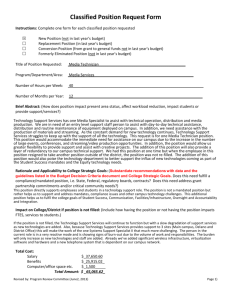

Report - Oakland University

advertisement

ATTACHMENT A Oakland University Annual Energy Report Fiscal Year 2007 Submitted, September 6, 2007 by James Leidel Energy Manager www.oakland.edu/energy TABLE OF CONTENTS page Executive Summary ...................................................................................................... ..3 Introduction ................................................................................................................... ..4 Historical Consumption and Cost .................................................................................. ..8 Utility Cost per FYES and Square Footage ................................................................... 10 Natural Gas Purchasing Update .................................................................................... 11 Phase Two Energy Services Project ............................................................................. 12 Diesel Generator Project ............................................................................................... 12 Wind Power Feasibility Study ........................................................................................ 13 Biomass (Waste Wood) Boiler Feasibility Study ........................................................... 13 LIST OF TABLES AND FIGURES Table 1 Table 2 Table 3 Table 4 Table 5 Average unit cost per utility with comparisons to previous year ............... ..4 Utility consumption & cost with comparisons to previous year ................. ..4 PROJECTED FY2008 consumption and cost .......................................... ..5 Heating and cooling degree days with comparisons to previous year ..... ..5 PROJECTED FY2008 average unit cost per utility .................................. ..6 Figure 1 Figure 2 Recent increases in the Detroit Edison electric rate ................................ ..6 Eight year combined west campus utility expenditures with cost per square foot of facility space ..................................................................... ..7 Total utility cost for the main campus per FYES & building square foot. .. ..8 Main campus monthly electrical cost and consumption ........................... ..9 Main campus monthly natural gas cost and consumption........................ ..9 Main campus monthly water & sewer cost and consumption................... 10 Natural gas purchase contracts ............................................................... 11 Figure 3 Figure 4 Figure 5 Figure 6 Figure 7 2 EXECUTIVE SUMMARY Oakland University’s Facilities Management Department provides the Board of Trustees with an Annual Energy Report that details utility usage and costs, both historical and projected. Increasing utility rates were the driving force behind a $557,000 increase in annual energy costs in FY2007. Natural gas unit expense was up 21.5% from the previous year; electricity expense was up 9.2%. Although FY2007 was colder than the previous year, weather patterns still remain warmer than the historical averages. In spite of the colder winter, natural gas consumption was held in check, for a less than one percent increase compared to FY2006. Both electric and domestic water consumption were down as compared to the previous fiscal year, -4.0% and -11.5%, respectively. Projections for FY2008 are for a 2.1% increase in overall utility expenditures based on a projected small increase in natural gas rates, offset by a decrease in electrical rates. Electric rates have continued to creep up over the past few years. The retail open market has not been advantageous, so the University remains with Detroit Edison. We are beginning a partial, interruptible electric rate with Detroit Edison, taking advantage of the new 3.3 MW backup diesel generator installation. This new interruptible rate is projected to reduce the unit cost per kilowatt-hour by 5.2% for FY2008. Presently, firm gas contracts have been obtained for 100% of FY2008, 60% of FY2009, and 31% of FY2010. The energy services and diesel generator projects are both substantially complete. Final commissioning on a few items will continue into the fall, but all of the mechanical and electrical systems are fully installed. Feasibility studies for on-campus wind power generation as well as conversion of our Central Heating Plant to biomass fuel are both underway and will be completed this winter. 