Thomas Heinze Vera Haack Stephan Rensing Kompetenzzentrum

advertisement

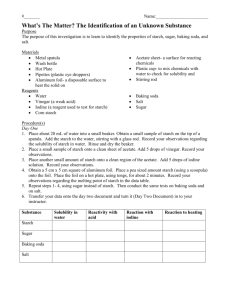

Thomas Heinze Vera Haack Stephan Rensing Kompetenzzentrum Polysaccharidforschung Friedrich-Schiller-Universitat Jena, Jena, Germany Starch Derivatives of High Degree of Functionalization. 7. Preparation of Cationic 2Hydroxypropyltrimethylammonium Chloride Starches Water-soluble starch derivatives containing quarternary ammonium groups of high degree of substitution are prepared by reacting starch with 2,3-epoxypropyltrimethyl-ammonium chloride in different reaction media. The reaction was carried out in aqueous sodium hydroxide under dissolution of the product, in dimethyl sulfoxide homogeneously, and completely heterogeneously in ethanol/water. The DS values of up to 1.1 in an one-step synthesis of the samples can be controlled by adjusting the molar ratio of cationization agent to anhydroglucose unit and are only slightly dependent on the amylose content of the starting starch material. A two-step reaction yields products of a DS of up to 1.5. The structure of the cationic starch derivatives was confirmed by means of elemental analysis, FTIR- and NMR spectroscopy as well as GC-MS. Keywords: Polysaccharides; Chemical modification; Cationic starch derivatives; Structure characterization; NMR spectroscopy 1 Introduction Starch derivatives containing cationic moieties of low degree of substitution (DS, up to 0.2) are important commercial products, used as additives, for example in the paper, textile or cosmetic industry. These derivatives are produced by reaction of starch with reagents such as 3-chloro-2hydroxypropyltrimethylammonium chloride or 2,3-epoxypropyltrimethylammonium chloride under heterogeneous conditions. Various processes have been described in numerous patents and publications [1-7]. Usually, the starch samples are reacted in an aqueous alkaline suspension in the presence of gelantinization inhibitors such as Na2SO4 [8]. Kweon et al. described that the addition of water-miscible organic solvents to the aqueous alkaline media can be used to minimize starch swelling and hence to avoid usage of the gelatinization inhibitor salt [9]. Recently, solvent-free etherification processes, so-called dry cationization of starch, were proposed and applied [10]. Most of the cationic starch derivatives which are available commercially have a degree of substitution (DS) less than 0.2. Recently Merta et al. published studies about the interaction of cationic starch derivatives with a rather high DS of 0.8 and anionic surfactants [11,12]. Correspondence: Thomas Heinze, Kompetenzzentrum Polysaccharidforschung Friedrich-SchillerUniversitat Jena, Hum-boldtstraBe 10, D-07743 Jena, Germany, Fax: +49-(0)3641 -948-272, email: Thomas.Heinze@uni-jena.de. In the context of our work in the field of starch derivatives, the interest was focused on cationic starch products with high DS [13-18]. Therefore, we studied various paths for the synthesis of cationic starch derivatives. In the present paper, the influence of media and conditions of reaction on the achievable DS depending on the starting starch material was investigated. In particular, a heterogeneous-and a homogeneous procedure as well as a reaction system starting heterogeneously and dissolving the product during the course of reaction were evaluated. The obtained starch derivatives were characterized by means of elemental analysis, FTIR- and NMR spectroscopy as well as GC-MS. 2 Materials and Methods 2.1 Materials The starch materials used were Hylon VII (70% amylose, National Starch & Chemical GmbH, Neustadt, Germany), potato starch (28% amylose, Emsland-Starke GmbH, Emlichheim, Germany), wheat starch (26% amylose, Kroner-Starke, Ibbenburen, Germany), maize starch (28% amylose, National Starch & Chemical GmbH, Neustadt, Germany) and waxy maize starch (amioca powder, 1% amylose, National Starch & Chemical GmbH, Neustadt, Germany). The starches were dried at 100°C under vacuum before use. 3-Chloro-2-hydroxypropyltrimethylammonium chloride (CHPTAC. QUAB188) and 2,3epoxypropyltrimethyl-ammonium chloride (GMAC, QUAB®151) were obtained from DegussaHuls AG, Germany and were used as 69% and 70% (w/v) aqueous solution, respectively. Dimethyl sulfoxide (DMSO) was purchased from Fluka (Buchs, Switzerland). 