P0387/12A

advertisement

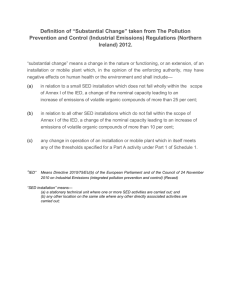

Decision Document Part A Q57/15 Version 0 Decision Document for ERE Development Ltd Permit Number P0387/12A CONDITION(S) 1.1The permitted activities 1.2.1 The site 1.3 Overarching Management 1.4 Pre-operation1.4.1 1.4.2 conditions 1.4.3 1.4.4 1.4.5 1.4.6 Page 1 of 11 JUSTIFICATION The permit relates to the burning of non-hazardous waste in a co-incinerator. The nominal mass of waste that can be burned is 20 tonne/hr which is stated in table 1.1 as required by Article 45(1)(b) of the Industrial Emissions Directive 2010/75/EU (IED). The permit also covers directly associated activities including the combustion of virgin timber. The IED Article 3(41), defines co-incineration plant as any plant whose main purpose is the generation of energy or material products from waste. The proposed installation is designed to achieve an electrical output of 0.8MWe/tonne of waste or greater. The main purpose of the plant is the generation of electricity. The activity is prescribed under Schedule1, Section 5.1 Incineration and Co-incineration of waste, para (c) - an installation involving the incineration of non-haz waste in a coincinerator with a capacity of 3 tonnes or more per hour. The site boundary is area highlighted by the black line on the site plan and incorporates all activities associated with the operation. This is a standard condition requiring a management system, organisational structure and resources to ensure compliance with the conditions of the permit. Condition 1.4.1. – The operator is to provide details of the on site water drainage plans. Condition 1.4.2. – The Permitted Installation shall not be brought into operation until a commissioning programme has been agreed by the Chief Inspector. This is required to ensure emissions are managed during the hot commissioning phase of the installation. Condition 1.4.3. – requires a monitoring proposal for post commissioning noise levels. This is included to ensure that actual noise emissions are in line with those predicted in the permit application. Condition 1.4.4. – is required to ensure the waste quality is managed and does not result in the co-incinerator feed material having high concentration of halogens or mercury. The exact means of doing this has yet to be agreed, however it is likely that it will involve the sampling of waste received on site and the setting of upper concentrations for substances that require control. Further measures such as supplier agreements and third party audits are also likely to be required. Condition 1.4.5. – is included to ensure that the sampling facilities for emissions to air from the co-incinerator meet the requirements of BS EN 13284 (Stationary Source Emissions – Determination of low range mass concentration of dust) and BS EN 15259 (Stationary Source Emissions – “Requirements for the measurement sections and sites and for the measurement objectives, plan and report”). Condition 1.4.6 – The environmental impact with a 39 m stack is considered acceptable. However, IPRI’s assessment showed that for a modest increase in stack height a significant reduction in the environmental impact could be achieved. Decision Document Part A Q57/15 Version 0 1.5 Off site conditions 1.6 Minor operational changes There are no-off site conditions. These are standard conditions requiring agreement from the Inspectorate before carrying out certain changes. 2.1 In process controls Conditions 2.1.1 to 2.1.4 are standard conditions. Conditions 2.1.5 to 2.1.11 include the requirements of the Chapter 4 of IED as detailed in the table below. 2.2.1 Emissions into air (other than odour, noise and vibration) Page 2 of 11 Permit Condition Condition 2.1.5 Condition 2.1.6 Condition 2.1.7 Condition 2.1.8 Condition 2.1.9 IED Condition Article 50 paragraph 2. Annex VI Part 6 (2.1) (b) Article 50 paragraph 4 Article 45 paragraph 1(f) Article 47 Condition 2.1.10 Article 46 paragraph 6 Condition 2.1.11 Condition 2.1.12 Article 45 paragraph 1 (a). Article 50 paragraph 2. Comments 850ºC for 2 seconds requirement for co-incineration. Temperature measurement requirement. The automatic stopping of waste feed. Requirement to cease operation if CEMs fail. Requirement to shut down in case of breakdown of pollution control equipment. Requirement to shut down after 4 hours of emission exceedances and up to a maximum