Spectral Analysis For Solar Control Coatings - W. Theiss Hard

advertisement

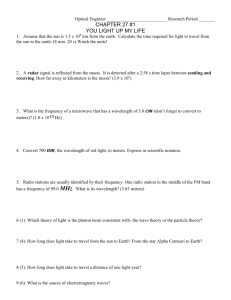

1 Online Spectrophotometry and Layer Design Tools in Solar Control Coatings For esthetical reasons architects like to have a defined and constant color on the glass. Color of a flat glass pane is the only critical effect for the one, who is looking at a building and therefore the primary reason for complaints. The functional part of the architectural glass – solar control - is of course more and more important but not visible. Especially with all debates about reducing CO2 emission, with increasing energy prices, architects have to think about energy saving, when heating or cooling houses. By sputtering coating layers on glass or on flexible polymers (foils), these become an important part of solar control in architecture and automotive. Applying this process, the color of the glass may change with viewing angle, especially when using double (or multiple) silver layer coatings. If the production process is unstable - and the glass panes mounted on a building front will have different colors - complaints of clients will cause tremendous costs. An On-Line Color Control will ensure a stable process. 1 Applications Low-E Glass In regions where weather is typically cold, energy shall be kept inside; this is provided by appropriate coating and window glass arrangement. Picture 1 Modern online spectrophotometers have to take care of that problem. It is not enough to measure with one specific condition. Just like a pedestrian, who walks around the house and thus changes his viewing angle, the measurement device has to measure the spectral curves with different illumination and different viewing angles. Not only in the architectural field is color of the pane important but also in the automotive industry. Modern cars have also solar control glases which change colors by the viewing angle. While the car is approaching to an observer, the viewing angle and the color are changing. See picture 2. Solar Protection Glass On the other hand there are regions with strong sun shine. Here the glass shall keep the sun´s infrared energy out of the building to keep the rooms cooler. For this reason the glass is coated with specific layer structures, which are able to reflect the infrared radiation to the outer space. These layers will also influence the color perception of the glass surface. Using On-Line spectrophotometry, the color effect of coating layer structure can be monitored during the production process. This helps to ensure constant product quality. 2 Online Spectrophotometers of GretagMacbeth GmbH Glass in automotive and architectural applications is typically a non-scattering material. If we look at a glass pane, we always see the mirror image in the glass typically the sky, or/and we are looking through the pane. For this reason we have to measure the glass in reflectance and in transmission to describe precisely the visual impression. The transmission measurement is quite easy to handle: Light is sent through the glass pane and on the other side a detector receives the light that passed the glass. This light is directed to a high resolution spectrophotometer. 2 The reflectance measurement of glass is different to the measurement of other surfaces (which typically have high scattering). Only laboratory instruments which have a sphere geometry (d:8°, specular component included) can measure the pane, but just with one viewing condition. Only light which is reflected on the surface at 8° is measured. All other angles are neglected. The better technology is to have a measurement directly in the specular direction. With the instrument ER 56 PA(T) from GretagMacbeth GmbH light is sent at 15° and at 60° to the specimen. On the other side at -15° and -60° the light is registered sequentially and directed to a high resolution spectrograph. This allows quality control for steep angles and flat angles. In the following Picture 3 you can see the ER 56 PA built in a flat glass pane coating production line. The sonar sensor in front of the instrument detects the glass pane and triggers the color measurement. instrument in reflectance mode and with 250 mm distance in transmission mode. During the measurement the sample is illuminated by a white light (Xenon flash lamp, daylight quality) for approx. 1 / 1000 sec. In the specular angles of 15° and 60° the reflected light is registered sequentially and directed to a high-resolution spectrograph. In Picture 4 you can see a principal drawing of the geometries. The two lamps illuminate the sample with an angle of 15° and 60°. On the other side are the optics which direct the light to the spectrograph. Picture 4 Parallel to the sample measurement a reference measurement of the lamp is done by a second identical spectrograph (dual-beam system design). Optionally, transmisson measurement is performed at the same time with an other module placed at the reverse side of the glass pane. In each spectrophotometer light signal is dispersed into 401 wavelength ranges (330 nm up to 730 nm) via a corrected, concave grating. An integrated photo diode cell array with more than 400 detectors measures each wavelength range. The result is a true spectral resolution of 1 nm. The measurement signals are amplified and digitized with high resolution. A fast processor in the measure-ment head processes them into corrected spectral reflectance values. From these 401 reflectance values, colorimetric readings for any illuminant or standard observer can be calculated (e.g. CIELAB for D65 / 10°). The transmission measurement is done at the same measurement spot with the same principle. Picture 3 2.1 Spectral the ER 56 PA(T) measurement with The spectrophotometer ER 56 PA(T) is typically used on glass coating lines after the vacuum coaters, directly between transportation rollers. There is no need to destroy the glass pane for sample preparation. The ER 56 PA(T) is a compact On-Line spectral color measurement system with special measurement geometry for specular reflectance using two viewing angles and with an optional transmission measurement module. The glass pane is measured in a non-contact way in 10 mm to 22 mm distance to the Automatic calibration of the instrument includes the calibration of intensity for each wavelength, and the absolute wavelength calibration for excellent measurement accuracy and long-time stability. The measuring instrument is controlled by a computer (PC), to which the measurement data are transferred. Besides the RS 232 there is a RS 422 interface, allowing distances up to 1000 m between the measuring system and the evaluation