Abstract - American Society of Safety Engineers

advertisement

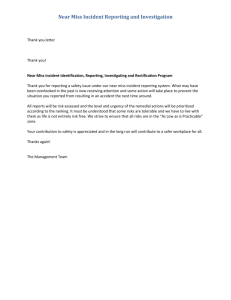

Intervention Effectiveness Research Engineering Design of Safety and Health Programs by Optimizing Intervention Activity Joel M. Haight, Ph.D., P.E., CSP, CIH Assistant Professor Penn State University University Park, PA 16802 Abstract Safety and health programs are often implemented without a quantified design. The objective of this study was to determine if a safety and health program could be quantified and optimized through a design that minimizes incident rates and the percentage of available human resources required to implement it. A model was developed for this purpose. In a two-phase empirical study, an oil production operation was analyzed. Four categories of interventions were studied 1) behavior modification, incentives, awareness; 2) training; 3) job/procedural design; 4) equipment. The percentage of available time spent implementing interventions in these categories was the independent variable and the incident rate was the dependent variable. Findings show a mathematical relationship between interventions and incident rate. The resulting best-fit equation is an intuitively expected exponential function showing a decreasing incident rate with an increasing intervention application rate. This model can be used to analyze the mathematical function for a minimized incident rate, aiding in design of optimized safety and health programs. In the second phase, an attempt was made to determine whether a designed safety and health program could be optimized to minimize the loss producing incident rate. In this phase, the objective was to use the mathematical function developed in phase 1 to formulate a model that calculates a minimized incident rate. Evaluating 81 application rate level combinations of four intervention categories and subjecting them to management constraints accomplished this. The resulting model provided insight into the design of a safety and health program that prescribes the appropriate amount of human resource time that should be assigned to specific safety and health intervention activity. Actual verification data were used to test the adequacy and accuracy of the optimization model. Findings indicate that the model predicts with reasonable accuracy, intuitively expected results. The model shows promise as a potential tool to aid safety and health engineers in designing their safety and health programs. It also shows promise in providing some predictability of safety and health performance under given safety and health program designs (Haight, Thomas, Smith, Bulfin and Hopkins, 2001). Introduction Workplace injuries and property damage—and the safety programs designed to prevent them—are expensive facets of contemporary industrial, agricultural, and military activities. Indeed, the National Safety Council estimates that the cost of work place injuries totaled $128 billion in 1999, a value approximately equal to the combined profits of the top 30 Fortune 500 corporations (National Safety Council Website). Optimizing intervention strategies to decrease rates of injury and property damage with less costly safety programs would contribute to improved productivity and economic vitality in all activities that involve such risks. The results could lead to improved safety practices and improved profitability in American industry. It is difficult to predict the future. Even in some of today’s more established sciences, we have trouble predicting what might happen tomorrow and beyond. What will tomorrow’s weather be? What will the stock market do next week or next year? Who will win the NCAA football championship next year? It is even more difficult to predict the future in less established sciences. What will your injury rate be next year? What is your target rate or goal? How will you know? How will you get there? How much manpower will you need (Figure 1)? These are questions that many in the safety engineering profession, would like to be able to answer scientifically. 