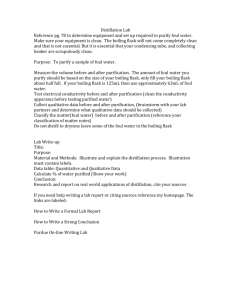

Fractional Distillation Set-up

advertisement

Laboratory Manual Experiments IN Organic Chemistry for Biology Section Chem 270 General Information LABORATORY RULES AND SAFETY PRECAUTIONS General Policies : 1. Each student is expected to attend each laboratory session and to be in the laboratory on time. Those students who come early, should wait inside the laboratory but never gather in the corridors. 2. Each student must wear a clean, ironed and buttoned up laboratory coat. 3. Each student is responsible for keeping the laboratory clean and in good order. All working areas, balances must be kept clean by wiping them with a cloth or a sponge. 4. Powdered drugs, greasy or waxy materials or any insoluble waste materials will block the sink if thrown into it. Dispose of them properly in a waste-basket. Water-immiscible organic solvents and other liquids should be discarded in a designated waste-solvent can but never poured into a sink. 5. Coats, books and personal belongings should be kept in your lockers. Do not bring them along with you to the laboratory. 6. Smoking, drinking, eating or chewing gum are prohibited in the laboratory. 7. Each student is expected to work quietly and independently. 8. Familiarize yourself with the location of fire extinguishers and safety showers, and know how and when to use these devices. 9. Do not carry reagent bottles to your desk. 10. Never return excess material to reagent bottles. 11. Students should bring two hand towels, a sponge, detergent, matches, a marker and a calculator with them to each laboratory session. Safety Precautions: 1. Eye protection must be worn at all times in the laboratory, regardless of what is being done. Prescription glasses (not sunglasses) are acceptable. Contact lenses provide no protection. 2. If chemicals are splashed in or near your eyes, wash immediately with clean, cold running water (remove contact lenses). Continue washing the eyes for 10- 15 minutes. Consult a physician afterwards. 3. When inserting glass tubing or thermometers into rubber stoppers, always lubricate both the glass tubing and the hole with glycerin and protect hands with a towel. 4. Never taste any compound in the laboratory. 5. To determine the odor of a compound, bring the stopper of the bottle cautiously towards the nose, do not inhale. 6. Avoid any contact of chemicals with the skin, especially the face. Wash hands as soon as possible after making transfers or other manipulations. 7. When heating a test tube or carrying out a reaction in one, never point the tube toward yourself or your neighbor. 8. Never, heat an organic liquid directly over a flame except under a condenser. When refluxing a liquid, be sure that the condenser is tightly fitted. If a temperature below 95 oC is sufficient, use a steam bath rather than a burner. 9. Before lighting a flame check to see that volatile liquids are not being poured or evaporated in your vicinity. 10. Always turn a burner off as soon as you have finished using it. 11. As general practice, and particularly if a burner is in use, avoid loose-fitting long sleeves and cuffs; long hair should be tied back during laboratory work. 12. Any experiment involving the use or production of objectionable (i.e. poisonous or irritating) gases must be performed in the hoods. Warning Signs Warning signs are used to properly identify and warn of possible hazards. They should be black text on a yellow background and should always include a pictorial symbol danger slippery surface electric shock trip hazard mind your head fire risk fork lift explosive noise radiation acid scull non danger of ionizing death radiation COMMON LABORATORY GLASS WARE AND EQUIPMENT Beaker Glass rod Funnels Separation Funnel Spatula Test tubes Test Tube Holder Test Tube Rack Bunsen Burner Water Bath Conical Volumetric Flask Round Bttomed Flask Graduated Cylinder Hot Plate Balance Lab 1 Purification Of Organic Compounds 1- Purification Of Solid Organic Compounds : Crystallization : Crystallization is : " The process in which a solid substance separates from saturated solution as crystals ". It is a technique which used to purify solid compounds , It is based on the principles of solubility and depends on : 1) Dissolving organic compounds (solutes)in hot liquids (solvents) 2) Filtration to remove impurities . 