2.2 Measurements Elemental analysis was carried out by means of a LECO CHNS/932 ultimate analyzer (LECO Instrumente GmbH, Monchengladbach, Germany). FTIR spectra were recorded on a Nicolet Impact 400 spectrometer (Thermo Electron GmbH, Dreieich, Germany) using KBr pellets. 1H- and 13C NMR spectra were acquired on a Bruker AMX spectrometer (Rheinstetten, Germany) in D2O. The viscosity of the cationic starch derivatives dissolved in water (2% w/v) was measured in a rotational rheometer RS150 (Haake, Karlsruhe, Germany) using a DG41 Ti measuring container at 25 ± 0.1 °C. The weight-average molar mass (Mw) was measured with a GPC equipment 150C (Waters, Milford, USA) with integrated HPLC system, using an Rl- (refractive index) detector, MALLS (multiangle laser light scattering) -Dawn detector - DSP (Wyatt Technologie Inc., St. Barbara, USA) with an Ar-ion-laser (488 nm) and a K5-dis-charge cell as analyzer. A SUPREMA-gel column set (PSS Mainz, Germany, exclusion borders 108-106, 2x106-5x104, 105-103) and 0.5 M NaNO3 with 0.02% NaN3 as eluent with a flow rate of 0.74 mL/min was used. The starch materials were dissolved in DMSO and the cationic starch derivatives in water. The degree of substitution (DS) was calculated from the nitrogen- (DSN) and chloride analysis (DSCl) according to the following equations: 2.3 Methods Starch 2-hydroxypropyltrimethylammonium chloride derivatives synthesized with QUAB®151 in NaOH/H20 (products H1-H3, P1-P3, W1-W3, M1-M3, WM1-WM3, WM10) Dried starch (20 g, 0.123 mol) was suspended in a sodium hydroxide solution (0.5 g in 100 mL H2O). The mixture was heated to 60°C and kept for 1 h at that temperature. Subsequently, a solution of 53 mL QUAB®151 (0.246 mol, molar ratio QUAB®151/AGU = 2) was added dropwise to the starch suspension. The reaction mixture was additionally stirred for 6 h at 60°C. A highly swollen gel was formed and the polymer dissolved. The mixture was diluted with 100 mL water. After cooling down, the solution was neutralized with 1 M HCI and the product was isolated by precipitation in ethanol. Finally the product was purified by dialysis against water and freeze-dried. Sample P3 Yield: 40.2 g, 93% based on DSN. Elemental analysis: C 44.80%, H 8.39%, N 4.57%, Cl 11.38%. DSN = 1.05, DSCl = 1.01, reaction efficiency = 52%. IR (KBr): 3425 (s, OH), 2928 (CH), 1154, 1082, 1022 (starch backbone) cm-1. 1 H-NMR (D20,60°C): 3.5 (CH3-N+), 3.7-4.60 (starch backbone and CH2-CH-CH2), 5.6 (C1Hstarch), 5.9 (C'Mi-starch) ppm. 13 C-NMR (D2O, 60°C): 54.7 (CH3-N+), 60.9 (C6), 65.5 (CH2-CH-CH2), 68.5 (CH2-N+), 70.6-80.7 (starch backbone and CH2-CH-CH2), 96.6 (C'1H-starch), 99.25 (C1H-starch) ppm. The molar ratio of QUAB®151 to anhydroglucose unit (AGU) was varied from 1 to 2 mol/mol in order to control the DS (see Tab. 1). Starch 2-hydroxytrimethylammonium chloride derivatives synthesized homogeneously in DMSO (products H4, P4, W4, M4, WM4) Dried starch (15 g, 0.0925 mol) was suspended in 200 mL DMSO and kept at 80°C for 1 h under continuous stirring. The starch dissolved completely. The solution was cooled down to ambient temperature and a solution of 0.5 g sodium hydroxide in 20 mL dist. water was added. The temperature was increased to 60°C (bath temperature) and 0.092 mol of QUAB®151 was added dropwise under stirring within 30 min. The mixture was kept at 60°C for 24 h. After cooling to ambient temperature, the solution was neutralized with 1 M HCI and precipitated in ethanol, filtered off, washed with ethanol and dried under vacuum. Sample WM4 Yield: 24 g, 99% based on DSN. Elemental analysis: C 44.41%, H 7.49%, N 3.22%, Cl 8.24%. DSN = 0.57, DSCl = 0.58, reaction efficiency = 57%. IR (KBr): 3425 (s, OH), 2928 (CH), 1154, 1082, 1022 (starch backbone) cm-1. 