Simulations of CCI-2 test with TOLBIAC-ICB : modelling and

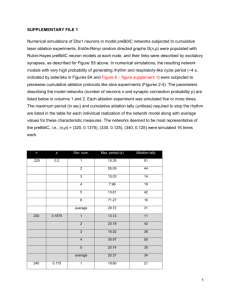

advertisement

MCCI Project Seminar 2007, Cadarache October 10-11 2007 Simulation of CCI-2 test with TOLBIAC-ICB: modelling and sensitivity studies B. SPINDLER, E. DUFOUR CEA, Grenoble, France Abstract The first simulations of CCI-2 performed with TOLBIAC-ICB were presented in the frame of the benchmark organized in the frame of the MCCI Project. After the benchmark was closed, new data concerning the concrete composition were given. The results of the simulation of CCI-2 test with TOLBIAC-ICB are presented here using the final experimental data, and the up-to-date version of TOLBIAC-ICB with the NUCLEA07 data base for GEMINI. Sensitivity studies are also presented, concerning mainly the initial conditions: initial temperature, initial composition, effects of melt composition and initial transient. These sensitivity studies are related to the model used in TOLBIAC-ICB: phase segregation and liquidus temperature of the melt used at the interface between the melt and the crusts. The specific point of the ablation observed in CCI-2 test above the expected melt level is also discussed in relation with the simulation results of TOLBIAC-ICB. 1. Introduction The CCI-1, CCI-2 and CCI-3 tests performed in the frame of the MCCI project give useful data concerning the corium concrete interaction, for various concrete compositions. The large lateral ablations observed in CCI-1 and CCI-3 are still not well understood, and the simulation of these tests is therefore of low interest. On the other hand, the CCI-2 test gives more comprehensive results, with a long test duration. It is therefore very useful for the code validation. A short presentation of the model used in TOLBIAC-ICB is first given, then the successive simulations of CCI-2 test with TOLBIAC-ICB within the MCCI project. Then the results obtained with the final data proposed for CCI-2 and the up-to-date code version are given. Finally sensitivity studies are presented, which illustrate the characteristics of the model. 2. MCCI modelling in TOLBIAC-ICB code The TOLBIAC-ICB code is developed by CEA in the frame of an agreement with EDF. It is based on the phase segregation model. Due to the high liquidus temperature of oxide melts and despite the melting of concrete and the presence of gas issued from concrete decomposition, a solid crust is assumed to form at the concrete wall. The species that encrust are the most refractory species. A low crust growth, a high liquid diffusivity and a small diffusion boundary layer thickness are also assumed. With this view, the pool is only composed of liquid and consequently has a low viscosity. The interface temperature between the liquid pool and the solid crust is equal to the liquidus temperature corresponding to the current composition of the remaining liquid phase. The crust thickness is calculated using a steady state assumption. Physico-chemistry (liquidus temperature, crust composition, chemical reactions) in TOLBIAC-ICB code is calculated with an intrinsic coupling to the GEMINI2 code, developed by THERMODATA. The code user may select the heat transfer correlations that are used. In the calculations presented here, the same heat transfer correlation (BALI correlation) for the different interfaces is used. 1 MCCI Project Seminar 2007, Cadarache October 10-11 2007 3. Successive results 3.1 Presentation Successive simulations of CCI-2 test were performed in the frame of the MCCI project. Table 1 gives the code version, thermodynamical data base and input conditions that were used. Date Code version geometry and data base June 2004 TOLBIAC-ICB V2.0 Pre-calculation NUCLEA-03 November 2004 TOLBIAC-ICB V2.1 Blind calculation NUCLEA-03 April 2005 TOLBIAC-ICB V2.2 Post-calculation NUCLEA-03 September 2007 TOLBIAC-ICB V3.0 rectangular Input power Initial mass kW kg 150 400 Concrete decomposition 9.8 % MgO 28 % gas cylindrical 120 400 9.8 % MgO 28 % gas rectangular 120 311 9.8 % MgO 28 % gas rectangular 120 311 12.2 % MgO NUCLEA-07 34.6 % gas Table 1: conditions of the successive simulations of CCI-2 test with TOLBIAC-ICB. The results are presented on figure 1 (melt temperature versus time), figure 2 (ablation depths versus time) and figure 3 (final shape of the cavity). The main changes in the results