Chapter 3: Atom Economy

advertisement

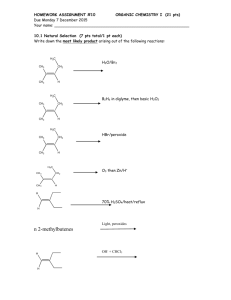

Chapter 3: Atom Economy Green Context: A central concept in green engineering is to minimize the complexity of the reaction sequences used for the production of new molecules. One way in which this is determined is through a measure of atom economy. Atom economy is defined as the percentage of the raw materials and reagents used in the synthesis that actually end up in the final product. The more of the material that remains in the product, the less that is disposed of as waste. Problem Scope: This problem illustrates the concept of atom economy through the use of a new reaction pathway that was developed for the synthesis of ibuprofen, an important pharmaceutical product. This process was named a Presidential Green Chemistry Challenge recipient in 1997. Problem Statement: BHC Company developed a new synthetic process to manufacture ibuprofen, a wellknown, nonsteroidal, anti-inflammatory painkiller marketed under brand names such as Advil™ and Motrin™. Commercialized since 1992 in BHC's 3,500 metric-ton-per-year facility in Bishop, Texas, the new process was cited as an industry model of environmental excellence in chemical processing technology. For its innovation, BHC was the recipient of the Kirkpatrick Achievement Award for "outstanding advances in chemical engineering technology" in 1993. This process was awarded a Presidential Green Chemistry Challenge Award in 1997. The new technology involves only three catalytic steps, with approximately 80 percent atom utilization (virtually 99 percent including the recovered byproduct acetic acid) and replaces technology with 6 stoichiometric steps and less than 40 percent atom utilization. The use of anhydrous hydrogen fluoride as both a catalyst and solvent offers important advantages in reaction selectivity and waste reduction. As such, this chemistry is a model of source reduction, the method of waste minimization that tops EPA's waste management hierarchy. Virtually all starting materials are either converted to product or reclaimed byproduct, or are completely recovered and recycled in the process. The generation of waste is practically eliminated. The BHC Process for the manufacture of Ibuprofen: O H3C H3C The BHC process replaces the original Boots process, patented in the mid-1960’s. The Boots process consisted of six steps, some of which included substantial derivatization. O O CH3 H3C HF CH3 CH3 CH3 H O Raney Nickel H2 H 3C H 3C CO/Pd CH3 COOH CH3 CH3 CH3 OH The Boots process for the manufacture of ibuprofen: O H3 C H 3C CH3 H O O CH3 H3 C AlCl3 CH3 CH3 H3C O CH3 NaOC2H5 COOH CH2ClCOOC2H5 CH3 H3C - NH3 CH3 CH3 COOC2H5 H3 C N O CH3 H+ H 3C OH H3C N CH3 - H2O H2O O NH2OH CH3 In terms of atom economy, determine which method of the synthesis of Ibuprofen is preferred. Atoms appearing in red are atoms that are wasted.