AL_D&T_Product Desig..

advertisement

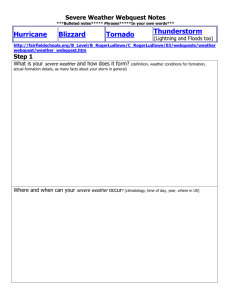

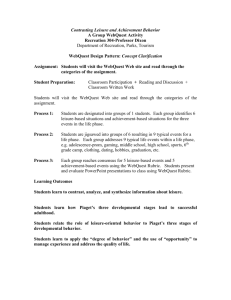

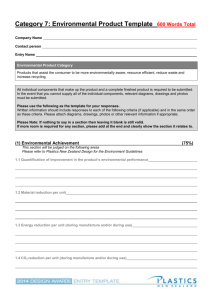

Please note this is a draft version until the course is fully published. AS Unit 1 – PROD1 Materials Components and Application Topic Print Resources (Subheadings) Page Number Electronic Resources Chapter 1 Materials, Components and Application Specification Reference 3.1.1 Section A: Materials and Components Learning Objectives become familiar with the range of materials and components available be able to identify materials and their main characteristics give reasons why material(s) and components have been used for particular applications Chapter 1 Electronic Resources: On your marks: Materials, components and application Revision quiz: Plastics Revision quiz: Metals and woods Revision quiz: Smart and modern materials Answers: Examination-style questions Answers: Product analysis exercises (student book) Answers: Product analysis exercises (online) Images Plastics Elastomers Plastics - Introduction to plastics - What are plastics? - Why are plastics so popular? - Sources of plastics - The main types of plastics (polymers) - General properties of plastics - Improving the properties of plastics: additives - Applications for thermoplastics - Biodegradable plastics - Processing plastics - Applications for thermosetting polymers - Thermoplastic and thermosetting materials 1-14 Case study: Polythene Webquest: Thermoplastics Elastomers - Thermoplastic elastomers (TPE) - Liquid silicon rubber (LSR) - Other thermoplastic and thermosetting materials - Identifying plastics’ processes 14-19 Webquest: Thermosetting plastics 20-28 Webquest: What are composites and what are their applications? Product analysis exercise: Car body kit Product analysis exercise: Biodegradable polymers Animation: Injection moulding Animation: Blow moulding Animation: Rotational moulding Animation: Plastics extrusion Case study 1: Plastics: - Plastics used in detergent packaging: bottled detergents Product analysis exercise 1: Thermoplastics - Plastic drinks bottle Composite materials Composite materials - Types of composite material - Common fibre-reinforced composites - Particle-based composite materials - Sheet-based composites © Nelson Thornes 2008 2 - Products where traditional materials have been replaced by composites Case study 2: Composite materials - Carbon fibres in bicycles Product analysis exercise 2: Glass-reinforced plastics Product analysis exercise: Carbon-fibre product – artificial leg Metals Metals - Types of metal - Sources of metals - Availability of metals - The structure of metals - Ferrous metals: iron and steel - Iron and carbon 29-31 Non-ferrous metals Non-ferrous metals 31-32 Alloys and alloying Alloys and alloying - Benefits of alloying - Alloying steels - Work hardening and heat-treating metals - Processing metals - Wasting processes (relating to metals) - Casting processes - Forging Product analysis exercise 3: Alloys - Pipe fittings, taps and valves Product analysis exercise 4: Non-ferrous metals - Aluminium drinks can 32-53 Webquest:Metals Case Study: Stainless steel Case Study: Mocha express coffee jug Product analysis exercise:Pressformed product – Sweet tin Product analysis exercise: Sand cast product – Wood burning stove Product analysis exercise: Pressure die casting – Utility knife Animation: Press Forming Animation: Cupping & Deep Drawing Animation: Pressure die casting Wood Wood - Sources of wood - Types of wood - The structure of wood 54-56 Veneers, laminates and composites Veneers, laminates and composites - Veneers - Laminates - Wood-based composites (man-made boards) 57-60 Case Study: Formica Case Study: Aalto Product analysis exercise: Wood based composite product Case study 3: Wood - Natural timber and manufactured boards Webquest: Wood – manufactured boards Product analysis exercise 5: Wood and manufactured boards - Laminated dining chair Glass Glass - Glass as a material - Manufacturing with glass - General properties of glass - Glass versus polymers 61-64 Webquest: Glass Ceramics Ceramics - Introduction to ceramics - Engineering ceramics - Manufacturing ceramic products 64-67 Webquest: Ceramics Papers and boards Papers and Boards - Types of paper - Paper properties and uses - Manufacturing with papers and boards - Cards and boards 67-69 Webquest: Papers and Boards Case Study: Paper cup Printing Printing - Printing processes - Electrostatic printing processes 70-75 ‘Smart’ and ‘modern’ materials ‘Smart’ and ‘modern’ materials - Introduction to ‘smart’ materials - Thermochromic pigments - Thermocolour film - Thermometers - Batteries - Phosporescent pigments 76-87 Product analysis exercise: Shape memory alloys 3 - Shape memory alloys - Piezoelectric devices - Smart grease - Smart fluids - Electroluminescent wires - Glowsticks - Smart textiles - Quantum tunnelling composites - Electronic smart glass - Modern materials - Fibre optics - Liquid crystal displays - Engineering timbers - Kevlar - Carbon fibre - Metals - Polymorph - Precious metal clays - Microfibres - Dichroic glass - Man-made boards Product analysis exercise 6: Tefal ‘red spot’ pans Chapter 2 Hand and commercial processing Specification Reference 3.1.3 Section C: Processes and Manufacture Learning Objectives understand how materials and components are processed to create the product from the design understand further processes related to joining, the deterioration of materials, finishes and finishing processes, and testing materials understand the general nature of manufacturing systems used to produce commercial products Chapter 2 Electronic Resources: On your marks: Revision quiz: Joining techniques Revision quiz: Finishes and properties Answers: Examination-style questions Answers: Product analysis exercises (student book) Answers: Product analysis exercises (online) Images Joining processes Joining processes - Introduction - Choosing a joining method - Summary of joining process 88-90 Joining metals Joining metals - Processes involving forming - Processes involving heat 91-98 Joining wood Joining wood - Self-assembly furniture - Wood adhesives 99-101 Joining polymers Joining polymers - Mechanical means - Adhesives - Ultrasonic welding - Plastic welding - Integral fixings 101-103 Joining ceramics Joining ceramics - Adhesives 103-105 Webquest: Hand and commercial processing Animation: Spot welding Webquest: Adhesives Animation: KD fitting – barrel nut Case study: The Dyson DC01 vacuum cleaner Product analysis exercise 1: Joining processes - Aluminium bicycle frame Product analysis exercise 2: Joining processes - Stainless steel saucepan Corrosion, decay and degradation Corrosion, decay and degradation - Corrosion of metals - Decay of woods - Degradation of plastics 105-108 Webquest: Corrosion, decay and degradation 4 Product analysis exercise 3: Corrosion, decay and degradation Finishes and finishing processes Finishes and finishing processes - Introduction - Why include a finishing process? - Finishing materials - Finishing processes for metals - Finishing processes for woods Product analysis exercise 4: Finishes and finishing processes - Applied barriers 108-116 Case Study: Teflon Properties and materials testing Properties and materials testing - General properties of materials - Materials’ properties and structures - Materials’ properties and products - Definition of materials’ properties - Materials testing 117-123 Webquest: Properties and materials testing Chapter 3 Design, environment and ergonomics Specification Reference 3.1.2 Section B: Design and Market Influences Learning objectives understand the environmental and sustainability issues that influence Product Design practise analytical skills and develop an understanding of how products can be designed to meet human needs appreciate how products are designed to meet safety criteria understand some of the human and social values in Product Design, such as designing for disabled people and other groups. Chapter 3 Electronic Resources: On your marks: Revision quiz: Design and market influences Answers: Examination-style questions Answers: Product analysis exercises (student book) Answers: Product analysis exercises (online) Images Environmental and sustainability issues Environmental and sustainability issues - Why sustainable design? - The role of designers and manufacturers - The three Rs - Eco-design improvements to a mobile phone 124-125 Webquest: Environmental and sustainability issues Case Study: Sustainable and ethical toys Ergonomics and anthropometrics Ergonomics and anthropometrics - Ergonomics - How does ergonomics influnce design? - Anthropometrics Product analysis exercise 1: Ergnomics - Mobile phone Product analysis exercise 2: Ergonomics and anthropometrics - Personal stereo 126-128 Webquest: Ergonomics and anthropometrics Product analysis exercise: Overmoulded product 5 Inclusive design Inclusive design - Adapted products - Designing for other groups in society 129-130 Consumer safety Consumer safety - The British Standards Institution (BSI) - Safety features in a garden hedge trimmer 130-132 Case Study: Ball point pen Page Number Electronic Resources Unit 2 – PROD2 Learning Through Designing and Making