are due to the modifications of the initial conditions or to the modifications of the model used, but some also are due to the improvements, corrections or modifications made in the successive versions of the code and the data base. 2600 temperature, K june 04 november 04 2400 april 05 september 07 2200 2000 1800 0 60 120 180 240 300 time, min Figure 1: Melt temperature versus time, successive results with TOLBIAC-ICB. 3.2 Pre-calculation The pre-calculation was performed using the rectangular geometry corresponding to the test section, and with the test conditions that were defined before the test. The initial temperature is lower than the liquidus temperature, and therefore there is a first period during which the ablation 2 MCCI Project Seminar 2007, Cadarache October 10-11 2007 does not occur, but the input power is used to increase the melt temperature. After about 10 minutes, the liquidus temperature is reached and the ablation begins. 3.3 Blind calculation Blind calculation was performed using a cylindrical geometry that was imposed for the comparison with the other codes results, and the reduced input power which was effectively used in the test. Compared to the pre-calculation, the difference is low concerning the temperature. It is large for the ablation and shape of the cavity, due to the power input change on one hand, and on the scaling factor used for the cylindrical geometry. 0.30 june 04 0.25 november 04 april 05 ablation, m 0.20 september 07 0.15 0.10 0.05 0.00 0 60 120 180 240 300 time, min Figure 2: Ablation depth versus time, successive results with TOLBIAC-ICB. The same axial and radial ablation depths are obtained. 3.4 Post-test calculation The post test calculation is performed with a rectangular geometry. The main change concerns the initial melt mass, which is reduced because the initial splattering is taken into account. Therefore the light oxide proportion becomes larger than in the previous calculations, and consequently the liquidus temperature and melt temperature are significantly reduced. An other modification is that the ablation by radiation above the melt level is taken into account. The final shape of the cavity is consequently largely modified. 3 MCCI Project Seminar 2007, Cadarache October 10-11 2007 1.0 height, m 0.8 june 04 0.6 november 04 april 05 september 07 0.4 0.2 0.0 0.0 0.2 0.4 0.6 0.8 width, m Figure 3: Final shape of the cavity, successive results with TOLBIAC-ICB. 3.5 Actual reference case The main modification in this last calculation is the use of a modified composition of the CCI-2 concrete, with more gas and more magnesia. The consequence is a reduced final temperature. 4. Reference case compared to the experiment The actual reference case is now compared with the experimental results. 4.1 Melt temperature Figure 4 shows the comparison between the reference case calculated by TOLBIAC-ICB and the measurements. The initial temperature is lower than the liquidus temperature, and therefore there is a first period during which the ablation does not occur, but the input power is used to increase the melt temperature. After about 10 minutes, the liquidus temperature is reached and the ablation begins. At about 90 minutes, there is a large temperature decrease, which corresponds to the end of the oxidation of chromium. Before that, GEMINI found two liquid phases, one metallic and one oxidic, and the liquidus temperature corresponded to the temperature corresponding to the miscibility gap. After 90 minutes, the calculated temperature is close to the measured temperature. At 300 minutes water aspersion occurs and the melt temperature reduces. It can be seen also that the liquidus temperatures corresponding to the samples compositions that were analysed after the test (red points on figures 4), also correspond to the measured melt temperature and the calculated temperature. This phenomenon is in favour of the phase segregation model used in TOLBIAC-ICB. 4 MCCI Project Seminar 2007, Cadarache October 10-11 2007 2600 temperature, K 2400 2200 2000 1800 1600 0 60 120 180 240 300 360 time, min Figure 4: Melt temperature versus time, reference case with TOLBIAC-ICB, and liquidus temperatures corresponding to the sampling compositions (red points). 