Toluene Hydrodealkylation Process

advertisement

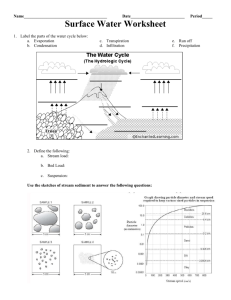

CHE 304 Optional Homework (Due May 27 2009) A basic simulation of the toluene hydrodealkylation process is required using Provision. Deliverables: (1) Your own drawing of the PFD and a specification table for the toluene hydrodealkylation process. (2) PFD from the simulation (PROVISION). Stream Property Tables are required. Toluene Hydrodealkylation Process (Revised from Senior Project of Patricia Quinones, 2002) The hydrodealkylation of toluene1 (HDA) is a process used to produce benzene. The main reaction in the process is: Toluene + H2 Benzene + CH4 Toluene and hydrogen are converted in a reactor packed with catalyst to produce benzene and methane. Typically the reaction reaches a conversion of 90%. The reaction is highly exothermic and the typical operating conditions are 500 C to 660 C, and 20 to 60 bar. Figure 1 shows the block diagram of the HDA process. H2 Recycle Fuel Gas Hydrogen Reactor Benzene Separator Toluene Distillation Toluene Recycle Figure 1: Toluene Hydrodealkylation Block Flow Diagram 1 Analysis, Synthesis, and Design of Chemical Processes Richard Turton, Richard C. Ballie, Wallace B. Whiting, Joseph A. Shaelwitz. Prentice Hall, PTR. New Jersey, 1998. 15 The HDA process begins with mixing fresh toluene with a stream of recycle unreacted toluene, the mixing is achieved in a storage tank. The toluene is then pumped to combine it with a stream of mixed hydrogen and fresh hydrogen gas. The mixture of hydrogen and toluene is preheated before it is introduced to the heater or furnace. In the furnace the stream is heated to 600 C, the reaction temperature, then introduced into the reactor. The reactor is where the main reaction happens: C7H8 + H2 = C6H6 + CH4 This reaction is irreversible, and it requires catalyst. The catalyst consists of chromium or molybdenum oxides, platinum or platinum oxides, on silica or alumina. Another minor reversible side reaction2 is often observed: 2 Benzene = Diphenyl + H2 The catalytic process occurs at lower temperatures and offers higher selectivity but requires frequent regeneration of the catalyst. The products are then cooled and introduced into a pair of separators that separate the unreacted hydrogen. Portion of the unreacted hydrogen is compressed and recycle back to the feed and the reactor. The products leaving the separators are then heated before being introduced into a distillation column, where toluene is separated from the stream and recycle to the feed. This allow for greater conversion. Then further fractionation separates methane and toluene from the benzene product. The heating requirements are achieved with low, high and medium pressure steam. The cooling requirements are achieve by cooling water at temperature of 30 C and pressure of 1 bar. The process begins with the first phase of a process: the reactor feed preparation. This begins with combining 108.7 kmol/hr of a fresh stream of toluene at 25oC, and 1.9 bar, with a recycle stream of unreacted toluene in a storage tank TK-1 at 112oC and 2.43 bar. Toluene is then pumped through pump P-1, the discharge pressure of the pump must be 25.5 bar, this is pumped to a second storage tank TK-2 where toluene is combined with a combined stream of fresh and recycle of hydrogen. The new two-phase stream is preheated in E-1 to 163.9oC, high pressure steam at 45 barg is used for this purpose. The stream exists the pre-heater as a onephase stream because the toluene was vaporized. The stream is then introduced into the heater, H-1, this fired heater is a type of furnace which uses air to combust fuel gas to produce enough heat to raise the temperature of the stream to 600oC. The reactor feed preparation has now been completed. The stream is at the desired pressure, 24.81 bar, and temperature, 600oC, necessary for the reaction to occur. The stream is then introduced into the reactor R-1, this reactor is a vertical vessel packed with catalyst. This is the main part of the process where the main reaction, which produces benzene, happens: “Benzene”. Kirk-Othmer Encyclopedia of Chemical Technology William Fruscella. John Wiley & Sons, Inc., 1992. 