Composite Pages 1-6

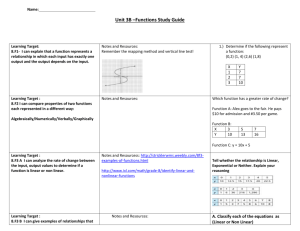

advertisement

Team UAH 2009 Concrete Canoe Design Report “ITZ Civilized” Analysis We welcome this year’s requirement for a common hull design Looks can be deceiving: because it allows direct comparisons to be made between different Our boat is significantly teams’ choices of critical parameters and design requirements, different from all others. hydrodynamic designs, structural analyses, concrete technology and managerial strategies, as well as construction, compliance to dimensional requirements, and overall performance. In this report, we will show that while our entry might look deceptively like our competitors’ canoes, its unique attributes place it a league ahead in both design and performance. Critical Parameters: Many of the methods used and assumptions made to design traditional reinforced concrete structures cannot be applied to produce advanced cementitious composites (Vaughan and Gilbert 2001). In the design of our concrete canoe, for example, the structure cannot be allowed to crack, so knowledge of the concrete compressive strength is not as important as it is in other applications. It is the elastic modulus and tensile strength of the cementitious matrix, as well as the bond strength between the matrix and the reinforcement, that impact our design most. As mentioned below, we relied on material symmetry and multi-layered reinforcement to maintain structural integrity, and took advantage of molecular and atomic interactions to strengthen the ITZ and the matrix/fiber interface. Even though the exterior dimensions of this year’s hull are fixed (NCCC Rules 2009), boats of similar shape will not be equally efficient because their structural integrity, dynamic response, and modal parameters will depend on the density, stiffness, and position of the materials employed during fabrication, as well as the physical constraints imposed by structural members and boundary conditions encountered while racing (Gilbert et al. 2006). Canoe mass (weight) is one of the most critical parameters and we established ours at 97.5 kg (215 lb) based on buoyancy calculations involving our women’s sprint team. We determined that a combined mass (weight) equal to 226.8 kg (500 lb) would give us sufficient draft [12 cm (4.75 in.)] so that our bow was slightly submerged, with the waterline extending along the entire length of the canoe. This critical racing condition makes the hull displace water efficiently and allows all of our teams to achieve maximum hull speed by having the largest possible waterline length. For a given reinforcement and geometrical configuration, the stiffness ratio of the reinforcement to the matrix controls the stress transfer (Biszick and Gilbert 1999) and the Major Considerations: choice of materials alters the characteristics of the fundamental modes Strength, stiffness, (Ooi et al. 2004). As explained below, we dynamically tuned our hull to geometry, and weight. lower our canoe’s deceleration and increase our teams’ average velocity. Service Loads: The stress distribution in a concrete canoe changes as it is transported and paddled. During past competitions, our competitors have studied these loading conditions using numerical techniques (Design Reports 2009) but ambiguities in results reported for critical loads indicate a lack of sophistication and the need for making further refinements in their models. Our predecessors developed an empirical method by mounting strain gages on a composite prototype (Team UAH 2006). We followed their lead and mounted gages on our prototype at all of the critical locations reported by the major competitors (Design Reports 2009). After testing our boat under transport and racing conditions, we unequivocally proved that the peak strain occurs directly beneath the bow paddler during the men’s endurance race. We modeled this critical section by pure bending and loaded a test plate, having a cross section identical to that used in our Methods of Analysis: prototype, until the critical strain was reached. For our men’s endurance Strain gages on prototype; team, we determined that the critical service load was equivalent to a test plate in pure bending. 0.28 N-m (2.5 in-lb) moment applied to a 2.54 cm (1 in.) wide plate. Composite Lay-Up: Our structural design relies on the large difference in stiffness between the constituents in a composite section to drive the internal stress from a flexible cementitious matrix to multiple layers of a relatively stiff graphite mesh. We recognized that the thickness of our canoe would ultimately depend upon the specific weight of our concrete. But we felt that we could easily place a 9.53 mm (0.375 in.) thick composite section and used this value for design and testing purposes. We reinforced the section with three layers of mesh and placed materials symmetrically to form an adaptive section optimized to resist stress reversals (Biszick and Gilbert 1999; Biszick et al. 2006). We selected the elastic modulus of last year’s mix [E = 2.76 GPa Assumptions: 9.53 mm (400 ksi)] as a benchmark, and positioned two layers of mesh as close as thick section; matrix with possible to the upper and lower surfaces of the section to increase the elastic modulus 2.76 GPa. “It’s what’s inside that counts.” 