1 H-NMR (D2O, 60°C): 3.5 (CH3-N+), 3.7-4.6 (starch backbone and CH2-CH-CH2), 5.6 (C1Hstarch), 5.9 (C1H-starch) ppm. 13 C-NMR (D2O, 60°C): 54.7 (CH3-N+), 61.0 (C6), 65.5 (CH2-CH-CH2), 68.6 (CH2-N+), 71.5-80.7 (starch backbone and CH2-CH-CH2), 96.7 (C'1H-starch), 99.6 (C1H-starch) ppm (see Tab. 2.) Starch 2-hydroxypropyltrimethylammonium chloride derivatives synthesized with QUAB®188 in C2Hs0H/Na0H/ H2O (products H5-7, P5-7, W5-7, M5-7, WM5-7) Dried starch (20 g, 0.123 mol) was suspended in 80 mL ethanol and 17 g sodium hydroxide dissolved in 40 mL water and 80 mL ethanol was added to the starch suspension. Subsequently, a solution of 99 mLQUAB®188 (0.369 mol, molar ratio QUAB®188/AGU = 3) was added dropwise to the suspension. The mixture was kept at 60°C for 6 h. After cooling down to ambient temperature, the product was neutralized with 1 M HCI, filtered off and washed with ethanol. The product was purified by dialysis against water and freeze-dried. Sample H7 Yield: 35.3 g, 95% based on DSN. Elemental analysis: C 42.86%, H 7.96%, N 3.68%, Cl 10.05%. DSN = 0.91, DSC| = 0.89, reaction efficiency = 30%. IR (KBr): 3425 (s, OH), 2928 (CH), 1154, 1082, 1022 (starch backbone) cm-1. 1 H-NMR (D2O, 60°C): 3.5 (CH3-N+), 3.7-4.6 (starch backbone and CH2-CH-CH2), 5.6 (C1Hstarch), 5.9 (C1H-starch) ppm. 13 C-NMR (D2O, 60°C): 54.7 (CH3-N+), 60.9 (C6), 65.5 (CH2-CH-CH2), 68.5 (CH2-N+), 70.6-80.7 (starch backbone and CH2-CH-CH2), 96.6 (C'1H-starch), 99.25 (C1H-starch) ppm. The molar ratio of QUAB®188 to AGU was varied from 1 to 3 mol/mol in order to control the DS (see Tab. 3). 3 Results and Discussion The syntheses of starch 2-hydroxypropyltrimethylammo-nium chloride derivatives were carried out using three different reaction media, i) aqueous sodium hydroxide under dissolution of the product formed ii) completely homogeneously in dimethyl sulfoxide and iii) heterogeneously in ethanol/water. As cationization reagents 3-chloro-2-hydroxypropyltri-methylammonium chloride (CHPTAC, QUAB®188) and Fig. 1. Reaction scheme of the cationization of starch with QUAB®188 and QUAB®151 in different media. 2,3-epoxypropyltrimethylammonium chloride (GMAC, QUAB®151) were applied (Fig. 1). Different factors affecting the degree of substitution, namely the molar ratio of cationization agent to AGU, source of starch material, and sodium hydroxide concentration were studied. 3.1 Reaction media and starch material In a first set of experiments, the cationization reactions were carried out in aqueous sodium hydroxide under dissolution (procedure i), using molar ratios of cationization agent per AGU of 0.5 to 2 (Tab. 1). Comparing the different starch materials, the lowest DS value of 0.42 was obtained with the amylose-rich starch Hylon VII applying a molar ratio of 1. Waxy maize starch leads to a product of a comparably high DS of 0.60. The cationization reaction of potato, wheat- and maize starch results in products with a DS of about 0.5. By increasing the molar ratio of cationization agent to AGU to 1.5, products were obtained with high DS between 0.62 and 0.78. Products with DS values up to 1.0 could be obtained with a molar ratio of 2. A rather high efficiency of about 50% was reached independently of both the starch material and the molar ratio of cationization agent to AGU. The homogeneous reaction in DMSO as solvent (method ii) yields cationic starch derivatives starting from Hylon VII and potato starch with similar DS (about 0.4) using a molar ratio of cationization agent per AGU of 1 compared to method i (Tab. 2). In contrast, applying wheat, maize, Tab. 1. Results of the reaction of different starch materials (20 g) with 2,3epoxypropyltrimethylammonium chloride (QUAB-151) in aqueous sodium hydroxide. Tab. 2. Results of the reaction of different starch materials (15 g) with 2,3-epoxypropyltrimethylammonium chloride (QUAB®151) (molar ration of 1) and 0.5 g sodium hydroxide as catalyst in DMSO. and waxy maize starch, products with DS values of 0.37, 0.41, and 0.57, respectively, were accessible, indicating a different reactivity depending on the reaction medium. To avoid the formation of solutions of high viscosity, reaction under heterogeneous conditions were studied (method iii, Tab. 3). Ethanol was added as swelling inhibitor to suppress the swelling of the starch material during the reaction. In this case the process can be carried out with a significantly lower amount of reaction medium. Applying a molar ratio of the cationization agent per AGU of 1 for Hylon VII, potato and maize starch, products with a DS of about 0.40 could be synthesized. Surprisingly, products with low DS only were obtained for wheat starch (DS = 0.17) and especially waxy maize starch (DS = 0.05), which showed the highest DS values applying procedures i and ii. In order to gain products with higher DS values, the molar ratio of cationization agent per AGU was increased to 2. For Hylon VII, potato and maize starch DS values in the range from 0.37 to 0.81 were reached, how- Tab. 3. Results of the reaction of different starch materials (20 g) with 3-chloro-2hydroxypropyltrimethylammonium chloride QUAB®188 in ethanol/water. ever the reaction efficiency was significantly lower. The efficiency dropped from 46% to 33% (Hylon VII) and in case of potato starch a reduction from 47% to 40% was found. Surprisingly in case of wheat starch the efficiency was increased from 17% at a molar ratio of cationization agent per AGU of 1 to 28% at a ratio of 2. The waxy maize starch still showed almost no cationization. Only a DS of 0.03 was obtained, which obviously results from the fact that the waxy maize starch consists of 99% amylo-pectin and no activation of amylopectin occurred in contrast to amylose. The same result was also found for the carboxymethylation of starch, however, the effect was less pronounced [14]. Even with a higher molar ratio of QUAB®188 to AGU a higher DS could not be achieved. For Hylon VII and wheat starch, products with a DS of about 0.9 were accessible by increasing the molar ratio of cationization agent per AGU to 3. The efficiency decreased to 30% and 29%, respectively. The reaction of potato and maize starch showed an efficiency of 24% and waxy maize starch gave products with a DS of 0.14 only. The lower efficiency of the heterogeneous method iii compared with the procedure i (aqueous sodium hydroxide as medium) may be explained by the fact that in the first case the charged groups are accumulated on the surface of the starch grains and the diffusion of further cationization agent into the inner parts is increasingly hindered. Using processes with homogeneous sequences (method i, ii), the cationic starch was dissolved and the reaction on the "new" surface of the grain is less impeded. Applying the described media and reaction conditions, DS values higher than 1.1 could not be reached in a one-step reaction even with molar ratios of cationization agent to AGU higher than 3. Therefore, the conversion of cationized starch with 2,3-epoxypropyltrimethylammonium chloride in water, which showed the highest efficiency during the previous experiments, was studied further. As shown in Tab. 4, after a second reaction step the DS values of the products were in the range from 1.13 for maize starch to 1.5 for Hylon VII applying a molar ratio of cationization per AGU of 10. In contrast, a molar ratio of 2 leads to no further cationization. 