3 INTRODUCTION Increasing utility rates were the driving force behind a $557,000 increase in annual energy costs. Forward purchasing in the natural gas market forestalled much of the recent price increases, but the University is now being impacted by these sustained market costs. The FY2007 natural gas unit cost was up 21.5% from the previous year, and the Detroit Edison unit cost was up 9.2%. Table 1 Average unit cost per utility with comparisons to previous year Electricity Natural Gas Water & Sewer FY2006 FY2007 Unit Cost Unit Cost Units $ 0.0705 $ 0.0770 per kW hour $ 8.762 $ 9.0870 per million BTU $ 46.30 $ 46.30 per 1000 gallons % Change from FY2006 +9.2% +21.5% 0% Although FY2007 was colder than the previous year, weather patterns still remain warmer than the historical average. In spite of the colder weather, natural gas consumption was held in check, for less than a one percent increase as compared to FY2006. Both electric and domestic water consumption figures were down as compared to the previous fiscal year, -4.0% and -11.5%, respectively. Although the University saw -11.5% change in water & sewer consumption as compared to FY2006, usage still remains higher than previous years. Deferred plant renewal projects in the Central Heating Plant will further reduce consumption of water by December 2007. These projects will result in noticeable reductions in water consumption. Table 2 lists the usage and cost for each of the three main utilities, serving the west campus, and compares these with the previous fiscal year. Table 2 Utility consumption & cost with comparisons to previous year Electricity Natural Gas Water & Sewer TOTALS FY2007 Usage Units % Change from FY2006 35,815,080 278,661 9,182 kW hours million BTU 1,000 gallons -4.0% 0.9% -11.5% FY2007 Cost (Millions) $ 2.75 $ 2.53 $ 0.43 $ 5.71 % Change from FY2006 +5.5% +22.6% -11.4% +10.8% Note 1: MMBTU = one million British thermal units Note 2: This data is for the main campus only, the general funded east campus utilities are under 2% of total expenditures. The annual expenditure for propane was $18,493. Propane heating is used for the Buildings & Grounds Maintenance building and a few other small out-buildings. Fuel oil for a temporary steam boiler during construction of the underground hot water system totaled $39,374. This boiler was used to heat the science, engineering, and library buildings for several months last winter. 4 Utilities for Ancillary activities, like the Golf and Learning Center and Meadow Brook Hall, are not reported here, but are accounted for by their respective management reports. Consumption escalations are projected in accordance with a typical 2 to 3% growth in the student body, measured in Fiscal Year Equivalent Students (FYES), coupled with the proliferation of additional computers and new academic programs. Historical averages and trends in the weather are considered. Lastly, a look at the past year’s consumption in relation to the year’s weather is taken into account. Table 3 PROJECTED FY2008 utility consumption & cost FY2008 Projected Usage Electricity Natural Gas Water & Sewer TOTALS 36,714,199 290,005 9,457 Units % Change from FY2007 kW hours million BTU 1,000 gallons 2.51% 4.07% 3.00% FY2008 Projected Cost (Millions) $ 2.69 $ 2.71 $ 0.438 $ 5.83 % Change from FY2007 -2.5% +6.9% +3.0% +2.1% The weather remains warmer than the historical averages for both the winter heating season and the summer cooling season. The FY2007 heating degree days were 8% above the FY2006, meaning it was an 8% colder winter. This is still almost 8% warmer than the historical average. The FY2007 summer weather was 11.2% cooler than FY2006, but still about 24% warmer than the historical average. Table 4 Heating and cooling degree days with comparisons to previous year Historical average Heating Degree Days Cooling Degree Days 6,444 736 FY2006 5,503 1,024 FY2007 5,945 909 % Change +8.0% -11.2% Degree Days are calculated from the difference between the average daily temperature and reference temperature (65 deg F). This gives a measure of how much heating and cooling effort is required to maintain a typical building’s indoor air comfort level. (data source 1) Future utility projections take into account the expected utility rates along with an assumption of a small increase in consumption. For natural gas, 100% of the FY2008 gas supply has already been contracted and the cost is locked in for an expected rate increase of less than 3%. Water rates have remained very stable and are not anticipated to change. 