of 60 hours of exceedances in a year. Categories of non-hazardous waste which may be accepted. This condition prevents the combustion of waste which contains more than 1% halogenated organic compounds as this requires a different combustion temperature. The ELVs to air as set out in the permit are those obligated by Annex VI of IED. The proposed installation will not give rise to significant ground-level pollution (as per Article 46, paragraph 1 of IED) and no statutory emission limit or objective will be exceeded due to emissions from the installation. The applicant and NIEA assessed the impact of emissions to air using the maximum daily average values specified in Annex VI of IED. The modelling was based on the assumption the plant will be emitting at the maximum daily average values for 100% of the time. A summary of the results from the applicant’s (using AERMOD) and NIEA’s (using ADMS) air dispersion modelling is tabulated. The background concentrations included contributions from other local sources. Decision Document Part A Q57/15 Version 0 Air Quality Objective Predicted max conc NIEA Model (μg/m3) Predicted max conc Applicants Model (μg/m3) Background conc (μg/m3) Air quality objective (μg/m3) % of air quality objective impacted based on NIEA Model PEC % of air quality objective impacted based on Applicant Model PEC NO2 annual mean 7.421 0.97 11.85 40 48.18% th NO2 99.79 %ile 52.242 24.6 23.7 200 37.97% of 1hr mean NOx annual mean 7.42 2.41 16.81 30 80.76% th SO2 99.2 %ile of 24.7 5.91 30.4 350 15.7% max 24 hour conc SO2 99.7th %ile of 1hr mean 26.07 20.89 30.4 125 45.18% concentrations SO2 annual mean 1.862 0.6 15.2 20 85.3% PM10 annual mean 1.2 0.42 12.9 40 35.3% th PM10 90.4 %ile 0.4 0.12 12.9 50 26.6% of 24hr mean 1 : 100% NO2 as per EA Guidance http://www.environment-agency.gov.uk/business/regulation/38791.aspx 2 : 50% NO2 as per EA Guidance http://www.environment-agency.gov.uk/business/regulation/38791.aspx 32.0% 24.15% 64.07% 10.37% 41.03% 79% 33.3% 26.04% PEC is the impact from the installation on top of background concentrations. Representative background air quality concentrations were taken at a location 1.6 km from the site. The conclusion from the NIEA dispersion modelling is that even using worse case emission concentration the local air quality objectives will not be threatened. According to the NIEA modelled data the SO2 annual mean is increased by 9% to 17 μg/m3 , which when combined with the background gives a total predicted environmental concentration of 85% of the air quality objective. This includes a contribution of 76% of the air quality objective from the existing background concentration. However, the modelled value is very conservative for several reasons: - The model assumed the plant will be emitting at the maximum daily average value prescribed in Annex VI of IED for Page 3 of 11 Decision Document Part A Q57/15 Version 0 - 100% of the time. The sulphur content of wood is typically very low at <0.2%; and Similar installations are known to operate at 1/10th of the SO2 emission limit value The Conditions 2.2.1.2 to 2.2.1.7 include the requirements of the Chapter IV of IED as detailed in table below. Condition 2.2.1.1 lists the point emissions sources from which emission to air are permitted. The source permitted is the coincinerator stack. Permit Condition IED Condition Condition 2.2.1.2 Annex VI Part 6, (2.1) & Annex VI Part 3 Comments Emissions limit values to air should have been determined for the co-incineration of waste using the mixing rule in Annex VI Part 4 of IED. The operator requested the flexibility to combust any ratio of virgin to waste wood so the elv’s set out in Annex VI Part 3 of IED assuming 100% combustion of waste wood were applied. Condition 2.2.1.3 Annex VI Part 3, (1) A 11% oxygen reference condition has been included. Condition 2.2.1.4 Condition 2.2.1.5 Annex VI Part 6 (1.3) & Annex VI Part 8 (1.2) Determination of half hour averages, including confidence intervals. Condition 2.2.1.6 Annex VI Part 8 (1.1) Condition 2.2.1.7 Condition 2.2.1.8 Annex VI Part 8 (1.2) Article 53 Compliance criteria have been included in line with Annex VI of IED. Discarding of values due to malfunction or maintenance. Includes the requirement of for the management of dry residues such as ash. Condition 2.2.1.10 is a standard condition requiring for the best available techniques to