Development of Compact Reconfigurable Synthetic Jet Actuators for

advertisement

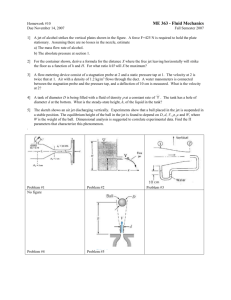

Progress Report Notes: T fm The progress reports are formatted so that the milestones and major tasks have their status listed immediately below the heading. For any one report, only the tasks that actually received effort during the reporting period will have material in their corresponding sections. Tasks that have not been worked on to the current date will be listed at 0% complete. Tasks that have been completed will be listed at 100% complete. The milestones, major tasks, dates and planned completion status are taken from the project-planning summary. Va ( Vi ) Armature (input) voltage Torques and moments Torque correction due to the angular Tc acceleration of the connecting rod Crankshaft inertia torque Tcs NOMENCLATURE Angles and frequencies Connecting rod axis to cylinder axis ,( k ) Crank angle (individual cylinders), referred to reference-cylinder axis L ( m ) Angular displacement of belt drive connected to motor (crankshaft) L ( m ) Crankshaft (motor) angular frequency Lengths Center of crankpin to center of piston pin (length of L connecting rod) Belt drive displacement Center of crankshaft to center of crankpin R rL ( rm ) Radius of belt drive at engine (motor) end xc , xe Rod lengths to rod cg xP Distance of piston pin from cylinder end (exit slot end) Masses Equivalent mass at joint of crankpin with connecting M2 rod Equivalent mass of connecting rod at crank pin end M R2 Mc Mass of crankpin M c2 Equivalent mass of crankpin at connecting rod end M c1 Equivalent mass of crankpin at crankshaft end MR Mass of connecting rod Mp Idealized mass at piston end (including connecting M R3 M ps rod) i.e, reciprocating mass Equivalent mass of connecting rod at piston end Mass of piston, piston rings etc Motor/input parameters Viscous damping in motor Bm i Jm Current through armature Polar moment of inertia of armature Ka Amplifier voltage gain K e ( KT ) Motor voltage (torque) constant Armature inductance Lm R Armature resistance Coulomb friction toque in motor TL Load (total engine) torque Tm Load (total engine) torque referred to motor shaft Tp Torque on crankshaft due to air pressure Torque due to inertia of the reciprocating part Tt Inertias Mass moment of inertia (actual) of connecting rod IL I L' Mass moment of inertia of idealized connecting rod J J cs Mass moment of inertia (general) Mass moment of crank shaft Load mass moment of inertia JL Miscellaneous Load divider constant A p ( As ) Piston (exit slot) area cg Center of gravity f ( M ) Force (moment) - general Acceleration due to gravity g Pressure at jet exit Po Rg Universal gas constant T C Temperature inside piston cavity Density of air in/out cavity Jet momentum coefficient U h U Jet exit velocity Width of jet exit Freestream velocity C F xp Reference or characteristic length Piston inertial force 1. Development of Compact Reconfigurable SJA’s for Distributed Control: Planned Status: Start April 15th, 2003 – 100% Complete Actual Status: 80% Notes Regarding Milestone: 1.1 Development of Modified Experimental Setups Planned Status: Start April 15th, 2003 – 100% Complete Actual Status: 100% Complete Notes Regarding Tasks: 1.1.1 Design Modifications to Wind-Tunnel Setups For the pitching moment about the model the single-SJA wing developed was mounted on the free-to-pitch setup shown in Figure 1. This figure is repeated here from an earlier report. The free-to-pitch setup is being expanded to also include free-to-plunge capabilities. Design is almost complete. Fabrication is anticipated to start in two weeks. 1.1.2 Fabricate and Assemble Parts for Modified Setups Figure 1. Free-to-Pitch wing setup. For the pitching moment tests the trailing edge of the wing was restricted from moving with a thin strut, which was equipped with a Futek in-line force sensor. This allowed us to perform a range of experiments, in which, for a variety of angles of attack and actuation operation parameters (particularly frequency), we measured the wing pitching moment directly from the load sensor and not by integrating the wing surface pressures. The freestream velocity of the experiment was 20 m/s. Data were obtained at angles from 17 degrees to 25 degrees. The frequency was tested to a