1 Analysis Team UAH 2009 Concrete Canoe Design Report “ITZ Civilized” moment of inertia. Dynamic Characterization: We fed the dimensions from our design drawings and the mechanical material properties of our section into a dynamic finite element model based on classical laminated plate theory (i.e., using NASTRAN software; Ooi et al. 2004). The model showed that the first mode was anti-symmetrical torsion while the second mode was “flutter” bending. Fibers in the outermost layers were aligned longitudinally and transversely with respect to the longitudinal centerline of the canoe so that they were positioned in the principal stress directions. We added a third layer of reinforcement at the center of the section with fibers oriented at plus and minus 45° to the structural axes. The additional layer and its strategic rotation increase the torsional stiffness and achieve a better balance between the fundamental modes, enabling the strain energy stored in the deformed shape to be more efficiently converted into forward propulsion (Team UAH 2005). Computer simulations show our boat’s movement mimics the locomotive motion of aquatic creatures and our lay-up resembles the semi-helically wound configuration found in a shark’s skin. Although we knew that the natural frequencies associated with the fundamental modes would be relatively high (~ 15-20 Hz) compared to our stroke rate (~ 1 Hz), our boat will decelerate less between strokes resulting in the higher average velocity that it will take for us to win in the water. Stress Analysis: We assumed that bending was the primary mode of loading and applied the standard transform section theory to perform a stress analysis using an Excel spreadsheet. For the critical load condition, the maximum tensile and compressive stresses in our Computational Tools: concrete mix were 1.19 MPa (173 psi) and the maximum stresses in the AutoCAD (hydrodynamics); reinforcement were 67.7 MPa (9.82 ksi). The graphite has a high tensile NASTRAN (dynamics); strength [3.65 GPa (530 ksi)] and, with a margin of safety of 54, there is Excel (stress analysis). little chance that the fibers will break. Since the compressive strength of Requirements: A boat a concrete mix is always higher than its tensile strength, our design having a mass of 97.5 kg relies on placing a 97.5 kg (215 lb) boat with a relatively flexible with a composite section concrete mix that has sufficiently high tensile and bond strengths to that can withstand 0.28 N-m withstand the critical loading. per 2.54 cm. Development and Testing Reinforcement Compliance: Team UAH introduced graphite fibers into the competition sixteen years ago (Team UAH 1993) because they are ten times stronger and five times lighter than steel. As described in our lay-up procedure (see page 1), we positioned three layers of fiber mesh in the composite section. Each layer of reinforcement consists of non-impregnated graphite fibers with 3,000 fibers per tow, spaced at 3.18 mm (0.125 in.) intervals. Each tow is 0.19 mm (0.0075 in.) thick by 1.07 mm (0.042 in.) wide. The manufacturer reports the elastic modulus and tensile strength of the fiber to be 231GPa (33.5 Msi) and 3.65 GPa (530 ksi), respectively. Primary Reinforcement: We calculated the minimum percent open area (POA), defined in Continuous graphite fiber Section 4.3.2 (NCCC Rules 2009), at 44 percent. We performed mesh with a POA of 44%. reinforcement thickness measurements in accordance with Section 4.3.1 (NCCC Rules 2009) and established the maximum reinforcement/thickness ratio for our final design to be 0.133. The procedures and results of the experimental tests that we conducted are included in our Engineer’s Notebook (Team UAH 2009). Mix Design: Although useful as a benchmark for structural design purposes, last year’s mix did not meet many of the requirements for the current competition. So we followed a comprehensive trial and error mix design process to arrive at a final mix. We began by combining equal parts of portland cement and fly ash to bind a matrix that consisted of cenospheres, water, latex, and air entrainment admixture. Our goal was to produce the lightest, strongest, and most flexible mix possible so our composite section could safely withstand the critical load. We geared our effort toward the current trends in industry to go “green” with a focus on sustainability in design and construction. Our final mix is “as green as it gets,” since 100 percent of the binders (excluding cement) and all of the aggregates are recyclables. Bond strength is very important and, as our work progressed, we realized a poly(vinyl butyral) (PVB) admixture and poly(vinyl alcohol) (PVA) fibers could be used to strengthen both the ITZ (Breton et al. 1993; Scrivener et al. 2004; Zheng et al. 2005) and the overall composite section (Friedrich et al. 2005). We evaluated a total of 83 trial mixes before selecting the one used to place our canoe. The final mix was designed and selected based on a method developed for fabricating structurally “It’s what’s inside that counts.” 