be used to control fugitive emissions to air. 2.2.2 Emissions into water 2.2.3 Emissions in to Page 4 of 11 The emission limits in condition 2.2.2.2 are for surface water run off only. Condition 2.2.2.3 & 2.2.2.4 are standard conditions for BAT and the protection of surface waters. All process water discharges will be to sewer. The elvs have been set from the NI Water Consent to Discharge Trade Effluent Decision Document Part A sewer 2.2.4 Emissions into land 2.2.5 Emissions to groundwater 2.2.6 Odour 2.3 Management 2.4 Efficient use of raw materials 2.5 Waste Handling and Storage 2.6 Waste recovery and disposal 2.7 Energy Efficiency 2.8 Accident prevention and control 2.9 Noise and vibration 2.10 Monitoring Page 5 of 11 Q57/15 Version 0 issued 14 Nov 2012, and a monitoring requirement for a monthly 24 hour composite sample. There are no process emissions to land from the proposed facility. There are no process emissions to groundwater from the proposed facility. These are standard conditions relating to control of odour on site. Standard conditions for the training of staff, maintenance of equipment and procedure for incidents Conditions 2.4.1 to 2.4.3 are standard conditions for the efficient use of raw materials, water and waste minimisation. Conditions 2.5.1 and 2.5.2 are standard conditions for the storage of waste on site. Conditions 2.6.1 -2.6.4 are standard conditions for the management and recording of waste sent for recovery/disposal from and on site. Condition 2.6.5 is added to include the requirement of the IED Article 53 requiring the harmfulness and amount of residues to be minimised and that they be recycled on site where appropriate. Condition 2.7.1 and 2.7.2 are standard conditions for the management of energy on site. Condition 2.7.3 is included as it is a requirement of IED Article 50(5) requiring that heat from the co-incineration plant is recovered as far as practicable. Condition 2.8.1 is a standard condition for a plan to prevent and control accidents on site. Conditions 2.8.2 and 2.8.3 are included as they are a requirement of Article 46(5) of IED for the control of spills and firewater. An IMP item has been included to address this. Conditions 2.9.1 and 2.9.2 are standard conditions for the control of noise. The conclusion of modelling exercise was that noise limits are predicted to be below those presented in BS4142 and WHO guidance and the site will be operating to BAT. The operator is required to assess the actual impact of noise emissions once the plant has been commissioned. This is required under Section 6 of the permit. Condition 2.9.3 was at the request of the district council and restricted the operation of the wood chipper to 08:00-18:00 Mon-Sat and not at all on Sunday or public holidays. Conditions 2.10.1, 2.10.2, 2.10.3, 2.10.5& 2.10.8 are standard permit conditions. Conditions 2.10.4, 2.10.6 & 2.10.7 include the requirement of IED. Condition 2.10.4 is included as it is a requirement of IED Annex VI Part 6 (1.2) for parallel measurement for calibration and continuous monitors. Condition 2.10.6 is included to deliver the requirements of IED Annex VI Part 6 (1.2) and BS EN 14181 clause 5.4. requirement for accredited quality assurance according to EN ISO/IEC 17025. Condition 2.10.7 specifies BS EN 15259 in accordance with IED Article 48(3) which requires the competent authority to lay down requirements for the sampling or measurement points. Decision Document Part A Q57/15 Version 0 2.11 Closure and Decommissioning 2.12 Multi Operator installations 2.13 Transfer to effluent treatment plant 3 –Records 4 – Reporting Conditions 2.11.1 to 2.11.4 are standard conditions requiring a closure plan and notification of closure. 5 - Notification Condition 5.1 is a standard condition requiring the notification of certain incidents. Notification of continuous emission monitors (CEMS) failure is also required. IMPROVEMENT PROGRAMME IMP 6.1- The Operator shall give a written notification of when commissioning is complete. This is required so the Inspectorate knows when commissioning has ceased and operation had begun. IMP 6.2 – Environmental commissioning report This is required to verify operation in accordance with Article 50(4) and Annex VI Part 6 (2.2) of IED. IMP 6.3 – Qual 2 of CEMs This is required in order to specify a time for the compilation of Qual 2 procedure as per Condition 2.10.4 and