maximum of 100 Hz. The aerodynamic moment was extracted from the measured forces after removal of loads due to the wing mass. The moments are measured about x/c = 0.36. Figure 2 shows the plots of the pitching moment as a function of angle of attack and actuation frequency. These data were also reported in our previous report. New data that were obtained at man more frequencies are included in Section 3.1. The results of the test show that the SJA produces a significant change in aerodynamic moment as the frequency is increased. Aerodynamic Moment Coeffecient vs. SJA frequency 0.03 Coeffecient of Moment 0.025 0.02 0.015 AoA=21.2 AoA=23.2 0.01 AoA=24.9 AoA=17.3 0.005 AoA=19.0 0 0 10 20 30 40 50 60 70 80 90 100 -0.005 -0.01 frequency (Hz) Figure 2. Pitching Moment vs. frequency of actuation 1.2 Control Wing with Single SJA, Form Guidelines for Distributed Actuation Planned Status: Start June 18th, 2003 – 100% Complete Actual Status: 70% Complete Notes Regarding Tasks: 1.2.1 Wind-Tunnel Testing of Modified Setups with Single Actuator 1.2.2 Data Reduction and Analysis for Wing/Flow/Control Characterization Based on the data gathered in the Phase I effort, we have begun to form guidelines for SJA control and have made progress in the controlled system identification: SJA-control and system identification progress report. Tasks accomplished in this area to date are: 1. Further developed mathematical models for representing the aerodynamic behavior using Radial Basis Function Networks. 2. We have also finalized the hardware for the testing of the closed –loop, free-to-pitch controller in the wind tunnel. This is quite an elaborate setup that interfaces DSpace and the control algorithm with the wing and wind-tunnel hardware. Closed-loop pitch control tests are anticipated to start in two weeks. 1.3 Design, Development and Installation of Reconfigurable and Distributable SJA Planned Status: Start April 15th, 2003 – 80% Complete Actual Status: 50% Complete Notes Regarding Tasks: Because of the inability of the original SJA design to provide control authority at low angles of attack (for < 12°), we have made it a priority to develop an SJA actuator that will fill this void. As discussed in the kick-off meeting presentation, we have decided to focus our initial efforts on designing and developing a “synthetic Gurney flap”: an actuator that can simulate a Gurney flap and provide the necessary authority at low angles of attack. New tasks and sections dealing with the synthetic Gurney flap (SGF) have been added as necessary to document the plans and effort associated with this new development. 1.3.1 Design New SJA Suitable for Distributive Control In this section, we study the behavior of the SJA by simulation of its nonlinear model under the condition of motor rotation at a constant angular velocity m m m first, and then under a step voltage input. Thus, we mainly focus on the behavior of the following four equations: m m (1) m Bm 1 K m 2m sin(3rml m ) T fm T i J mcs J mcs J mcs J mcs p1m p22m sin(3rml m ) p3T fm p4i (2) K R K i e m m i a Vi q2m q3i q1Vi Lm Lm Lm (3) 3 3 U rml m (a1 sin cos a2 sin 2 cos 2 a3 sin cos 2 a4 sin 2 cos ) , and , ai , i 1,,4 , J mcs J m Jcs , p1 Bm / J mcs , p2 / J mcs , q3 Rm / Lm , L rmlm , where 2 rml (4) 3 orml p3 1/ J mcs , p4 KT / J mcs , q1 Ka / Lm , q2 Ke / Lm , (5) Fig.3 shows the jet exit velocity curves at constant motor frequency f m m /( 2) 55 , 70 and 40 Hz. These curves show that the jet exit velocity changes periodically with time, and also changes as the motor rotation speed changes, i.e., m and f m changes. Furthermore, a simulation of the jet exit velocity surface is generated for a range of f m ( m ) values. Fig.4 simulates the jet exit velocity for f m from 100Hz to 140Hz around a nominal value of 120Hz in a 3-D plot. Notice the surface is periodic along the t axis. The 3-D plots in Figs.5-7 are for f m ranges of 60~120, 0~60, and 0~200 Hz. It shows that the velocity increases as f m increases, but the period decreases. Fig.8 shows the motor rotation frequency f m with oscillations when a constant step voltage input Vi 5.282 v is applied 15 fm = 70 Hz Jet Exit Velocity (m/sec) 10 55 Hz 5 30 Hz 0 -5 -10 -15 0 0.01 0.02 0.03 Time (sec) 0.04 0.05 Fig.3. Jet exit velocity curves for three different f m Fig.4. Jet exit