Specification Reference 3.2 Unit 2: Learning Through Designing and Making Teacher notes Introduction to coursework unit Exemplar coursework: Project approach ‘Water carrier for dogs’ Exemplar coursework: Portfolio approach Student guidance notes: Frequently asked questions Student guidance notes: Investigation and clarification of problems Student guidance notes: Development of design proposal Student guidance notes: Making / modelling Student guidance notes: Evaluation and testing Student guidance notes: Communication and presentation A2 Unit 3 – PROD3 Design and Manufacture Topic Print Resources (Subheadings) Chapter 4 Design and manufacture Specification Reference 3.3.1 Section A: Materials and Components Learning objectives: build on the work done in Chapters 1 & 2 by appreciating why particular materials have been chosen for a product become familiar with industrial and commercial testing of materials and products Chapter 4 Electronic Resources: On your marks: Revision quiz: Choosing the correct material - polymers Answers: Examination-style questions Answers: Product analysis exercises (online) Images Materials and components Materials and components Case study 1: Materials and components - Toothbrush Case study 2: Materials and components - Domestic 13-amp power plug 133-137 Webquest:Materials and components Case Study: Stratocaster guitar Case Study: Coca-cola bottle Product analysis exercise: Selecting materials – Patio 6 heater Product analysis exercise: Selection of polymers for manufacture Product analysis exercise: Applied finishes – Aesthetics v preservation Industrial materials testing Industrial materials testing - Industrial testing - Destructive testing 137-144 - Non-destructive testing Case study 3: Steels and alloys used in industry Chapter 5 Design and market influences Specification Reference 3.3.2 Section B: Design and Market Influences Learning objectives: understand how the design and innovation process starts, the key stages involved in design and manufacture and the individual roles in the design process understand market research, social and economical factors and their influence on the success of Product Design appreciate human factors such as ergonomics, anthropometrics and human consumer needs understand the constraints influencing design and manufacture such as legislation, safety and environmental factors understand how design and manufacture have been influenced by advancements in technology understand the influence of contemporary styles and historical practices. Chapter 5 Electronic Resources: On your marks: Revision quiz: Design & designers Revision quiz: Safety and human needs & factors Revision quiz: Technological innovation Answers: Examination-style questions Answers: Product analysis exercises (student book) Answers: Product analysis exercises (online) Images Roles in the design process Roles in the design process - The client - The designer - Inventors - The designer-maker - Makers - Users 145-148 Webquest: Design and market influences (roles in the design process) Webquest: Marketing functions The marketing function - The relationship between the user, designers and makers - The marketing mix Design methods Design methods - How designing starts 148-149 Design activity within organisations Design activity within organisations 149 The design process The design process - Identification of the problem - The brief - The specification - Analysis - Research - Market research - User-centred research techniques - Generation of ideas 149-153 Development Development - Manufacture 153-154 Testing and evaluation Testing and evaluation - How are ideas formed? 154-156 Patents Patents - Protecting designs (patents and intellectual 156-158 Webquest: Patents 7 properties) Communication and representation of design ideas Communication and representation of design ideas - Mood boards - 2-D/3-D sketching - Rendering - Orthographic projection - Modelling - Mock-ups - Prototypes - Presentation boards 158-159 Sustainability and environmental concerns Sustainability and environmental concerns - Introduction - Environmental legislation and regulation - Green design, ecodesign, sustainable design and sustainable innovation: what’s the difference? - Technological devlopment in eco light bulbs - The environmental impact of cars 160-168 Webquest: Environmental impact of cars Webquest: Sustainability and environmental concerns Product analysis exercise: Recycled plastic products Product analysis exercise: Power Safer Product analysis exercise 1: Design and the environment - Plastics in packaging Product analysis exercise 2: Design and the