for parallel measurement calibration of continuous monitors. IMP 6.4 – Noise Monitoring This is required to validate the conclusion for the monitoring report submitted as part of application. IMP 6.5 – Marking of drainage This is required to ensure drainage is suitably identified to prevent unauthorised discharges. IMP 6.6 – Demonstration of boiler cleaning techniques This is required to ensure boiler surfaces are cleaned as far as practicable to limit de-novo synthesis of dioxin/furans. IMP 6.7 – Testing of Ash characteristics This is required to aid in demonstrating Condition 2.6.5 and thus ensuring appropriate disposal or recovery. IMP 6.8 – On site storage This is required to ensure compliance with condition 2.8.3 and requirements of Article 46(5) of IED. IMP 6.9 – Environmental Monitoring Programme Page 6 of 11 This is a single operator site There are no transfers to an effluent treatment plant. Condition 3.1 is standard condition for the maintenance of records. Conditions 4.1 to 4.6 are standard conditions. Condition 4.2 requires the submission of reports as specified in the permit. Additional monitoring and reporting is required on account of Annex VI Part 6 (2.1) (b) of IED for monitoring of process operating parameters. Condition 4.6 is added to ensure the reporting of waste recovered on site is included in permit. Decision Document Part A Q57/15 Version 0 This is required to confirm that the actual environmental impact is in line with that predicted by the modelling. CONSULTEE COMMENTS Health and Social Services Board District Council Food Standards Agency NIEA Water Management Unit NIEA Conservation Designations and Protection Health and Safety Executive (NI) Londonderry Port Authority IMPACTS ON THE ENVIRONMENT European sites & ASSI Other environmental Page 7 of 11 Comments and measures in permit where applicable The Public Health Agency (PHA) commented that the primary potential health concerns in relation to the facility include emissions from the process. With the implementation of the mitigation measures identified, the PHA is reassured that the potential human health effects due to emissions from this biomass fuelled power plant facility, where non-hazardous waste wood is incinerated, will be minimal. The main points of Derry City Council’s response to consultation in relation to PPC where; (i) restriction of wood chipping operations to 08:00-18:00 Monday to Saturday and not at all on Sunday or public holidays (ii) the stack should be 39 m based on the Air Quality Impact Assessment. On the basis of the proposal to use non-hazardous waste it seems unlikely that activities planned for the site will have an adverse impact on the human food chain provided the plant is operated and maintained by appropriately trained staff. The limits and parameters associated with the discharge to surface water have been determined in consultation with WMU. The site was not previously regulated and there has been no pollution incidents recorded in relation to the site. The NIEA Conservation Designations and Protection division of the NIEA have determined the proposal to unlikely have a significant effect on any site selection features of any designated site. The proposed installation is 400m from River Foyle and 1.2 km from Faughan River. Both these are designated as ASSI and RAMSAR sites. There are no direct discharges to these waterways from the site apart from storm water run off. The air dispersion model predicted concentrations of emissions to be below air quality objectives. No comments on the proposal. No comments on the proposal. The River Foyle and Faughan River are Special Areas of Conservation (SAC). The NIEA Conservation Designations and Protection division of the NIEA determined the proposal unlikely to have a significant effect on any site selection features of any designated site. The proposed installation is 400m from River Foyle and 1.2km from the Faughan River. The proposed installation does not have any direct process discharges from the site to these waterways. Storm water off is to the River Foyle. There are emission limit values within the permit for the storm water which will prevent an adverse impact on the River Foyle. The air dispersion modelling predicted concentrations of emissions to have no adverse impact on air quality objectives. Condition 2.8.3 and IMP6.8 have been included requiring retention