2 Development and Testing Team UAH 2009 Concrete Canoe Design Report “ITZ Civilized” equivalent reinforced concrete composite plates (Raut et al. 2004). We placed an older mix that had a known elastic modulus over our reinforcement scheme and loaded a specimen [10.2 cm (4 in.) wide by 35.6 cm (14.0 in.) long] to failure by subjecting it to pure bending (ASTM C78). As we varied the constituents, we were able to determine the elastic modulus of a new mix by comparing the center deflections of the new plate with those of the old one. We placed our plates on a vertical template and measured the thickness variations from top to bottom so that shrinkage and consolidation could be taken into account during the placement of our concrete canoe. This procedure allowed us to perform concrete mix design while studying, concurrently, the impact a change in constituents had on the overall structural performance of our composite. Once we had achieved the desired composite properties, we tested the matrix alone. Binder Selection: We used portland cement (ASTM C150) and Class C fly ash (ASTM C618) as binders in the final mix and made sure all requirements on mass were satisfied (Section 3.3.1; NCCC Rules 2009). When mixed with lime and water, fly ash forms a cementitious compound (Joshi and Lohtia 1997). The particles are typically a few micrometers in diameter and nearly spherical in shape (Majko 2007). They can significantly alter material microstructure and mechanical properties and their addition favorably impacts environmental sustainability (Yang et al. 2007). In our case, the relatively small particles increase bond strength and fill in microscopic voids in the matrix, helping us to maintain the structural integrity of our composite section. Aggregate Selection: We used cenospheres as aggregates in the final mix and made sure all requirements imposed on aggregate proportioning were satisfied (Section 3.3.2; NCCC Rules 2009). As described on page 7, the cenospheres allowed us to meet the requirement to use recycled materials. They are thin-walled glass spheres comprised primarily of silica and alumina that are lightweight, inert, and hollow (Sphere Services 2009). The spheres are harvested from the surfaces of ash ponds and then processed and marketed for performance enhancement in many different products. While designing our mix, we strove to produce the smallest possible particle size distribution (see Appendix C) by allowing only 95% (by weight) of the particles to remain on the No. 100 sieve. This increased workability, allowed us to place thinner layers, and made it possible for us to easily patch our canoe. The smaller particles that constituted the remainder of the Sustainability: composite aggregate created a dense grain structure that helped prevent Excluding cement, all of our graphite fibers from buckling on the compressive side of the composite binders and aggregates are section. Aggregates were batched at hydroscopic moisture content recyclables. (ASTM C127). Secondary Reinforcement: Debonding may occur between the matrix and our fiber reinforcement due to shear deformation and fiber sliding (Friedrich et al. 2005). To counteract the potential debonding, we added poly(vinyl alcohol) (PVA) fibers to help bridge micro-cracks and strengthen the matrix. The fiber has a high tensile strength, a high modulus, and low specific gravity. PVA is obtained from poly(vinyl acetate) which is readily hydrolysed by treating an alcoholic solution with an aqueous acid or alkali (Zheng and Feldman 1995). The hydrophilic nature of PVA fibers cause them to bond well with the cementitious matrix (Wang and Li 2006). The formation of this microstructure is attributed to the effect PVA has on the nucleation of CH and CSH at the fiber surface and on the presence of polymer around the fibers (Wang and Li 2006; Feldman and Barbalata 1996). Admixtures: We used a latex admixture to enhance the bonding and flexibility of our matrix and added an air entrainment admixture (ASTM C260) at 1774 ml (60 oz) per 45.4 kg (100 lb) of cementitious materials (15 times the manufacturer’s recommended dose) to reduce weight and achieve the minimum air content (Section 3.34, NCCC Rules 2009). The overdose had no detrimental effects. Butvar B-79 (PVB) was employed to strengthen the ITZ and was selected because of its binding efficiency, adhesion, toughness, flexibility, and waterproofing properties (Lavin et al. 2008). The product comes in the form of a lightweight solid white powder that is completely insoluble in cementwater-mixes and does not crosslink or form polymers or covalent Strategy: A PVB admixture bonds. It is an already polymerized plastic similar to cellulose and and free PVA fibers were contains hydroxyl groups that have the potential to form a hydrogen used to strengthen the bond between molecules, or within different parts of a single molecule composite. (see page 7 for additional details). Testing: We studied micro-mechanical behavior and composite failure under combined loading by testing end-loaded cantilevers (based on ASTM D747). Then, we tested concrete specimens to obtain the elastic modulus [3.44 GPa (499 ksi)] and 7-day tensile strength [4.83 MPa (700 psi)]. “It’s what’s inside that counts.” 