Supplementary Information for Isolated nanographene crystals for

advertisement

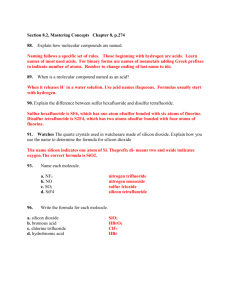

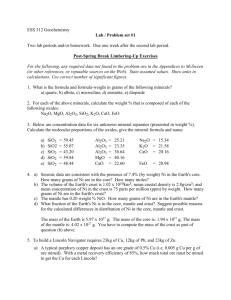

Supplementary Information for Isolated nanographene crystals for nano-floating gate in charge trapping memory Rong Yang1$, Chenxin Zhu2$, Jianling Meng1, Zongliang Huo2, Meng Cheng1, Donghua Liu1, Wei Yang1, Dongxia Shi1, Ming Liu2, Guangyu Zhang1٭ 1 Beijing National Laboratory for Condensed Matter Physics and Institute of Physics, Chinese Academy of Science, Beijing 100190, China 2 Laboratory of Nano-Fabrication and Novel Devices Integrated Technology, Institute of Microelectronics, Chinese Academy of Sciences, Beijing 100029, China $ These authors contribute equally to this work. ٭Corresponding author. Email: gyzhang@iphy.ac.cn. 1. SKPM measurements For the charge-trapping memory structures, the CPD induced by electrons or holes trapped in the electrets structures can be directly measured by SKPM under ambient conditions. This SKPM technique allows us to directly study the trapping properties of nanographene, including the trap density, uniformity, capture cross section, and retention, etc., and the charge types (electrons or holes) by using a simple nanographene/SiO2 structure. The SKPM measurement process includes two-steps: (1) charges injection. An electrically grounded Pt/Ir-coated Si tip was operated under the contact mode at room temperature. By applying a charge injection bias (e.g. 3V) to the silicon substrate, charges can be pulled out from the heavily doped Si, tunnel through the 4-nm oxide layer, and finally be trapped in nanographene or at the interface. (2) CPD measurements. The SKPM images were obtained with a twice scan to avoid topographic artifacts. The first scan was for topography under tapping mode and the second scan was for SKPM imaging under 50-nm lifted constant height mode. In this step, the CPD between the tip and the sample is obtained by detecting the real-time cantilever deflection. 2. Comparison of charge trapping effect in Al2O3/SiO2 and Al2O3/nanographene/SiO2 memory structures Figure S1. a and c, AFM image of Al2O3/SiO2 and Al2O3/nanographene/SiO2 structures. b and d, Corresponding SKPM images of the programmed state in these two memory structures. 3. Surface potential measurements of locally charged nanographene. Figure S2. SKPM images and measured CPD line profiles of nanographene samples (#1-5) with 1X1 um2 low electric field (-5.8MV/cm) charged cell. 4. Surface potential measurements of a control sample of charged Graphene flake. Graphene flakes were mechanically cleaved (from HOPG) on to 4 nm thermally grown SiO2 substrates by scotch tape [1]. Figure S3. AFM and SKPM images of a graphene flake after low electric field (-5.8MV/cm) charging. 5. The size and density distribution of Si nanocrystals. Silicon nanocrystals (Si-NCs) were also formed on 4 nm thermally grown SiO2 substrate with a two-step low pressure chemical vapor deposition (LPCVD) process [2]. By adjusting the pre-nucleation waiting time and deposition time, the density, size and uniformity can be effectively controlled. As shown in Fig. S4, uniform Si-NCs with a density of 8.2×1011 cm−2 with an average diameter of 5 nm, 4.4×1011 cm−2 with an average diameter of 10 nm, and 1.8×1011 cm−2 with an average diameter of 20 nm were used in our experiment for comparisons. Figure S4. a, AFM images of silicon nanocrystals (Sample #1-3). b, Size and density distributions of three samples. 