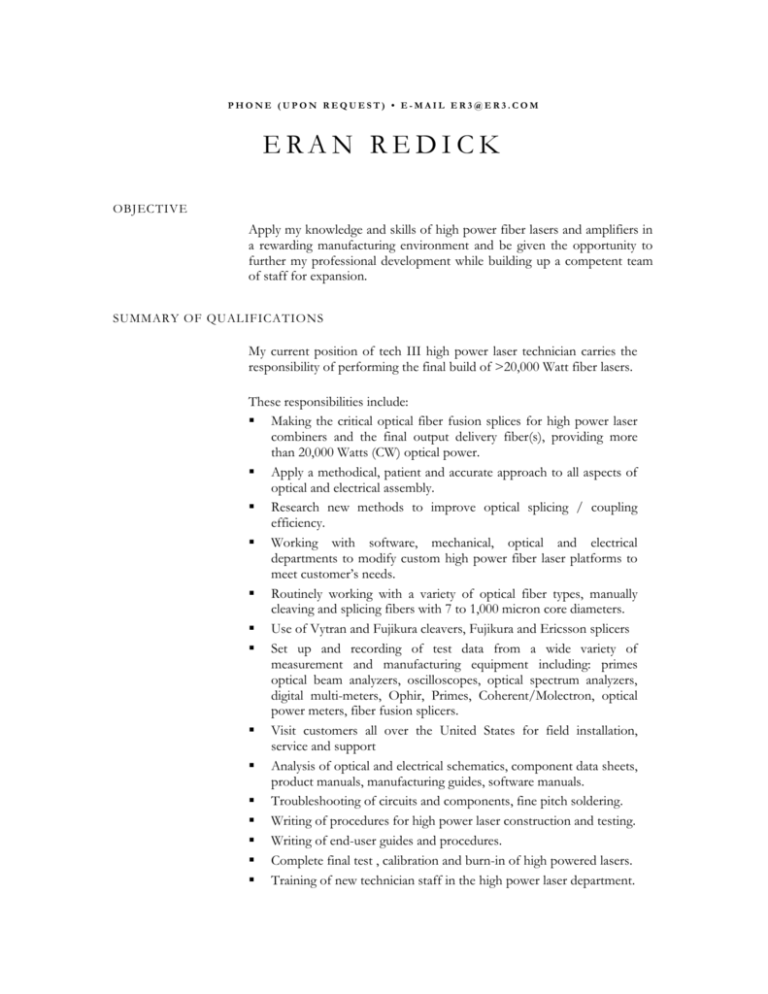

Eran Redick Resume

advertisement

PHONE (UPON REQUEST) • E-MAIL ER3@ER3.COM ERAN REDICK OBJECTIVE Apply my knowledge and skills of high power fiber lasers and amplifiers in a rewarding manufacturing environment and be given the opportunity to further my professional development while building up a competent team of staff for expansion. SUMMARY OF QUALIFICATIONS My current position of tech III high power laser technician carries the responsibility of performing the final build of >20,000 Watt fiber lasers. These responsibilities include: Making the critical optical fiber fusion splices for high power laser combiners and the final output delivery fiber(s), providing more than 20,000 Watts (CW) optical power. Apply a methodical, patient and accurate approach to all aspects of optical and electrical assembly. Research new methods to improve optical splicing / coupling efficiency. Working with software, mechanical, optical and electrical departments to modify custom high power fiber laser platforms to meet customer’s needs. Routinely working with a variety of optical fiber types, manually cleaving and splicing fibers with 7 to 1,000 micron core diameters. Use of Vytran and Fujikura cleavers, Fujikura and Ericsson splicers Set up and recording of test data from a wide variety of measurement and manufacturing equipment including: primes optical beam analyzers, oscilloscopes, optical spectrum analyzers, digital multi-meters, Ophir, Primes, Coherent/Molectron, optical power meters, fiber fusion splicers. Visit customers all over the United States for field installation, service and support Analysis of optical and electrical schematics, component data sheets, product manuals, manufacturing guides, software manuals. Troubleshooting of circuits and components, fine pitch soldering. Writing of procedures for high power laser construction and testing. Writing of end-user guides and procedures. Complete final test , calibration and burn-in of high powered lasers. Training of new technician staff in the high power laser department. Prior to my promotion to the position of High Power Laser technician III I first trained and worked on sub-200 Watt optical devices. Here I demonstrated my ability to learn new technologies and showed the required skills and proficiency over many years that singled me out for the more advanced laser position I have today: Installation and testing of high power laser diode pump sources. Installation and testing of high power active fiber gain stages. Installation of electrical control boards Complete start to finish construction of active optical fiber products. Calibration and adjustment of electronics and optics. Performance/Qualification testing of finished optical units. Many years of experience and familiarity of the following active optical single-mode fiber technologies: Erbium amplifiers (1W – 50W) Erbium lasers (1W – 50W) Ytterbium amplifiers (1W – 100W) Ytterbium lasers (1W – 3000W) Cascaded Raman fiber lasers (1W -5 W). Routinely dealt with specialty products that called for customization of standard optical, electrical and mechanical designs. These involved identifying mechanical and electrical rework requirements. Other skills include: Computer software: Primes beam analysis, All Windows Operating Systems, Outlook, Word, Excel, HTML, Web design. Safety Training: Laser, ESD, Health in Workplace, ISO. WORK EXPERIENCE [ 2000 - present ] IPG Photonics High Power Fiber Laser Optics and Electronics Technician III High Powered Fiber Laser Test and Calibration Technician for IPG Photonics [ 1998-2000 ] Net phone Inc, Marlborough, MA Telecommunications Private Branch Exchange, Electronics Technician Final Test, Troubleshoot, and Repair PCI slot PBX boards EDUCATION [ 1996-1998 ] Becker College Associates Degree Science - Highest Honors Worcester MA [ 1996-1998 ] Worcester Technical Institute Worcester MA Electronics Engineering Technology, Telecommunications and Networking Oxford, MA Certificate - Highest Honors