4.2 Ablation depth and shape of the cavity Figure 5 shows the comparison between the reference case calculated by TOLBIAC-ICB and the measurements. The same axial and radial heat transfer coefficients are used, and consequently the radial and axial ablation depths are the same. The ablation rate is rather good. However it can be seen that the ablation continues after water pouring at 300 minutes, which is not observed in the experiment. The final ablation depths are therefore overestimated, as can be seen on figure 6. The use of the radiation model which includes ablation by radiation above the melt level gives an ablation at the top of the cavity that is still underestimated, even if the results are better (see also the sensitivity studies hereunder). 0.35 0.30 ablation, m 0.25 0.20 0.15 CCI2 axial CCI2 radial S 0.10 CCI2 radial N 0.05 TOLBIAC axial and radial 0.00 0 60 120 180 240 300 360 time, min Figure 5: Ablation depths versus time, reference case with TOLBIAC-ICB. 5 MCCI Project Seminar 2007, Cadarache October 10-11 2007 CCI2 north and south 1.0 initial shape height, m 0.8 0.6 0.4 TOLBIAC 0.2 0.0 0.0 0.2 0.4 0.6 0.8 width, m Figure 6: Final shape of the cavity, reference case with TOLBIAC-ICB. 5. Sensitivity studies 4.1 Initial temperature 2600 temperature, K CCI2 2400 TOLBIAC reference 2200 TOLBIAC mod initial temperature 2000 1800 1600 0 60 120 180 240 300 360 time, min Figure 7: Melt temperature versus time, reference case and modified initial temperature. A calculation is performed changing only the initial temperature. A value of 2600 K is used, which corresponds to the liquidus temperature of the initial melt composition. The result is presented on figure 7. In this case, the ablation begins immediately, the end of oxidation occurs previously, but the melt temperature during the last period is the same as the temperature calculated for the reference case. Concerning the ablation rate, it is the same, the only difference consists in the start of ablation: time zero here, and deleted in the reference case. 6 MCCI Project Seminar 2007, Cadarache October 10-11 2007 4.2 Initial crust 2600 CCI2 temperature, K 2400 TOLBIAC reference TOLBIAC initial crust 2200 2000 1800 1600 0 60 120 180 240 300 360 time, min Figure 8: Melt temperature versus time, reference case and initial crust. An other calculation is performed in order to get an initial temperature equal to the liquidus temperature (fig. 8): part of the refractory material is supposed to be encrusted (5 cm crust) at the initial time, so that the liquidus temperature of the remaining melt corresponds to the initial measured temperature. The ablation then starts at time zero. After that, the initially encrusted material progressively melts, until the steady state crust thickness is reached. The consequence is that the melt temperature remains low, because the remelting of refractory material is compensated by the concrete ablation, and the liquidus temperature remains low. After about 90 minutes, the melt temperature is close to the reference temperature. The ablation rate is not modified; the only difference concerning the ablation depth is that the ablation begins at time zero. 4.3 Initial melt without chromium 2600 CCI2 temperature, K 2400 TOLBIAC reference TOLBIAC all Cr oxidized 2200 2000 1800 1600 0 60 120 180 240 300 360 time, min Figure 9: Melt temperature versus time, reference case and start with oxidized chromium. The run time in TOLBIAC-ICB depends on the run time in GEMINI2. This run time in GEMINI2 is high in case of a melt with both metallic and oxidic species. In order to reduce the run time, and to see the influence of the metallic phase of chromium, a calculation is performed supposing that all the chromium is oxidized at the initial time. Moreover the initial temperature is taken as the 7 MCCI Project Seminar 2007, Cadarache October 10-11 2007 liquidus temperature corresponding to the new initial composition. The result shows (fig. 9) that the melt temperature decrease is now regular, and the temperature corresponds to the reference case from time 90 minutes to the end. The ablation rate and shape of the cavity are the same. The conclusion is that this option (all chromium oxidized) is very useful for sensitivity studies. 