3.2 Effect of sodium hydroxide concentration To increase the DS of the samples, the one-step reaction of QUAB®151 with maize starch was conducted under variation of the amount of the catalyst NaOH, applying the aqueous sodium hydroxide medium (Fig. 2). By using 0.5 g of the base and a molar ratio of the cationization agent QUAB®151 to AGU of 1, a DS of 0.55 and a reaction efficiency of 55% was obtained. Under comparable reaction conditions (starch, solvent, cationization agent, time, temperature), a DS of 0.72 was observed, however, with an increased amount of NaOH (2.0 g). In contrast, a further increase in the amount of NaOH (3.0 g) leads to products of a comparatively low DS. Obviously, at high alkali concentration the hydrolysis of the epoxide to form the Tab. 4. Results of the reaction of cationic starch (20 g) with 2,3-epoxypropyltrimethylammonium chloride (QUAB®151) and 0.5% g NaOH in water. Fig. 2. Degree of substitution of cationic maize starch depending on the amount of NaOH (g NaOH/100 mL water; 20 g starch; molar ratio QUAB®:AGU 1, 60°C, 6 h). diol is increased. As expected, a certain NaOH concentration is necessary to activate the starch, on the one hand; on the other, the hydrolysis of the reagent should be as low as possible. 3.3 Characterization 3.3.1 NMR spectroscopy and GC-MS Standard 13C-NMR spectra were measured in deuterium oxide at 300 K. A representative 13C-NMR spectrum of a cationic starch derivative prepared from Hylon VII (H6, DS = 0.66) is shown in Fig. 3. The peaks of the unmodified AGU appear at 99.9 ppm (C-1) and for C2-C6 between 60 and 80 ppm. The introduction of the 2-hydroxypropyltrimethylammonium chloride moieties results in two new peaks at 103.2 ppm and 80.7 ppm for C1' and C2S, respectively. As shown in Fig. 3 as well, a splitting of the C1' signal appears with increasing DS. At a DS of 1.5 only the C1' signal appears, indicating a complete functionalization of O-2. As shown in detail in Fig. 4, both peaks become more intense with increasing DS, indicating that substitution starts at the 2-posi-tion. The 6 position is only modified slightly, reflected by the low intensity of the peak at 68.9 ppm. The peak assignment was verified by DEPT-135. The peaks of the CH2-groups at C6, C7, and C9 had negative intensities and can be easily distinguished from the CH-groups (Fig. 5). The signals of the 2-hydroxypropyl-trimethylammonium chloride group were determined at 73.3, 65.5 and 68.5 ppm for C7, C8 and C9, respectively. The three methyl groups of the ammonium moieties show an intense signal at 54.7 ppm (C10). The 1H-NMR spectra gave the expected peaks for the protons of C2 to C6 of the starch backbone between 3.70 ppm and 4.60 ppm. The proton at C1 of the unmodified AGU shows a peak at 5.6 ppm and at 5.9 ppm for the modified AGU. The methyl groups of the substituent were attributed to the signal at 3.5 ppm. The signals resulting from the hydrogen atoms of the substituent are expected to appear in the same range of the chemical shift as the AGU signals. As already mentioned, the splitting of the signals for the C1 and C2 in the 13C-NMR spectra and the two peaks of the hydrogens bound to C1 in the 1H-NMR spectra give strong evidences for the preferred reaction at position 2. To confirm the distribution of functional groups, the prod- Fig. 3. 13C-NMR spectrum of cationic starch sample H 6 (degree of substitution (DS) = 0.66) measured in D2O at 60°C (R = H or cationic group according to DS). Fig. 4. 13C-NMR spectra of cationic starch derivatives with degree of substitution from 0.13 to 1.50 (samples WM 7,0.13; H 6, 0.64; M 8, 1.13; H 5, 1.50). Fig. 5. DEPT-135 spectrum of cationic starch P 3 (degree of substitution = 1.05), numbering see Fig. 3. ucts were studied by means of combined gas-liquid chro-matography and mass spectrometry. For this examination the polymer was permethylated and depolymerized [19, 20]. The analysis indicates the preference of the substitution at the position 2 of the AGU. Moreover, it was found that the functionalization pattern does not follow the calculated Spurlin statistics, which should be the case if the three hydroxyl groups possess an equal reactivity. In contrast, it was found that a monofunctionalization is favored, which can be located at C2 position. The amounts of unsubstituted units and di-O-substituted units formed were lower than calculated. This distribution of cationic groups was found to be independent of the reaction conditions. 