computer. A galvanic separation of the data interfaces guarantees stable operation in a real-world production environment. Glass panes have to be measured on several spots after the coating process for quality 3 control. The ER 56 PA(T) can be placed between the transportation rollers on a linear track to measure in cross direction (CD) - left side, center and right side - of the glass pane. As soon as the pane is above the sonar sensor, it stops and the ER 56 PA(T) performs its measurements. To measure the next position, the pane will move for a specified distance. Then the procedure is repeated. If the cross direction of the coating is quite stable, one ER 56 PA(T) can be used on a fixed position. The result of each measurement is a spectral curve from 330 nm till 730 nm for reflectance and for transmission measurement. Picture 5 shows reflectance curves for 15° and 60° viewing angles at a double silver layer coated flat glass pane. 60 50 60° 15° Reflexion % 40 30 20 10 0 300 350 400 450 500 550 600 650 700 750 800 Wellenlänge nm Picture 5 The ER 56 PA(T) can be used in the laboratory as a desktop instrument, too. Mounted on a support frame it can measure even large architectural samples. The results correlate very well to the On-Line Measurement Mode and show exactly, what the human eye sees under these conditions (see Picture 6 – desktop). 4 Picture 6 2.2 Other online instruments from GretagMacbeth for glass or film measurements Like the ER 56 PA(T), the ER 54 PA(T) can measure glass in reflectance and transmission. The difference is, that the reflectance measurement is taken with just one geometry: +15°:-15°. A transmission measurement mode is optional, too. The ER 55 PA is applied only for measurements in transmission mode. This instrument determines color (L*, a*, b*), light transmission and non contact correlated haze – all readings are collected online. It can be used for glass, but also for plastic films – like interlayers in laminated glazing (see Picture 7). Picture 7 3 Layer Design The variation of color with changing observer position should be taken into account in the design of architectural glass coatings. If the number of layers and the possible variation in available optical constants in a coating line allow to satisfy both the functional demands of the coating (such as heat insulation or protection from solar radiation) as well as wishes for a certain color impression, the designer has some freedom to make choices. Due to the complexity of modern coatings their design is usually based on an optical model. If the optical constants of the applied materials have been carefully determined, and effects of 'layer interactions' that occur when depositing a sequence of layers in a coating line are understood and taken into account in the 5 model, the performance of the final product can be predicted with high accuracy. The CODE software of W.Theiss Hard- and Software contains all mechanisms needed to investigate the optical properties of materials like sputtered oxides, nitrides or metals and to predict technical data of coatings such as U, g, integrated transmission and reflection values as well as color coordinates. It also assists the designer with the computation of the color variation with viewing angle. In an intuitive manual design phase you can instantly watch the color variation while modifying layer thicknesses or optical constants with slider motions (fig.?). Having defined the wanted color variation as optimization target, the program finally tries to optimize the coating automatically. All computed technical data can simultaneously be used as fit targets. A human being as coating designer is still required, in particular to control the automated optimization by setting the relative weights of the individual target quantities. Screenshot with angle variation of color and thickness sliders Fig. ? The design software GenetiCode of W.Theiss Hard- and Software optimizes coatings using a different approach: The user defines the number of deposition stations (in most cases these are sputtering cathodes) in the coating line and the available materials for each station. The wanted performance of the coating is specified by a collection of target values like in the CODE software discussed above. Having defined the available deposition hardware and the wanted coating properties, the layer stack is then optimized using a genetic algorithm, usually in overnight sessions performing several evolutionary runs (fig ??). Since GenetiCode is not blocked by any design knowledge, it can be a valuable partner of experienced coating designers, either creating new, unusual solutions or confirming existing approaches as good solutions of the problem. GenetiCode screenshot Fig. ?? 4 Layer Correction using On-Line Spectrophotometry The production of modern glass coatings usually involves many sputtering cathodes in the coating line – each one contributing a certain amount of uncertainty about what is produced at the moment. An optical production control is required, providing online information about the coating produced at present. In most cases transmittance, reflectance or ellipsometry spectra are recorded, either inline between groups of cathodes or directly behind the coating line when the final products have left the vacuum. If the design of the coating has been done taking into account details of the coating line it is natural to use the optical model of the design for production control as well. In the case of CODE you can even take exactly the same program. CODE can be used to analyze the spectra recorded during production, driven as OLE automation server by the software that controls the production equipment, such as LabView (a product of National Instruments). Based on CODE, W.Theiss Hard- and Software has developed the software package BREIN which is dedicated to the optical control of the production of multilayer coatings in large coating lines. BREIN stands for BRight Eye INspection network: It manages several stations called 'Bright Eyes' (BE) which analyze optical spectra taken at a certain position in or after the coating line (fig ???). Before doing the analysis for a product, each BE picks up the results obtained by the BE prior in the line. This way only the newly deposited layers after the last BE have to be analyzed - the computational effort for each BE is usually quite low and can be done even on slow embedded computers. The main BREIN application collects the BE results and displays the current status of the production. The operators can use this information for making decisions about changes of the production conditions. BREIN scheme Fig. ??? 5 Conclusions