Microsoft Word

advertisement

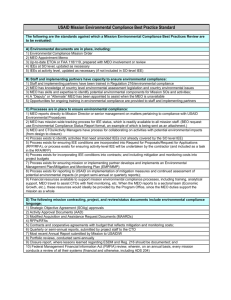

I Synopsis Synopsis The thesis entitled “Synthetic efforts towards FR901483, Microsclerodermin A&B and development of new methodologies in poly(ethylene glycol)” has been divided into three chapters. Chapter I: Chapter I deals with the brief introduction to immunosuppressants and synthetic efforts on FR901483. Chapter II: Chapter II describes the stereoselective synthesis of the C1-C20 segment of microsclerodermin A&B. Chapter III: This chapter deals with introduction to alternative solvents and poly (ethylene glycol) (PEG) as a reusable solvent for organic reactions. This chapter is further subdivided into two sections. Section A: Section A deals with poly(ethylene glycol) (PEG) as reusable solvent for the Heck reaction. Section B: This section describes poly(ethylene glycol) (PEG) as rapid and reusable solvent for OsO4 catalyzed dihydroxylation reactions. Chapter I: This chapter deals with the brief introduction to immunosuppressants and synthetic efforts on FR901483. INTRODUCTION: Organ transplant recipients can attribute survival, in part, to the discovery of the immunosuppressive agents cyclosporin A and FK-506 (tacrolimus). However, these compounds are toxic at high doses and, consequently, the identification of additional immunosuppressants which function by mechanisms of actions different from these two drugs remains an ongoing concern. To that end, the Fujisawa Company screened a number of microbial culture broths for the inhibition of 12-O-tetradecanoylphorbol 13acetate stimulated T-cell proliferation in the presence of exogenous IL-2, conditions which suppress the antiproliferative activity of tacrolimus. An attractive compound, FR901483 (1), was isolated from the fermentation broth of Cladobotrym sp. No. 11231 that was retrieved from litter collected at Iwaki, Japan. II Synopsis Experimental results suggest that FR901483 is likely to operate through an antimetabolite effect on immunocompetent cells by interfering with the enzymes adenylosuccinate synthetase and/or adenylosuccinase. Further information concerning the biological activity of this compound has not been forthcoming. However, one can speculate that the activity may result from FR901483 serving as a competitive inhibitor for inositol monophosphate (IMP) or an analogue of IMP. It was further demonstrated that FR901483 significantly prolongs graft survival time in the rat skin allograft model, and moreover, evidence was obtained which is suggestive of a different mechanism of action, namely, inhibition of purine nucleotide biosynthesis. The promising biological activity and structural novelty have elicited substantial interest in 1 at synthetic chemical level. MeHN OP(O)(OH)2 A N C B MeO OH FR901483 (1) Retrosynthetically, FR901483 (1) can be disconnected into two subunits azabicyclic amine 3 and -bromo ester 6. We envisioned that the azabicyclic amine 3 could be accessed via ‘Robinson annulation’ type reaction of the functionalized pyrrolidine carboxaldehyde 4, which in turn would be synthesized from commercially available trans-4-hydroxy-L-proline 5. The other subunit -bromo ester 6 would be synthesized from the Wittig product of anisaldehyde 8, after the Sharpless asymmetric dihydroxylation and regioselective deoxygenation. The retrosynthetic analysis is represented in scheme 1. III Synopsis Me HN A N FR901483 1 MeO 2 C O B OH Me TsN MeO O O N H Br CO2Me + 6 3 Me O TsN OMe N Boc MeO CHO 4 HO OH 7 CHO N H COOH MeO 8 5 