3) Cooling the hot solution to precipitate the organic compounds in crystal form. Organic solvent can be classified into: a) polar solvent : H2O , alcohol ( CH3OH , CH3CH2OH) Acetic Acid (CH3COOH) . b) Non Polar solvent : petroleum ether , toluene , benzene and chloroform Common solvents for recrystallization : Solvent Water Methanol Ethanol Petroleum Ether Acetone Ethyl Acetate Acetic Acid Chloroform Benzene Cyclo Hexane Structure H2O CH3OH CH3CH2OH CH3-O-CH2CH3(-CH2-OCH2-) CH3-CO-CH3 C2H5COOCH3 CH3COOH CHCl3 Boiling point (T0C) 100 64.5 78 60 - 100 56 78 61 80 81 Experimental Objective : Crystallization of Benzoic acid Material Needed : Glass ware : 2 conical flask , funnel , beaker, glass rod , stand , wire gauze clamp .filter paper. Chemicals : Benzoic acid , distilled water Procedure : 1- Place 2gm of Benzoic acid in a 100ml conical flask 2- heat 50ml of distilled water to boiling 3- add the water to the benzoic acid until it dissolve completely using glass rod 4- prepare a fluted filter paper and short –stem funnel , place it in a suitable conical flask and start to filtrate the hot solution rapidly . 5- leave the filtrate to cool at room temperature 6- filter the cold solution and collect the pure crystals . Recrystallization: Recrystallization is used to purify solids. Usually this method works best when there is only a small amount of impurity in the solid. Recrystallization depends on different solubilities of the target compound and other compounds present in the impure mixture. The goal of this method is to have one compound dissolved in a solvent while the other compound is not dissolved. If one compound is an un dissolved solid, it can be filtered out of the solution in order to separate it from all the other things that are in solution. Solubility in a solvent is a physical property of a material, just like its boiling point or melting point. Sodium chloride (table salt) has a particular solubility in cold water (35.7 g will dissolve in 100 mL) while sodium oleate (found in some soaps) has a different solubility in cold water (10 g per 100 mL). That difference can be exploited to separate these two compounds. Summary of Recrystallization Steps 1. 2. 3. 4. Add a small quantity of appropriate solvent to an impure solid. Apply heat to dissolve the solid. Cool the solution to crystallize the product. Use vacuum filtration to isolate and dry the purified solid. Recrystallization process: 1- Choose a solvent such that the impure compound has poor solubility at low temperatures , yet is completely soluble at higher temperatures. the point is to fully dissolve the impure substance when it is heated, yet have it crash out of solution upon cooling. 2- Add as small a quantity as possible to fully dissolve the sample. More solvent can be added during the heating process, if necessary. 3- Heat the suspension to fully dissolve the sample. Usually a hot water bath or steam bath is used, since these are gentle, controlled heat sources. A hot plate or gas burner is used in some situations. 4- One the sample is dissolved, the solution is cooled to force crystallization of the desired compound... 5- Slower cooling may lead to a higher purity product, so it's common practice to allow the solution to cool to room temperature before setting the flask in an ice bath or refrigerator. 6- Crystals usually begin forming on the bottom of the flask. It's possible to aid crystallization by scratching the flask with a glass rod at the air-solvent junction (assuming you are willing to purposely scratch your glassware). The scratch increases the glass surface area, providing a roughened surface on which the solid can crystallize. 7- Crystals of purified solid are isolated by filtration. This is usually done with vacuum filtration, sometimes washing the purified solid with chilled solvent. If you wash the product, be sure the solvent is cold, or else you run the risk of dissolving some of the sample. 8- The product may now be dried. Aspiring the product via vacuum filtration should remove much of the solvent. Open-air drying may be used as well. In some cases, the recrystallization may be repeated to further purify the sample. Sublimation Sublimation is : " The transition of a substance from the solid phase to the gas phase without passing through an intermediate liquid phase ". solid↔ vapor At normal pressures, most chemical compounds and elements possess three different states at different temperatures. In these cases the transition from the solid to the gaseous state requires an intermediate liquid state. Sublimation is a technique used by chemists to purify compounds. Typically a solid is placed in a sublimation apparatus and heated under vacuum. Under this reduced pressure the solid volatilizes and condenses as a purified compound on a cooled surface (cold finger), leaving a non-volatile residue of impurities behind. Once heating ceases and the vacuum is removed, the purified compound may be collected from the cooling surface. Examples: 1- Carbon dioxide Solid carbon dioxide (dry ice) sublimates readily at atmospheric pressure at -78.5°C (197.5 K, −104.2 °F), while liquid CO2 can be obtained at pressures and temperatures above the triple point (5.2 atm, -56.4°C). 