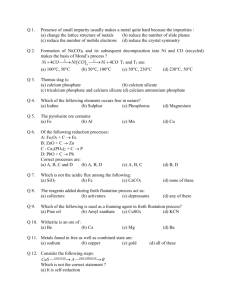

Sources of Metals

advertisement

Chapter 20 (James E. Brady – GENERAL CHEMISTRY, Principles & structures) METALS AND THEIR COMPOUNDS; THE REPRESENTATIVE METALS 20.1 OCCURRENCE AND METALLURGY Metallurgy is the science and technology of extracting metals from the earth and sea and bringing them to the point at which they can be put to practical use. It is a subject with a long and rich history, dating from the time when humans first fashioned tools and weapons from natural deposits of metals such as copper. Modern metallurgy touches our lives at every turn, from special alloys used in automobile engines to stainless steels used in surgical implants. Sources of Metals Most metals are obtained from land-based deposits that are called ores. An ore is a material that contains a particular constituent in a sufficiently high concentration that its extraction from the ore is economically worthwhile. Notice the stress on the economics of the process. Aluminium, for example, is present in the form of aluminosilicates in various kinds of rock, such as granite. However, there is no economical way of recovering the aluminium from these sources, so they are not considered aluminium ores. Instead, the ore of aluminium is a mineral called bauxite, in which the aluminium occurs as its oxide, Al2O3. As you learned in Chapter 18, aluminium can be extracted from its oxide by electrolysis in the Hall process. Some metals, such as gold, silver, and (occasionally) copper as free metals in nature. However, most metals exist in nature in compounds. Some are found in deposits of their carbonates or sulfates. Limestone, for example, is primarily CaCO3, and gypsum is a hydrate of calcium sulfate. Many important metal ores contain oxides. Two examples are aluminium (Al2O3) and iron (Fe2O3 and Fe3O4). Sulfides are the primary sources of lead (as PbS) and copper (as Cu2S). The oceans also are a source of some metals, which exist there primarily as soluble halides and sulfates. The principal source of magnesium, for example;e, is sea water, even though MG2+ is present at a concentration of only about 0.13 %. On the ocean floor, large deposits of orange-sized metal-rich manganese nodules that are rich in manganese (~25%) and iron (~15%)are found in certain locations. There has been some interest expressed in attempting to recover them, although at this time no commercial mining operations are under way. Once a metal ore has been obtained from either the earth or the sea, it must undergo a series of metallurgical processes that ultimately provide the finished metal for commercial use. Because of the wide variety of sources and the varying nature of the metal compounds in the ores, no single method can apply to the production of all metals. Nevertheless, it is possible to divide metallurgical processes into three principal categories. Concentration. Ores that contain substantial amounts of impurities, such as rock, must often be treated to concentrate the metal-bearing constituent. Pretreatment of an ore is also carried out to convert some metal compounds into substances that can be more easily reduced. Reduction. In their compounds, metals nearly always exist in positive oxidation states. Therefore, to obtain a metal from its ore it must be reduced. The particular procedure employed for a given metal depends on its ease of reduction to the free state. Refining. Often, during reduction, substantial amounts of impurities become introduced into the metal. Refining is the process whereby these impurities are removed and the composition of the metal adjusted (alloys formed) to meet specific applications. Concentration Not all ores have to be subjected to a pre-treatment step prior to reduction, although most of them must. These pretreatment procedures involve the separation of the metal-bearing component of the ore from unwanted or interfering impurities. This is particularly important for low-grade ores in which the desired metal is present only in small amounts. As expected, different methods are applied to different ores, depending on the specific properties of the impurities and the metal compounds. We can divide these procedures into two classes: physical separation, in which the chemical compositions of the constituents are not altered, and chemical separations, which use the chemical properties of the different substances in the ore. As noted above, some metals, such as silver and gold, are found in deposits as the free element, and their recovery simply involves removing them from the rock and sand with which they are mixed. One of the earliest forms of physical separation was used by the “forty-niners” in panning for gold. A mixture of sand containing (it is hoped!) particles of metallic gold is placed in a shallow pan with water. The mixture is swirled about and the sand is washed over the rim, leaving the gold dust in the bottom of the pan. The success of this procedure is based on the fact that gold is about nine times as dense as the sand and gravel impurities. As a result, the lighter impurities are more easily washed away than the more dense metal. Another way of removing metallic gold and silver from their ores is to treat the mixture with metallic mercury, a liquid in which silver and gold dissolve to form an alloy called an amalgam. The silver and gold are later recovered by distilling away the mercury, which is reclaimed and used again. You are probably familiar with silver and gold amalgams as the material used by dentists to fill teeth. A physical separation technique that can be applied to the sulfide ores of zinc, copper, and lead is called flotation. In this process, illustrated in Figure 20.1, the ore is pulverized and added to large vats of a mixture of water and oil containing suitable additives. The finely powdered metal-bearing sulfide particles of the ore become coated by the oil while the unwanted material, called the gangue, is wetted by the water. A stream of air is then blown through the mixture, and the oil-covered mineral is carried to the surface by bubbles where it is trapped in a froth that can be removed to recover the metal compound. The gangue, on the other hand, simply settles to the bottom of the apparatus and is later discarded. Iron, as you are probably aware, is society’s most important metal, and its ores have traditionally been rich deposits of reddishbrown hematite, composed primarily of Fe2O3. Through decades of mining, hematite deposits in regions such as the Masabi range of Minnesota have been nearly exhausted and other sources of iron ore have been sought. One such ore being mined today is taconite. Taconites have Fe3O4 as their iron-containing compound, and the better of them contain 30 to 40 % iron by weight. The compound Fe3O4 is called magnetite, and as its name suggests, it is magnetic. This provides the basis for the enrichment of taconite ores by a physical separation process. The rock-hard ore is first ground to give particles of very small size and then the Fe2O3 is pulled out with a powerful electromagnet. Chemical methods of concentrating the metal-bearing component of an ore vary considerably because of the variety of chemical properties exhibited by the metals and their compounds. As mentioned earlier, aluminium, whose electrolytic reduction was described in Chapter 18, occurs in deposits of bauxite, a form of Al2O3. In this case the ore is concentrated by taking advantage of the amphoteric behavior of aluminium. The bauxite is treated with concentrated base, which dissolves the Al2O3 to produce aluminate ion, AlO2-. Al2O3 + 2 OH- 2 AlO2- + H2O After the solution is removed from the gangue, it is neutralized with acid. This precipitates Al(OH)3, which yields pure Al2O3 when heated. heat 2 Al(OH)3 Al2O3 + 3 H2O This purified aluminium oxide serves as the raw material in the Hall process discussed previously. Another chemical pre-treatment, often given to a sulfide ore, is called roasting. Here the ore is heated in air, converting the metal sulfide to an oxide that is more conveniently reduced. 2PbS + 3 O2 2 PbO + 2 SO2 2 ZnS + 3 O2 2 ZnO + 2 SO2 The sulfur dioxide produced in the roasting process has been a severe source of air pollution, as described in Chapter 23.