ExampleFedBatch

advertisement

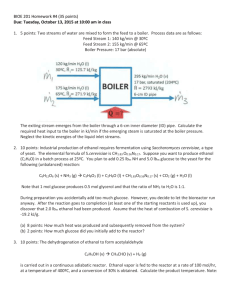

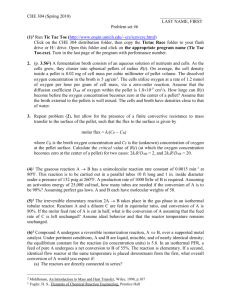

Introduction to API Process Simulation, Example 2 Fed-batch Reaction with Safety Constraint Objective The purpose of this example is to simulate and optimize the operation of a fedbatch reactor. The process being studied involves an exothermic reaction with a safety constraint. There is also a constraint on the maximum volume of material that can be contained within the reactor. The objective to determine a feed profile that will minimize the time required to achieve the desired product amount, while ensuring that the volume of material in the reactor does not exceed the specified limit, and also ensuring that the reactor can be shut down safely in the event of a cooling failure. feed1 header bulk jacket Process Description Exothermic Reaction: substrate + reagent → product Operating Conditions: Isothermal, fed-batch Objective: Minimize the time needed to produce a given amount of product Manipulated Variable: Feed rate of reagent Variables and Parameters: c X ,bulk , concentration of species X; Vbulk , volume of material in reactor; Vmax , maximum volume; qin , feed rate; c X ,header , concentration of X in header tank; k , kinetic rate constant; Tbulk , reactor temperature (normal operation); MTSR , Maximum temperature of synthetic reaction (temperature attained after cooling failure);, Tmax , maximum temperature; H r , heat of reaction; , density; c p ,bulk , heat capacity. Comments: In case of cooling failure the best strategy is to stop the feed. Yet due to the presence of unreacted components in the reactor, the reaction goes on, which will cause an increase in the reactor temperature. The maximum attainable temperature under cooling failure at any time t is given by the following expression: Introduction to API Process Simulation, Example 2 MTSR (t ) Tbulk min( c substrate,bulk (t ), c reagent,bulk (t )) (H r ) c p The term min( c substrate,bulk (t ), creagent,bulk (t )) represents the maximum extent of reaction that can occur after a cooling failure. Without any constraints, optimal operation would simply consist of adding all the available reagent at the initial time (i.e. batch operation). However, because of the safety constraint, the feeding of reagent has to account for the possible cooling failure. Additionally, the feed rate must be set to zero once the maximum volume has been attained. Optimal Feed Profile In general the optimal feed profile will consist of several segments as shown in the figure below (the number and order of segments of different types depends on the specific initial conditions and constraints). Maximum Flow: The feed is at its upper limit so that the concentration of reagent can build up in the reactor. The end point of this type of segment is determined by the time at which the safety or volume constraint is reached. Controlled Flow: The flow is set at an intermediate value to replenish the reagent that is being consumed by the reaction. No Flow: The feed is turned off due to one of the following reasons: (i) header tank is empty; (ii) reactor is full;. 3 1 qinMax q Max in 2 qincon qin qinMin 4 time Process Parameters The process parameters, operating bounds and initial conditions for Example 2 are given in the table below. k (rate constant) Tbulk (operating temperature) Theader (feed temperature) 0.0482 70 L/mol hr C 70 C Introduction to API Process Simulation, Example 2 H r (heat of reaction) c p ,bulk (heat capacity) -60 4.2 kJ/mol kJ/kg K c reagent,header (conc of reagent in header) 2.33 mol/L qinmin (minimum feed rate) 0 L/hr qinmax (maximum feed rate) 10 L/hr Tmax (maximum temp) 80 C Vmax (maximum volume) nC,des (desired product amount) c0,substrate,bulk (initial conc of substrate) 100 L 60 2 mol mol/L c0,reagent,bulk (initial conc of reagent) 0.49 mol/L V0 ,bulk (initial volume in reactor) 70 L V0,header (init volume in header tank) 30 L Mass of solvent in reactor Mass of solvent in feed tank UA (constant h.t. coefficient) sUA (specific h.t. coefficient) Coolant flow rate 60 25.75 100 0.5 0.1 kg kg W/K W/LK