the structural appraisal of two timber trestle bridges – a case

advertisement

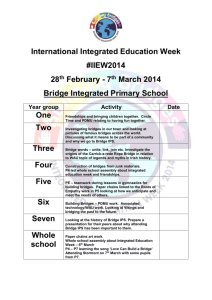

THE STRUCTURAL APPRAISAL OF TWO TIMBER TRESTLE BRIDGES – A CASE HISTORY DON McCOLL CP Eng, FIE Aust., Consulting Structural Engineer Yass NSW ABSTRACT There are approximately 700 timber bridges remaining in NSW. Many were built in the 1920’s, when prevailing loads were a four tonne traction engine at most. Expected life was about 30 years. Still in service, but suffering from obvious deterioration, these bridges are long overdue for replacement. But with the prevailing sentiment on the part of the Federal Government, the return of fuel taxes sufficient for replacement does not appear to be forthcoming. The two bridges covered by this paper had been load limited to 15 tonnes. Further analysis, load testing and strain gauge work, and consideration of typical semi-trailer geometry enabled relaxation of the limits. The bridges have been re-rated to a 38 tonne limit. This paper acknowledges permission from the Tumut Shire Council for release of its content. KEY WORDS Bridge, Load rating, Load testing, Strain gauge INTRODUCTION Encouraged by the fact the early timber bridges were still in service, many new similar bridges were still being designed as late as the 1950’s. A typical trestle is shown in Figure 1 for a single lane bridge. Girders were supported off 1800 long corbels, according to the D.M.R. standards of the time. The method of design was elegantly simple, conservative, and used working stress methods. A line of wheels was aligned on a girder centerline and simple support for girders assumed. The maximum bending moment and shears were obtained from influence lines, then reduced to allow for sharing through the medium of the deck planks, by dividing by an empirical factor of girder spacing/1.8. The required modulus for the girder was arrived at from f = M/Z. “f” is the allowable stress in bending for the species, M the applied bending moment and Z the section modulus. The required girder diameter was calculated from Z = Pi . d/32, plus an allowance for non-structural sapwood. Girder taper was ignored. It is immediately seen from the exponent that the strength in bending is very sensitive to the diameter. Shear at the ends of the girders would not control the girder size. Corbels of a nominal 450 diameter were used, and the dead and live loads computed for design of the headstocks. Usually, these were 300 x 150 sawn members, one checked into each side of the piles. Either shear or bending could control for headstocks, depending on the relationship of pile location, centres etc. Piles were driven with drop hammers, and capacity determined using the Hiley formula with a large “safety factor” of about three or four. These designs worked well. Unfortunately perhaps, it is their very longevity that is causing problems today. They are being called upon to cater for greatly increased axle loads, they are decaying, but still it seems, must remain in service. There is uncertainty of load path complicating the issues, which the early designers would have ignored in their design methods. Thus it is not simple to determine whether a given bridge is or is not overloaded, especially if multi-span. In structural design, it is easier to design for a given load than to determine with that same level of confidence the load that an existing structure can carry. The aim in bridge work is to rate the structure with the highest possible level of confidence that method allows, so as to comply with the load (safety) factors required by the codes. Measuring up an existing old trestle bridge, and applying the same simple analytical techniques as the original designers, the likely conclusion is many a bridge in as-new condition will not safely carry T44 loading, in any of the trailer wheelbase spacings (3 to 8 m.) required in the AUSTROADS 1992 Bridge Code. (T44 is taken in this paper as the load criteria). But if a check for inner piping rot by boring the members, and the simple analysis allows the structure to survive this scrutiny, on the assumption that pile capacity is not exceeded, then no load limit need apply. LOCATION AND REMEDIATION LOGISTICS OF Rimmer’s and Purcell’s bridges are on MR280 in the Shire of Tumut, across Adelong Creek. This road is a significant link between Batlow and Adelong, thence to the Hume Highway. It provides through transport for produce, timber and access to numerous farms. The imposition of a fifteen tonne limit caused significant inconvenience to users, denied the use of triple-deck stock transport and the use of semi-trailers which previously had enabled local fruit growers to economically market their seasonal produce. With the imminent harvest of crops and a crash program to upgrade the structures, Council was faced with an uncomfortable prospect. It appeared that intermediate trestles would have to be constructed urgently at midspan of both bridges, and at no small cost. “BEYOND THE BOUNDARIES” Deliberating over this dilemma, Council’s Assets Engineers realized that short wheelbase trailers rarely used the route. Rerating by load testing provided the answer. It was found that strengthening to upgrade to full unrestricted T44 loading was not nearly extensive as was first thought, and could be done within a much more suitable timeframe. DESCRIPTION Both bridges have four spans nominally of 10 m, are trestle type, single lane, employing a four girder layout decked by 200 x 100 mm cross timbers. Girders are of unknown species but probably ironbark. The girder/corbel/headstock configuration is as