0 % 50 % 100 % Figure 1. Available Human Resource Scale (How much human resource will be required?) Many organizations whose activities involve the risk of injury or destruction of property commit human and financial resources to intervention activities intended to prevent injuries, fires, spills, chemical releases, etc. Many of these “safety-related” interventions, including activities such as safety training and facility inspections, are commonplace enough that, often, little attempt is made to determine whether they are effective, whether they are at optimum levels and whether they might be improved. A model has been developed to help us determine which intervention activities are working to prevent or reduce incidents and to what extent they are working (Haight, et. al., 2001). From this model, we can determine the right “recipe” or correct design for our safety or loss prevention programs (Rinefort, 1977) in terms of usage of human resource power. The Model The basis for the model is a mathematical approach to designing an effective safety program developed by Haight, et. al. 2001. The model proposes the rate of incidents be I and Ai, i = 1, 2 … N, be the expenditure rate of human resources in intervention activities. The original model relating I and the Ai is a non- linear relationship: I f A1 ,..., AN ; p1 , ..., pM (1) in which the p’s are parameters controlling the application of the various intervention activities. After being determined empirically through statistical analysis of safety activities in an oil and gas production operation, the mathematical relationship was used to design an optimum safety intervention program that minimized expenditure of available human resource time in intervention activities while still minimizing incidents. The model thus represents a safety and health system (Figure 2). (Haight, et. al. 2001) There is currently a research effort in progress with a Canadian power company to further prove the model and give it wider applicability by extending it to other industries and government organizations. It is expected that as the database size increases and as more industries are represented, model results may become generalizable across other industries. INPUT (Independent) OUTPUT (Dependent) Intervention Application Rate Incident Rate Factor A – Behavior based activities, motivation, awareness, incentives, etc., interventions Factor B – Safety and skill enhancement training interventions Incident Rate Safety & Health System Model Factor C – Job Design interventions Factor D – Equipment interventions (e.g., inspections, preventive maintenance, etc.) Figure 2. This is a representation of the Safety and Health System Model (Haight et. al. 2001). In the application of the model, study participants record time spent by employees implementing four categories of interventions and the weekly rate of incidents. The analysis relies on data recorded by the study participants without intervention by the researchers. The incident rate is the dependent variable and the intervention application rates for four categories of intervention activity are the independent variables. All variables are normalized by worker hours. The observed data thus compare the fraction of available worker-hours applied to implementing interventions to the rate at which incidents occur. The data analysis process takes account of the individual and interactive effects of four main intervention activities, producing 15 independent variables whose contributions are isolated through regression techniques. The effects of safety intervention activity are neither instantaneous nor permanent. The timedelay and carry-over effects are detected using moving average and exponential smoothing techniques to identify changes in statistical relationships between the dependent and independent variables over the course of the forward projected averaging and smoothing periods. The resulting empirical version of Equation 1 for the particular firm being studied becomes the objective function in a mathematical programming model that can be used to determine optimum strategies for obtaining minimum incidents at a reduced cost of intervention. If such a strategy is adopted by the firm on which the model is based, then subsequent observations either validate the model or reveal new aspects of that safety program that must be investigated. The initial application of the model to an oil production operation showed that a strong mathematical relationship exists between the independent and dependent variables and that the function was optimizable using operations research-based mathematical modeling techniques. Post analysis observation of incident rate data indicates that the lowest injury and incident rates occurred when the organization’s safety program was operating in the optimum range of human resource commitment (Haight, et. al. 2001). Discussion of a Completed Study A previous two-phase study on intervention effectiveness was done in 1998/1999 in an oil and gas production operation in Central Asia (Haight, et. al. 2001). Safety programs are often implemented without a quantified design. Research has now shown that a loss prevention system can be quantified, designed, and therefore, optimized as any engineering-based system. In support of this effort, a statistically significant mathematical relationship was shown between the intervention activity