trans-4-hydroxy-L-proline Scheme 1 Our first goal was to devise an efficient route to azabicyclic amine 3. Accordingly initial modification of trans-4-hydroxy-L-proline 5 was done by sequential esterification and protection of amine as its tert-butylcarbamate to give 9 in 95% yield. The next step of the synthesis was the transformation of the hydroxyl group in 9 to the corresponding azide 10. For this purpose, a two-step sequence was used. The mesylation of the hydroxy function of 9, followed by azidation furnished the azido compound 10 in 90% yield (scheme 2). IV HO Synopsis HO COOH N H Boc2O, iPr2EtN,THF 95% 6 COOMe N N3 a. MsCl, DIPEA CH2Cl2, 95% CH3COCl, MeOH, reflux Boc COOMe N b. NaN3, DMF, 90% 9 Boc 10 Scheme 2 The obtained azide 10 was subjected to ‘Staudinger reaction’ using TPP in THF/H2O at room temperature to afford the corresponding amine 11 in 86% yield. The tosylation of amine with TsCl, DIPEA followed by methylation using CH3I, K2CO3 furnished the tosyl protected methylamino compound 13 in 88% yield. The construction of the pyrrolidine carboxaldehyde 4 was now investigated from 13. After reduction of the carboxylic ester in 13 with LiAlH4 in diehyl ether, the resulting primary alcohol 14 was oxidized to the requisite aldehyde 4 utilizing CrO3 in quantitative yield (scheme 3). N3 H2 N TsHN Ph3P, THF,H2O N Boc COOMe TsCl, DIPEA r.t. 86% COOMe N Boc 10 N COOMe -10 82% 12 Me TsN CrO3, pyridine LiAlH4, ether oC, COOMe Boc Me TsN K2CO3, MeI N 11 Me TsN Acetone, r.t. 88% CH2Cl2, r.t. 90 % Acetone, r.t. 90% N N CHO Boc 4 OH Boc Boc 13 14 Scheme 3 The azaspiro-ring system could be assembled by Michael addition followed by aldol condensation. Accordingly, the conjugate addition of pyrrolidine carboxaldehyde 4 to methyl vinyl ketone in the presence of K2CO3, and catalytic amount of tetra-n-butyl ammonium bromide provided 15 as a diastereometic mixture which was subjected to the intramolecular aldol condensation induced under the alkaline condition using catalytic amount of alcoholic KOH yielded enone 16 in 78% yield along with small amount of hydroxy ketone 16a. Mesylation of 16a with methanesulfonyl chloride, TEA followed by column chromatography on silica gel, gave enone 16 after elimination (scheme 4). V Me TsN Synopsis O N CHO Boc 4 Me TsN N K2CO3, nBu4NBr Toluene, r.t. to-10 oC 48% Me TsN O 15 KOH, Et2O, r.t. 78% O + N OH 16a CHO Boc Me TsN N H O Boc 16 MsCl, TEA Scheme 4 The resulting enone 16 was subjected to catalytic hydrogenation using 20% Pd(OH)2/C in benzene to afford the ketone 17 in 96% yield. Subsequent ketalization of 17 with ethylene glycol under acid catalyzed process by the azeotropic removal of water provided the compound 18 in 85% yield. In the final transformation, deprotection of the N-Boc group of 18 was accomplished by treatment with TFA:CH2Cl2(1:1) leading to free amine 3 (scheme 5). Me TsN Me TsN O Benzene, r.t. 96% N Boc Pd(OH)2, H2 16 (CH2OH)2, pTSA Benzene, r.t. 85% N 17 Boc Me TsN Me TsN O O N Boc O O TFA:CH2Cl2 r.t. 70% 18 O N H 3 Scheme 5 At this juncture, we were positioned to synthesize -bromo ester 6 that commenced with the preparation of methyl cinnamate 19, which was easily obtained as a VI Synopsis single isomer in 95% yield via Wittig reaction of aldehyde 8 with a stabilized Wittig reagent (MeO2CCH=PPh3). Next, Sharpless asymmetric dihydroxylation using AD-mix- was explored to incorporate the vicinal dihydroxy group followed by selective hydrogenolytic removal of the benzylic hydroxy group furnished the -hydroxy ester 7 in 