Intramolecular Lactonization of Polymers Prepared via Reversible

advertisement

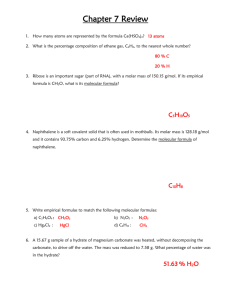

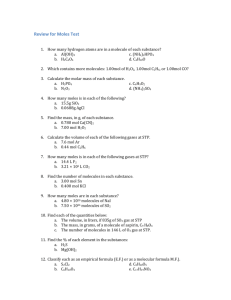

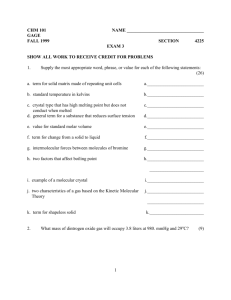

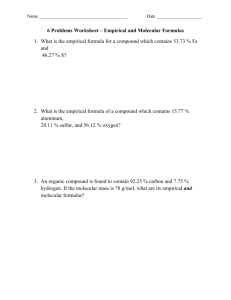

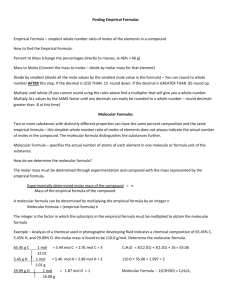

Transesterification of Poly(Ethyl--Hydroxy-methacrylate) Prepared via Reversible Addition Fragmentation Chain Transfer (RAFT) Polymerization T. Y. Joan Chiu, Martina H. Stenzel, Thomas P. Davis and Christopher BarnerKowollik SUPPLEMENTARY INFORMATION Materials Ethylhydroxy methacrylate (EHMA)1 was purified by percolating over a column of basic alumina prior to use. Cumyl dithiobenzoate (CDB) was prepared using the method described by Oae et al.,2 with n-hexane as the solvent. The purity of the RAFT agent was close to 99% as verified by 1H-NMR and elemental analysis.3 2,2- Azobis(isobutyronitrile) (AIBN, Aldrich, 99%) was re-crystallized twice from ethanol prior to use. 1 EHMA was kindly provided by Mr Taizo Matsueda, New Chemicals Development Dept., Nippon Shokubai Co. Ltd., 1-2-2, Uchisaiwai-Cho, Chiyoda-ku, Tokyo 100, Japan. 2 Oae, S.; Yagihara, T.; Okabe, T. Tetrahedron 1972, 28, 3203. 3 Feldermann, A.; Coote, M. L.; Davis, T. P.; Stenzel, M. H.; Barner-Kowollik, C. J. Am. Chem. Soc., 2004, 126, 15915. RAFT polymerization of EHMA AIBN (1·10-3 mol L-1) and CDB (5·10-3 mol L-1) were dissolved in EHMA and then separated into reaction vials, each containing about 2 mL of solution, and sealed with rubber septa (Aldrich). The reaction mixture was subsequently deoxygenated by purging with a pure nitrogen stream for 30 min. The deoxygenated, sealed vials were then placed in a 60 °C water bath and removed at pre-selected reaction times. The reactions were stopped by quenching in ice bath and the addition of hydroquinone monomethyl ether. The polymeric material was recovered by dissolving in chloroform and subsequent precipitation in n-hexane. 1 Intramolecular Transesterification of poly(EHMA) Dry poly(EHMA) (1·10-3 mol L-1) was dissolved in deuterated DMSO with a trace of p-toluene sulfonic acid as the catalyst. The reaction mixture was then transferred into an open top reaction vessel and placed in a 150 °C oil bath with stirring. Samples were taken at pre-selected times and transferred in a small sealed vial and dried with molecular sieves – this is crucial as the presence of water in the sample can appear in the NMR spectra, partially overlapping with the lactone signal. Analytical Methods Size Exclusion Chromatography Molecular weight distributions were measured via size exclusion chromatography (SEC) on a Shimadzu modular system, comprising an auto injector, a Polymer Laboratories 5.0 m bead-size guard column (50 x 7.5 mm), followed by three linear PL columns (105, 104 and 103 Å) and a differential refractive index detector. The eluent was tetrahydrofuran (THF) at 25 ºC with a flow rate of 1 mL min-1. The system was initially calibrated using narrow polystyrene standards ranging from 540 to 2·106 g mol-1. The resulting molecular weight distributions have been recalibrated using the Mark-Houwink parameters for poly(EHMA) (K = 16.66·10-5 dL g-1, a = 0.62). The Mark-Houwink parameters for polystyrene read (K = 14.1·10-5 dLg-1 and a = 0.70). Nuclear Magnetic Resonance Spectroscopy NMR spectra were recorded on Bruker Avance 300 MHz instrument. 2 poly(EHMA) PDI=1.5 poly(EHMA)-lactone PDI=1.5 Transesterification 8h 20 25 30 35 40 retention time / min Figure S1 45 20 25 30 35 40 45 retention time / min Full molecular weight distribution before and after transesterification as described in the Communication. The molecular weight distribution does clearly not broaden (as would be expected when intermolecular transesterification was operational), underpinning the notion that intramolecular lactonization is the main reaction pathway. 3 1.5 60000 -3 1.0 -1 [CDB] = 5.5·10 mol L -3 -1 [CDB] = 11·10 mol L o T = 60 C -3 -1 [AIBN] = 1·10 mol L -1 50000 Mn / g mol PDI 2.0 40000 30000 20000 10000 0 0.0 0.1 0.2 0.3 conversion Figure S2 Evolution of the number average molecular weight, Mn, vs monomer to polymer conversion in the cumyl dithiobenzoate mediated EHMA polymerization at 60 °C for two initial CDB concentrations. The molecular weights given are absolute molecular weights. The dashed lines are linear best fits. 4