implemented to reduce the incident rate (independent variable) and the incident rate itself (dependent variable). Many literature studies are available evaluating the effectiveness of individual intervention activities (examples are Fellner and Sulzer-Azaroff, (1984); McKelvey, Engen and Peck, (1973); Kalsher, Geller, Clark, and, Lehman (1984)). Building on these studies, this initial research evaluated a complete loss prevention system exploring all main effects from a comprehensive set of interventions as well as the interactive effects between interventions. The study integrated all components of a defined loss prevention system in order to establish a mathematical relationship that would allow for the design and optimization of a complete loss prevention program (Haight, et. al. 2001). Experimental Method and Design of the Original Study During Phase 1 of the study, the subject organization operated with 130 employees. Collectively, these employees worked approximately 5500 hours per week. For 26 weeks, the employees tracked and reported the amount of time they spent implementing four categories of interventions and the resulting weekly incident rate (both the traditional and total incident rates). “Traditional incident rates” included spills, fires, injuries, toxic releases, etc., while “total incident rates” included the traditional incidents as well as unplanned process upsets or shutdowns and equipment damage, etc. Reported data were used for the research. The researcher did not intervene in the implementation of the program (Haight, et. al. 2001). The independent variables were quantified each week using the amount of man-hours applied by the work group of 130 employees to the defined intervention activities. These hours were normalized as percentage of total available hours, referred to as the “intervention application rate”. The dependent variable was developed by recording the number of incidents that occurred during each week, multiplying it by 200,000 hours and dividing it by the number of hours worked by the 130 employees, yielding the “incident rate.” This was done for both traditional incidents and total incidents (Haight, et. al., 2001). Analysis and Results The combined 26 weeks of intervention application rate and incident rate data were recorded for the four factors (main effects) and the two incident rates. The cross multiplication products of the main effects to account for interactive effects between factors were computed. To integrate all interactive effects from the two- , three- , and four-factor interactions, 15 independent variables resulted. A representation of the spreadsheet is shown in figure 3. Figure 3. This is a representation of data collection and totaling spreadsheet (Haight, et. al. 2001). Week Factor A Factor B Factor C Factor D AxB nxn AxBxC nxnxn AxBxCxD 1 2 n Xa1 . Xan Xb1 . Xbn Xc1 . Xcn Xd1 . Xdn . Xabc1 . Xabcn . . . . . . Xab1 . Xabn . Traditional Incident Rate Ytr1 . Ytrn Total Incident Rate Yt1 . Ytn To determine a best-fit function for these data, several regression analyses were carried out using the least squares method, considering both linear and non-linear fits. To evaluate how long the effect of an intervention lasts, weekly data points were used. To calculate two- , three- , four- , five- , and six-week effects, forward projected moving average and exponential smoothing techniques were applied. From this, one can determine if any effect from week one carries over to week two, three, four, etc., by assessing the quality of the regression fit. The forward-projected exponential smoothing equation was adapted from Elsayed and Boucher (1994): (Haight, et. al. 2001) Xt = Xt + (1-)*Xt+1 + (1-) 2*Xt+2+(1-) t+2*X1 + (1-) t *X0 Discussion of Results Analysis showed that the best fit occurs when regressing the four-week moving average model and traditional incident rate. The resulting function was exponential, with an R2 = 0.982209, F0 = 25.764 vs. F=.01,15,7 = 6.31, and Mean Square Error (MSE)= 0.78069. A strong fit also occurs in: 1. The non-linear four-week exponential smoothing model for the traditional incident rate with an R2 = 0.978429, F0 = 21.16714 vs. F=.01,15,7 = 6.31, and an MSE = 0.949857, and; 2. The non-linear five-week moving average and exponential smoothing, traditional incident rate cases, with R2 values = 0.963596 and 0.968286, F0 = 10.587, and 12.21272 vs. F=.01,15,6 = 7.56, and MSE values = 1.01647 and 0.89773 respectively. Figure 4 shows graphically the total intervention application rate curve. As demonstrated, the exponential trend line is fit to the total intervention application rate, and it still generates an R2 value of 0.5317 without all the interactive effects shown. As was noted above, with