3 Development and Testing Team UAH 2009 Concrete Canoe Design Report “ITZ Civilized” We cast concrete cylinders (ASTM C31) and performed compression tests (ASTM C39) to get the 28-day compressive strength [13.10 MPa (1900 psi)]; and measured the unit weights [1094.6 kg/m3 (68.4 lb/ft3) and 1101.1 kg/m3 (68.7 lb/ft3)] (ASTM 138) and air contents [6.6 % and 6.1%] by the gravimetric method, for the mixes described on pages B1 and B2, respectively. Finally, we computed the thickness [1.27 cm (0.5 in.)] required to obtain the target weight based on the individual weights of the concrete, reinforcement, flotation, stain, sealant, and graphics. Although our main structural mix (see page B2) had an elastic modulus Final Design: Thickness 1.25 times that assumed for our benchmark, when we tested a 1.27 cm adjusted to obtain target (0.5 in.) plate in pure bending, our composite section resisted a weight; margin of safety moment of 20.2 N-m (178.6 in-lb) applied to a 10.2 cm (4 in.) wide equal to 17.9. plate giving us a margin of safety of 17.9! Project Management and Construction Following last year’s unsuccessful campaign, the alumni that attended the conference scheduled a meeting with our faculty advisors to discuss why things didn’t go well and how they might help. Several problems were identified, particularly in the areas of fundraising, faculty support, safety, and project management. In response, our alumni made several commitments. They agreed to help raise funds, supervise concrete canoe design and construction, and train the paddling Alumni Support: Serious team. A past president, who had recently returned to study Engineering commitments were made Management, volunteered to become president again, if the membership to ensure our success. was agreeable. He prepared a position paper outlining his goals and expectations while explaining that he intended to train his fellow officers so they could take the helm in future stints. The paper was sent by email to all Chapter members and the response was so overwhelming that he was later elected unanimously by affirmation. Fundraising: The advisors explained that during the 2007-2008 academic year UAH was facing large budget cuts and strict guidelines had been placed on fundraising by the administration. The Chapter was barred from approaching all potential sponsors, and was therefore unable to obtain the physical resources and financial backing it needed. This year, with the restriction on contacting donors eased, the team was able to utilize their alumni’s experience with vendors and marketing to prepare a professional fundraising packet that showcased the Chapter’s contributions to the Civil Engineering community. While the economic downturn has limited the amount of funding available, we improved our Chapter’s relationship with both the university and local businesses, and created fundraising and professional development opportunities for the future. Our efforts paid off immediately prior to the regional conference when we secured the largest single donation in our Chapter’s history. The majority of the materials required for construction of the mold and concrete canoe (listed in the bill of materials on page 10) were either salvaged or donated. We spent an additional $4,600 on materials and supplies. Faculty Support: Last year, increased faculty workload resulted in less time for advisor interaction with Chapter members. This year, we worked to establish a plan and schedule prior to the start of the school year. This plan required regular briefings, so the faculty advisors were able to schedule meetings with the team leaders well in advance. Safety: During construction of the 2008 practice boat, the Canoe Chair nearly lost his thumb while working with a table saw. The accident itself, and the subsequent infection and rounds of surgery, completely removed him at a critical point in the project. This year, we strictly enforced a safety policy requiring at least two team members to be present at all times and mandated that all chapter members working on equipment take a rigorous shop course. Additionally, no power tools may be operated in the work area without the Canoe Chair or the Chapter President present. Challenges Faced: We stressed the responsibility of working safely, used personal Fundraising, technology protective equipment, and followed guidelines suggested by the transfer & documentation. Occupational Safety and Health Administration (OSHA 2009). All of our members were required to attend seminars presented by the UAH Environmental Health and Safety Office. We secured manuals and educational safety videos to supplement this training and reviewed the Material Safety Data Sheet for each material with which we worked. Project Management: Last year, there was no redundancy in the team leadership. Knowledge resided with specific individuals with little overlap; therefore, the sudden absence of the Canoe Chair threw the team into turmoil. Individuals who had previously been in supporting roles were suddenly cast “It’s what’s inside that counts.” 