82% yield. The hydroxy functional group of compound 7 was converted to bromo ester 6 in two steps. Accordingly, 7 was treated with MsCl and DIPEA to furnish mesylate. Displacement of mesylate with LiBr proceeded with complete inversion to provide the desired compound 6 in 90% yield (scheme 6). O CHO OMe Ph3P=CHCO2Me Benzene, r.t. 95% MeO MeO AD-mix- tBuOH-H 19 2O, 0 oC, 86% 8 OH O O OH MeO OMe Pd(OH)2, H2 OMe MeOH, Methanolic-HCl(cat) r.t. 82% 20 OH MeO 7 O MsCl, DIPEA, DCM LiBr, acetone reflux, 90% OMe Br MeO 6 Scheme 6 Now the two fully functionalized fragments, azabicyclic amine 3 and -bromo ester 6 are ready to couple to get the tricyclic core of the target molecule 1 via 21 which is being pursued in our research group (scheme 7). Me TsN Me TsN O O N H O DIPEA, DCM, 6 r.t. N MeO 3 O CO2Me 21 Scheme 7 1 VII Synopsis Chapter II: Chapter II describes the stereoselective synthesis of the C1-C20 segment of Microsclerodermin A&B. Studies of sponges of the order Lithistida have provided many bioactive metabolites, most of which are peptides that contain unusual amino acids. Detailed studies of the metabolites of different populations of lithistid sponges are valuable in both the structure activity and chemotaxonomic arenas. The microsclerodermins are a growing family of cyclic peptides. Faulkner et al., reported the isolation and structural elucidation of two new cyclic peptides microsclerodermin A and B from a deep-water sponge and commented on the nature of the symbiotic filamentous bacterium associated with the sponge. The crude aqueous extract showed antifungal activity against Botrytis cinerea, Candida albicans, Fusarium oxysporum, Helminthosporium sativum, and Pyricularia oryzae. The basic structural motif of the microsclerodermins consists of a 23-membered ring constructed from six amino acid residues three of which namely glycine, N-methyl glycine and (3R)-4-amino-3-hydroxybutyric acid (GABOB), are common to all members of the family. The variable units are a modifieded tryptophan residue, an unusual 3aminopyrrolidone-4-acetic acid moiety and various ω-aromatic 3-amino-2,4,5- trihydroxyacids. As a continuation of our studies on the synthesis of structurally novel and challenging natural products, we have attempted the total synthesis of these unique cyclic peptides. This chapter describes an efficient synthesis of the C1-C20 fragment of this potent natural product. 37 H N O 30 COOH 32 H N N 28 O O NH 26 H N R O HN 40 O 42 OH N H OH O 21 O 22 R=OH: Microsclerodermin A R=H: Microsclerodermin B 47 N H 1 20 OH OH 3 OMe 18 11 5 HO 14 19 VIII Synopsis Our retrosynthetic analysis envisioned the late installment of the four contiguous stereocenters of 23 through the application of an iterative asymmetric dihydroxylation on diene ester 26. This inturn could be obtained by deoxygenative rearrangrment of alkynol 27 which was further synthesized from commercially available S-(-)-citronellol 28 (scheme 8). 37 H N O 30 COOH 40 N 28 O R=OH: Microsclerodermin A R=H: Microsclerodermin B R O HN H N 32 47 O NH 26 H N 42 OH N H 21 O O OH N H O 22 1 OH OH 20 OMe 18 3 11 5 HO 14 19 OMOM O O O OH O O O NHBoc HO 23 MeO NHBoc 24 + PPh3 Cl + MeO 25 OH OH BnO OEt BnO 27 CO2 Et 26 O 28 (S)-(-)- Citronellol Scheme 8 We initially investigated the synthesis of diene ester 26 from S-citronellol 28. The S-(-)-citronellol 28 was protected as its tetrahydropyranyl ether 29. The compound 29 was subjected to ozonolysis to furnish aldehyde, which was elaborated to unsaturated ester 30 by Wittig