all interactive effects and variables included, the R2 is 0.98209. Figure 4. This graph shows the total percentage of available man-hours vs. traditional incident rate, with the exponential function shown (Haight, et. al. 2001) Incident Rate Incident-vs-Intervention Application Rates 30 25 20 15 10 5 0 -5 0 y = 25e-0.248x R2 = 0.5317 10 20 30 40 Intervention Application Rate (% of Available Manhours) Series1 Expon. (Series1) The resulting function for the four-week case linear transformed function is shown in Figure 5. Figure 5. This mathematical function shows the relationship between the incident rate and all 15 regressor variables LnY=Xabcd*lnmabcd+Xbcd*lnmbcd+Xacd*lnmacd+Xabd*lnmabd+Xabc*lnmabc+Xcd*lnmcd+Xbd*lnmbd +Xbc*lnmbc+Xad*lnmad+Xac*lnmac+Xab*lnmab+Xd*lnmd+Xc*lnmc+Xb*lnmb+Xa*lnma+b LnY=Xabcd*(ln0.00188)+Xbcd*(ln3.826E+16)+Xacd*ln(2014.943)+Xabd*ln(6.966)+Xabc*ln(4.2998E +12)+Xcd*ln(1.85E13)+Xbd*ln(.001597)+Xbc*ln(7.01E65)+Xad*ln(0.150024)+Xac*ln(5.82E11 )+Xab*ln(.000517)+Xd*ln(404.4604)+Xc*ln(1.063E+45)+Xb*ln(449.5E+7)+Xa*ln(526.9246)+1.03 E-7. Where Y is the incident rate, Xi is the individual intervention values for each of the 15 factors, and mi is the slope at each represented point on the curve. The function shown here contains actual m value (Haight, et. al. 2001) Introduction - Phase 2 In the second phase, an attempt was made to determine whether a designed loss prevention program could be optimized to minimize the loss producing incident rate while minimizing the intervention application rate. The primary objective was to use the phase 1 mathematical function to formulate a model that calculates a minimized incident rate. Evaluating 81 application rate level combinations of the four intervention categories and subjecting them to management constraints accomplished this. A theoretical minimum incident rate could be achieved evaluating the objective function, using the 81 different combinations of the four categories of intervention activities. The resulting model provided insight into the design of a safety or loss prevention program that will prescribe an appropriate amount of human resource time that should be assigned to safety intervention activity. The secondary objective was to use verification data with phase 1 data to test the adequacy and accuracy of the optimization model. The findings indicated that the model predicts with reasonable accuracy, intuitively expected results. Verification data shows that the model’s “optimum” intervention application rate was within the actual observed lower incident rate range. The model mathematically generated incident rates from which minimum values could be observed and chosen. (Haight, et. al. 2001) Experimental Method This phase involved experimental and theoretical application of data to the mathematical model. The best-fit equation from the four-week moving average model, for traditional incident rates was chosen for the objective function. A total intervention application rate constraint of less than or equal to 20% of available man-hours was established. The process induced a constraint) requiring the incident rate (y) to be greater than or equal to 0 (i.e. no incidents produces an incident rate of 0. The objective function that resulted is shown in Figure 6. Figure 6. This objective function covers the relationship between the incident rate and all 15 regressor variables Minimize: LnY=Xabcd*lnmabcd+Xbcd*lnmbcd+Xacd*lnmacd+Xabd*lnmabd+Xabc*lnmabc+Xcd*lnmcd+Xbd*lnmbd+ Xbc*lnmbc+Xad*lnmad+Xac*lnmac+Xab*lnmab+Xd*lnmd+Xc*lnmc+Xb*lnmb+Xa*lnma+b S.T. XA +XB+XC+XD <= 20% Y => 0 Shown with the m values included, the complete objective function is as follows: LnY=Xabcd*ln(0.00188)+Xbcd*ln(3.826E+16)+Xacd*ln(2014.943)+Xabd*ln(6.966)+Xabc*ln(4.2998E +12)+Xcd*ln(1.85E13)+Xbd*ln(.001597)+Xbc*ln(7.01E65)+Xad*ln(0.150024)+Xac*ln(5.82E11 )+Xab*ln(.000517)+Xd*ln(404.4604)+Xc*ln(1.063E+45)+Xb*ln(449.5E+7)+Xa*ln(526.9246)+1.03 E-7. This function became the objective function for the mathematical model. Y is the incident rate, and Xa, Xab, Xabc, etc., were the individual intervention values for each of the 15 factors, including crossmultiplied interactive effects; mi is the regression coefficient. (Haight, et. al. 2001). The intervention combinations were developed using the original data from phase 1. The (max/min) range of intervention application rate values for each of the intervention categories was divided into three equal segments to represent three levels of each factor. The median value in each range (one-third) was chosen to represent that level for each factor, generating three levels for each of the four factors. This was then used in the design of a three-level, four-factor experimental design (34). The