Surfacing Construction

advertisement

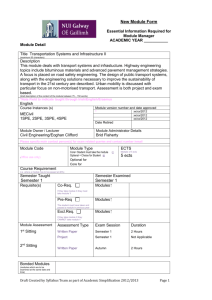

Qualification Details Qualification New Zealand Certificate in Bituminous Surfacing Construction with strands in Bituminous Mixes, Chipseal, and Slurry (Level 4) Credits 85 Detail Strategic purpose statement: This qualification is designed to provide the infrastructure works industry with capable staff who have attained the knowledge and skills to produce quality bituminous surfacing. This qualification provides strong theoretical grounding coupled with the practical skills and knowledge to ensure that graduates are able to safely and effectively work in the surfacing sector on both small and large operations, while contributing to the building of quality infrastructure. These people will able to work with limited or no supervision, and may be become leading hands or second-in-charge to the site supervisor. . Expiring qualifications: This qualification, and the New Zealand Certifcicate in Bituminous Surfacing Consruction with strands in Chipseal, Mixes, and Slurry (Level 4) replaced the following qualifications: National Certificate in Pavement Surfacing (Plant Operation) (Level 3) [Ref:1428] Graduates of this qualification will be able to: Understand the hazards, precautions, and safety and environmental protections required in bituminous surfacing operations Understand bituminous surfacings and their uses Understand materials used in bituminous surfacing Understand the types and purpose of plant and equipment used in surfacing construction Understand the control measures required to ensure quality products are produced on-site Communicate with relevant parties on the worksite Graduates of the Bituminous Mixes strand will be able to: National Certificate in Pavement Surfacing (Asphalt Paving Machine Operation) (Level 3) [Ref:1429] National Certificate in Pavement Surfacing (Bulk Bitumen Equipment) with strands in Gangbar Sprayer, Handbar Sprayer, and Tank Wagon) Understand the design fundamentals of bituminous mixes Understand the equipment and processes required to construct a bituminous mix layer Interpret site paving instructions and construct bituminous mix layers Keep records and take test samples for asphalt paving construction Graduates with the Chipseal strand will be able to: 1 (Level 3/4) [Ref:1427] National Certificate in Pavement Surfacing (Asphalt Production ) (Level 4) [Ref:0466] National Certificate in Pavement Surfacing (Hot Mix Asphalt Design) (Level 5) [Ref:0467] National Certificate in Pavement Surfacing (Chipseal Design) (Level 5) [Ref:0196] Understand design fundamentals and treatment selection of chipseal Understand the equipment and processes required to construct a chipseal Interpret chipseal design and treatment instructions and apply the techniques required to construct a quality chipseal Understand the techniques required to construct a quality chipseal Keep records and take test samples for chipseal construction Graduates with the Slurry strand will be able to: Understand the design fundamentals of slurry Understand the equipment and processes required to construct a slurry surface Interpret paving instructions and apply the techniques required to construct a quality slurry surface Understand the techniques required to construct a quality slurry surface Keep records and take test samples for slurry surfacing construction Special conditions related to this qualification: It is recommended that people achieve the New Zealand Certificate in Infrastructure Works (Level 3), and the New Zealand Certificate in Infrastructure Works Plant and Equipment Operation (Level 3), or demonstrate equivalent knowledge, skills and experience, before attempting this qualification. At least ONE strand must be chosen to fulfil the requirements of this qualification. Appropriate traffic management for the level of roads to be attained. Appropriate licences and licence endorsements must be attained – W, T, R Transition arrangements: People currently working towards any of the replaced qualifications may either complete the requirements for that qualification by 31 December 2016 or transfer to this qualification. It is important to note that the replaced qualifications may be substantially different to the new qualification, and may relate to more than one new qualification. The last date for entry into programmes leading to the replaced qualifications is 31 December 2015. 2 Qualification outcomes Ind. Credits Conditions M/O 1 10 Must include and understanding of: M Understand the hazards, precautions, and safety and environmental protections required in bituminous surfacing operations Recommended unit standards - environmental impacts of materials, and methods for protecting the environment - emergency procedures and safe disposal of bituminous materials NEW B01 (L4C10) - hazards associated with bituminous materials and their controls 2 3 4 Understand bituminous surfacings and their uses Understand materials used in bituminous surfacing Understand the types and the purpose of plant and equipment used in surfacing construction 6 - safety precautions, emergency procedures and first aid associated with handling bituminous materials/product Must include an understanding of: 6 - the range of surfacings (bituminous mixes, chipseal, slurry, micro-surfacing) and the context in which they are used: primes, membranes, sandwich, first coat, second coat, resurfacing, cracked pavement Must include an understanding of: 6 - the materials, production plants, modified binders, and the sampling and testing requirements for materials used for bituminous surfacings Must include an understanding of the purpose and function of plant and equipment used in bituminous surfacing construction; this includes: M NEW B02 (L4C6) M NEW B03 (L4C6) M NEW B08 (L4C6) 3 - chipseal construction plant - asphalt paving construction plant - slurry or micro-surfacing construction plant 5 Understand the control measures required to ensure quality products are produced on-site 6 - general plant and equipment used for surfacing construction Must include an understanding of: M - selecting appropriate plant; and the selecting and handling materials - quality requirements for construction and post-construction processes, and site meetings and records NEW B09 (L4C6) - managing the impact of weather 6 Communicate with relevant parties on the worksite 4 - reporting and recording on