MODULE TITLE

advertisement

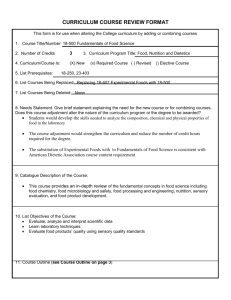

MODULE TITLE Food Technology Module Code Semester of Delivery State whether module is Mandatory, Elective or Option Level (4/5/6/7) Credit Points Assessment Pattern: Components & Weighting Pre-Requisite Modules (if applicable) Breakdown of Student Learning Hours by Type* 19-5F10-00L 1 and 2 Mandatory/ Elective: According to route Module Leader & School Module Banding Will Module be offered via Blackboard? Date of Original Approval Date of Next Review 1 5 20 50% Coursework 50% Exam Food Composition and Safety 60 hours direct contact 40 hours directed / supported open learning 100 hours personal private study Keith Proudlove School of Sport and Leisure Management C Yes RATIONALE This module provides a foundation in food technology on which the food industry is based. The appropriate to studying (food technology) involves consideration of module questions and preservation processes. Relationships will be established between processes and product quality. The module is designed to enable the student to appreciate how food processing may change the organoleptic and nutritional characteristics of food substances in addition to the effects on storage life. The module will apply the principle and practice of food technology in practical laboratory based exercises. 2 SUMMARY OF AIMS The aim of the module is to introduce students to the objectives and principles of food processing, enabling them to experience the use of experimental pilot plant. Various parameters involved in food processing and preservation will be investigated and their influence on product quality. 3 ANTICIPATED LEARNING OUTCOMES On successful completion of the module students will be able to: 4 demonstrate an understanding of the main module operations used in food processing (KU); select relevant module operations to design appropriate processing lines for food products (C); undertake numerical calculations needed to understand the basis of processes. Use necessary numerical calculations, formulae and graphical methods to assess the efficiency of a process (K); apply knowledge of micro-organisms to an understanding of the principles of food presentation (S); assess the effects of processing on the quality of processed products (K); use necessary numerical calculations, formulae and graphical methods to assess the efficiency of a process. Undertake numerical calculations needed to understand the basis of processes (C); develop an ability to produce food products using pilot plant equipment (S); Select an appropriate experimental design to investigate effects of processing conditions. Select or design appropriate sensory techniques, analyse sensory data and present results effectively (C). LEARNING AND TEACHING STRATEGY AND METHODS, INCLUDING RESOURCES Strategy The learning and teaching strategy is designed to promote the learning of food module operations and preservation techniques and an ability to assemble module operations into a processing line to produce a food product on a commercial basis. The strategy recognises individual differences in the rate at which practical processes can be assimilated and used in a practical environment. Methods Lectures and tutorials Will be read to develop an understanding of all the necessary module operations and food preservation operations. The use and application of numerical methods to the understanding of fundamental processes will be developed during the tutorials. Supported Open Learning Students are guided to a set textbook and reading is required as preparation for each lecture. Students are also given a handbook to help with the development of their technical skills required for the module tutors to assist when requested to do so. Self-Directed Learning Students are required to direct their own learning to the assessments on the module. Drop in sessions are available should they be needed. Laboratory practical sessions Laboratory experiments will be executed over 4 (activities) sessions: planning, practical exercises, evaluation of products or results and analysis of results (e.g. using SPSS). There will be a series of 5 linked laboratory exercises covering the experimental production of food, the analysis of the process and sensory testing of the products. Resources The modules will make use of pilot-scale equipment, sensory suite and ICT facilities. 5 ASSESSMENT AND FEEDBACK STRATEGY AND METHODS Assessment Strategy The module will be assessed by coursework (50%) and examination (50%). The coursework will comprise of three laboratory reports based on the practical sessions. 6 SPECIFIC ASSESSMENT CRITERIA Students achieving a pass in this module will demonstrate: 7 an understanding of the principles of food processing questions and food processes; the ability to carry out food calculations; the ability to design experiments and report the results correctly; selection and design of appropriate sensory analytical techniques and analyse the results correctly. INDICATIVE CONTENTS, READING LIST AND RESOURCES Module operations used in food processing; cleaning, sorting, grading, size reduction, mixing and blanching. Principles of food preservation, industrial practice, critical aspects for food safety and quality parameters. Processes to be covered: heat sterilisation, pasteurisation, chilling, freezing, drying, preservation using sugar or salt, and irradiation. Application of sensory techniques in assessing food products. Use of relevant statistical techniques for the analysis of sensory data. Indicative Reading Proudlove R. K., (2001), The Science & Technology of Foods, Forbes Publications, London. Fellows P., (1988), Food Processing Technology: Principles and Practice, Ellis Horwood. Brennan, Butters, Colwell & Lilley, (1990), Food Engineering Operations 3rd ed. Elsevier. Fennema O. E. (Ed), (1975), Principles of Food Science Part 2: Physical Principles of Food Preservation, Marcel Dekker. H J Heinz Company (1993), Principles and Practices for the Safe Processing of Foods, D. A. Shapton & N. F. Shapton Butterworth/Heinemann. Bender A. E., (1999), Dictionary of Nutrition and Food Technology 7th ed., Woodhead. Gould W. A., (1996), Unit operations for the food industries CTI Pub. Baltimore. Rosenthal A. J., (1999), Food Texture, Aspen Pub. Main website for most food topics: http://www.ifst.org 8 MODULE BANDING OTHER THAN A C