olefination (scheme 9). IX OH Dihydropyran p-TSA (5 mol%) OTHP Synopsis O3, -78oC, CH2Cl2, 30 min Ph3P=CHCO2Me benzene, r.t. 84% CH2Cl2, r.t. 2h, 98% 28 MeO2 C OTHP 30 29 Scheme 9 The stepwise reduction of 30 with Mg-MeOH caused the selective reduction of olefin to give saturated ester 31 followed by ester reduction to primary alcohol 32 was achieved using LiAlH4. The primary alcohol group in 32 was protected as its benzyl ether 33 by treatment with NaH and benzyl bromide in 90% yield. The selective release of one of the primary alcohols was achieved by using p-TSA in MeOH to realize 34 (scheme 10). This allowed us to extend the right side of the fragment. MeO2 C 30 LiAlH4, THF 0 oC-r.t. OTHP Mg/MeOH r.t. 12h, 86% MeO2 C HO 96% 32 BnO 33 OTHP p-TSA (5 mol%) MeOH, r.t. 2h, 93% OTHP OTHP 31 NaH, BnBr THF, 0 oC- r.t. 90% BnO 34 OH Scheme 10 The oxidation of 34 using IBX furnished the aldehyde 35, which was immediately exposed to lithiated ethylpropiolate to realize the formation of hydroxy alkynoate 27 as a diastereomeric mixture, which was unseparated. The critical diene ester intermediate 26 has been obtained from hydroxy alkynoate 27 by triphenylphosphine mediated deoxygenative rearrangement via allene. This rearrangement allowed us to obtain the diene ester ready for the incorporation of stereoselective hydroxy groups via iterative Sharpless asymmetric dihydroxylation (scheme 11). X Synopsis H IBX BnO 34 BnO OH O DMSO-THF, r.t. 95% 35 LiHMDS, -78 oC CO2 Et THF, 86% BnO 26 CO2 Et OH Ph3P BnO benzene, r.t. 90% 27 CO2 Et Scheme 11 At a first glance Sharpless asymmetric dihydroxylation followed by Sharpless asymmetric aminohydroxylation reaction seemed to be an apparent option to establish the required four stereogenic centers at C2-3, C4-5 in 23. The enantio and regioselective Sharpless asymmetric dihydroxylation of diene ester 26 with AD mix- in tBuOH:H2O (1:1) provided the diol 36 which was masked as its acetonide 37 using 2,2-dimethoxy propane and catalytic camphorsulfonic acid (CSA) in 85% yield (for two steps) with 96% de. The major isomer was separated by column chromatography (scheme 12). OH BnO 26 CO2 Et AD mix- HO CO2 Et BnO tBuOH-H o 2O, 0 C, MeSO2NH2, 24 h 36 O O 2,2 DMP, CSA (5 mol%), DCM, r.t. 2 h, 85% CO2 Et BnO 37 Scheme 12 The regioselective incorporation of cis-aminohydroxyl group was planned in next step by Sharpless asymmetric aminohydroxylation. However this method was unsuccessful. Thus we envisaged that, this issue could be well addressed by another asymmetric dihydroxylation-double inversion (at C-3) sequence. Thus we changed the strategy to a second Sharpless asymmetric dihydroxylation on 37, with a diastereomerically matched chiral reagent AD mix- in tBuOH-H2O at 0 oC to afford the XI Synopsis diol 38 in 87% yield with excellent diastereoselectivity (10:1) (scheme 13). Efforts to introduce the amine functionality at C-3 always ended up with the elimination product. O OH O O CO2 Et BnO AD mix- tBuOH-H 2O, 0 24 h, 87% 37 O CO2 Et oC, BnO OH 38 Scheme 13 To avoid the competitive elimination reaction, the dihydroxy ester 38 was reduced to triol 39 with LiAlH4 in THF. Then, the triol 39 was subjected to regioselective 1,2-acetonide protection using 2,2-DMP in DCM under acid catalyst p-TSA to give 40 in 85% yield. Treatment of the diacetonide 40 with Tf2O in the presence of pyridine gave triflate 41. The sequential displacement of the triflate 41 by bromide ion (Bu4NBr) followed by azide ion (NaN3) provided the nitrogen function with retention of