Problem Set 4 Due date

advertisement

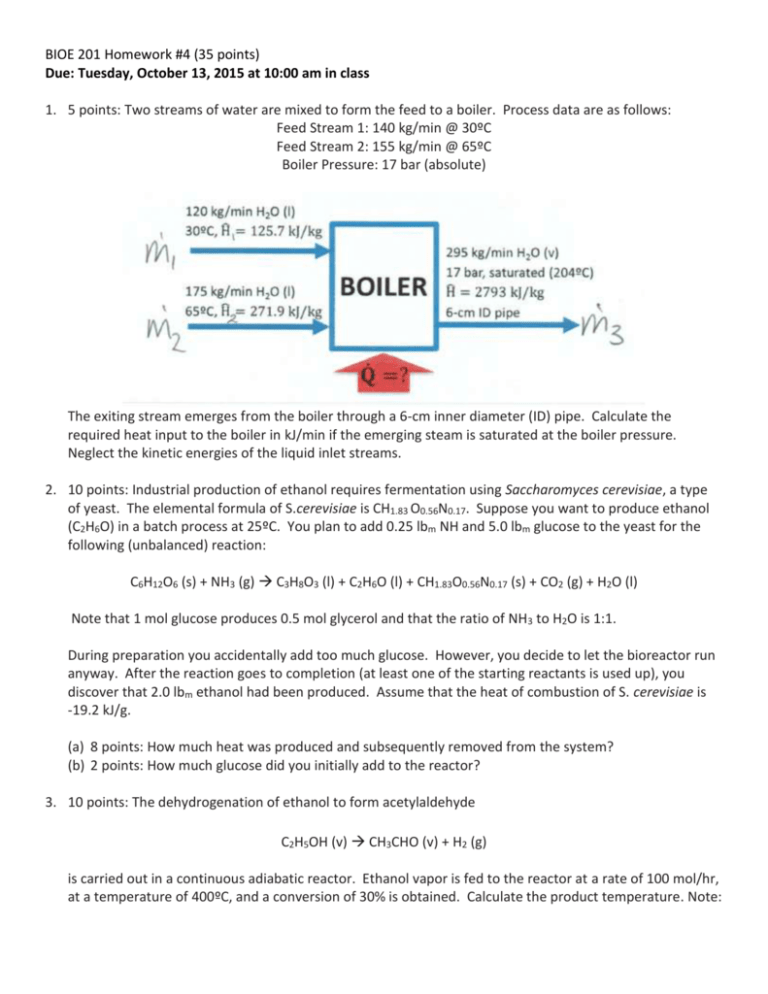

BIOE 201 Homework #4 (35 points) Due: Tuesday, October 13, 2015 at 10:00 am in class 1. 5 points: Two streams of water are mixed to form the feed to a boiler. Process data are as follows: Feed Stream 1: 140 kg/min @ 30ºC Feed Stream 2: 155 kg/min @ 65ºC Boiler Pressure: 17 bar (absolute) The exiting stream emerges from the boiler through a 6-cm inner diameter (ID) pipe. Calculate the required heat input to the boiler in kJ/min if the emerging steam is saturated at the boiler pressure. Neglect the kinetic energies of the liquid inlet streams. 2. 10 points: Industrial production of ethanol requires fermentation using Saccharomyces cerevisiae, a type of yeast. The elemental formula of S.cerevisiae is CH1.83 O0.56N0.17. Suppose you want to produce ethanol (C2H6O) in a batch process at 25ºC. You plan to add 0.25 lbm NH and 5.0 lbm glucose to the yeast for the following (unbalanced) reaction: C6H12O6 (s) + NH3 (g) C3H8O3 (l) + C2H6O (l) + CH1.83O0.56N0.17 (s) + CO2 (g) + H2O (l) Note that 1 mol glucose produces 0.5 mol glycerol and that the ratio of NH3 to H2O is 1:1. During preparation you accidentally add too much glucose. However, you decide to let the bioreactor run anyway. After the reaction goes to completion (at least one of the starting reactants is used up), you discover that 2.0 lbm ethanol had been produced. Assume that the heat of combustion of S. cerevisiae is -19.2 kJ/g. (a) 8 points: How much heat was produced and subsequently removed from the system? (b) 2 points: How much glucose did you initially add to the reactor? 3. 10 points: The dehydrogenation of ethanol to form acetylaldehyde C2H5OH (v) CH3CHO (v) + H2 (g) is carried out in a continuous adiabatic reactor. Ethanol vapor is fed to the reactor at a rate of 100 mol/hr, at a temperature of 400ºC, and a conversion of 30% is obtained. Calculate the product temperature. Note: 𝒌𝑱 (Cp)acetaldehyde(𝑚𝑜𝑙∗ º𝐶) = 0.05048 + 1.326 × 10−4 𝑇 − 8.050 × 10−8 𝑇 2 + 2.380 × 10−11 𝑇 3 . Use Table E.1 to obtain heat capacity (constant P) coefficients and Table E.9 to obtain heat of combustion values (DO NOT USE TABLE E.7, TABLE E.7 HAS ERRORS!) 4. 10 points: The ethanol dehydrogenation reaction in problem #3 is now carried out with the feed entering at 300ºC. The feed enters the reactor at a rate of 150 mol/s and contains 90.0 mole % ethanol and the balance is acetylaldehyde. To keep the temperature from dropping too much and thereby decreasing the reaction rate to an unacceptably low level, heat is transferred to the reactor. When the heat addition rate is 2440 kW, the outlet temperature is 253ºC. Calculate the fractional conversion of ethanol achieved in the reactor.