6. Surface potential measurements of locally charged silicon nanocrystals. Figure S5. SKPM images and measured CPD line profiles of silicon nanocrystals (Sizes: 5nm, 10nm, 20nm) with 1X1 um2 negatively (-5.8MV/cm) charged cell. 7. Estimation of charge densities of nanographene from CPD The measured CPD from surface potential can be relative to the spatial distribution of charges, which in principle can be calculated by solving the Poisson equation. Therefore, by using one-dimensional Poisson equation, the approximate total charge density can be estimated from the measured CPDs as follows: 2 Si kT qLD Si ( I ) Si CPD I exp( Si ) Si 1 np0 pp0 exp( Si ) Si 1 dOX OX (1) (2) where σSi is the static surface charge density of silicon, ψSi is the electrical potential at silicon surface, εOX and dOX are the permittivity and thickness of the SiO2 layer. From Eqs. (1)-(2) we can obtain an equation on σI (cm-2), which is the trapped charge density at the nanographene/SiO2 interfaces. The total trapped charge density σt in the sample can then be obtained L by t 1 I dx , where L is the lateral scan distance. L 0 8. Other device performance characterization of metal/Al2O3/Nanographene/SiO2/Si (MANGOS) memory structure. Under a high gate voltage sweeping of 13 V, more than 7 V Vth shift is achieved in the MANGOS device (as shown in Fig.S6). Such a large memory window might be favorable for multilevel cell storage if the ten-year retention is allowed. Figure S6. CV curves of MANGOS device at high sweeping gate voltage. Fig.S7 shows the cycled retention characteristics of MANGOS device. It shows an extrapolated 10-year 55% loss in memory window after 1000 cycled operations at 85 oC. The performance degradation could be attributed to the overlap of the nanographene dots as well as the quality of blocking Al2O3 layer. Further optimization is needed to improve the retention characteristics by tuning the nanographene sizes and densities and by improving the quality of the high- layers. Figure S7. Cycled retention characteristics of MANGOS device. Fig.S8 illustrates the program/erase (P/E) and endurance characteristics of MANGOS device. The program curve is taken with light-assisted voltage pulses to generate electron carriers. The P/E curves shows 4.5 V Vth shift with 12 V operation voltage at 10 ms. There is no obvious degradation in device performance after 1K P/E cycles. It should be pointed out that the capacitor structure could limit the P/E speed performance and the transistor device structure will be further studied. Figure S8. P/E and endurance characteristics of MANGOS device. Fig.S9 shows the uniformity of MANGOS device. All the cell size is 60*60 µm2 with capacitor structure. These devices show good uniformity of 4.5 V memory window with 8 V P/E voltages and 6.2 V memory window with 12 V P/E voltages between 40 cells. Figure S9. Device uniformity of MANGOS device. 9. Raman spectra of nanographene on the Al2O3 and HfO2 dielectric layers. Raman spectra of nanographene grown on Al2O3 and HfO2 ALD dielectric layers were listed in Fig. S6. For both samples, the typical G peak around 1589 cm-1 , high D peak around 1351 cm-1, D’ peak around 1620 cm-1, and 2D peak around 2705 cm-1 were observed, which confirmed the sp2 graphitic bonded nanographene with abundant edge structures. Compared with nanographene grown on SiO2, the wider and lower D peak intensities may be caused by the amorphous substrates which have numerous dangling bonds. Besides, the comparable ID’/IG relative intensities still revealed that the average grain size is small (might be around 8-10 nm). Figure S10. Raman spectra of nanographene on Al2O3 and HfO2. Reference: 1. Novoselov, K.S. et al. Electric Field Effect in Atomically Thin Carbon Films. Science 306, 666-669 (2004). 2. Wang, Y. et al. Optimization of silicon nanocrystals growth process by low pressure chemical vapor deposition for non-volatile memory application. Thin Solid Films 519, 2146-2149 (2011).