4 Project Management and Construction Team UAH 2009 Concrete Canoe Design Report “ITZ Civilized” into leadership positions without the necessary knowledge or experience. This year, we elected experienced leaders with the specific intention of training and developing new chapter leadership. Rather than relying on a novice to gain on-the-job knowledge, we’ve learned that leaders produce leaders. Our emphasis on training means we have “understudies” available to take over when necessary. In previous years, we compartmentalized the project by assigning each task to a different team. This method relied heavily on each team leader having a high level of experience, organization, and communication skills in order to integrate each team’s product into the whole. Given the small size of our chapter this year, we simply did not have enough team members with that skill set. This year, we used a systems approach to look at the project holistically to see where the overlaps and interactions lay. At our first chapter meeting, we formed a coordinating committee consisting of the Project Manager (chapter president), Project Engineer (Concrete Canoe Chair), and consultants (faculty and graduate advisors). These key stakeholders acted as a Skills Developed: Project configuration control board to manage scope and monitor project planning, risk management, status, budget, and corrective actions throughout the project. safety & teambuilding. While our new approach does increase the workload for key team members, we’ve seen a significant improvement in efficiency and decision-making. By looking at the big picture, we were able to minimize the conflicts and misunderstandings that have crippled our efforts over the last few years. We are not only improving our chapter this year, but we are also building a foundation for future efforts. Teambuilding: The Project Manager and Project Engineer evaluated the strengths and weaknesses of past teams and elected to follow the team building approach developed by recent teams at UAH. To this end, the coordinating committee asked all team members to go through a corporate training and development course offered by an Air Force veteran turned behavioral consultant (Bentley 2009). As part of the course, a DISC profiling system (Inscape 1996) was used to uncover our strengths, weaknesses, motivations, and behavioral tendencies. Each team member discovered how he or she tended to behave under stress, in a team, when in conflict, when communicating, when fearful, when avoiding certain activities, and when problem solving. More important, they learned how others tend to react in the same situations. Given this insight into our teammates, we learned how to interact efficiently by utilizing each other’s strengths and compensating for each other’s weaknesses. We quickly realized it’s what’s inside that counts, and subsequently learned to identify the attributes required to become not only champions but also successful engineers: initiative, integrity, innovation, determination, leadership, and teamwork. You’ll see these listed on the interior of our boat. Critical Path: With the help and guidance of our alumni, the coordinating committee created an organizational breakdown structure (OBS) in which organizational relationships were identified and used as the framework for assigning work responsibilities. Milestones were established and the critical path was determined by defining tasks that had no float. The critical path and the milestones are displayed on the project schedule (see page 9). Table 1 below highlights the major tasks. Table 1: Project Milestones and Differences Milestone Difference Reason Structural Analysis 1-week delay Stress Analysis Mix Design 7-week delay Material Procurement Construction 3-week delay Mold Construction Documentation 1-week delay Mold Construction The coordinating committee studied the projected duration of each critical path activity, overlaps in activities in the schedule, and the milestones experiences by previous teams, and they modified our schedule to reduce the risks of overrun. Each major milestone marked a significant transitional event for the project. Although leadership during design and construction was turned over to individuals with expertise and experience, a conscientious effort was made to recruit, retain, train, and rely on new members. Recognizing the possibility that future events may cause adverse effects, we adopted a policy of continuous risk management (Murphy et al. 2006). We applied the underlying principles for decisionmaking in many phases of the project ranging from team organization and mix design to construction and safety. Risks were resolved or, when they turned into problems, handled. Work-hours were compiled for each major activity prior to the conference competition: 220 for structural analysis, 400 for mix design and structural testing, 1,500 for canoe construction, and 1,000 for paddling. Approximately 380 hours were spent during this period on other tasks including management, “It’s what’s inside that counts.” 