3.3.2 Flocculation behavior The flocculation behavior of cationic starch materials showed a strong dependency on both the DS and the content of branched amylopectin. In case of monofloccu-lation, the cationic starch derivatives prepared from waxy (i.e. amylopectin-rich) starch gave the highest degree of dewatering, while the amylose (Hylon VII) derivatives showed comparatively low dewatering. The cationic derivatives of maize and potato starch have similar efficiencies because both have the same content of amylose. In addition, in any case the dewatering effect was increased with increasing DS as discussed in detail in [21]. 3.3.3 Viscosity and GPC The cationic starch derivatives obtained by the described methods are soluble in water to give viscous solutions. The aqueous solutions of the starch derivatives (2%, w/v) showed viscosities in the range of 0.025 to 1.303 Pas for a shear rate of 1 s-1 (Tab. 5). The viscosity shows a typical nonNewtonian behavior [21], which depends on the DS but also on the starch material. The cationic Tab. 5. Weight-average molar mass of the starting starch materials and the cationic starch products. potato starch with a DS value of 0.70 shows a viscosity of 1.23 Pas, whereas the viscosity of the cationic maize starch of same DS was found to be of only 0.12 Pas. Obviously, there is no simple relation between the DS and the viscosity. To check the polymer degradation during the reaction, the weight-average molar mass of the samples was determined by GPC. In any case, the Mw of the cationic products is decreased compared with the starting starch sample (Tab. 6). Tab. 6. Viscosity (η) of cationic starch samples with different degrees of substitution (DSN) dissolved in water (2%, w/w) measured at 25 ° at a shear rate of 1 s-1. 4 Conclusions It was shown that it is possible to produce cationic starch derivatives with high degrees of substitution up to 1.4. The products can be easily prepared with 3-chloro-2hydroxypropyltrimethylammonium chloride in a suspension of starch and ethanol/water, homogeneously in DMSO, and under dissolution applying aqueous NaOH with 2,3epoxypropyltrimethylammonium chloride. The starting material does not influence the DS value except in the case of waxy maize starch in a heterogeneous medium. High degrees of substitution up to 1 are obtained by a one-step reaction with a molar ratio of cationi-zation agent per AGU of 2 in aqueous sodium hydroxide. The DS value reached by these reactions can be adjusted by the amount of cationization agent used in the reaction. The aqueous sodium hydroxide medium shows the highest efficiency for a molar ratio of agent/starch of 2, but more liquid must be applied compared to the slurry reaction in ethanol/water. For higher DS values (up to 1.5), a second cationization step is necessary. The obtained starch materials are soluble in cold water and show promising properties. Recently, their efficiency as flocculation agents in waste-water clarification was shown [21]. Moreover, the cationic derivatives show a significant antibacterial behavior [22]. Acknowledgement We like to thank the Fachagentur Nachwachsende Roh-stoffe e.V. (Agency of Renewable Resources) for the general financial support within the framework of the project FKZ 97NR136. Further results of the project were already published in [13,15, 23]. References [1] T. Vihervaara, A. Paakkanen, J. Kaki EP 0737210 B1 (1999), Raisio Chemicals Oy; Chem. Abstr. 120 (1994) 301471. [2] A. Likitalo, J. Kaki WO 99/62957 (1999), Raisio Chemicals Oy; Chem. Abstr. 