velocity surface for f m of 100 ~ 140 Hz Fig.5. Jet exit velocity surface for f m of 60 ~ 120 Hz Fig.6. Jet exit velocity surface for f m of 0 ~ 60 Hz Fig.7. Jet exit velocity surface for f m of 0 ~ 200 Hz Motor Rotation Frequency (Hz) 25 20 15 10 5 0 0 0.2 0.4 0.6 0.8 1 1.2 1.4 1.6 1.8 Time (sec) 2 Fig 8. Motor rotation frequency f m at a constant Vi The above graphs provide information on the performance of the jet exit velocity for various motor angular velocities. These studies are useful for the design of a controller that will command a certain jet exit velocity time history. The nonlinear model of a high-power, compact synthetic jet actuator used in open loop flow separation control has been derived. We developed the state space nonlinear model from the voltage input to the jet exit velocity. Simulations of the jet exit velocity at various motor rotation frequencies were performed to demonstrate the results. Furthermore, a simulation was carried out of the motor rotation velocity/frequency response for a step voltage input. Current research is focused on validating the model via open loop experiments and subsequently using the model in closed-loop control and the development of robust controllers. For the dynamic model, we will do further simulations together with the controller development. 1.3.2 Fabricate New SJA with Dynamically Reconfigurable Slot Geometry 1.3.3 Fabricate Distributable SJA (with Dynamically Reconfigurable Slot Geometry) Task Notes: To this point, we have not fabricated an SJA with an integrated reconfigurable slot (see discussion of reconfigurable slot, section 1.3.5). We have concentrated our efforts more on the development of the synthetic Gurney flap. The integration of the new SJA’s and SGF’s require a more compact actuator. 1.3.4 Design and Evaluation of Synthetic Gurney Flap Controller Although it has been demonstrated that control of flow separation can be used for pitch control at high angles of attack, this mechanism is neither available nor viable at low angles of attack, where aerodynamic efficiency would be marred by large-scale flow separation. At low incidence, the most receptive and effective location for modification to generate pitching moment is the trailing edge. Obvious modifications are the flap. Moments are generated through flap deflection by movement of the rear stagnation point yielding increased vertical momentum transfer. Other trailing edge modifications are pneumatic; either a virtual jet flap, where a high velocity jet is issued from the trailing edge or a blown flap, where the jet is directed over the flap. Super-circulation may also be Gurney flap achieved by using blowing in concert with a Coanda type trailing edge. All these methods are Fig. 9 Typical Gurney flap installation. effective but may require significant quantities of air for operation. The Gurney flap has been shown to be a highly effective, small-scale (typically 0.75 – 1.5% of the chord) modification that can achieve significant lift and pitching moment generation. A typical Gurney flap installation is shown in Fig. 9. The flap functions by essentially increasing the downward deflection of the trailing edge flow, facilitated through the formation of a series of counter-rotating vortices, similar to those of a von Karman vortex street. A consequent effect is an apparent violation of the trailing edge Kutta condition. Experimental data show that finite loading is carried to the trailing edge. For hinge-less flow control the basic tenet of the Gurney flap is attractive, but its implementation would require moving parts. Consequently, we have suggested the implementation of a “Synthetic” Gurney flap, where the flap is pseudo-formed using a jet developed by a SJA or continuous pneumatic supply. Experimental Details For initial proof of concept testing, a continuous air supply was implemented using an external high pressure source. A wing was manufactured from foam and balsa to accommodate the continuous jet or SJA. The wing was then covered with heat sink to ensure a smooth surface. A NACA 0015 profile was used. The wing was equipped with end plates to mimic two-dimensional flow. Figure 2 shows the wing and blowing slot details. The width of the slot was 1mm, giving a slot exit area of 0.0002m 2. The slot was located 15mm from the wing’s