Linewidth Enhancement Factor in Strained InGaAsP/InP Quantum

Linewidth enhancement factor in compressively strained single- and multiple-layer InGaAsP quantum wire lasers

M Abul Khayer and A Haque 1

Department of Electrical and Electronic Engineering, Bangladesh University of Engineering and

Technology, Dhaka-1000, Bangladesh

1 Present address: Department of Electrical and Electronic Engineering, East West University,

Dhaka-1212, Bangladesh

Corresponding e-mail: ahaque@ewubd.edu

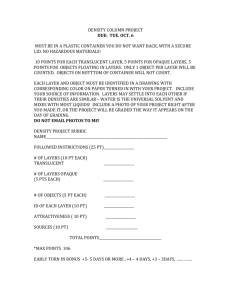

Abstract: Linewidth enhancement factor, also termed as the α-factor, of compressively strained

(CS) InGaAsP/InP quantum wire (QWire) lasers is theoretically investigated using an 8 band k.p

method including elastic strain relaxation effects. The structure under our consideration consists of vertically stacked single or multiple layers of In

1-x

Ga x

As y

P

1-y

compressively strained (CS)

QWires with 1.07% misfit CS and lattice-matched (LM) or tensile-strained (TS) barriers grown on

(001) InP substrate. In all our analysis, the height of the wires and the barriers are 7 nm and 12 nm, respectively, along the crystal growth direction. All the calculations are for TE polarization which is dominant in CS structures. It is found that, for a certain wire width the α-factor is larger in case of single-layer QWires and is reduced with the introduction of the multiple-layer stacks in the active region. Two competing effects take place in case of multiple-layer stacks. On one hand, multiple layers increase the modal gain. On the other hand, material gain per layer is reduced due to increased strain relaxation. Therefore, the increase in modal gain in multiplelayer stacks is less than what is normally expected. Our results show that the α-factor depends on the device parameters, such as, wire width, barrier strain compensation, number of vertically stacked layers etc., in a complicated way owing to the complex interactions between 2D quantum confinement and elastic strain relaxation effects. The presented results are important for designing CS QWire lasers with reduced values of the α-factor.

1. Introduction

Semiconductor lasers are one of the most successful photonic devices benefited by the quantum-size effects. These devices are required to have lower threshold current, higher differential gain and lower linewidth enhancement factor. Their operational characteristics have drastically been improved by the introduction of quantum well (QWell) structures in the active region [1]. Recent efforts have concentrated on reducing the dimensionality further to quantum wire (QWire) and quantum dot (QDot) devices in which the carriers are restricted to one or zero dimensions, respectively [2], [3]. A number of different techniques exist for fabricating QWire laser structures. Compressively strained (CS) multiple quantum wire (MQWire) lasers based on InP substrate have successfully been realized using a fabrication method that combines electron beam lithography (EBL), CH

4

/H

2

reactive ion etching

(RIE) and organometallic vapor-phase-epitaxial (OMVPE) regrowth [4]. Owing to the greater position controllability offered by this fabrication technique, this approach is particularly suitable for fabricating photonic integrated circuits containing low dimensional semiconductor structures [5].

Carrier induced coupling between the gain change and the refractive index change in the active region of a semiconductor laser is described by the linewidth enhancement factor, also termed as the

α-factor. Henry first derived the detail theory for laser linewidth [6], [7]. It has been shown that introduction of lowdimensional structures in the active region reduces the α-factor [8]. In general, the

α-factor is reduced with increasing degree of confinement [9]. Willatzen et al . [10] calculated the αfactor for GaAs/AlGaAs QWires and QDots including valence band mixing effects. Oksanen et al. [11] calculated the α-factor for InGaAs QDot and QWell structures using parabolic band approximation and showed that QDots offer lower value of the α-factor compared to the QWells.

In this article, the α-factor of InGaAsP/InP CS QWire laser structures is calculated and the dependence of the α-factor on the number of vertically stacked QWire layers is investigated. The

effects of other device parameters such as QWire width, barrier strain compensation, etc. on the αfactor are presented elsewhere [12].

2. Theory

Figure 1(a) shows the schematic structure of InGaAsP Fabry-Perot QWire laser while figure 1(b) shows the cross-sectional diagram of an unit cell. The coordinate axes are also shown. The wire axis is along the crystallographic [110] direction (x-direction). The crystal growth is along the [001] direction

(z-direction). L y

and L z

are the width and the height of a QWire, respectively.