kg/s DynoChem Model Summary The process can be simulated using the DynoChem library template for a fed-batch reactor with accumulation effects. This template for this example has been provided in the file TemplateFedBatch.xls. The following information is specified under the Components tab, Process tab and Scenarios tab. Components. The components defined for this example include the solvent (MW=18), coolant (MW=18), reagent (MW=18), substrate (MW=18), and product (MW=36). Process Definition (Statements). The process statements define the bulk liquid and header tank phases, heat transfer through a jacket, and the transfer of feed material from the header tank into the bulk liquid. A reaction with the appropriate reactants and products is defined for the bulk liquid phase. The rate constant should match the value from the table above. The MTSR value is calculated from the bulk liquid temperature, and concentrations of substrate and reagent. Scenarios (Initial Values and Parameters). The table above contains the process parameters and initial values for process variables. These can be entered into the scenario tab after conversion to the appropriate units (Note: The DynoChem model is set up to use number of moles rather than concentrations to specify the amount of reactants). Finally, the data sheet for the fed-batch scenario specifies the imposed feed profile and temperature profile for the reactor. Jacket Parameters. The DynoChem model in the spreadsheet incorporates heat transfer through a jacket. For isothermal operation, the temperature in the jacket must be adjusted to compensate for the heat of reaction. DynoChem will perform the required Introduction to API Process Simulation, Example 2 calculations if the desired value for the bulk liquid temperature is imposed in the datasheet. The overall heat transfer coefficient is calculated from the relationship UAtot=UA+sUA*V, where V is the volume of material in the reactor, and sUA is the specific heat transfer coefficient. The UA and sUA values from the table above should be entered into the scenario tab. Feed and Temperature Profiles for Fed Batch Reactor 80 70 see legend 60 50 Qin L/hr 40 Temperature C 30 20 10 0 0 200 400 600 800 1000 1200 1400 Time, min Optimization of feed profile The rate of addition of B is constrained by the need to maintain the MTSR below the specified Tmax value. This will ensure the safe shut down of the reactor in the event of a cooling failure. The simulator plots the MTSR variable defined in the process description. The feed profile in the datasheet can be adjusted manually to ensure that the MTSR value remains below Tmax at all times. The feed must be set to zero once the volume of material in the reactor reaches the maximum value. The simulation can be used iteratively to determine the feed profile which minimizes the time at which the amount of product reaches the desired value while satisfying all constraints. Introduction to API Process Simulation, Example 2 Results Simulation results include plots of the volume of material in the reactor and the MTSR as a function of time. In the initial period the reactor flow is kept at the maximum value until the MTSR constraint becomes active, after which the flow is controlled to keep the MTSR at the maximum value until the volume reaches the maximum value. At this point the feed is turned off and the reaction proceeds until the desired amount of product is obtained. Controlled flow Volume (l) 110 100 90 Volume (l) 80 70 60 0 200 400 600 800 1000 1200 1400 Time (min) Maximum flow No flow Safety constraint active Volume constraint active Temperature (C) MTSR 80.5 80 79.5 79 78.5 78 77.5 77 76.5 MTSR 0 200 400 600 800 Time (min) Safety and volume constraints inactive 1000 1200 1400 Introduction to API Process Simulation, Example 2 Additional simulation runs can be made to determine the impact of the volume constraint on the reaction time. Volume constraint no longer active 120 110 Vol (l) 100 Run1 90 Run2 80 70 60 0 200 400 600 800 1000 1200 1400 Time (min) 70 Product (mol) 60 50 40 Run1 30 Run2 20 10 0 0 200 400 600 800 Time (min) 1000 1200 1400