configuration at C-3. The required five contiguous asymmetric centers at C2-C6 for the key building block 23 are now been established by the synthesis of azido compound 43 (scheme 14). O O CO2 Et BnO OH LiAlH4, THF BnO DCM, r.t. 1 h, 85% 39 OH -10 oC, 15 min 40 O O nBu OTf BnO O O O O O NaN3, DMF, BnO Br 42 65 oC, 4 h, 82% N3 BnO Scheme 14 43 4NBr, DCM r.t. 8 h, 86% 41 O O O O O O Tf2O, Py, CH2Cl2 2,2-DMP, p-TSA (cat) OH O O OH BnO 0 oC-r.t. 2 h, 80% 38 O OH O OH O XII Synopsis At this point a one-pot deprotection-reduction-protection strategy was utilized. The azide 43 was subjected to Pd(OH)2/C catalyzed hydrogenation in presence of (Boc)2O effected the benzyl ether deprotection, azide reduction and Boc-protection of the resulting amine to afford the compound 24 in 92% overall yield.The alcohol 24 was oxidized with IBX to furnish the desired aldehyde, which was subjected to Wittig olefination with (4-methoxy-phenylmethylene) triphenylphosphorane in THF was used to provide 44 as a mixture of E/Z isomers in a ratio of 3:2 in 70% yield. Treatment of the mixture of E/Z isomers with catalytic amount of Pd(CH3CN)2Cl2 in 0.5 M DCM at room temperature caused the isomerization of the double bond and afforded the isomerically pure E-isomer 45 in 92% yield (scheme 15). O O O O O Pd(OH)2/C, H2 N3 BnO O a. IBX, THF:DMSO (Boc)2O, MeOH HO r.t. 5 h, 92% 43 O O NHBoc 24 27 b. BuLi, THF, r.t., 70% O O O O O O O O NHBoc 44 NHBoc Pd(CH3CN)2Cl2, DCM r.t. 12 h, 92% MeO 45 MeO Scheme 15 The terminal acetonide in 45 was selectively deprotected under mildly acidic conditions (PPTS in MeOH) to give the diol 46. The two liberated hydroxyl groups were protected selectively. The TBS group was introduced regioselectively at the primary hydroxyl group to yield 47. The introduction of methoxy methyl protection at the remaining free hydroxyl group was achieved by the reaction of 47 with MOMCl and diisopropylethylamine in DCM to obtain 48 in 90% yield. The conditions for the regioselective removal of protecting group from 48 were investigated next. It was possible to remove the TBS protecting group utilizing TBAF in THF to provide the key fragment 23, which could be oxidized at a later stage (scheme 16). All these transformations completed the stereoselective synthesis of C1-C20 segment of microsclerodermins A and B. XIII Synopsis NHBoc OH O O O OH O O O PPTS, MeOH, 75% NHBoc 46 45 oC 45 MeO MeO O OH OTBS O NHBoc TBSCl, imidazole O O DCM, 1 h, 90% 47 DMAP (3 mol%), MeO DCM, r.t. 12 h, 85% MOMCl, DIPEA, O OMOM OTBS O TBAF, THF NHBoc NHBoc r.t. 1 h, 70% 48 23 MeO MeO Scheme 16 OMOM OH C1-C20 segment XIV Synopsis Chapter III: Introduction to alternative solvents Solvents are widely used in commercial manufacturing and service industries. Despite abundant precaution, they have inevitably contaminated our air, land and water because they are difficult to contain and recycle. Researchers have therefore focused on reducing solvent use through the development “solvent alternatives” like, supercritical fluids, ionic liquids or fluorous phases. However, these approaches have their limitations. Environmental advantage alone probably will not enable alternative solvents to achieve widespread applicability. The pollution prevention technologies must include not only environmental or “green” advantages, but also advantages related to performance, health and cost. To addresses some of these issues, we initiated a new program to identify any liquid polymer or low melting polymer can be used as reusable reaction medium