result was 81 factor-level combinations for the reported intervention application rate and these combinations were used to evaluate the model. As a demonstration, some of the resulting combinations are represented in Figure 7. Figure 7. This table is an abbreviated representation of the factor level combinations of the four factors that were run in the optimization model (Haight, et. al. 2001) Factor Level Combinations A1B1C1D1 A1B1C1D2 A1B1C1D3 A1B1C2D1 A1B1C2D2 A1B1C2D3 . . A3B3C3D3 Cross-product multiplication results to account for interactive effects are represented in Figure 8. Figure 8. A representation of the cross-product multiplication is shown. This accounts for factor interactive effects. There were 15 variables to consider. (Haight, et. al. 2001) A B C D AB AC AD BC BD CD ABC ABD BCD ACD ABCD Each of the 81 combinations of the 15 input variables was then plugged into the objective function. The objective function yielded 81 different possible incident rates (y). The resulting (y) value was then converted to a natural log, to account for a linear transformation of the original exponential function that resulted when the mathematical relationship was first established. All results yielding an intervention application rate greater than 20% and a (y) less than 0 were discounted as being outside the constraints. “Minimum “y” values were sorted to the top of the list for consideration. Finally, verification data were compared to the theoretical minimum incident rates to validate the model. Analysis and Results The 81 intervention combinations were systematically evaluated. The highest 20 combinations (or the 20 lowest “(ln y)”) values were selected for comparison to verification data. The total intervention application rate for the four main effects in these 20 results ranged from approximately eight to seventeen percent of the total available man-hours. From phase 1 data only, it was evident that when the total intervention application rate was in the 5.01–10% range, the mean traditional and total incident rates were significantly lower than when intervention application rate was in the 0-5 % range and the 10.01% and above ranges. The same phenomenon is evident when the eleven-week verification data are incorporated into the database. This is consistent with the findings of the theoretical model, which showed the lowest incident rates (lowest 5 results) to be in the 8–10% range (Haight, et. al. 2001). Discussion of Results The theoretical minimum incident rate is achieved when the total intervention application rate is in the range of 8-17 % (results of the 20 lowest incident rates generated by the operations research model). The three lowest results, as seen in Table 1, indicate a design using levels 1) A1B1C1D1, 2) A1B1C2D1, and 3) A1B1C3D1, with a total input of 8-9%. This can be illustrated by applying an example. If design number one (A1B1C1D1) were selected, the intervention application rate ranges for each factor-level combination would be: Factor A (level 1): 2.754% - 4.151% Factor B (level 1): 0.602% - 1.224% Factor C (level 1): 0.128% - 0.669% Factor D (level 1):5.271% - 10.187% This design generated a total intervention application rate, at the low end, of 8.755% (by adding above listed minimum values in the above listed ranges for each level) and at the high end of 16.231% (by adding above listed maximum values in the ranges for each level). This result is within the range obtained by using the 20 lowest incident rates produced by the model (8–17%). It appears that the total incident rates may also follow this same convex pattern, with the minimum being achieved in the 5.01-10 % range. However, the means are not sufficiently different from each other to make a “minimum result” claim, as with the traditional incident rates. In each case, lower incident rates are achieved at intervention application rates greater than 20%, but they do not meet the constraint criteria. (Haight, et. al. 2001) Conclusions Safety interventions are implemented in safety programs because they are expected to reduce the incident rate. Intuitively, one would expect that the more intervention activity applied to the safety program, the lower the incident rate would be. One might also expect that at some point, an effect would be present, but the incident rate reduction would be diminishing as more intervention activity is applied. The model showed this to be true for the oil production operation. This research indicates strongly that the incident rate is sensitive to the intervention application rate for traditional incidents and that a statistically significant relationship exists between the interventions and the incident rate. The function appears to allow for prediction