outlined in the introduction. Bolted to the decks, are running timbers 200 x 50 mm which appear to be an addition subsequent to original construction. A few of the girders and some of the piles have been replaced since the date of original construction. The streams are permanent, with flow varying from that which one can walk across to some measure of flood. Superstructure clearances are about 4 m. to low water. Considering their obvious age, these structures have stood the test of time remarkably well and indeed have outlived many a modern concrete bridge suffering from “concrete cancer”, alkaliaggregate reaction or other durability problem resulting from poor construction quality control. Council’s Engineers had become concerned that these structures might be overloaded; The opinion determined a safe load assessment for each element of each bridge in as-new condition, and separately in an “asis” condition. For example, girders in Span 1 might carry a T19 load in bending, T30 in shear. And that the headstocks in a trestle would carry T25 in bending and T15 in shear etc etc. The lowest controlled the limit and hence the 15 tonne rating. The opinion, in order to attain T44 rating, recommended the early replacement of some of the piles (piped), some of the (split) corbels, piped girders, braces, and carrying loads with insufficient load factors. Limit state philosophy, introduced by the 1992 AUSTROADS BRIDGE CODE, displaced working stress methods and safety factor terminology. There is little difference in the outcome in timber design using limit state theory compared to working stress. Engineers other than non-practising structurals will find reference to working stress more convenient, and thus is utilized in this paper to expound the principles used to re-rate these bridges. Council duly sought structural opinion. This considered the full range of trailer axle spacings called up in the Code, which varies from 3 m to 8 m. for T44 (truck) loading. (Lane loading does not control for short span bridges such as these). The short wheelbase loading was obviously the most critical. Loading T44 uses 96kN per axle for bogies and 48 kN front, as shown in Fig. 2. recommended the bolting up of some of the split members, not otherwise beyond rejection. REMEDIATION The author was engaged to advise on the remedial work that would upgrade these bridges to unconditional T44 loading. It is useful here to compare T44 with legal loads – requiring no travel permit. Whilst RTA regulations allow for a brace of configurations – single axle front steer, dual front steer, single axle trailer, dual or triple axle trailer, for the sake of simplicity, only three configurations are shown in Figs 3, 4 and 5. These are the likely local configurations that would apply. Thus one sees that the code standards do not directly relate to legal loads -T44 aggregates 432 kN (44 tonnes), whilst fig 2 shows an aggregation of 39 tonnes, and the tri-trailer axle configuration of Fig 3 allows 42.5 tonnes. Presumably, code writers are satisfied that T44 safely provides for the multiplicity of configurations that the statutory law allows, and according to the laws of probability on which engineering design is based. The relevant load factors called for by the Bridge Code are two for live load, (closely translated to a safety factor of 2) and 1.2 for dead load. The difference is that dead loads can be more reliably predicted than live. The code also requires a live load deflection limit of span/800. This appears to apply to new work, and is derived from comfort considerations. In the case of high speed traffic, undue vertical accelerations will be felt if the more usual structural limit of span/360 was used. The deflection limit rather than strength frequently controls in bridge design. The subject bridges are on a poor alignment. Traffic will slow to some 15 kmh. (This also will reduce dynamic loadings). In terms of remedial work, it is not considered realistic to endeavor to work to the modern day code deflection limit. Council’s Engineers accepted the author’s view that these bridges be instrumented and load tested. For with the realisation that vehicles of GVM around 40 tonnes had been using the bridges, with a live load factor of 2 allowed by the code, thoughts were that a limit nearer 20 tonnes might be allowed, rather than a conservative fifteen. The first load test was to apply 10 tonne bogie axle loads from a rigid frame test truck, with wheel lines aligned over the girders, one at a time, in each span. With a precision level, deck deflections were recorded, including adjacent unloaded spans. From span length, girder diameter, and standard deflection formulae, the theoretical deflections, were calculated, allowing the empirical girder load sharing factor of 1.8. Support was taken as simple. Girders have to be idealized at circular, taper ignored, and assumption made as to the modulus of the timber. The deflection figures were compared, measured vs theoretical. If in such a case, the measured deflection is significantly less than the theoretical, then the deck is significantly much stiffer and stronger then one would expect. The deflection results are compared. The product of E, the elastic modulus of the timber and I, the second moment of area being the denominator in the deflection equation, is the stiffness of a system. From the data in the case in point, it was found that the measured deflection over the loaded girder in some spans was about one third of that expected from theory. Thus the inference was that the stresses in the outermost fibres of the subject girder