We apply the 8-band k.p method [13] to calculate the electronic energy band structures. The multiband effective mass equation for the envelope function F n is described by n

/

8

1

H nn

/

( r ,

) F n

/

( r )

EF n

( r )

--- (1).

Here, H is the multiband Hamiltonian matrix and E is the eigenenergy. Equation (1) is solved by applying the eigenfunction expansion method [13]. Calculation of electronic states of CS QWires using this approach has been discussed in detail in [14].

The material gain g act

is calculated as [15] g act

1

n act

e

0

2 cm

0

2 c

, v

cv

M cv

2

f c

f v

---- (2), where n act

is the refractive index of the active region, ρ cv

is the reduced density-of-states, f c

(f v

) is the electron (hole) occupation probability and M cv

is the transition matrix element for the interband transitions.

Since the gain depends on the carrier density, real part of the refractive index also changes with gain. Once gain is calculated, the changes in the imaginary part of the refractive index with changes in the carrier density,

n

//

can be evaluated from the following relation

n

//

G mod

4

------- (3), where ħω is the photon energy and G mod is the modal gain including the broadening due to intra-band relaxation. The real and the imaginary parts of the refractive index (

n

/

,

n //

) are related by the

Kramers-Kronig (KK) dispersion relationsship [7],

n

/

( E )

1

2

2

P

0

G mod

E

/ 2

( E

/

) dE

E

2

/

----- (4), where P indicates taking the principal value of the integral.

Finally, the α-factor is expressed as [6],

n

/

n

//

------ (5).

Figure 1 (a) The schematic structure of a QWire laser and (b) Cross-sectional diagram of a unit cell of a vertical stack of Multiple QWires.

3. Results and Discussions

QWire structures under our consideration are assumed to be fabricated by EBL, RIE and two-step

OMVPE growth [4]. The structure consists of multiple layers of InGaAsP CS QWires with 1.07% misfit strain and tensile strained (TS) or lattice-matched (LM) barriers grown on (001) InP substrate. The height of the barriers are 12 nm along the crystal growth direction. Unless otherwise mentioned, the height of the QWires are 7 nm. Intraband relaxation time

in

0 .

1 ps. The material parameters for the quaternary In

1-x

Ga x

As y

P

1-y

are obtained by linear interpolation among the binary alloys GaAs, InAs, InP and the ternary alloy In

0.532

Ga

0.468

As (latticematched to InP) using Vegard’s law [16]. The values of the parameters for these four basic alloys are taken from [13].

The dispersion relationships of the lowest two conduction and the highest three valence band levels in a 10-nm-wide QWire are presented in figure 2(a), 2(b). LM and 0.60% TS barriers are considered.

For LM barriers, the effective mass of the highest hole subband is high near the zone center due to the band mixing. Suppression of strain relaxation by SC barriers decreases the carrier effective mass.

It is found that

E h 12

28 .

5 meV with LM barriers and

E h 12

30 .

7 meV with 0.60% TS barriers.

These results demonstrate the complex interactions between elastic strain relaxation and quantum confinement effects.

Figure 3 shows peak broadened material gain per QWire layer, G p1

as a function of the injected carrier density in a 20-nm-wide QWire for different numbers of vertically stacked QWire layers in the active region. Transverse electric (TE) polarization with the electric field of the radiation along the

QWire axis is considered. This is the polarization in which lasing of these CS QWires takes place [4]. It is observed that G p1

is lower for the multiple-layer QWires compared to their single-layer counterpart.

When multiple layer structures are used, strain relaxation increases [14]. Thus peak gain per QWire layer is decreased.

600

300

0

(a) LM barriers

10-nm wide QWire

600

300

0 (b) 0.60% TS barriers

-800 -800

0.0

0.4

0.8

Wave vector, k (1/nm)

-900

0.0

0.4

0.8

Wave vector, k (1/nm)

Figure 2 Dispersion relationships for the lowest two conduction and the highest three hole subbands in a 10-nm-wide QWire with (a) LM and (b)

0.60% TS barriers.