trailing edge. As implemented, the flap is a jet flap, with a large jet inclination (90 deg) angle. Geometric details of the model are a chord of 0.71m and a span of 0.235m. The tests were carried out in Texas A&M University’s 3’ by 4’ closed-loop wind tunnel. A freestream velocity of 15m/s was used yielding a Reynolds number of 0.7x106. Tunnel turbulence intensity has been measured at less then 0.5%, assuming isotropic turbulence. Data acquisition was facilitated using a 3-component Pyramidal balance. Balance output voltages were read using a 16-bit A/D board. A dedicated software slot exit side plate compressed air supply support strut Fig. 10 Wind tunnel model details acquisition code has been written for this facility and was used for acquisition and processing. Prior to use for these experiments, the Pyramidal balance was re-calibrated. Subsequent balance verification through application of pure and combined loads suggests accuracies better then 0.6% for lift, drag and pitching moment. Figures 10 and 11 shows the wing installed in the wind tunnel (nearest end plate omitted for clarity). To achieve blowing, shop air was used as the pneumatic source. Slot exit jet momentum coefficients were measured using a British Standard (Part 1042) orifice plate. The orifice facilitated the measurement of the mass flow rate, which in conjunction with continuity allowed determination of the jet slot exit velocity. The measurement technique was verified using a TSI calibrator which allows accurate measurement of an air jet exhausting from Fig. 11 Model tunnel installation its settling chamber. Air to the calibrator was supplied through the orifice plate. Slot exit velocities were measured and compared with predictions using the orifice. Agreement was generally within 1.5%. Lift Coefficient Lift Augmentation Ratio Force Balance Results In all data, the effects of the jet reaction on lift and pitching moment coefficient have been removed through tare runs; consequently, pure aerodynamic loading is shown. Results are summarized in Figs. 12 and 13. The effects of the jet momentum coefficient, Cmu on the measured lift are shown in figure 12. Also included is a plot showing the lift augmentation ratio. This ratio is defined as (Cl Cmu≠0ClCmu=0)/Cmu for the present jet configuration. The ratio clearly shows how the effectiveness of the jet relates to the supplied momentum. A coefficient greater then 1 indicates that augmentation is greater then if the jet had been used purely for its reactive lift. Also included in the data are results for a 0.75% of chord Gurney flap, which was positioned at the same location as the jet. This is a typical size for a Gurney flap, and provides a reference for the lift and moment alteration provided through blowing. The data in figure 12 show that the jet flap shifts the angle of attack for zero lift to negative values, as does a conventional flap. A momentum coefficient of 0.0068 is seen to provide similar lift augmentation to the gurney flap. The 15 magnitudes of the recorded lift also suggest that the end plates were not large enough to ensure 2D flow. Notice that all lift curves appear to have a non-linear increase around 10 4 deg, as seen on low aspect ratio wings. However, this does not affect the comparative nature of the data presentation. The effectiveness of the blowing may be gauged by examining the lift augmentation 5 ratio (ClCmu≠0- ClCmu=0)/Cmu) shown in the top of the multi-part figure (Fig. 12). As 0.8 0.75% Gurney may be seen, the jet greatly augments the Cmu = 0 lift compared to the momentum added to the flow. Greatest augmentation is seen for the Cmu = 0.0037 lower Cmu’s; increasing the jets momentum 0.6 Cmu = 0.0068 reduces the relative benefit if not the Cmu = 0.01 magnitude of the augmentation. The augmentation ratios are of similar Cmu = 0.029 magnitude to those calculated by Lockwood 0.4 and Vogler (1958). 