at the point of maximum bending moment, was much less than the theory would have one to fear. Elastic theory dictated that either the applied bending moment, M, was overestimated in the calculations, or the value of I and/or the value of E was too low. Better than expected load sharing among the girders via the deck, or unexpected continuity span to span could explain an anomalous M. Determination of the value of I (and hence the derived value of section modulus, Z in a calculation of extreme fiber girder stress) is sensitive to the measurement of girder diameter “d”. It was also suspected that the lengthy running planks might be assisting the stiffness of the deck, with effective horizontal shear transfer, courtesy of their multitudinous connecting bolts. Computations showed a very significant lift in the neutral axis and in the values of I and Z, if it was assumed the deck Fig. 3 Max. GVM tonnes* Max dual axle group Max front Min dimension A Min B 39 16.5 t. 6 t. 5.8 m. front 8.2 do. Fig. 4 Max. GVM tonnes** Max dual axle group Max tri-axle group Max front Min dimension A Min B 40 16.5 t. 20 t. 6 t. 5.0 m. at GVM 9.2 do. Fig. 5 MaxGVM Max dual axle group Max front Min dimension A *Sum of front and axle group(s) 22tonnes* 16 t. 6 t. 3.5 m. ** Max allowed, as tabulated for Dimension,B, ref RTA web site MAXIMUM RECOMMENDED LOADINGS FOR RIMMERS ANID PURCELLS BRIDGES IN THEIR CONDITION AS OF DECEMBER 2000 - TUMUT SHIRE COUNCIL Don McColl CP Eng FIE Aust Consulting Structural Engineer YASS NSW PHIFAX 02 6227 1231 donmcwiloonsulting@bigpond.com.au running planks were contributing to the stiffness and hence strength of the deck. Some spans deflected much more than others, and this correlated where piped girders had been found. Measurement of the annulus in piped girders is imprecise, and thus determination of “Z” is doubtful, because of the cubic exponent. species was not known, reliance can be made on the code for short term values of E, because the range between the heavy stress grades in hardwood is not great. Timber in contrast to steel, within elastic limits behaves in a nonlinear fashion. The value of E is load time dependent. That is to say the material creeps. This introduces further judgement into the matter. This uncertainty led to the decision to measure strain with a Demec gauge in a reload of the spans combined with a re-read of deflections of the loaded and adjacent spans. The Demec is a mechanical gauge which is essentially a precision dial gauge connected to an invar bar, with points at a nominal 200 mm centres, one of which swings and operates the dial. (Electric resistance circuitry calibrated to the mechanical gauge is another option). The procedure is to affix precision Demec button points to the element undergoing strain, and to record dial readings before and after loading; the difference is strain. The instrument is very sensitive and will give consistent readings of plus or minus ten micron. Using E for the timbers, the stress is easily arrived at and can be compared with the timber code listed value, F’b = 22mPa basic for ironbark. Notwithstanding the girder Gauge readings showed the running planks were in compression under the test load, showing that they were working as structural elements. Apart from the immediate replacement of a weak girder at Rimmer’s Bridge, the headstocks in the bridges were found to be the critical elements, being inadequate in shear for the short wheelbase trailer. It was also found that the long wheelbase trailer configuration in T44 for the subject bridges applied only 78% of the headstock shear compared to the short wheelbase, the resulting stress level being acceptable. In due course, the headstocks will be replaced with parallel flange channels; short wheelbase trailers can then traverse the bridges. The prevailing traffic pattern for MR280 is long wheelbase. So that the users in the area would not be inconvenienced by the 15 tonne load limit, relaxation was made immediately after the strain results were assessed, to allow the usual full legal axle loadings for the longer wheelbase trailers. The bridges were sign posted accordingly until headstock remediation and a few other minor repairs and pile strengthening can be undertaken. There is no recognised method of testing pile carrying capacity without loading the piles. Boring piles was relied on to check for pipes. The assumption was made that either in skin friction or end bearing they could continue to carry the applied loads, the justification for which is that there will be warning of this event from distortion of bridge geometry. Notwithstanding the above methodology having being applied to obtain extended life and increased load rating of these bridges, it is unlikely that a life of more than another ten years can be delivered. In the meantime, the bridges must be kept under observation. And flood damage might force the issue. BIOGRAPHICAL The author was employed in industry for some years before joining contractors, Hornibrook and Pearson Bridge, on bridge construction. In 1968, he joined the Kempsey Municipal Council as Deputy Engineer, becoming Municipal Engineer in 1970. In 1972, he was employed by a Sydney based firm of structural engineers. For eight years, he was their site representative, retained to design and supervise the construction of the National Gallery and the High Court and other major buildings in Canberra. In 1980 the current practice was established. Of recent times the author is once again heavily involved in bridge work. Don McColl “Ceridale” Gums Lane Yass 2582 email donmccollconsulting@bigpond .com