of incident rates. The question of how long the effect of a particular intervention lasts appears to have been answered for the organization studied (four weeks). Interestingly, the interventions did not appear to have a strong effect on “total incidents.” (These are the unplanned process upsets and shutdowns and/or equipment damage cases.) Possibly, it can be suggested that many of the mature and developed safety interventions in practice have developed over time with the intent of only preventing “traditional incidents”. Many modern industrial organizations tend to refer to all incidents as the same, regardless of their consequences (e.g., production down time vs. an injury is the same). Relative to the effect of the interventions in this study, that may not be the case. This is left for further and future research. Employing the mathematical relationship from phase 1, the optimization model produces a minimized incident rate. The model appears to be valid for the facility that it was designed to represent. However, it could be refined through further testing against more extensive field data. The study provides a valuable potential approach to assist engineers in designing future safety and health programs. The model appears to provide intuitively expected and verifiable results that facilitate design and optimization of a program. The design minimizes the incident rate while facilitating selection of intervention application rates that are well under the total application rate constraint suggested by management. Limitations An adequate amount of error degrees of freedom exist for this study. However, the study could have been strengthened with more data. However, since it takes considerable time to collect the data, extending the study would introduce the risk of having the program change in the middle. The results of this model are not transferable. It is based on the specific performance data from the organization being studied. Other organizations employ different interventions of different qualities and different management philosophies, etc. The model works, but to apply this model, an organization would need to accumulate its own data. Eventually, it is expected that the database will grow sufficiently to allow for more generalization and transferability of results. Future Research This study evaluated the effect of changing the quantity of the loss prevention interventions. Further, the quality of the interventions was not studied. Intervention quality is an important aspect of any safety and health program, and that aspect should be incorporated into future research. In this study, quality of the interventions was not changed throughout the study. This study lends itself to further research. Other types of operations should be studied and other loss prevention systems with different interventions should be investigated. Larger databases applied to the models would lend more confidence to the results. References Bailey, Charles W., Pedersen, Dan. (1989). Using Perception Surveys to Assess Safety System Effectiveness. Professional Safety, The Journal of the American Society of Safety Engineers, Vol. 34, No. 2, pp. 22-26. Brigham, Colin J. (1981). Safety Program Evaluation: One Corporation’s Approach. Professional Safety - The Journal of the American Society of Safety Engineers, Vol. 26, No. 5, pp. 18-24. Champanis, Alphonse, (1960). Men, Machines and Models. Presidential Address delivered at the Society of Engineering Psychologists. Annual Convention #68, Chicago, IL, 113-131. Cleveland, Robert J., Cohen, Harvey H., Smith, Michael J., Cohen, Alexander. (1979). Safety Program Practices in Record Holding Plants. National Institute for Occupational Safety and Health Report. Crites, Thomas R. (1995). Reconsidering the Costs and Benefits of a Formal Safety Program. Professional Safety, The Journal of the American Society of Safety Engineers, Vol. 40, No.12, pp. 28-32. Diehl, A. E., Ayoub, M. A. (1973). Cost, Effectiveness and Allocation of Resources, Occupational Safety and Health Standards, North Carolina State University, 49-64. Donaldson, Gerald, A. (1988). Safety Spending: Usually Begrudged, Often Misallocated, Highway at the Crossroads. Publication by American Society of Civil Engineers (ASCE), Proceedings of a conference sponsored by (ASCE), 140-150. Elsayed, Elsayed A., Boucher, Thomas O. (1994). Analysis and Control of Production Systems. International Series in Industrial and Systems Engineering. New Jersey, Prentice Hall. Chapter 2, Section 2.6. Firenze, Robert J. (1984). Evaluation of Safety and Health Program Effectiveness. Lecture presented by Indiana Labor and Management Council, Inc. Fox, David K., Hopkins, B. L., Anger, W. Kent. (1987). The