2% chord 0.2 0.0 0 4 8 12 Angle of Attack, deg Fig. 12 Effect of Cmu of measured lift coefficient and lift augmentation ratio In the present application, the primary significance of the jet is in its impact on the pitching moment, so as to be suitable for hinge-less control. The negative shift of the pitching moment curve, typical of a trailing edge flap, is clearly seen, see Fig. 13. As 16 noted for lift, the zero pitching moment Zero Angle of Attack Increment caused by Cmu = 0.0068 is comparable to that generated by a 0.75% chord Gurney flap. The magnitudes of the moment generated, although towards the low end of what a conventional trailing edge flap may generate, are sufficient for pitch control at low angles of attack. Additionally, the required jet momentum coefficients are not excessively large, and are achievable using a SJA (as will be tested in the next phase). Pitch control would be achieved by locating a jet slot on the upper and lower surface, allowing control of the vehicles incidence. Also shown in figure 13 are the dependencies of the zero lift increments of Cm and Cl on the jet momentum coefficient. As may be seen, the greatest augmentation occurs at the lowest Cmu’s, with the increment appearing to monotonically approach a bound for increasing Cmu. Analytic expressions due to Spence (1958) suggest a dependency proportional to Cmu1/2 for Cl. 0.15 0.10 FlowVisualization Pitching Moment Coefficient To gain an insight into the similarities/differences of the trailing edge 0.05 flow physics between the Gurney and Jet Cm Cl flap, flow visualization using Titanium 0.00 Dioxide was used. A thin plate was attached parallel to the side plates. Visualization of -0.05 the skin friction lines on the stream-wise plate would then give an indication as to the -0.10 fluid behavior. Please note that due to the 0.00 0.01 0.02 0.03 effects of gravity on the fluid medium, the Cmu results are purely qualitative and no 0.10 inferences should be made as to precise locations or trajectories of flow features. Cmu = 0 Figure 14 presents acquired images for the 0.75% Gurney flap and Jet flap (Cmu = 0.01) Cmu = 0.0037 0.05 at a freestream velocity of 15m/s. The results Cmu = 0.0068 indicate that despite similar aerodynamic effects, the flow physics present are Cmu = 0.01 somewhat dissimilar. The jet flap shows 0.00 Cmu = 0.029 evidence of significant turning of the flow around the trailing edge such that the jet exit becomes functionally the rear separation point. The jet is seen to expand rapidly and deflect streamwise; initially due to pressure -0.05 gradients across the jet and later due to entrainment and absorption of the free stream axial momentum (Jordinson 1956). The Gurney flap appears to shed a fairly thick -0.10 0 4 8 12 16 wake extending from the separation bubble formed behind the flap. The visualized wake Angle of Attack, deg may correspond to the von Karman vortex Fig. 13 Effect of Cmu on Pitching Moment street identified by Jeffrey (2000). The Coefficient and Zero Lift Coefficient Increments significant turning of the flow seen with the jet flap is not observed. A line indicating the approximate trajectory of the shear layer shed from the flap extremity is also observed. Comparison of the skin friction patterns also suggests that while the jet flap draws the lower surface boundary layer away from the surface, the Gurney causes deceleration and recompression. It may thus be tentatively inferred that the Gurney augments lift by violating the Kutta condition while the jet flap increases flow turning and hence effective camber near the trailing edge. Jet exit Gurney flap Fig. 14 Stream-wise flow patterns 1.3.5 Design and Development of Dynamically Reconfigurable Slot Exit Geometry Notes: In this section, we reiterate our design for reconfigurable slot geometry. Depending on the performance of the synthetic Gurney flaps (SGF’s) and SJA’s, and the relative complexity to the reconfigurable slot, we will maintain slot reconfiguration as a viable option. 1.3.6 Manufacture/Purchase Instrumentation for Testing/Verification of New SJA Two 32-channel pressure scanners from Pressure Systems Inc. have been ordered to serve in pressure data acquisition for the remainder of the project. Aeroprobe has begun manufacturing two fast-response fivehole probes for use in flow diagnostics during the project. The sensors for these probes have a rather long delivery time, and we are still waiting for these sensors. 