20_SWP_Handling Liquid Nitrogen_MD

advertisement

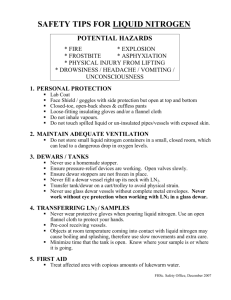

OHS026 Safe Work Procedure Faculty/Division Medicine Document number SOMS.CGM.SWP020 School/ Divisional Unit School of Medical Sciences Initial Issue date 26.6.09 Current version 1.0 Current Version Issue date 26.6.09 Next review date 26.6.12 The Writing Safe Work Procedures Guideline (OHS027) should be consulted to assist in the completion of this form. Safe Work Procedure Title and basic description Title: Liquid Nitrogen Safety Description: Using liquid nitrogen for storage of biological samples Associated risk assessment title and location: RISK ASSESSMENT: 20_RA_Handling Liquid Nitrogen_MD Describe the activity or process Background Liquid nitrogen is a cryogenic liquid used to snap freeze various cell/tissue/fluid samples for long term storage and preservation. There are many safety issues associated with the use of liquid nitrogen as it has the ability to freeze living tissue and can also cause asphyxiation (suffocation) and must be used with the extreme safety. Liquid nitrogen dewars (containing samples) are stored within a designated room (lower ground floor room 9 (LG9)- accessible by the goods lift or Stairs in the Wallace Wurth building). The liquid nitrogen room is equipped with an exhaust fan and oxygen level detector for your safety (see ‘suffocation danger’ for details). Handling of liquid nitrogen dewars Before entering the liquid nitrogen facility, check the oxygen detector (on left side of door) to ensure that the oxygen level is within a safe range within the facility (18-21). Also check that the fan exhaust set to High (also on left side of door). If either the yellow or red alarms (above the door are lit) do not enter room and notify your lab manager immediately. 1. 2. 3. 4. 5. 6. 7. 8. 9. If no alarms are detected and oxygen levels are safe, it is safe to enter the facility. Keep doorway partly or completely open whilst inside the facility to avoid suffocation. Appropriate personal protective equipment (gloves, face shield and long sleeve lab coat) is provided within the facility and must be worn prior to opening liquid nitrogen dewar. Unlock dewar and lift lid upwards (lid should automatically move upwards). Samples are stored within cryovials in boxes which are secured within racks in the dewar. To store new samples, lift rack from dewar carefully and wait for remaining liquid nitrogen to drain out of boxes. Remove the rack from dewar and use the step ladder provided to aid with this. Place rack upon a piece of Styrofoam to avoid damage to the floor and wait a couple of seconds for any remaining liquid nitrogen to evaporate. Remove the metal bar securing the boxes and place new cryovials into appropriate box. ALWAYS KEEP FACE SHIELD ON AS CRYOVIALS CAN EXPLODE WHEN REMOVED FROM LIQUID NITROGEN IF ANY AIR LAEKS INTO VALS. Replace metal bar and place rack back into the dewar slowly to avoid any liquid nitrogen splashing. Close lid and lock dewar. Remove PPE and close door (door automatically locks). List all resources required including plant, chemicals, personal protective clothing and equipment, etc Personal Protective Equipment (PPE) • Wear clean and dry clothing that covers arms and legs. • The clothing should be loose, so it is easy to remove it when an accident happens. • Avoid wearing open trouser pockets and wrapped sleeves. • Wear cryogenic gloves (provided) under the sleeves so no liquid can fall in the gloves. • Wear safety glasses and the face shield provided to ensure complete protection of the face and neck. • Wear non-slip closed footwear and a lab coat which has long sleeves (provided). ___________________________________________________________________________________________________________ ___________ Page 1 of 3 Safe Work Procedure Date Effective: 01/01/2007 Uncontrolled document when printed Current Version: 1.2, 15/08/2007 List potential hazards and risk controls including specific precautions required Suffocation danger • Make sure there is enough ventilation in the facility as liquid nitrogen immediately turns into a gas when exposed to the atmosphere and removes oxygen from the air. Keep door of the facility open when inside. • Avoid transporting liquid nitrogen in lifts carrying other persons – use the goods lift provided. • Carbon dioxide in air is a potential danger. Concentrations from 2.5% cause breathing problems and a concentration of 20% is deadly within some seconds (also when there is still enough oxygen available) Damage to surfaces and footwear · Liquid nitrogen makes stone floors, normal shoe soles and plastic materials crisp and crumbles easily, so take care! (use the step ladder or Styrofoam lid if necessary) · Normal thermos flasks cannot handle low temperatures and the danger of explosion is present. A. REFILLING DEWARS IN LABORATORIES 1. Never refill Dewars or transfer Liquid Nitrogen alone. 