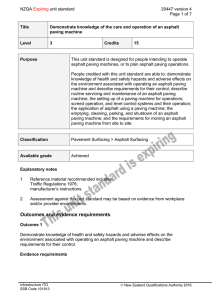

CC/SURF/3/11/01

advertisement

SAQA ___________________ Title: Operate a hot mix asphalt paving machine Unit Standard Number: CC/SURF/3/11/01 Level: 3 Credit: 15 Field: Physical Planning and Construction Sub-Field: Civil Engineering Construction Issue Date: Review Date: Learning Assumptions: It is assumed that people starting to learn towards this unit standard are already able to: Use and Maintain hand tools, have a appropriate license to operate in the workplace. Purpose: This unit standard will be useful to people who contribute to the blacktop aspects for the construction of roads. People credited with this unit standard are able to: Perform basic maintenance on a paver, prepare to operate machine, operate the machine, control feed to hopper during hot mix asphalt paving, clean, park and shut down the machine 2/18/16 CC/SURF/3/11/01 1 Specific Outcomes and Assessment Criteria: Specific Outcomes 1: Perform basic maintenance on a paver Assessment criteria 1.1 Paving machine is checked for maintenance requirements and minor adjustments are made in accordance to manufacturers instructions. Range: checks – fuel level, oil level and cleanness (engine and screed plate heaters), lubricants, hydraulic fluid level and cleanness, water levels, looses nuts and bolts, machine controls and gauges. 1.2 Daily inspection is carried out and, where necessary, adjustments are made and specialized maintenance requirements are reported to the supervisor for work to be carried out in accordance to company policy. Range: includes but is not restricted to checking wear on the screed plate, and on the tamping bar if fitted, knowledge of when to call for specialised servicing 1.3 Paving machine is free of debri, and build up and operator area is free of rubbish Specific outcome 2: Prepare to operate machine Assessment criteria: 2.1 Machine is mounted and dismounted in a safe manner 2.2 Pre-start checks are carried out in accordance with manufacturers instructions Range: includes but is not restricted to walk around, tyre condition and air pressure or track tension and drive sprockets, gauges and controls including governor on engine, hopper, conveyors, flow gates and auger 2.3 Paver screed is set up in accordance with paver operating manual Range: screed attack angle, longitudinal grade, transverse grade, crown, level, thickness 2.4 paver screed controls are set up accordance with paver operating manual Range: manual controls, automatic sensors and control systems 2.5 Tamper bar and/or vibrator controls are set in accordance with manufacturers instructions 2.6 Standard start up procedures are carried out in accordance with manufacturers instructions 2/18/16 CC/SURF/3/11/01 2 Range: Specific outcome 3: includes but is not restricted to visibility, park brake, throttle position, engine, hydraulic and electronic controls are checked after starting and warming the engine, screed is heated Operate paving machine and control feed to hopper during hot-mix asphalt paving Assessment Criteria: 3.1 Feed trucks are discharged in accordance with paver operating manual. 3.2 Instructions are communicated to driver in accordance with company procedures Range: Hopper gate settings, hot mix asphalt feed, paver speed, auger setting 3.3 Machine is operated without risk of damage or loss to machine, property or injury to people 3.4 Machine performance is monitored and corrective action is taken when necessary, in accordance to manufacturers specifications 3.5 Paver speed and hot mix asphalt feed are monitored and maintained to match the delivery rate of the material in accordance to job requirements Specific outcome 4: Clean, park and shut down machine Assessment Criteria: 4.1 Machine is cleaned down in accordance with company requirements 4.2 Machine parking and braking are carried out in accordance with manufacturers instructions Range: Includes but is not restricted to parking on level ground and securing the machine 4.3 Screed is lowered and parked as per manufacturers instructions 4.3 Standard shut down procedures are carried out in accordance with manufacturers instructions Range: 2/18/16 includes but is not restricted to setting control levers and transmission controls, and to idling before stopping CC/SURF/3/11/01 3 Accreditation options: 1. Anyone assessing a learner against this unit standard must be registered as an assessor with the construction ETQA 2. Any institution offering learning that will enable achievement of this unit standard or will assess this unit standard must be accredited as a provider with the construction ETQA 3. Moderation of assessment will be overseen by the construction ETQA according to the moderation guidelines Moderation options: The moderation requirements of the construction ETQA must be met in order to award credit to learners for this unit standard Notes: 1. Essential embedded knowledge is dealt with under the specific outcomes where demonstrate knowledge and understanding is required 2. Range statements are included with specific outcomes as necessary Critical Cross Field Outcomes: This unit standard promotes, in particular, the following cross-field outcomes: Identify and solve problems Work effectively with others in team Organise and manage oneself and ones activities responsibly and effectively Communicate effectively using visual, mathematical and/or language skills Use science and technology effectively and critically Understand the world as a set of inter-related parts of a system Contribute to the full development of oneself 2/18/16 CC/SURF/3/11/01 4