1 National Oceanic and Atmospheric Administration, National Center for Environmental Prediction, ftp://ftpprd.ncep.noaa.gov/pub/cpc/htdocs/products/analysis_monitoring/cdus/degree_days/archives/ 5 Table 5 PROJECTED FY2008 average unit cost per utility Electricity Natural Gas Water & Sewer FY2007 FY2008 Unit Cost Unit Cost Units $ 0.0770 $ 0.0730 per kW hour $ 9.0870 $ 9.3373 per million BTU $ 46.30 $ 46.30 per 1000 gallons % Change from FY2007 -5.2% 2.8% 0% Detroit Edison electric rates have continued to creep up over the past few years, as seen below in Figure 1. The retail open market has not been advantageous for the past 4-5 years, so the University remains with Detroit Edison. We are just beginning a partial, interruptible gas rate with Detroit Edison, taking advantage of the new 3.3 MW diesel generator installation. The interruptible rate is projected to reduce the cost per kilowatthour by 5.2% for FY2008. Dollars per kWhr $0.085 $0.080 $0.075 $0.070 $0.065 $0.060 $0.055 $0.050 Monthly Electric Cost per kWhr Trend in Increase = 3.7% per year $0.045 $0.040 2004 Figure 1 2005 2006 2007 Recent increases in the Detroit Edison electric rate 6 Figure 2 illustrates the previous cost savings from the electrical Retail Open Access purchasing program in FY2003 & FY2004, followed by several years of rapidly increasing utility unit costs (mostly in natural gas). Fiscal Year 2008 should see a leveling off of these recent increases in gas, but electricity will continue to creep upward. $7.0 $3.00 Total Main Campus Utility Cost Total Main Campus Utility Cost per Square Foot $5.71 $5.83 $2.50 $5.0 $2.00 $4.39 $4.0 $3.84 $3.71 $3.73 $3.56 $3.0 $2.0 $1.00 $0.50 $1.0 $- $FY01 Figure 2 $1.50 Dollars per Square Foot $5.16 ESTIMATED Total Utility Cost in Millions of Dollars $6.0 FY02 FY03 FY04 FY05 FY06 FY07 FY08 Eight year combined west campus utility expenditures with cost per square foot of facility space 7 UTILITY COST PER FYES AND SQUARE FOOTAGE Figure 3, below, depicts this same information adjusted for building square footage and FYES. This figure is based on our present main campus size of 2,375,000 million square feet, and 14,635 FYES. For a full time, resident undergraduate student with 15 or more credit hours per semester ($7,927 for both fall and winter semesters), this equates to less than 5% of their annual tuition. $450.00 $3.00 $400.00 $2.50 Cost per Annual FYES Estimated $300.00 $2.00 FY2007 $390 / FYES or $2.40 / Sq Ft $250.00 $1.50 $200.00 $150.00 $1.00 $100.00 Cost per Annual FYES $50.00 $0.50 Cost per Building Square Foot $- $FY01 Figure 3 FY02 FY03 FY04 FY05 FY06 FY07 FY08 Total utility cost for the main campus per FYES and per building square foot. 8 Cost per Building Square Foot $350.00 HISTORICAL CONSUMPTION AND COST Figures 4, 5, and 6 illustrate the monthly utility usage and resulting trends over the past decade. $3.0 $2.8 Annual Cost (Millions of Dollars) $2.6 40.0 $2.7 35.0 $2.4 $1.9 $1.9 $2.0 25.0 $1.7 $1.6 $1.5 $1.8 $1.8 20.0 $1.3 $1.3 $1.2 $1.2 15.0 $1.0 10.0 $0.5 5.0 Figure 4 FY08 FY07 FY06 FY05 FY04 FY03 FY02 FY01 FY00 FY99 FY98 FY97 FY96 0.0 FY95 $- Historical main campus annual electrical cost and consumption $3.0 350,000 $2.7 Annual Cost (Millions of Dollars) Natural Gas Cost (millions of dollars) million kilowatt-hours 30.0 $2.5 Annual Consumption (Millin BTU) 300,000 $2.5 $2.1 250,000 $2.0 $1.6 $1.5 $1.5 $1.6 $1.6 $1.7 200,000 150,000 $1.0 $0.7 $0.7 $0.8 $0.8 100,000 $0.6 $0.5 $0.5 50,000 FY08 FY07 FY06 FY05 FY04 FY03 FY02 FY01 FY00 FY99 FY98 FY97 FY96 0 FY95 $- Figure 5 million BTU Electrical Cost (millions of dollars ) Annual Consumption (kWhrs) $2.5 Historical main campus annual natural gas cost and consumption 9 $3.0 120,000 Annual Consumption (Thousand Gallons) $2.5 100,000 Linear (Annual Consumption (Thousand trendline Gallons)) $2.0 80,000 $1.5 60,000 $1.0 40,000 $0.5 $0.30 $0.31 $0.30 $0.29 $0.29 $0.26 $0.32 $0.43 $0.32 $0.48 $0.44 $0.33 $0.32 Figure 6 20,000 FY08 FY07 FY06 FY05 FY04 FY03 FY02 FY01 FY00 FY99 FY98 FY97 0 FY96 $- thousands of gallons Water & Sewer Cost (millions ofdollars) Annual Cost (Millions of Dollars) Historical main campus annual water & sewer cost and consumption 10 NATURAL GAS PURCHASING UPDATE Natural gas prices continue to be volatile and continue to increase. Summertime natural gas NYMEX future prices remain in the range of $7-$8 per million BTU and wintertime future prices have been fluctuating between $9 and $10 per million BTU. Prices are not expected to fall substantially. Multiple, forward purchases have been very helpful to hold down costs, minimize risk, and provide fiscal year budget stability. Figure 7, below, is an illustration of the University’s gas purchases, their cost, and duration. The different colored blocks represent individual purchase contracts. Multiple blocks are layered in at different times to supply the total gas needs represented by the black line. Facilities Management continually monitors the energy futures markets and corresponds with several industry consultants to make prudent gas purchases. 