2- Water Snow and ice sublimate, although more slowly, below the melting point temperature. This allows wet cloth to be hung outdoors in freezing weather and retrieved later in a dry state. In freeze-drying the material to be dehydrated is frozen and its water is allowed to sublimate under reduced pressure or vacuum. The loss of snow from a snowfield during a cold spell is often caused by sunshine acting directly on the outer layers of the snow. Ablation is a process which includes sublimation and erosive wear of glacier ice. 3- Other compounds a. Camphor being sublimated. Note the white purified camphor on the cold finger, and the dark-brown crude product. b. Iodine produces fumes on gentle heating. It is possible to obtain liquid iodine at atmospheric pressure by controlling the temperature at just above the melting point of iodine. c. Naphthalene, a common ingredient in mothballs, also sublimates easily. Arsenic can also sublimate at high temperatures. Various substances appear to sublimate because of undergoing chemical reactions or decomposition; for example, ammonium chloride when heated decomposes into hydrogen chloride and ammonia. 2- PURIFICATION OF LIQUID ORGANIC COMPOUNDS Distillation : Distillation is the process of heating a liquid until it boils, capturing and cooling the resultant hot vapors, and collecting the condensed vapors. Distillation is a powerful tool, both for the identification and the purification of organic compounds .It is used to purify a compound by separating it from a nonvolatile or less-volatile material. When different compounds in a mixture have different boiling points, they separate into individual components when the mixture is carefully distilled. Types of Distillation : There are many types of Distillation 1- Simple distillation : Simple distillation is designed to evaporate a volatile liquid from a solution of non-volatile substances; the vapour is then condensed in the water condenser and collected in the receiver. The apparatus consists of a round-bottomed distilling flask bearing a stillhead connected to a water condenser (Liebig condenser). This is attached via a vented delivery bend to the receiver, also a round-bottomed flask. The stillhead has a thermometer adapter with a thermometer. Notes: The bulb of the thermometer is opposite the exit to the condenser. You want the temperature of the exit vapours since it is these that will condense. The delivery bend is vented so that when the apparatus is heated the joints aren't pushed apart by expanding gas. Never draw a closed apparatus. Water goes in at the bottom of the condenser jacket and out at the top. Note the structure of the condenser - the water jacket is separate from the tube down the middle! Fractional Distillations: A fractional distillation is used when Mixtures of liquids whose boiling points are similar (separated by less than 70°C) cannot be separated by a single simple distillation . Fractional distillation is the separation chemical compounds by heating them to a temperature at which several fractions of the compound will evaporate. Generally the component parts boil at less than 25 °C from each other under a pressure of one atmosphere (atm). If the difference in boiling points is greater than 25 °C, a simple distillation is used. Fractional Distillation Set-up The photo below is of a fractional distillation set-up. The only difference between this set-up and that of a simple distillation set-up is the inclusion of a fractionating column (see close-up below) between the round bottom flask and the Y-adaptor. In the illustration, the fractionating column is a regular condenser filled with glass beads. Note that you do not hook the tubing connectors on this fractionating column/condenser to tubing and water. Heat source, such as a hot plate with a bath, and ideally with a magnetic stirrer. Distilling flask, typically a round-bottom flask Receiving flask, often also a round-bottom flask Fractionating column Distillation head Thermometer and adapter if needed Condenser Vacuum adapter (not used in image to the right) Boiling chips, also known as anti-bumping granules Standard laboratory glassware with ground glass joints, e.g. quickfit apparatus. The