20

0

20-nm-wide QWire

-20 1 QWire layer

3 QWire layers

5 QWire layers

-40

0 2 4 6

Carrier density (10

18 cm

-3

)

8

Figure 3 Peak material gain per QWire layer

G p1

as a function of the injected carrier density in a 20-nm-wide QWire with 0.15% TS barriers for different numbers of vertically stacked layers.

Figure 4 presents the α-factor as a function of the injected carrier density in two different QWire structures with 0.15% TS barriers for various numbers of QWire layers stacked vertically in the active region. It is found that the α-factor is larger in case of single-layer QWires and is reduced with the introduction of the multiple-layer stacks in active region of the QWires. Two competing effects take place in multiple-layer stacks. On one hand, multiple layers increase the modal gain. On the other hand, material gain per layer is reduced due to increased strain relaxation. Therefore, the increase in

the modal gain in multiple-layer stacks is less than what is normally expected. Corresponding reduction in the α-factor is also suppressed.

0.7

0.6

(a) 20-nm wide QWire

1 QWire layer

3 QWire layers

5 QWire layers

4

3

(b) 50-nm wide QWire

1 QWire layer

3 QWire layers

5 QWire layers

0.5

2

0.4

1

0 2 4 6

Carrier density (10

18 cm

-3

)

8 0 2 4 6

Carrier density (10

18 cm

-3

)

8

Figure 4 The α-factor as a function of the injected carrier density at gain peak energies of QWire structures for different numbers of vertically stacked layers with 0.15% TS barriers for wire widths of 20-nm (a) and 50-nm (b).

4. Conclusion

The α-factor of CS InGaAsP/InP QWire lasers is theoretically studied. When multiple QWire layers are stacked vertically, the α-factor decreases owing to the increase in the modal gain. However in multiple

QWire stacks, the reduction is less than what is normally expected. It is due to the fact that increased strain relaxation in multiple layer stacks decreases the gain per layer in these structures. Our results will be useful in designing CS InGaAsP QWire lasers with the minimum α-factor and an optimum performance.

References

[1] N. Holonyak, Jr., R. M. Kolbas, R. D. Dupuis, and P. D. Dapkus, IEEE J. Quantum Electron. 16 ,

170 (1980).

[2] Y. Arakawa, and H. Sakaki, Appl. Phys. Lett. 40 , 939 (1982).

[3] M. Asada, Y. Miyamoto, and Y. Suematsu, IEEE J. Quantum Electron. 22 , 1915 (1986).

[4] H. Yagi, T. Sano, K. Ohira, T. Maruyama, A. Haque, and S. Arai, Jpn. J. Appl. Phys., part 2 42 ,

L748 (2003).

[5] K. Ohira, T. Maruyama, H. Yagi, S. Tamura, and S. Arai, IEEE Photonics Technol. Lett. 17 , 264

(2005).

[6] C. H. Henry, IEEE J. Quantum Electron. 18 , 259 (1982).

[7] C. H. Henry, R. A. Logan, and K. A. Bertness, J. Appl. Phys. 52 , 4457 (1981).

[8] C. A. Green, N. K. Dutta, and W. Watson, Appl. Phys. Lett. 50 , 1409 (1987).

[9] A. A. Ukhanov, A. Stintz, P. G. Eliseev, and K. J. Malloy, Appl. Phys. Lett. 84 , 1058 (2004).

[10] M. Willatzen, T. Tanaka, Y. Arakawa, and J. Singh, IEEE J. Quantum Electron. 30 , 640 (1994).

[11] J. Oksanen, and J. Tulkki, J. Appl. Phys. 94 , 1983 (2003).

[12] M. A. Khayer, and A. Haque, Int. Conf. EPMDS-2006 Proc. D13 (2006).

[13] D. Gershoni, C. H. Henry, and G. A. Baraff, IEEE J. Quantum Electron. 29 , 2433 (1993).

[14] A. Haque, H. Yagi, T. Sano, T. Maruyama, and S. Arai, J. Appl. Phys. 94 , 2018 (2003).

[15] S. W. Corzine, R. Yan, and L. A. Coldren, in Quantum Well Lasers. P. Zory, Ed. New York:

Academic Press, 28 (1993).

[16] R. E. Nahory, M. A. Pollack, and W. D. Johnston, Jr., Appl. Phys. Lett. 33 , 659 (1978).