2 16 C7H8 + H2 = C6H6 + CH4 Toluene + Hydrogen = Benzene + Methane This is a catalytic exothermic reaction, and the temperature is controlled by injecting hydrogen into the reactor. Hydrogen is injected at 40.4 kmol/hr 44.96oC and 25.5 bar. The exiting stream exits at 24.81 bar and 671oC, it contains methane, benzene, toluene, and hydrogen. The one pass conversion is typically around 75%. The process then continues to the separator feed preparation phase. This process phase begins with introducing the stream into a cooling water heat exchanger E-2. This heat exchanger cools the product stream to 38oC, which condenses most of the toluene and benzene in the stream. The stream then proceeds to the final phase of the process: the separation. In this phase, the desired product is separated from the by products and the unreacted components. That is, benzene is separated from unreacted toluene, unreacted hydrogen and the by-product methane. This is achieved by introducing the two-phase stream containing benzene, methane, hydrogen and toluene into a high-pressure phase separator, F-1. In this flash drum the vapor and liquid are separated. In the overhead mainly hydrogen and methane exits, and in the bottom some hydrogen, methane, and mainly all the toluene and benzene exit. The overhead stream is split into two streams; one stream is compressed to 25.5 bar in compressor C-1 and is recycle back to the feed and to the reactor, the other stream is a portion of the fuel gas stream. The separation happens at a temperature of 38oC and 23.9 bar. The partially separated stream is then introduced in a second separator, F-2, where mainly all the methane and hydrogen is separated in the overhead stream. This separator is a low-pressure separator. The liquid exiting the low-pressure flash drum consist of mainly toluene and benzene and traces of dissolved hydrogen and methane. The separation is then completed by heating the stream in heat exchanger E-3, and then introducing it to a distillation column, T-1. The stream is heated to a temperature of 90oC in E-3, low pressure steam is used for this purpose. The distillation column is used to purify the benzene product by separating all the unreacted components and the by products. This tower consists of 42 sieve trays, a reboiler E-6, a condenser E-5, a reflux drum F-3, and a reflux pump P-2. Toluene exits as a liquid in the bottom at a temperature of 112oC and 2.43 bar. The overhead containing benzene, traces of hydrogen and methane, is condensed in E-5 at a temperature of 112oC and a pressure 2.5 bar. Cooling water is used to condense the vapor exiting the column. A remaining hydrogen and methane are then separated in the reflux drum F-3; this vapor stream is combined with the other gases streams: the overhead of the first separator F-1, and the overhead of the second separator F-2, which are combined to form the fuel gas. The liquid stream exiting in the bottoms of the reflux drum is pumped to a discharge pressure of 3.3 bar. The pumped stream is separated in two streams. One stream is feed to tray one of the column and the other stream is cooled down to 38oC in heat exchanger E-4. The cooled product stream is then sent to storage. Simulation Description Figure 2 shows the PFD of the simulation; the following description refers to this PFD. The simulation requires certain inputs for each type of equipment. Table 1 is the desired inputs in stream S1 and S17, the toluene and hydrogen streams, and Table 2 is the desired output streams S22 and S27. 17 Figure 3: Simulation Process Flow Diagram Hydrodealkytion of Toluene C1 SP2 Recycle Hydrogen S 14 S 12 S 13 S 20 S 15 S 22 S 11 M5 Fuel Gas M6 S 16 S 25 SP1 S 17 M2 S7 Hydrogen M4 S9 S 18 R1 S6 S8 M3 S4 S3 SC2 S 28 S5 E2 E1 E5 S2 T ol uene S 26 F1 S 23 S1 S 10 M1 S 27 P1 Benzene F2 E4 S 19 S 21 E3 SC1 S 24 Toluene Recycle Figure 2: Simulation PFD for the toluene hydrodealkylation process. 18 Table 1: Input streams for the HDA process. Inputs Stream: S1 Stream: S17 Molar Rate: 108.7 kmol/hr Molar Rate: 301.0 kmol/hr Temperature: 25 C Temperature: 25 C Pressure: 1.9 bar Pressure: 25.5 bar Molar Composition: 1.00 Toluene Molar Composition: 0.95H2 0.05 CH4 Table 2: Output streams for HDA process. Outputs Stream: S22 Stream: S27 Molar Rate: 304.1 kmol/hr Molar Rate: 105.6 kmol/hr Temperature: 35.7 C Temperature: 38 C Pressure: 2.5 bar Pressure: 2.955 bar Molar Composition: 0.001 C7H8 Molar Composition: 0.004 C7H8 0.587 H2 0.996 C6H6 0.403 CH4 0.009 C6H6 The inputs required in each type of equipment are shown in Table 3 (Specification Table). Table 3: Input data for process simulation. Simulator Equipment Simulator Number