non-conformance Must include M - identifying and notifying those affected by site works, to the nature and extent of the works 7 Bituminous Mixes strand 32 7a Understand the design fundamentals of bituminous mixes 6 Must include an understanding of: - mix design fundamentals for bituminous mixes, including the components of bituminous mixes, mix types, the factors that impact performance, and the tests for volumetric and mechanical properties of mixes and adjustments required to achieve a job mix formula 26781 (L4C4) M NEW B26 (L4C6) 4 - treatment selection for bituminous mixes, including the site conditions, courses, surface preparations for different mix types, selecting combinations of mix type, mix binder, and mix additives for specific requirements, mix types for noise reducing surface layers 7b Understand the equipment and processes required to construct a bituminous mix layer 6 Must include an understanding of: M - the equipment used in laying bituminous mixes and their suitability and limitations for sealing jobs NEW B027 (L4C6) - the preconstruction, construction, and post construction processes involved in laying a bituminous mix layer 7c Interpret site paving instructions and construct bituminous mix layers 14 Must include interpreting instructions for at least three jobs with various requirements M - instructions for pre-treatment and plant and equipment requirements, laying and compaction specifications, Site safety and environmental protection factors, sampling and testing requirements 7d Keep records and take test samples for the construction of a bituminous mix layer 6 Must include preparing and constructing bituminous mix layers as per site paving instructions Must include: - completing and storing paving, plant and labour, and site records - core samples taken, labelled and the surface levels, shape, skid resistance, and texture are tested and recorded NEW B028 (L4C14) M NEW B029 (L4C6) 5 8 Chipseal strand 32 8a Understand the design fundamentals of chipseal 6 Must include an understanding of: M Chipseal design fundamentals - the effect of texture, traffic, site, and chip shape on the design, and factors affecting final treatment - design of residual binder s and application rates for seals - design of chipseal in terms of additives , and how construction factors and chip application rates affect the quality of the final seal NEW B022 (L4C6) Treatment selection of chipseal - types of pavement surface and their surfacing requirements - site assessments - surface treatment selections and their impact on design processes 8b Understand the equipment and processes required to construct a chipseal 6 Must include an understanding of: M - the equipment used in constructing chipseal and their functions and limitations - emergency equipment and safety features of bitumen distributors and other chipseal equipment NEW B023 (L4C6) - the preconstruction, construction, and post construction processes involved in laying a bituminous mix layer 8c Interpret chipseal design and treatment instructions and apply the techniques required to construct 14 Must include - interpreting chipseal design instructions for at least three sites covering four different surface M NEW B024 (L4C14) 6 types such as – granular, stabilised, chipseal, bituminous mix a quality chipseal - preparing to construct: must include working on at least three contracts covering each of the following surfaces, binders, and seals in any combination: surfaces – granular, stabilised, chipseal, bituminous mix; binders – hot bitumen, cut back, emulsion, PMB, polymer modified emulsion, latex modified emulsion; seals –first coat, two coat, reseal, membrane - construct chipseal surfacings 8d Keep records and take test samples for chipseal construction 6 Must include: M - completing and storing of paving, plant and labour, and site records - chip samples taken, and labelled, prior to sealing, and after the first binder spray run; and also for PSV test NEW B025 (L4C6) - samples of binder loads are taken and labelled 9 Slurry strand 32 Slurry surfacing is the generic term for a mix of asphalt emulsion binder, crushed aggregate, and stabilising filler. A development of slurry using a polymer modified binder and selected aggregates is known as micro surfacing. 9a Understand the design fundamentals of slurry 6 Must include an understanding of: - mix design fundamentals for slurry/microsurfacings in terms of their components and performance, and the job mix formula M NEW B030 (L4C6) - determining the condition and composition of 7 the existing surface, and determining appropriate treatment systems to suit different situations and specific requirements 9b Understand the equipment and processes required for slurry surfacing 6 Must include an understanding of: M - the slurry machine and its components, functions and limitations - effects of machine faults on the quality of the surfacing NEW B031 (L4C6) - other equipment used when needed - the preconstruction, construction, and post construction processes involved in constructing slurry surfacings 9c Interpret paving instructions and apply the techniques required to construct a quality slurry surface 14 Must include: M - Interpreting instructions for at least three jobs with various requirements. Instructions include: pre-treatment, and plant and equipment requirements, laying specifications, and paving instructions, site safety and environmental protection, sampling and testing NEW B032 (L4C14) - preparing to construct slurry surfacings - constructing slurry surfacings for at least three contracts covering each of the following slurry types --1, 2, 3, 4, cape seal, rut fill 9d Keep records and take test samples for slurry surface construction 6 Must include: - completing and storing paving, plant and labour, and site records M NEW B033 (L4C6) - slurry samples are taken and recorded, from 8 aggregate stockpiles, and the emulsion tank 10d Understand the hazards, precautions, and safety and environmental protections required in bituminous surfacing operations 10 Must include and understanding of: M - environmental impacts of materials, and methods for protecting the environment - emergency procedures and safe disposal of bituminous materials NEW B021 (L4C22) - hazards associated with bituminous materials and their controls - safety precautions, emergency procedures and first aid associated with handling bituminous materials/product 9