4.4 Alternative scenario beginning at time 60 min An alternative scenario was proposed in the post-test calculations performed in the frame of the MCCI-OECD benchmarking work. In this scenario, the simulation starts at 60 minutes, a time at which a steady state ablation regime seams to be established. An estimation of the melt composition at 60 minutes including addition of some concrete (ablation during the first 60 minutes given by the experimental curves) is used. The ablation depth at 60 minutes is also used for the ablation depth evolution. The results show that the temperature evolution is close to the reference temperature after 90 minutes (fig. 10). Concerning the ablation depth, the ablation rate is the same (slopes of the curves of fig. 11), but the estimated ablation depth used in the new calculation leads to final ablation depth larger than the reference case. 2600 CCI2 temperature, K 2400 TOLBIAC reference TOLBIAC modified scenario 2200 2000 1800 1600 0 60 120 180 240 300 360 time, min Figure 10: Melt temperature versus time, reference case and modified scenario. CCI2 axial 0.40 CCI2 radial S 0.35 CCI2 radial N ablation, m 0.30 TOLBIAC reference 0.25 TOLBIAC mod scenario 0.20 0.15 0.10 0.05 0.00 0 60 120 180 240 300 360 time, min Figure 11: Ablation depths versus time, reference case and modified scenario. 8 MCCI Project Seminar 2007, Cadarache October 10-11 2007 4.5 No ablation above the melt level The experimental shape of the cavity shows that ablation occurs at a high level of the cavity. In the blind calculation of the benchmark, a shape of the cavity with such an ablation at a high level was obtained in the results of TOLBIAC-ICB by EDF, using the option “ablation by radiation above the melt level”. This option is used in the reference case presented here. A calculation was performed without this option: radiation but no ablation above the melt level. The result (fig. 12) shows that the shape of the cavity is very different from what is observed. CCI2 north and south 1.0 reference height, m 0.8 0.6 0.4 no ablation by radiation 0.2 0.0 0.0 0.2 0.4 0.6 0.8 width, m Figure 12: Final shape of the cavity, reference case and no ablation by radiation. 4.6 Void fraction model An other way to get ablation at a high level of the cavity, without ablation by radiation, is to modify the void fraction model. The classical Zuber and Findlay model is used in TOLBIAC-ICB, which gives a void fraction of about 0.3 at the beginning of the simulation and 0.2 at the end. An other calculation is performed multiplying the void fraction by 3. The result (fig. 13) shows that the shape of the cavity obtained is equivalent to that corresponding to the calculation supposing ablation by radiation. It cannot be concluded from these calculations which model is the good one. However it is doubtful that ablation by radiation is obtained in some experiments (CCI-2) and not in others (CCI-1, CCI-3). On the other hand, a factor 3 in the void fraction model is very large. The void fraction model seams to be revised, and a comprehensive study of the different MCCI tests available is necessary. 9 MCCI Project Seminar 2007, Cadarache October 10-11 2007 CCI2 north and south 1.0 reference height, m 0.8 0.6 mod void fraction 0.4 0.2 0.0 0.0 0.2 0.4 0.6 0.8 width, m Figure 13: Final shape of the cavity, reference case and modified void fraction. 6. Conclusion The successive results of the simulation of CCI-2 test with TOLBIAC-ICB, show a decrease of the melt temperature. This decrease is due to the modification of the test conditions used in the code data set: first decrease of the initial mass, second modification of the concrete composition. It is an illustration of the sensitivity of TOLBIAC-ICB code to the melt composition, because the melt temperature in TOLBIAC-ICB is directly related to the liquidus temperature. The reference case shows that the melt temperature after 90 minutes (end of chromium oxidation) is correctly evaluated by TOLBIAC-ICB. By the way the final temperature level corresponds to the liquidus temperature calculated with the final samples composition, which is consistent with the phase segregation model of TOLBIAC-ICB. The sensitivity studies that are presented show a low dependency of TOLBIAC-ICB concerning the initial temperature level. An other important point concerns the high experimental level of the ablation in the cavity. It is simulated in TOLBIAC-ICB either using ablation by radiation above the melt level, or with a multiplying factor of 3 of the void fraction. 10