environment - Pepsi can Safety Safety - Risk assessments - Safety legislation & manufacturing - Risk asssessments Case study 1: Safety in JCB manufacture - Safety legislation and the user Case study 2: Safety features in a domestic, 3-pin electrical plug 169-173 Human needs and human factors Human needs and human factors - Ergonomics and anthropometrics Product analysis exercise 3: Computer workstation Product analysis exercise 4: Car interior 173-177 - Design for disabled people Product analysis exercise 5: Design for disabled people Major developments in technology Major developments in technology - Introduction - Technological developments and the radio - 1930s - 1940s and 1950s - 1960s - 1970s - 1970s to recent years - The development of MP3 - Technological developments and the battery - Technological developments and the TV - Technological development in the telephone - The impact of information and communication technology (ICT) - Intelligent systems and interlinked products - ICT and the internet - Radio Frequency Identification Tags (RFID) - Fluidic self assembly (FSA) - Nanotechnology - Products using nanotechnology Product analysis exercise 6: Major developments in technology - Mobile phones - Technology push and market pull 178-193 Product and life cycles and historical influences Product life cycles and historical influences - Introduction and launch - Growth - Maturity - Decline 193-195 Case Study: The Mini 8 - Planned obsolescence The work of past and present designers The work of past and present designers - The machine age - The product age - Design movements Case study 3: Clarice Cliffe (1899-1972) - The work of past designers inspired by nature 195-205 Case Study: Mies van der Rohe Case Study: Maclaren buggy Case Study: Alessi Case Study: Tizio lamp Product analysis exercise 7: Historical influences - Bauhaus chair Product analysis exercise 8: Historical influences - Super Lamp Chapter 6 Processes and manufacture Specification Reference 3.3.3 Section C: Processes and Manufacture Learning objectives: gain a thorough understanding of the factors affecting choice of process, along with the systems available that support those processes. There are a range of example examination questions available on the web be aware of the diversity of modern manufacturing systems including the use of ICT and robotics in manufacturing. Chapter 6 Electronic Resources: On your marks: Revision quiz: Quality in product design Revision quiz: Robotics in the car industry Revision quiz: ICT in modern manufacturing systems Answers: Examination-style questions Answers: Product analysis exercises (student book) Answers: Product analysis exercises (online) Images Selecting a process Selecting a process 206-207 Modern manufacturing systems Modern manufacturing systems - Introduction - Quick response manufacturing (QRM) - Electronic point of sale (EPOS) - Just in time (JIT) - Kanbans - Sequencing - Master production schedule (MPS) - Telematics - Flexible manufacturing systems (FMS) 207-211 Product analysis exercise: Oneoff/batch production – Investment casting ICT in manufacturing ICT in manufacturing - Introduction - Scales of production - One-offs - Batch production - Mass production (high-volume production) - Continuous production 211-213 Product analysis exercise: Scales of production – Jigs and fixtures Product analysis exercise: Scales of production – High volume products ICT applications in product design and manufacture ICT applications in product design and manufacture - Computer-aided design (CAD) 213-220 Product analysis exercise: CAD/CAM product – JCB Case study: Josiah Wedgwood and Sons - Virtual reality modelling (VR) - Computer-integrated manufacture (CIM) - Computer-aided engineering (CAE) Product analysis exercise 1: ICT applications in product design and manufacture - CAD - Computer-aided manufacturing - Robotics - Robot configurations - Programming methods - The benefits of using robots - The drawbacks of using robots Product analysis exercise 2: Computer-aided manufacturing 9 Unit 4 – PROD4 Design and Making Practice Specification Reference 3.4 Unit 4: Design and Making Practice Teacher notes Introduction to coursework unit Exemplar coursework: Project approach ‘Music stand’ Student guidance notes: Frequently asked questions Student guidance notes: Context and objectives Student guidance notes: Plan of action and clarification of problem Student guidance notes: Development of design proposal Student guidance notes: Manufacture / modelling Student guidance notes: Conclusions, evaluations and recommnedations Student guidance notes: Communication and presentation