and we have found that poly (ethylene glycol) (PEG) is an efficient reusable reaction medium for organic reactions. Poly (ethylene glycol) (PEG) was used as solvent medium for very few reactions in the literature, but not extensively studied. The complete toxicological profiles are available for a range of PEG molecular weights. Their low-toxicity, low volatility, and biodegradability represent important environmentally benign characteristics, which are particularly attractive when combined with their relatively low cost as a bulk commodity chemical. This material is widely used in food and beverages and medical purposes, which is a testament to its benign character. In addition, aqueous PEG solutions may often substitute for expensive and often toxic PTCs. The developed state of knowledge with regard to the toxicological properties of PEG is of considerable current advantage compared to the paucity of knowledge for many other potential alternative solvent systems. Considering all these attractive “green” advantages, we explored the PEG as a potential alternative solvent medium and here we described the Heck reaction and dihydroxylation reactions. XV Synopsis Section A: Section A deals with a poly(ethylene glycol) (PEG) as reusable solvent for the Heck reaction. Palladium catalyzed arylation and vinylation of olefins called as the Heck reaction. Heck reaction is normally carried out in the presence of phosphine ligand and base under inert atmosphere. However, the relatively high price of the palladium complex has greatly limited the industrial application of the Heck reaction, and some of the phosphine ligands are sensitive to air and moisture. In view of the economy of the reaction, the recovery as well as recycling of the expensive palladium catalyst is required. In addition, phosphine-freed reaction conditions are highly desired due to the environmental effects associated with phosphine. Here, we report poly(ethylene glycol) (PEG) is an efficient reusable reaction medium for the Heck reaction (scheme 17). We have noticed the following advantages. The Heck reaction proceeded without phosphine ligands, which are expensive, toxic, and contaminates the products. The stereo and regioselectivities are also different from those with conventional solvents and ionic liquids. The reaction works very well for electron-deficient and electron-rich olefins, with equal ease and with high regio and stereoselectivities. One major advantage of the present protocol is that the catalyst is easily reusable up to five runs without loss activity even after fifth run we could obtain product in 70% yield. Benign character of PEG as well as easy operation makes the present Heck reaction attractive. Br R + X X = Ph, COOEt R = Cl, OMe OBu methylenedioxy Pd(OAc)2 (3 mol%) Triethylamine PEG(2000), 80 oC Scheme 17 X R + R Time = 8-16 h Yields = 82-95% X XVI Synopsis Table 1. Pd catalysed Heck reaction of and electron deficient and electron rich olefins in PEG Ethyacrylate time, %yield Substrate S. No Styrene time, %yield nButylvinyl ether time, %yield (E:Z) O Br OBu OEt 1 + 10 h, 93% 8 h, 90% O OBu Br + OEt 2 MeO MeO MeO 3 O O OBu O OEt OBu O + O O O MeO 16 h, 82%, 70:30 12 h, 85% O Br 70:30 MeO 12 h, 91% O OBu 12 h, 88%, 80:20 O OBu O 12 h, 95% 15 h, 80%, 75:25 13 h, 89% O Br OBu OEt 4 + Cl Cl 8 h, 90% 9 h, 89% O 5 Br OBu 14 h, 90%, 100:00 OBu OEt 10 h, 89% Cl Cl Cl + 12 h, 90% OBu 15 h, 87%, 75:25 Section B: This section describes poly(ethylene glycol) (PEG) as rapid and reusable solvent