132 (1999) 24080. [3] P. R. Bhirud, F. W. Sosulski, R. T. Tyler, M. Kweon US 5827372 (1998), Grain Tech Consulting; Chem. Abstr. 125 (1994)2132685. [4] D. B. Solarek: Cationic starches, in Modified Starches: Properties and Uses (Ed.: O. B. Wurzburg) CRC Press, Boca Raton, Florida, 1987, p. 113. [5] E. F. Paschal: Production and uses of cationic starches, in Starch: Chemistry and Technology (Ed.: R. Lester) Academic Press, New York, 1967, 403-423. [6] R. L Shogren: Starch: Properties and Materials Applications, in Biopolymers from renewable Resources (Ed.: D. L. Kaplan) Springer Verlag, Berlin, Heidelberg, NewYork, 1998, 30-46. [7] J. R. Daniel, R. L Whistler, H. Roper: Starch, in Ullmann's Encyclopedia of Industrial Chemistry, 7th ed., Electronic Release, Wiley-VCH, Weinheim, 2004. [8] E. Carr, M. O. Bagby: Preparation of cationic starch ether: A reaction efficiency study. Starch/Starke 1981, 33, 310-312. [9] M. R. Kweon, F. W. Sosulski, H. S. Han: Effect of aqueous ethanol cationization on functional properties of normal and waxy starches. Starch/Starke 1997, 49, 202-207. [10] G. Hellwig, D. Bischoff, A. Rubo: Production of cationic starch ethers using an improved dry process. Starch/Starke 1992,44,69-74. [11] J. Merta, P. Stenius, E. Pirttinen: Interactions between cationic starch and anionic surfactants III. Rheology and structure of the complex phase. J. Disp. Sci. Technol. 1999, 20, 677-697. [12] J. Merta, P. Stenius: Interactions between cationic starch and mixed anionic surfactants. Colloids and Surfaces A: Physicochem. Eng. Aspects 1999, 149, 367-377. [13] Th. Heinze, P. Talaba, U. Heinze: Starch derivatives of high degree of functionalization, 1. Effective, homogeneous synthesis of p-toluenesulfonyl (tosyl) starch with a new functionalization pattern. Carbohydr. Polym. 2000, 42, 411-420. [14] Th. Heinze, K. Pfeiffer, W. Lazik: Starch derivatives of high degree of functionalization 3. Studies about the influence of reaction conditions and starting materials on the molecular structure of carboxymethyl starch. J. Appl. Polym. Sci. 2001,87,2036-2044. [15] R. Dicke, K. Rahn, V. Haack, Th. Heinze: Starch derivatives of high degree of functionalization 2. Determination of the functionalization pattern of p-toluenesulfonyl starch by per-acylation and NMR spectroscopy. Carbohydr. Polym. 2001, 45, 43-51. [16] Th. Heinze, U. Heinze, C. Grote, J. Kotz, W. Lazik: Starch derivatives of high degree of functionalization 4. Homogeneous tritylation of starch and subsequent carboxymethyla-tion. Starch/Starke 2001, 53, 262-268. [17] K. Pfeiffer, Th. Heinze, W. Lazik: Starch derivatives of high degree of functionalization 5. Stepwise carboxymethylation of amylose. Chem. Papers 2002, 56, 261-266. [18] W. Lazik, Th. Heinze, K. Pfeiffer, G. Albrecht, P. Mischnick: Starch derivatives of high degree of functionalization 6. Multi step carboxymethylation of starch. J. Appl. Polym. Sci. 2002, 82, 743752. [19] O. Wilke, P. Mischnick: Determination of the substitution pattern of cationic starch ethers. Starke/Starch 1997, 49, 453-458. [20] O. Wilke, P. Mischnick: Analysis of cationic starches, determination of the substitution pattern of O-(2-hydroxy-3-trimethylammonium)propyl ethers. Carbohydr. Res. 1995, 275,309-318. [21] V. Haack, T. Heinze, G. Oelmeyer, W.-M. Kulicke: Starch derivatives of high degree of functionalization, 8. Synthesis and flocculation behavior of cationic starch polyelectrolytes. Macromol. Mater. Eng. 2002, 287, 495-502. [22] V. Haack, T Heinze, M. Schmidtke, U. Mollmann, H.-M. Dahse, A. Hartl.: DE 10200717.9 (2003). [23] U. Heinze, V. Haack, Th. Heinze: New highly functionalized starch derivatives, in Biorelated Polymers: Sustainable Polymer Science and Technology (Eds. E. Chiellini, H. Gil, G. Braunegg, J. Buchert, P. Gatenholm, M. van derZee) Kluwer Academic/Plenum Publishers, Dordrecht, Boston, London, 2001,277-319. (Received: August 6, 2003) (Accepted: September 10, 2003)