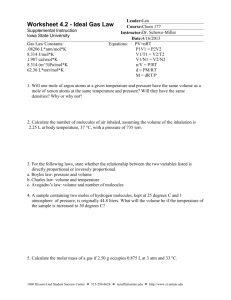

Supplemental A Schematic diagram of custom-built steam

advertisement

Supplemental A Schematic diagram of custom-built steam-treatment device 1 Supplemental B (Part 1) Correlation between solid residues yield (ST and HWE) and non-modified P-factor. Fitting parameters of solid residues yield data using Eq. (4) listed in Supplemental B (Part 2) (ST: α = 92.36 ± 2.25, = -1.2567(E-6) ± 3.1051(E-7), R2 = 0.6422; HWE: α = 95.87 ± 2.71, = -1.5606(E-6) ± 3.5543(E-7), R2 = 0.6935). 100 Solid residue yield (%) Measured data Fitting line ST HWE 90 80 70 60 0 50000 100000 150000 200000 250000 Non-modified P-factor (min) Supplemental B (Part 2) Reasons for using modified P-factor to describe the intensity of ST and HWE The chemical reactions that occur during water-based prehydrolyses (ST and HWE) typically consist of carbohydrate hydrolysis, along with some delignification and lignin condensation. Although the reaction system is very complex, if we do not attempt to understand the mechanism, these macroscopic reactions can normally be described by pseudo-first-order reaction kinetics (Kobayashi and Sakai 1956). Based on this kinetic argument and an average activation energy (Ea, 134 kJ/mol) for delignification of hardwood and softwood in alkali pulping processes, previously, an H-factor (Eq. (1)) has been used to combine reaction temperature and time into a 2 single variable, to allow comparison and control of processes (Vroom 1957). Following the research conducted by Brasch and Free (1965), Lin (1979) extended the H-factor principle to the prehydrolysis process, and developed another control factor (called the P-factor, Eq. (2)) using an Ea of 125.6 kJ/mol for the cleavage of glycosidic bonds of carbohydrate in wood (eucalyptus). Later, also based on the above kinetic considerations, Abatzoglou et al. (1992) formalized the concept of severity factor (R0, Eq. (3)), originally proposed by Overend and Chornet (1987). It is reasonable to believe that these three factors essentially similar. The expressions for the three factors are: t Ea, L Ea, L H Exp 0 R 373.15 R Tt dt (1) t Ea, H Ea, H P Exp 0 R 373.15 R Tt dt (2) t T 373.15 R0 Exp t dt 0 14.75 (3) where, Ea,L (134 kJ/mol) is the average of the activation energies for hardwood (117 kJ/mol) and softwood (150 kJ/mol) delignification in the alkali pulping process, and Ea,H (125.6 kJ/mol) is the activation energy for hydrolysis of fast-hydrolyzing xylan in eucalyptus chips. These three factors have been regarded as ordinates to describe the prehydrolysis processes of lignocelluloses. For example, without any modification, mass loss and hemicellulose removal during ST and HWE correlated well with the H-factor (Yoon et al., 2008; Liu 2010), R0 (Overend and Chornet 1987; Caparros et al., 2006) and P-factor (Sixta 2006; Duarte et al., 2011). However, probably because of the different 3 cell wall structures for different lignocellulosic materials, the Ea used in the traditional factors does not necessarily apply to all raw materials. To improve the fitting between experimental prehydrolysis results and these process parameters (H-, P- and severity factor), different Ea values obtained from the kinetics of the corresponding process have been used to modify both the P-factor and R0 (Borrega et al., 2013; Garrote et al., 2002; Luo et al., 2013b). The exponential correction of solid residue yield with P-factor is obtained for both ST and HWE (Fig.1 (a)). The prediction function was given as YSolid Exp( P) (4) where, α can be interpreted as maximum mass loss and would be a parameter used to differentiate two prehydrolysis methods (ST and HWE), which probably cause different cell wall structure of bamboo chips during reaction process. By using Eq. (4), the fitting correlation coefficients (R2) between the solid residue yields obtained in this study (Supplemental B (part 1)) and the non-modified P-factor are < 0.7, indicating the inapplicability of the empirical Ea (125.6 kJ/mol). Modifying the P-factor by replacing the empirical Ea by an average Ea (46.5 kJ/mol) for pentosan dissolution from green bamboo during HWE (44.9 kJ/mol, Ma et al., 2011) and ST (48.1 kJ/mol, Luo et al., 2013b) gave better fitting results (R2 for both ST and HWE > 0.9). Our previous study (Luo et al., 2013b) also showed that the empirical Ea used in the equation for R0 should be modified to achieve satisfactory fitting results for the relationship between pentosan removal and R0 during ST of green bamboo. For this reason, the intensities of ST and HWE have been described by 4 a modified P-factor in this study. Cited References Abatzoglou N, Chornet E, Belkacemi K, and Overend RP (1992) Phenomenological kinetics of complex systems: the development of a generalized severity parameter and its application to lignocellulosics fractionation. Chem Eng Sci 47(5): 1109-1122 Borrega M, Tolonen LK, Bardot F, Testova L, Sixta H (2013) Potential of hot water extraction of birch wood to produce high-purity dissolving pulp after alkaline pulping. Bioresour Technol 135: 665–671 Brasch DJ, Free KW (1965) Prehydrolysis-kraft pulping of Pinus radiata grown in New Zealand. TAPPI 48(4): 245-248 Caparrós S, Garrote G, Ariza J, and López F (2006) Autohydrolysis of Arundo donax L., a kinetic assessment. Ind Eng Chem Res 45(26): 8909-8920 Duarte GV, Ramarao BV, Amidon TE, Ferreira PT (2011) Effect of hot water extraction on hardwood kraft pulp fibers (Acer saccharum, sugar maple). Ind Eng Chem Res 50(17): 9949-9959 Garrote G, Domı ́nguez H, Parajó JC (2002) Interpretation of deacetylation and hemicellulose hydrolysis during hydrothermal treatments on the basis of the severity factor. Proc Biochem 37(10), 1067-1073. Kobayash T, Sakai Y (1956) Hydrolysis rate of pentosan of hardwood in dilute sulfuric acid. Bull Agric Chem Soc Jpn 20(1): 1-7 Lin CK (1979) Prehydrolysis-alkaline pulping of sweetgum wood. Department of Wood and Paper Science. North Carolina State University: Raleigh, NC, USA Liu S (2010) Woody biomass: Niche position as a source of sustainable renewable chemicals and energy and kinetics of hot-water extraction/hydrolysis. Biotechnol Adv 28(5): 563-582 Luo XL, Ma XJ, Hu HC, Li CH, Cao SL, Huang LL, Chen LH (2013) Kinetic study of pentosan solubility during heating and reacting processes of steam treatment of green bamboo. Bioresour Technol 130: 769–776 Ma XJ, Huang LL, Chen YX, Chen LH (2011) Preparation of bamboo dissolving pulp for textile production; Part 1. Study on prehydrolysis of green bamboo for producing dissolving pulp. BioResources 6(2): 1428–1439 Overend RP, Chornet E, Gascoigne JA (1987) Fractionation of lignocellulosics by steam-aqueous pretreatments [and discussion]. Phil Trans R Soc Lond A 321(1561): 523–536 Sixta H (2006) Handbook of Pulp, Wiley-VCH, Weinheim, pp 325–365 and 1009–1067 Yoon SH, Macewan K, Van Heiningen ARP (2008) Hot-water pre-extraction from loblolly pine (Pinus taeda) in an integrated forest products biorefinery. Tappi J 7(6): 27-32 Vroom KE (1957) The “H” factor: a means of expressing cooking times and temperatures as a single variable. Pulp Paper Mag Can 58(3): 228-231 5 Supplemental C Effect of active chlorine charge on dioxide chlorine bleaching performance D1 D2 Active chlorine charge (%) pulp yield (%) Pentosan content (%) Alpha-cellulose content (%) Ash content (%) Kappa number Brightness (% ISO) Cellulose viscosity (mL/g) 1.14 1.52 1.90 2.28 0.20 0.40 31.0 30.6 30.3 29.6 26.8 26.6 2.38 2.20 1.84 1.81 1.40 1.33 96.93 97.25 97.55 97.62 97.29 97.89 0.32 0.28 0.23 0.19 0.16 0.15 3.0 2.2 1.9 1.3 1.0 1.2 56.1 66.2 73.2 78.5 86.8 88.2 977 949 927 879 794 759 0.60 0.80 1.00 26.2 25.9 25.7 1.31 1.31 1.29 97.84 98.11 98.18 0.17 0.15 0.16 1.1 1.2 0.9 88.5 88.3 88.6 680 630 632 6