag is confirmed protein production can occur.

Since the research into this new method of insertion was done very late in the process, we are in the middle of the protein production.

Class of 2006 Department of Chemistry Clarkson University