photo below is of two different styles of fractionating column. The upper one is an ordinary condenser filled with small glass beads. This is the style you will use in the organic chemistry teaching labs. The lower one is a Vigreux column Vacuum Distillation: Vacuum distillation is : distillation of liquids performed at a pressure lower than atmospheric pressure to take advantage of the fact that reducing the pressure lowers the boiling point of liquids. This permits the distillation of liquids that are temperature sensitive and avoids any degradation of such liquids Vacuum Distillation Set-up A vacuum distillation set-up differs from a simple distillation with the inclusion of a securely attached round bottom flask as the receiving flask (note in the picture, it is clamped with a small pronged clamp) and a vacuum line connected to the vacuum adaptor. The vacuum line in this particular set-up is connected to a "water-trap", which is a side-arm flask. The water-trap itself is connected to a water aspirator (not shown). Preferably, you would connect the vacuum line from the vacuum adaptor to a mechanical vacuum system. Instead of a boiling chip, use a spin bar inside the round bottom flask. A boiling chip cannot be used in vacuum distillation, since the reduced pressure sucks the trapped air from boiling chips and thus they do not work to prevent bumping. A rapidly spinning spin bar does prevent bumping. Place a stir motor under the heating source for the round bottom flask. Steam Distillation Distillation of 2-immiscible liquids , this technique can be used for purification of high boiling liquids which decompose near their boiling points and these liquids are immiscible with water Determination of Physical Properties For Organic Compounds 1- Melting Points The melting point of a solid substance is : " The temperature at which the transition from solid to liquid occurs at atmospheric pressure " ( solid ↔ liquid ) It is unaffected by changes in external pressure A pure solid has a sharp melting point and will melt within a narrow range of less than two degrees. Melting Point Determination Melting points are relatively easy and inexpensive to determine, they are handy identification tools to the organic chemist. If you want to use the melting point to identify a solid compound which you have isolated in the lab, you will need to compare its melting point with that of the true compound. If the compounds are sold slightly impure, the melting point range will reflect this fact. 2- Boiling Points The boiling point is : " The temperature at which the vapor pressure of the liquid phase of a compound equals the external pressure acting on the surface of the liquid ". The external pressure is usually the atmospheric pressure. For instance, consider a liquid heated in an open flask. The vapor pressure of the liquid will increase as the temperature of the liquid increases, and when the vapor pressure equals the atmospheric pressure, the liquid will boil. Different compounds boil at different temperatures because each has a different, characteristic vapor pressure. As a liquid is heated, the temperature is increased. As the temperature increases, the kinetic energy increases which causes increasing molecular motion. Eventually the molecular motion becomes so intense that the forces of attraction between the molecules is disrupted to the extent the molecules break free of the liquid and become a gas. At the temperature of the boiling point, the liquid turns into a gas. The molecules are not in contact each other in the gaseous state. compounds with higher vapor pressures will boil at lower temperatures. EXTRACTION WITH SOLVENTS Extraction : Separation and isolation of organic substances from the mixtures , it can be subdivided into : 1- Extraction of Solids: e.g. perfume essence from flowers by using solvents ( H2O , CHCl3 , acetone , ether ,…) by using Soxhelt System 2- Extraction of Solutions : Technique used for isolation dissolved substances by shaking its solution with immiscible solvent in a separatory funnel On standing, the two immiscible phases ( usually organic and aqueous) from two separate layer ( upper and lower) that can be separated by separating funnel . Experimental Objective : Separating a two-liquid component Material Needed : Glass ware : separatory funnel , 2conical flask ,stand , wire gauze, clamp holder, filter paper. Chemicals : Ether ,water Procedure 1- Place 50ml of water and 50ml of ether in a separating funnel 2- Shake it well 3- Draw off the lower aqueous layer into a flask and repeat extraction of the lower phase 