5 Project Management and Construction Team UAH 2009 Concrete Canoe Design Report “ITZ Civilized” fund raising, and documentation. We expect to spend an additional 1800 hours preparing for nationals. Mold Construction: For the past thirteen years, Team UAH has placed our concrete canoes over male molds. This year, we decided to place our canoe within a female mold. This process eliminated waste during placement, since all concrete remained in the boat. As compared to working with a male mold, concrete settled to the bottom of the hull keeping the center of gravity lower. The process also allowed us to capitalize on shrinkage during form removal. It afforded an excellent outer surface that required little sanding and the ability to precisely replicate the given dimensions while making the adjustments in thickness required to obtain our target weight. The true shape eliminated the need for checking dimensional tolerances after the fact using time consuming and complex contouring methods. We began by modifying the supplied AutoCAD file that was provided to us by the rules committee by including an offset equal to the thickness of the facing materials that were to be used during mold construction. We produced design drawings at cross sections located at 30.5 cm (12 in.) intervals along the length and used them to create 1.27 cm (0.5 in.) thick plywood templates that we mounted and aligned on a wooden strongback. We then ripped 3.8 cm (1.5 in.) wide strips from 0.64 cm (0.25 in.) thick plywood sheets and nailed the strips to the inner surfaces of the templates. We further refined the shape using drywall compound and relied on spotlighting techniques to identify discontinuities. Problem areas were marked and filled with drywall until all discontinuities were removed. Once the mold was finalized, we applied two layers of fiberglass to harden the surface. Foam cross sections were fabricated and inserted into the mold to check for dimensional accuracy throughout the mold construction process. We constructed a composite prototype to verify the critical load and serve as a practice boat. After evaluating our design, we coated the interior of the mold with automotive primer and clear coat. The clear coat was then buffed smooth to prevent the concrete from adhering to imperfections on the surface. Quality Control: We strove to produce a stunning product and chose not to include inlays to keep it defect free. In addition to completely changing our mold construction scenario, we enacted new procedures for testing, documentation, concrete mixing, and placement. Our quality control program relied on training sessions and advanced planning for quality assurance. Everyone involved was required to attend informational sessions to ensure a consistent level of education, experience, and attention to detail. Tasks such as proportioning materials were completed in advance Problems Solved: to ensure efficiency throughout the placement process. Quality control/assurance To ensure a uniform hull thickness, we developed a series of brought us to within 1% of instruments, inspired by bluetops, to gauge the thickness of each layer our target weight. of concrete. During construction, measurements were taken in a 15.24 cm (6 in.) grid to identify high and low spots. These significantly reduced the amount of sand and fill necessary during the finishing stage and brought us to within one percent of our target weight. Canoe Construction: To begin, the team prepared several small batches of white concrete mix and used drywall knives to level the concrete to the interior of the mold. Once the first layer of concrete cured to firmness, the first layer of graphite mesh was draped in the mold, taking care to align the fiber with the axis of the canoe. The second layer of gray concrete was placed carefully over the mesh, to avoid pulling the fibers out of place. After the second layer of concrete cured firm, we draped the second layer of graphite mesh into the mold at a 45 degree angle to the long axis of the canoe and placed another layer of gray concrete. The third layer of graphite reinforcement was then added along with foam floatation and the final layer of white concrete was placed over the entirety of the interior. We secured the foam flotation in the bow and stern using small sheets of graphite mesh. Additional reinforcement was placed over the flotation to minimize cracking. We also added a wooden strip around the upper perimeter of the canoe to serve as added flotation and as a gunwale. We trimmed overhanging reinforcement and wrapped it around the wood before placing concrete over the entire configuration. Latex spheres in the mix coalesce to form a film that coats the aggregate particles and the hydrating cement grains. Since the water required for hydration is held in the system (Biszick and Gilbert 1999), we simply left our canoe to dry. We hand-sanded the interior of the canoe while it was still on the mold and filled any remaining voids with our main structural mix. The bottom was left rougher than the sides to help hold our seats in place during the races. We removed the canoe from the mold 17 days after placement and discovered that we had to do a minimal amount of finishing on its exterior surface. During our corporate training program, we learned that people often wear masks to hide their critical flaws. Following the adage that “less is more,” we decided to feature the natural beauty of our canoe by removing masks from its surfaces. To that end, we kept stains and graphics to a minimum and applied a clear sealer that met ASTM C1315 standards, according to manufacturer’s recommendations. “It’s what’s inside that counts.” 6 Project Management and Construction