Equipment M-1 Mixer M-2 Mixer M-3 Mixer Mixer M-4 Mixer M-5 M-6 Mixer Pump P-1 C-1 Compressor Input Output Streams Streams S1 S24 S2 S17 S14 S16 S16 S3 S4 S6 S15 S7 S11 S18 S20 S20 S25 S22 S2 S3 S12 S13 19 Required Input Pressure Drop = 0 bar Pressure Drop = 0 bar Pressure Drop = 0 bar Pressure Drop = 0 bar Pressure Drop = 0 bar Pressure Drop = 0 bar Outlet pressure = 25.5 bar, Efficiency 75% Outlet pressure = 25.5 bar, Efficiency 75% E-1 E-2 E-3 E-4 E-5 F-1 F-2 SP-1 SP-2 R-1 SC-1 SC-2 Pre-heater S4 Heater S5 Heat Exchanger S19 Cooler S26 Cooler S8 Flash Drum S28 Flash Drum S10 Splitter S9 Splitter S13 Reactor S7 Stream Calc. S21 Stream Calc. S23 S5 S6 S21 S27 S28 S9 S18 S11 S14 S8 S23 S25 Outlet Liquid Fraction = 0 Outlet temperature = 600 C Outlet temperature = 90 C Outlet temperature = 38 C Outlet temperature = 38 C S10 Pressure = 23.9 bar, Temp = 38 C S19 Pressure = 2.8 bar, Temp = 38 C S12 Recycle stream flowrate = 440 kgmol/hr S15 Recycle to the reactor = 40 kgmol/hr Duty = 0, product phases, global temp = -22.2 C 75% conversion Overhead product = 99% benzene, S24 Bottoms product = 98.85 % toluene S26 Overhead product = 100% H2, 100% CH4 The thermodynamic system used for this simulation was the Soave- Redlich-Kwong (SRK). The simulation starts with combining the fresh toluene stream S1 with the recycle toluene stream S24 in the mixer M-1 to form stream S2. This mixer simulates the mixing that happens in TK-1 in the original PFD figure 2. The stream S2 is then pumped (P-1) to 25.5 bar and is combined in a mixer M-3 with stream S16, this stream is a mixture of fresh feed hydrogen mixed with unreacted hydrogen, it also contains traces of toluene benzene and methane. Pump P-1 is simulated with an efficiency of 75%. Mixer M-3 simulates the mixture of the liquid phase and gas phase that happens in TK-2 in the original process. The stream S16 is the outlet of mixer M-2, this mixer combines the fresh stream of hydrogen S17 and the unreacted recycle stream of hydrogen S14. To simulate the mixers only the pressure drop is required, which in this case is 0 bar. The two phase stream exiting the mixer M-3 is then introduced into heat exchanger E-1 in the tube side. High-pressure stream is used in this heat exchanger in the shell side to heat up the tube side process stream S4 to an outlet temperature of 163.9 C. The outlet stream S5 is a one-phase stream of all vapor. The pressure drop for all the heat exchangers are set to be 0.345 bar to simulate a real heat exchanger. The process stream is then introduced into the heater E-2, where it is heated up to 600 C. This temperature is the required temperature that will allow the reaction to happen in the reactor. The now heated up stream S6 is combined with recycle compress hydrogen S15 in mixer M-4. Since the reaction is highly exothermic, the temperature is controlled by injection of quench hydrogen at the reactor, this is simulated by the use of mixer M-4. The feed is then introduced to the main part of the process the reactor R-1. A conversion reactor is used to simulate this stoichiometric reactor. The reaction stoichiometry must be entered in order to appropriately use this reactor. This reactor type is used since only the reaction is known, no other data equilibrium data is known. In order to simulate an exothermic reactor the duty of the reactor must be specified to be zero Btu/hr. Also the toluene conversion of 75% must be entered. This is the typical conversion that is realistic for this process. The process stream now containing a high amount of benzene exits the reactor at 671oC, this temperature must be decreased in order to separate the unreacted components with the products. This is achieved by introducing the product stream S8 to 20 heat exchanger E-5. In this heat exchanger the process stream is cooled to 38oC, by using cooling water. The outlet stream, S28, is a two-phase stream that is introduced into the first separator F-1. This knock out drum separates mostly all hydrogen and methane and it also contains traces of toluene and benzene. The pressure and temperature of this flash drum must be specified to 23.9 bar and 38oC. The overhead stream S9 is then split into two streams S11 and S12 in splitter SP1. For this splitter an estimate of what is recycled back is given in table 3. Table 3 shows the estimates needed for the recycle streams S12, and S15, for splitters 1 and 2. Stream S12 is compressed in