4- Draw off the other layer into another flask . CHROMATOGRAPHY Thin Layer Chromatography - TLC Thin layer chromatography (TLC) is a method for identifying substances and testing the purity of compounds. TLC is a useful technique because it is relatively quick and requires small quantities of material. Separations in TLC involve distributing a mixture of two or more substances between a stationary phase and a mobile phase. The stationary phase is a thin layer of adsorbent (usually silica gel or alumina) coated on a plate. The mobile phase is a developing liquid which travels up the stationary phase, carrying the samples with it. Components of the samples will separate on the stationary phase according to how much they adsorb on the stationary phase versus how much they dissolve in the mobile phase. when the Rf of a compound is compared with the Rf of a known compound (preferrably both run on the same TLC plate). A TLC plate is a sheet of glass, metal, or plastic which is coated with a thin layer of a solid adsorbent (usually silica or alumina). A small amount of the mixture to be analyzed is spotted near the bottom of this plate. The TLC plate is then placed in a shallow pool of a solvent in a developing chamber so that only the very bottom of the plate is in the liquid. This liquid, or the eluent, is the mobile phase, and it slowly rises up the TLC plate by capillary action. As the solvent moves past the spot that was applied, an equilibrium is established for each component of the mixture between the molecules of that component which are adsorbed on the solid and the molecules which are in solution. In principle, the components will differ in solubility and in the strength of their adsorption to the adsorbent and some components will be carried farther up the plate than others. When the solvent has reached the top of the plate, the plate is removed from the developing chamber, dried, and the separated components of the mixture are visualized. If the compounds are colored, visualization is straightforward. Usually the compounds are not colored, so a UV lamp is used to visualize the plates. Column Chromatography In column chromatography, the stationary phase, a solid adsorbent, is placed in a vertical glass (usually) column and the mobile phase, a liquid, is added to the top and flows down through the column (by either gravity or external pressure). Column chromatography is generally used as a purification technique: it isolates desired compounds from a mixture. The mixture to be analyzed by column chromatography is applied to the top of the column. The liquid solvent (the eluent) is passed through the column by gravity or by the application of air pressure. An equilibrium is established between the solute adsorbed on the adsorbent and the eluting solvent flowing down through the column. Because the different components in the mixture have different interactions with the stationary and mobile phases, they will be carried along with the mobile phase to varying degrees and a separation will be achieved. The individual components, or eluants, are collected as the solvent drips from the bottom of the column. Column chromatography is separated into two categories, depending on how the solvent flows down the column. If the solvent is allowed to flow down the column by gravity, or percolation, it is called gravity column chromatography. If the solvent is forced down the column by positive air pressure, it is called flash chromatography, a "state of the art" method currently used in organic chemistry research laboratories Gas Chromatography In gas chromatography (GC), the stationary phase is a high-boiling liquid and the mobile phase is an inert gas. GC is used as an analytical tool to find out how many components are in a mixture. It can also be used to separate small amounts of material. The GC Instrument The process of gas chromatography is carried out in a specially designed instrument. A very small amount of liquid mixture is injected into the instrument and is volatilized in a hot injection chamber. Then, it is swept by a stream of inert carrier gas through a heated column which contains the stationary, high-boiling liquid. As the mixture travels through this column, its components go back and forth at different rates between the gas phase and dissolution in the high-boiling liquid, and thus separate into pure components. Just before each compound exits the instrument, it passes through a detector. When the detector "sees" a compound, it sends an electronic message to the recorder, which responds by printing a peak on a piece of paper.