50,000 Natural Gas Usage FY07 100% 45,000 FY09 60% Contracted FY08 100% Contracted Contracted 40,000 FY10 31% Contracted 25,000 $8.06 30,000 $9.95 Gas in Millions of BTU 35,000 $7.25 20,000 $9.465 Contract $5.00 15,000 10,000 Future $9.50 Budgeted $8.99 Contract State of Michigan consortium $9.306 Contract thru Dec 2009 5,000 $8.32 Contract thru June 2010 $6.50 Contract Figure 7 May-10 Mar-10 Jan-10 Nov-09 Sep-09 Jul-09 May-09 Mar-09 Jan-09 Nov-08 Sep-08 Jul-08 May-08 Mar-08 Jan-08 Nov-07 Sep-07 Jul-07 May-07 Mar-07 Jan-07 Nov-06 Sep-06 Jul-06 0 Natural gas purchase contacts (prices are in dollars per million BTU) 11 PHASE TWO ENERGY SERVICES PROJECT UPDATE The energy services project is substantially complete. Final commissioning on a few project items will continue into the fall, but all of the mechanical and electrical systems are fully installed and operational. The project installations have contributed a portion of this year’s 4.0% drop in electrical consumption, an 11.5% drop in domestic water consumption, and minimized our natural gas consumption by several percent, all in comparison to the previous fiscal year. The energy and maintenance cost savings are on target to achieve $470,000 per year, which includes a portion of the diesel generator project savings (discussed below). DIESEL GENERATOR PROJECT Two packaged diesel generators were installed in a joint effort between the Energy Services project and the Facilities Management Department. An additional $500,000 was approved by the Board of Trustees to supplement the Energy Services Agreement to install these units at our central campus substation. These units will provide emergency backup power for approximately one half of the campus while simultaneously allowing for a cost savings from a Detroit Edison interruptible electric rate. Plans for additional generators will be presented to the Board of Trustees in coming years as the savings from these two machines are accumulated. The expectation is that 100% of the campus will have emergency backup power in the next 3 to 6 years. 12 WIND POWER FEASIBILITY STUDY A 50 meter tall wind sensor tower was installed in February 2006, and has been collecting wind data for use in a wind power assessment of campus. The Facilities Management Department initiated the collection of wind data, and the President’s Resource Development Fund provided assistance to undertake a full feasibility study as well as a second year of wind data collection. The study will include a full pro forma for a number of utility sized wind turbines in the range of 1 to 1.5 megawatts each. Several sites on the golf course and south side of the main campus are under consideration for siting the turbines. The approach of the study is to ascertain if a project can be developed with a positive cash flow over a 10 to 15 year financing period. The results of the study and recommendations will be presented to University management this winter. BIOMASS (WASTE WOOD) BOILER FEASIBILITY STUDY Facilities Management has obtained a $25,000 grant from the Southeast Michigan Resource Development Council to study the addition of an urban wood waste fueled boiler for our campus. Wood is a relatively inexpensive source of fuel, and the relative abundance of locally derived urban waste wood has the potential to make this project financially attractive. Central Michigan University presently operates a wood fueled heating plant to provide most of their campus heating, and Northern Michigan University is presently designing a wood boiler addition, capable of providing both heating and power production to their campus. Wood storage silo and smokestack steam plume from the wood boiler at the Central Michigan University Heating plant When combusted in a properly designed, industrial boiler, wood burns cleanly, resulting in nothing but water vapor and carbon dioxide out of the chimney. The combustion of biomass fuels are considered carbon neutral due to the fact that the growth of the wood fuel pulls carbon from the atmosphere which is then released back during combustion. There is no sulfur, mercury, or other contaminants in the emissions that are produced in coal fired power plants. The only issues will be with properly managing the ash and managing the logistics of fuel delivery and storage. This type of operation involves additional maintenance and staff. However, a multimillion dollar reduction in fuel cost could potentially pay for the additional staff and new equipment needed. This study will review the technical, fuel procurement, and business cases for a possible project. If a positive cash flow project looks feasible, the results and recommendations will be presented to University management this winter. 13