for OsO4 catalyzed dihydroxylation reactions. Undoubtedly, the dihydroxylation of olefins using catalytic amounts of OsO4 is the most sought after method for the preparation of vicinal diols. The importance of this reaction has been enhanced substantially through the use of cinchona alkaloids, which result in chiral vicinal diols as reported by Sharpless et al. Even though the products of dihydroxylation have a prominent role in pharmaceuticals and fine chemicals, the cost of osmium and chiral ligands as well as the high toxicity and volatility of the osmium component has restricted its use in industry. To addresses this issue several groups investigated this reaction in reusable solvents. We intended to apply our procedure to Oscatalysis (scheme 18) to attempt all the above-mentioned issues and found very interesting observations. XVII Synopsis OsO4 in PEG not only as a recoverable and reusable system for dihydroxylation but also as a medium where reaction is rapid (2h) and high yielding at very low concentrations (0.5 mol%) of OsO4. All the reported protocols require 1–5 mol% catalyst and 12–48 hours time for completion for a similar result. Reusability of the solvent and the catalyst have been achieved up to five runs without loss of activity even after fifth run we could isolate diol in 90% yield. OsO4, 0.5 mol% NMO.H2O, (1.3 eq.) R' R OH R = alkyl, aryl R' =H, alkyl, aryl R' R PEG (400), r.t OH 2-3 h Yields = 88-97% Scheme 18 Encouraged by these results, then we attempted the asymmetric dihydroxylation of olefins according to the Sharpless procedure and we have observed very interesting results (scheme 19). Conventionally, this reaction required longer reaction times (up to 24 h) and addition of 1 equivalent of methanesulfonamide is required for dihydroxylation of internal olefin. In our method the reaction is quite rapid (2 h) and no additional reagent like metanesulfonamide is required. R R' R = alkyl, aryl R' =H, alkyl, aryl OsO4, 0.5 mol% (DHQD)2 PHAL, 2mol% NMO.H2O, (1.3 eq.) PEG (400), r.t 2-3 h OH R R' OH Yields = 88-97% ee = 44-96% Scheme 19 Reusability: To check the reusability of OsO4 and possibly ligand as well as trans-stilbene was subjected to asymmetric dihydroxylation (table 3). After 2 h, the product was separated by ether extraction and fresh trans-stilbene was added. To our great surprise, in the second run diol was obtained with more than 80% ee. Further addition of 0.5-mol% ligand helped us to obtain diol with more than 90% ee (Table 2). XVIII Synopsis Table 2: Reusability of OsO4 and (DHQD)2PHAL in PEG Run ee (%)a 94 92(81)a 95(83)a 92(80)a 90(65)a 95 91 92 92 91 2 2 2 2 2 1 2 3 4 5 aee's Yield (%) Time(h) in paranthesis obtained without adding an additional ligand Table 3. Dihydroxylation of olefins using OsO 4 in PEG S. No Olefin Proudct Time/Yield(%)a OH OH 2h, 94 1 OH OH 2h, 97 2 OH 2h, 95 3 OH OH 4 3h, 90 OH O 5 OEt 2h, 93 OEt 2h, 95 OEt OH OH O O 6 O OH OEt OH MeO MeO OH 7 3h, 92 OH 8 OH 3h, 89 OH 9 OH 2h, 95 9 9 NBoc 10 OEt O NBoc OH 3h, 92b OEt O O O 11 BnO OH O 3h, 88c OH HO O bde O O O BnO aYields OH based on isolation of chromatographically homogeneous products 55% (by NMR). c de 91% (by NMR) O XIX Synopsis Table 4. Asymmetric dihydroxylation using (DHQD) 2 PHAL, OsO4 and NMO.H2O in PEG S. No Time/Yield/ee (%)a Product Olefin OH 2h, 95%, 94% ee 1 OH OEt OEt 2 OH O OEt OEt 3 4 n n n=9 2h, 94%, 96% ee OH MeO MeO 2h, 92%, 91% ee OH O aThe O OH O n=9 OH OH products ee was determined by chiral GC analysis (Cyclosil-B) 2h, 96%, 44% ee