2. Make sure that there is good ventilation. Open a door if you are in a small room. NEVER LEAVE A DOOR OPENED IF YOU ARE NOT IN THE ROOM 3. Use Dewars rated for liquid nitrogen a. Never use a Dewar that does not have a pressure relief valve or pressure venting lid/stopper. b. Never use Dewars with makeshift or homemade lids/stoppers. c. Use pressure venting lids/stoppers supplied by the Dewar manufacturer 4. Dewars larger than 20 Litres will be lifted and poured by two people 5. Do not use a Funnel 6. Wear Required Personal Protective Equipment: a. Cryogenic Gloves b. Lab Coat with sleeves pulled over cuffs of Cryogenic Gloves c. Liquid proof Shoe Covers/Spats d. Chemical Splash Goggles or Laboratory Face Shield B. DISPENSING LIQUID NITROGEN FROM STORAGE TANKS 1. Dispense only into Dewars that are rated for liquid nitrogen. (See A.3 above) 2. Dispense only into Dewars that are: a. Equipped with carrying handles or wheels b. Stable/not in danger of tipping over easily 3. Persons filling Dewar(s) will be in constant attendance during filling 4. Prevent Splashing. Place filling hose at or below the mouth of the receiving Dewar 5. Wear Required Personal Protective Equipment (see A.6 above) C. TRANSPORTING LIQUID NITROGEN BETWEEN BUILDINGS 1. Use Dewars rated for liquid nitrogen. (See A.3 above) 2. Never Transport Liquid Nitrogen in an Open Container 3. Wear or Carry Required Personal Protective Equipment (see A.6 above) 4. Do not use unstable wheeled carts or Dewars 5. Avoid grates, large cracks in sidewalks/pavement, or other hazards that could cause tipping D. TRANSPORTING LIQUID NITROGEN WITHIN LABORATORIES AND BETWEEN LABORATORIES IN THE SAME BUILDING 1. Use Dewars rated for liquid nitrogen (see A.3 above). 2. Do not transport Liquid Nitrogen in Open Containers 3. Wear Required Personal Protective Equipment (see A.6 above) 4. If you are carrying a Dewar containing Liquid Nitrogen: a. Make sure Dewar is your ONLY load (no books, coffee, other items) b. Carry transport Dewar as far away from your face and body as possible c. Watch for other people who may run into or bump you List emergency shutdown instructions List clean up and waste disposal requirements If liquid nitrogen is spilt inside a building make sure there is adequate ventilation to avoid suffocation. If spill occurs outside, keep up wind of the spill. Evacuate the area until the liquid has evaporated and oxygen levels are at normal atmospheric levels. A claw can be used to retrieve samples/tubes. In this case, please contact Merideth Hatton (xn 52536). If there is a large spill, or if a vessel is leaking, contact emergency services (UNSW Emergency, xn 56666) and notify the supplier. ___________________________________________________________________________________________________________ ___________ Page 2 of 3 Safe Work Procedure Date Effective: 01/01/2007 Uncontrolled document when printed Current Version: 1.2, 15/08/2007 List legislation, standards and codes of practice used in the development of the SWP NSW OHS Act 2000 NSW OHS Regulation 2001 Australia Dangerous Goods Code Code of Practice for the Labelling of Workplace Substances AS/NZS 2243.2:2006. Safety in laboratories. Part 2: Chemical aspects AS/NZS 2161.1:2000 Occupational Protective Gloves – Selection, Use and Maintenance AS/NZS 1336:1997 Recommended Practices for Occupational Eye ProtectionSafe Work Procedure Form (OHS026) Supervisory approval, training, and review Supervisor: Peter Gunning Signature: Plant custodian: Signature List competency required – qualifications, certificates, licensing, training - eg course or instruction: Training as per Training Needs Analysis, Induction to Lab, Training in this SWP ___________________________________________________________________________________________________________ ___________ Page 3 of 3 Safe Work Procedure Date Effective: 01/01/2007 Uncontrolled document when printed Current Version: 1.2, 15/08/2007