1.3.7 Integrate New SJA into NACA-0015 Wing 2. Experimental Data Acquisition with New SJA and/or Feedback Sensors Planned Status: Start September 24th, 2003 –11% Complete Actual Status:15% Complete Notes Regarding Milestone: Our CMOS camera needed for the PIV work is damaged. It has been shipped to the manufacturer for repairs. What delays us is the need to determine the cause of the damage. This is a very expensive piece of equipment and we could not afford to risk again damaging it. 2.1 Testing of Synthetic Gurney Flap Controller Planned Status: Start September 24th, 2003 – 27% Complete Actual Status: 15% Complete Notes Regarding Tasks: We have completed the design of our high-precision, rotary (Wankel type) SJA for use at the wing’s trailing edge as synthetic gurney flap. The actuator is now being fabricated using our CNC machine. 2.2 Testing/Verification of New SJA/Slot Design in Benchtop Testing Planned Status: Start September 24th, 2003 – 27% Complete Actual Status: 0% Complete Notes Regarding Tasks: 2.3 Perform Time-Resolved PIV on New SJA Planned Status: Start September 24th, 2003 –20% Complete Actual Status: 0% Complete Notes Regarding Tasks: 2.4 Acquire Steady/Unsteady Data During Testing of SJA/Wing System with Feedback Sensors Planned Status: Start December 17th, 2003 – 4% Complete Actual Status: 0% Complete Notes Regarding Tasks: 3. Development of Aerodynamic Models for Wing with Distributed SJA Planned Status: Start March 15th, 2004 – 0% Complete Actual Status: 10% Complete Notes Regarding Milestone: 3.1 Develop Aerodynamic Models for Distributed Actuation Planned Status: Start March 15th, 2004 – 0% Complete Actual Status: 20% Complete Notes Regarding Tasks: To develop control laws for closed loop synthetic jet actuation, wherein a desired angle of attack is to be achieved through hinge-less actuation, static experiments were first conducted to model the pitching moment coefficient of the wing section. This model is then utilized to design control laws for set point tracking of the angle of attack. The control law development will be carried out in two phases. The first phase would involve development of a PID controller for set point tracking. The PID architecture is chosen for the ease of implement ability and to gain sufficient insight into the control related issues. The second phase involves development of an adaptive controller to account for uncertainties that could be parametric in nature or un-modeled dynamics. Objective: 1. To learn the static relationship between angle of attack, jet frequency and moment coefficient. Free Variables: Angle of attack ( ), Jet Frequency (f), Free Stream Velocity ( U ). Measurement Variables: Pitching moment coefficient ( cm ). Experiment Procedure: For a fixed value of angle of attack and free stream velocity (20m/s), we varied the jet frequency from 30Hz to 100Hz with the interval of 10Hz . Then keeping the free stream velocity same, we varied the angle of attack from 17 to 27 with the interval of 2 . Results: Figure 15 shows the pitching moment variation with angle of attack for various synthetic jet frequencies. From the Figure it is clear that pitching moment about pivot point always increases with positive change in angle of attack or jet frequency. The MRAN algorithm mentioned in previous reports was used to approximate static pitching moment data. As the available experimental data corresponds to static experiments, we model pitching moment as function of angle of attack and jet frequency. M f , f Figure 16 shows the variation of modeled and experimental moment data for zero jet frequency. From the figure it is clear that we were able to model the static pitching moment data within experimental error tolerances. Figures 17 and 18 show the modeled and experimental pitching moment data variation with angle of attack for various jet frequencies. Further, Figure 19 shows the modeled and experimental pitching moment data variation with jet frequency for different angles of attack. It is important to mention that we required only 8 Gaussian functions to model the static pitching moment data. It should be noticed that SJA is more effective for 22o . Pitching Moment vs -0.5 -1 Moment (N-m) -1.5 0Hz 30Hz 40Hz 50Hz 60Hz 70Hz 80Hz 90Hz 100Hz -2 -2.5 -3 -3.5 17 18 19 20 21 22 23 24 25 26 27 (deg.) Figure 15: Static Experiment Moment Data Plots for Different Jet Frequencies. Jet Freq. 0 Hz -0.8 Expt. Data Modeled Data -1 -1.2 -1.4 Moment (N-m) -1.6 -1.8 -2 -2.2 -2.4 -2.6 -2.8 17 18 19 20 21 22 23 24 25 26 27 (deg.) Figure 16: Pitching Moment vs Angle of Attack (Jet