a compressor of efficiency of 75% to a pressure of 25.5 bar. The compressed gas S13 is then introduced into splitter SP-2, which splits the splitter into stream S14 and S15. Stream S14 is mixed with the fresh feed of hydrogen, and stream S15 is used to control the temperature of the reactor. The amount of the splits is given in Table 3. The stream S11 is part of the fuel gas. The bottom stream S10 of the separator F1 is introduce into the second separator F2, which separates more hydrogen and methane from benzene and toluene. The liquid bottom stream S19 is then heated up in heat exchanger E-3 to 90oC. The overhead stream S18 is combined with the overhead of the first separator F-1 in mixer M-5 to makeup portion of the fuel gas. Stream S19 is then introduced into a distillation column, which is simulated by a stream calculator, SC1. In this piece of equipment the separation required must be specified. In this case 99% of the benzene must exit at the overhead and 98.85% of the toluene must exit at the bottom of the separation unit. The temperature and pressure of the overhead and the bottom must be specified in order for the simulation to be properly represented. The temperatures are 112oC and 2.43 bar. The bottoms of this stream calculator S24 is the recycle toluene that is mixed in M1 with the fresh toluene feed. The overhead of this separator is then introduced into another stream calculator SC2, which simulates the condenser and reflux drum and pump of the distillation tower. This stream calculator separates all the hydrogen and methane in the overhead S25, from the toluene and benzene in the bottoms S26. The stream S25 is then combined in a mixer M6 with the rest of the gas that composes the fuel gas. The stream S26 is then introduced into a heat exchanger E4 where the benzene product is cooled down to 38oC before is sent to storage. Table 4 lists the results of the material balance of each stream in the simulation. 21 Table 4: Simulation Material Balance Stream Name Stream Description Phase Temperature Pressure Flowrate Composition TOLUENE H2 METHANE H2O AIR BENZENE Stream Name Stream Description Phase Temperature Pressure Flowrate Composition TOLUENE H2 METHANE H2O AIR BENZENE S1 S2 S3 S4 S5 S6 S7 S8 Toluene Liquid Liquid Liquid Mixed Vapor Vapor Vapor Vapor C 25.000 48.242 49.160 43.219 163.905 600.000 586.293 671.015 BAR 1.900 1.900 25.500 25.500 25.155 24.811 24.811 24.811 KG-MOL/HR 108.700 144.653 144.653 845.265 845.265 845.265 885.653 885.653 1.000 0.000 0.000 0.000 0.000 0.000 S9 C BAR KG-MOL/HR 0.993 0.000 0.000 0.000 0.000 0.007 S10 0.993 0.000 0.000 0.000 0.000 0.007 S11 0.170 0.618 0.206 0.000 0.000 0.005 S12 0.170 0.618 0.206 0.000 0.000 0.005 S13 0.170 0.618 0.206 0.000 0.000 0.005 S14 0.163 0.617 0.215 0.000 0.000 0.006 S15 Vapor Liquid Vapor Vapor Vapor Vapor Vapor 38.000 38.000 38.000 38.000 44.958 44.958 44.958 23.900 23.900 23.900 23.900 25.500 25.500 25.500 740.254 145.400 300.254 440.000 440.000 399.612 40.388 0.001 0.591 0.399 0.000 0.000 0.009 0.243 0.004 0.021 0.000 0.000 0.732 Stream Name Stream Description Phase Temperature Pressure Flowrate Composition TOLUENE H2 METHANE H2O AIR BENZENE S17 S18 Hydrogen Vapor Vapor C 25.000 38.000 BAR 25.500 2.800 KG-MOL/HR 301.000 3.117 Stream Name Stream Description Phase Temperature Pressure Flowrate Composition TOLUENE H2 METHANE H2O AIR BENZENE S26 0.000 0.950 0.050 0.000 0.000 0.000 0.007 0.165 0.766 0.000 0.000 0.063 0.001 0.591 0.399 0.000 0.000 0.009 S19 0.001 0.591 0.399 0.000 0.000 0.009 S20 0.004 0.000 0.000 0.000 0.000 0.996 S21 0.001 0.591 0.399 0.000 0.000 0.009 S23 0.001 0.591 0.399 0.000 0.000 0.009 S24 S16 Vapor 36.672 25.500 700.612 0.001 0.745 0.249 0.000 0.000 0.005 S25 Liquid Vapor Mixed Vapor Liquid Vapor 38.000 35.487 90.000 112.000 112.000 112.000 2.800 2.800 2.455 2.155 2.425 2.500 142.283 303.371 142.283 106.329 35.954 0.731 0.248 0.000 0.005 0.000 0.000 0.747 0.001 0.587 0.403 0.000 0.000 0.009 S27 S22 S28 Benzene Fuel Gas Liquid Liquid Vapor Mixed C 112.000 38.000 35.661 38.000 BAR 3.300 2.955 2.500 24.466 KG-MOL/HR 105.598 105.598 304.102 885.653 0.004 0.000 0.000 0.000 0.000 0.996 0.001 0.591 0.399 0.000 0.000 0.009 0.041 0.495 0.337 0.000 0.000 0.127 0.001 0.585 0.404 0.000 0.000 0.009 22 0.041 0.495 0.337 0.000 0.000 0.127 0.248 0.000 0.005 0.000 0.000 0.747 0.004 0.000 0.007 0.000 0.000 0.989 0.970 0.000 0.000 0.000 0.000 0.030 0.000 0.023 0.977 0.000 0.000 0.000