Long Term Effects of a Token Economy on Safety Performance in Open Pit Mining. Journal of Applied Behavior Analysis, 20 (3), 215224. Geller, E. Scott, Rudd, James R., Kalsher, Michael J., Streff, Fredrick M., Lehman, Galen R. (1987). Employer-Based Programs to Motivate Safety Belt Use: A Review of Short-Term and LongTerm Effects. Journal of Safety Research, 18 (1), 1-17. Guastello, Stephen J. (1993). Do we really know how well our occupational accident prevention programs work?. Safety Science, 16 (3-4), 445-463. Haight, Joel M., Thomas Robert E., Smith, Leo A., Bulfin, Robert L. and Hopkins, Bill L., (2001). Evaluating the Effectiveness of Loss Prevention Interventions: Developing the Mathematical Relationship Between Interventions and Incident Rates for the Design of a Loss Prevention System (Phase 1), Professional Safety - The Journal of the American Society of Safety Engineers, Vol. 46, No. 5, pp. 38-44. Haight, Joel M., Thomas Robert E., Smith, Leo A., Bulfin, Robert L. and Hopkins, Bill L., (2001). An Analysis of the Effectiveness of Loss Prevention Interventions: Design, Optimization, and Verification of the Loss Prevention System and Analysis Model (Phase 2), Professional Safety The Journal of the American Society of Safety Engineers, Vol. 46, No. 6, pp. 33-37. Haure, Ezra. (1983). An Application of The Likelihood/Bayes Approach to the Estimation of Safety Countermeasure Effectiveness. Accident Analysis and Prevention, 15 (4), 287-298. Hermann, Jaime A. (1979). Effects of a Safety Program on the Accident Frequency and Severity Rate of Automobile Workers. Unpublished Dissertation, University of Kansas. Kalsher, Michael J., Geller, E. Scott, Clark, Steven W., Lehman, Galen R. (1989). Safety Belt Promotion on a Naval Base; A Comparison of Incentives vs. Disincentives. Journal of Safety Research, 20 (3), 103-113. Laufer, Alexander M., Ledbetter, William B. (1986). Assessment of Safety Performance Measures at Construction Sites, Journal of Construction Engineering, 112 (4), 530-542. Lutness, John O. (1987). Self-Managed Safety Program. Safety and Health, 135, 42-45. Magyar, Stephen V. Jr. (1983). Measuring Safety Performance (a Management Guide). Professional Safety, Journal of the American Society of Safety Engineers, Vol. 28, No. 11, pp. 18-25. Manuele, Fred A. (1981). How do you know your hazard control program is effective?. Professional Safety, Journal of the American Society of Safety Engineers, Vol. 26, No. 6, pp. 18-24. McKelvey, Robert K., Engen, Trygg, Peck, Marjorie B. (1973). Performance Efficiency and Injury Avoidance as a Function of Positive and Negative Incentives. Journal of Safety Research, 5 (2), 90-97. Montgomery, Douglas C., Runger, George C. (1994). Applied Statistics and Probability for Engineers, Chapter 10, Multiple Linear Regression, New York, New York: John Wiley and Sons, Inc. Montgomery, Douglas C. (1991). Design and Analysis of Experiments, Chapter 15, Regression Analysis, New York, New York: John Wiley and Sons, Inc. National Institute for Occupational Safety and Health (NIOSH). (1996). National Occupational Research Agenda (NORA), U.S. Department of Health and Human Services, Document # 96115, 46-47. National Institute for Occupational Safety and Health (NIOSH). (1972). The Present Status and Requirements for Occupational Safety Research, Report by Arthur D. Little, U.S. Department of Health, Education and Welfare, 61-72. Oi, Walter Y. (1974). On the Economics of Industrial Safety, Law and Contemporary Problems, Duke University School of Law, 92-104. Ray, Paul S., Bishop, Phillip A. (1995). Can Training Alone Ensure a Safe Work Place?. Professional Safety, The Journal of the American Society of Safety Engineers, Vol. 40, No. 4, pp. 56-59. Rinefort, Foster C. (1992). Directions in Safety; The Economics. Professional Safety - The Journal of the American Society of Safety Engineers, Vol. 37, No. 5, pp. 42-45 (5), 42-45. Rinefort, Foster C. (1977). A New Outlook at Occupational Safety, Professional Safety, The Journal of the American Society of Safety Engineers, Vol. 22, No. 9, pp. 36-48. Rummler, Geary A., Brache, Alan P., C. (1990). Improving Performance: How to Manage the White Space on the Organizational Chart. New York, New York: Jossey-Bass, Inc., 15-28, 31. Smith, Michael J, Cohen, Harvey H., Cohen, Alexander, Cleveland, Robert J. (1978). Characteristics of Successful Safety Programs. Journal of Safety Research, 10 (1), 5-15. Smith, Robert S., (1978). The Feasibility of an “Injury Tax” Approach to Occupational Safety, Law and Contemporary Problems, Duke University School of Law, 92-104. Tarrants, William E. (1979). The Evaluation of Safety Program Effectiveness, Selected Readings in Safety, International Safety Academy, 17.