Freq. = 0 Hz.). Jet Freq. 30 Hz Jet Freq. 40 Hz -0.5 -0.5 Expt. Data Modeled Data Expt. Data Modeled Data -1 Moment (N-m) Moment (N-m) -1 -1.5 -2 -2.5 -3 16 -1.5 -2 -2.5 18 20 22 24 26 -3 16 28 18 20 (deg.) 22 24 Jet Freq. 50 Hz -1 Expt. Data Modeled Data Expt. Data Modeled Data -1.5 Moment (N-m) -1 Moment (N-m) 28 Jet Freq. 60 Hz -0.5 -1.5 -2 -2.5 -3 16 26 (deg.) -2 -2.5 -3 18 20 22 (deg.) 24 26 28 -3.5 16 18 20 22 24 26 28 (deg.) Figure 17: Pitching Moment vs. Angle of Attack for Various Jet Frequencies Jet Freq. 70 Hz Jet Freq. 80 Hz -1 -1.5 Expt. Data Modeled Data Expt. Data Modeled Data -2 Moment (N-m) Moment (N-m) -1.5 -2 -2.5 -2.5 -3 -3 16 18 20 22 24 26 -3.5 16 28 18 20 (deg.) 22 24 Jet Freq. 90 Hz 28 Jet Freq. 100 Hz -1.5 -1.5 Expt. Data Modeled Data Expt. Data Modeled Data -2 Moment (N-m) -2 Moment (N-m) 26 (deg.) -2.5 -2.5 -3 -3 -3.5 16 18 20 22 24 26 28 -3.5 16 18 20 (deg.) 22 24 26 28 (deg.) Figure 18: Pitching Moment vs. Angle of Attack for Various Jet Frequencies =21o =23o -1 -0.5 Expt. Data Modeled Data Moment (N-m) Moment (N-m) -2 -2.5 -3 -3.5 Expt. Data Modeled Data -1 -1.5 -1.5 -2 -2.5 -3 0 20 40 60 Jet Frequency (Hz) 80 -3.5 100 0 20 =25o 100 -0.5 Expt. Data Modeled Data -1 Expt. Data Modeled Data -1 -1.5 Moment (N-m) Moment (N-m) 80 =27o -0.5 -2 -2.5 -1.5 -2 -2.5 -3 -3.5 40 60 Jet Frequency (Hz) 0 20 40 60 Jet Frequency (Hz) 80 100 -3 0 20 40 60 Jet Frequency (Hz) 80 100 Figure 19: Pitching Moment vs. Jet Frequency for Various Angle of Attacks We can use this RBFN model to compute the slopes of pitching moment with respect to angle of attack and jet frequency at different operating points thereby enabling us to do quasi-steady control of the SJA wing. 3.2 Develop Artificial Neural Network (ANN) to Incorporate Aerodynamic Models Planned Status: Start March 15th, 2004 – 0% Complete Actual Status: 0% Complete Notes Regarding Tasks: 4. Development and Verification of Feedback Control Methods for a Wing with Distributed SJA’s Planned Status: Start February 18th, 2004 – 0% Complete Actual Status: 10% Complete Notes Regarding Milestone: 4.1 Develop Closed-Loop Control Methodologies Planned Status: Start February 18th, 2004 – 0% Complete Actual Status: 20% Complete Notes Regarding Tasks: The equation of motion for a SJA controlled, free to pitch wing can be represented as: I M ( , f ) M 0 where I is the Moment of Inertia of the wing about the pivot point, is the angle of attack f is the SJA frequency and M 0 is the static moment acting due to the offset between the centre of gravity of the wing and the pivot point.. The nonlinear moment function M ( , f ) is unknown and can be learnt online/off-line by RBFN as described in previous report. But now the control variable f appears in a non-affine way which makes the control problem more difficult. To be able to characterize these and other nonlinear control effects better, we first investigate the efficacy of simple PID based fixed/scheduled gain controllers for quasi-steady control of the SJA wing in the wind tunnel. Further, from Figures 15,16 and 17, it is apparent that the moment variation with respect to angle of attack and jet frequency is predominantly linear and therefore the moment function can be approximated as follows: M ( , f ) M Cm Cm f f Where, Cm and Cm f represents the pitching moment slopes w.r.t. angle of attack, α and jet frequency, f and approximate values for these slopes can be obtained from RBFN fit of static data. I Cm Cm f f M 0 Hence, We mention that M 0 in above equation also includes the effect of M term (pitching moment when f 0 ). The control objective is to track a trajectory in terms of r which is at least twice differentiable with respect to time (So r , r can be determined). The reference trajectory can be designed as a step function from one angle of attack value to another or a smooth 5th order polynomial, so that the jerk is minimized. Let e be the error between the actual and the reference angle of attack: e r Cm f Cm M f 0 r Hence e I I I Adding and Subtracting Cm I r on the right hand side, we get: e Cm e I Cm f I Cm M f r 0 r I I The control law calculates the control as a summation of two components, such that f f1 f 2 . The first component performs PID control on the tracking error: f1 K1 edt K 2 e K3e and the second component of the control performs dynamic inversion to cancel the known terms Cm M r 0 r I I Cm M I f2 r 0 r Cm Cm f Cm f f So the closed loop error dynamics can be written as: Cm Cm f K1 edt K 2e K 3e I I Cm K3 Cm f K 2 Cm Cm f K1 e f edt 0 e e I I I I e e Introducing new state variable z1 edt , z2 e and z3 e , we get: z1 0 z z2 0 z C K 3 m 1 f I 1 0 Cm K 2 Cm f I I 0 z1 z Az 1 2 Cm f K 3 z3 I The asymptotic stability of the system now corresponds to having the eigenvalues of the closed loop matrix ‘A’, to lie in the open left half plane which leads us to the following conditions: Cm f K 3 Cm f K 2 Cm 0 0, I I I I Cm f K 3 Cm f K 2 Cm Cm f K1 0 I I I I Cm f K1 0, As Cm f 0 (moment increases with the jet frequency) therefore K1 , K3 should be greater than zero and K 2 Cm Cm f . Thus by making a judicious choice for various gains, asymptotic tracking of the reference trajectory can be achieved. The above control law assumes that Cm and Cm f are known accurately, so that the dynamic inversion Cm M r 0 r . But that is not the case in reality, I I component of the control law can cancel out the terms and hence to handle any disturbance due to modeling errors we can design indirect adaptation laws for Cm and Cm f as discussed in Subbarao (2001). Further, from figure 3 it is apparent that there are two values for Cm for α < 22o and α > 22o. To take care of that we will schedule the gains i.e. we need to choose different values of controller gains for α < 22o and α > 22o. We also mention that the PID controller requires the knowledge of the rates of angle of attack which are not being measured in the current set up. To obtain estimates of the rate of change of angle of attack, we will use a first-order lead filter, or a first/second order difference of the filtered angle of attack measurements as discussed in Singla et al. (2003). k 1 k t 4 k 1 3 k k 2 2 t Beside this, the design of control law for non-affine RBFN model is also in progress. We mention that the control law discussed in this report will be used only to control the SJA wing in quasi-steady manner. Tentative Schedule: Test PID controller discussed is this report by 25th October. Complete free to pitch experiment to learn the dynamic model of the wing by first week of November. 4.2 Verify Closed-Loop Control Methodologies Planned Status: Start August 8th, 2004 – 0% Complete Actual Status: 5% Complete Notes Regarding Tasks: The controller of the closed-loop simulations for free-to-pitch motions has been developed. It incorporates the SJA dynamical model, the wing aerodynamics model and the wing dynamics model. Simulations are being run at present. 5. Demonstration of Distributed Sensing/Actuation/Control Planned Status: Start October 13th, 2004 – 0% Complete Actual Status: 0% Complete Notes Regarding Milestone: 5.1 Demonstration of Distributed Actuation/Sensing and Feedback Control in Experimental Setup Planned Status: Start October 13th, 2004 – 0% Complete Actual Status: 0% Complete Notes Regarding Tasks: 5.2 In-Flight Demonstration of SJA and Control on UAV Platform Planned Status: Start October 13th, 2004 – 0% Complete Actual Status: 0% Complete Notes Regarding Tasks: 5.2.1 Integrate Distributed Sensing/Actuation Modules into UAV Platform 5.2.2 Flight Test on UAV Platform for Final Verification of Distributed SJA and Controllers 6. References Jeffrey, D. Zhang, X., and Hurst, D. W., 2000, “Aerodynamics of Gurney Flaps on a Single-Element High-Lift Wing," Journal of Aircraft, Vol. 37, No. 2, pp. 295-301. Jordinson, R., 1956, “Flow in a Jet Directed Normal to the Wind,” R&M 3071, London. Lockwood, V. E., and Vogler, R. D., 1958 “Exploratory Wind-Tunnel Investigation at High Subsonic and Transonic Speeds of Jet Flaps on Unswept Rectangular Wings,” NACA TN 4353. Singla,, P., J.L. Crassidis and J.L. Junkins, 2003, “Spacecraft Angular Rate Estimation Algorithms for StarTracker Based Attitude Determination,” Paper # AAS 03-191, AAS/AIAA AIAA space Flight Mechanics Meeting February 9-13, 2003, Ponce, Puerto-Rico Spence, D. A., “Some Simple Results for Two-Dimensional Jet-Flap Aerofoils, 1958, ” The Aeronautical Quartely, pp. 395-406. Subbarao K., 2001,“Structured Adaptive Model Inversion: Theory and Applications to Trajectory Tracking for Non-Linear Dynamical Systems,” Ph.D Dissertation, Aerospace Engineering Dept., Texas A&M University.