of any potentially contaminated fire water. Decision Document Part A receptors People Q57/15 Version 0 The site is located 6km to the NE of Londonderry on the east bank of the River Foyle. It is bounded on the North and West by Temple Road and to the east by Maydown Road with the Lisahally Industrial Estate situated to the SE of the proposal. The nearest sensitive receptors are located 350m to the south. The Strathfoyle housing estate is located approximately 780m SE and the houses along Culmore Point on the opposite side of the River Foyle are located approximately 550m N. Impact on air Quality The dispersion of NOx SO2, and PM10, emitted by the proposed installation were modelled using AERMOD and ADMS dispersion modelling software. The result of the exercise led to the conclusion that local air quality standards will not be exceeded by the proposed installation. The assessment took into account the background concentrations which includes contributions from other local sources. See section 2.2.1. Total particulate emissions to air from co-incineration will be controlled via the limits specified in IED. The ground level concentrations of the heavy metals were also modelled and found to be acceptable. The are 3 Local Air Quality Management Areas within the Derry area. Derry City AQMA encompasses parts of the Creggan Road, Windsor Terrace on Infirmary Road, Creggan Street and Marlborough Terrace on Lone Moor Road. This AQMA is located 6.6 km from the proposed location. Dale’s Corner AQMA incorporates all on Ebrington Terrace and Columba Terrace on Limavady Road and No1-19 Glendermott Road. This AQMA is located 6km from the proposal. The third AQMA is at the junction of the Buncrana Road/ Racecourse Road and incorporates all of St Patrick’s Terrace, all of Maybrook Terrace and No. 1-12 Collen Terrace to the South East. This AQMA is located 4.5km from the proposal. At over 1 km from the installation the predicted long term air quality concentration for NO2 resulting from the installation is less than 0.5 μg/m3 i.e. less that 1.25% of the Air Quality Objective for NO2. The impact on the AQMA will not be significant. Both PCBs and PAHs are for the most part either destroyed or their formation prevented due to the high temperatures maintained during the incineration process. Any PCBs or PAHs which remain in the exhaust gas would be absorbed by the injected activated carbon before release to the environment. The operator is required to monitor the emissions of PCBs and PAHs every three months for the first 12 months of operation and bi-annually thereafter. The emission limit as laid down in IED, for dioxins and furans from the proposed facility is 0.1ng/m3 TEQ (Toxicity equivalents). Page 8 of 11 Decision Document Part A Q57/15 Version 0 The report “Dioxins and Dioxin-like PCBs on the UK Environment” published by DEFRA in 2002 quotes typical mean ambient dioxin concentrations in the urban environment as 103fg/m3. Whilst there are no statutory air quality standards for dioxins, using NIEA modelling data at the point of maximum impact the predicted increase in the long term concentration would be some 2.53% of the typical background value. Impact on Food Chain The primary route of exposure for dioxins is ingestion with inhalation being a minor route of exposure. The applicant’s initial application stated a daily dry deposition rate of dioxins of 0.08053ng/m2/day. Clarification was sought and the dioxin assessment calculation was repeated to give 8.64*10-5 ng/m2/day compared to NIEA calculated daily dry deposition of 4.6*10-4 ng/m2/day. Using the applicant’s modelling data at the point of maximum impact the predicted increase to the typical soil background value over a 25 year period would be 3.94%. Using NIEA’s modelling data at the point of maximum impact the predicted increase to the typical soil background value over a 25 year period would be 21.06%. Assumptions made in the calculations: Dry deposition velocity of 0.2cm/s used Environment Agency H1 Annex F – Air Emissions recommend the value of 3 as a nominal factor to convert dry deposition to total deposition. UK Soil and Herbage Pollutants Survey 2007 gives mean measured value of dioxins in NI urban soils of 1.57 ng/kg. Soil core samples taken to depth of 5cm. Depth of soil used to calculate the total deposition was 5cm in line with the UK Soil and Herbage Pollutant Survey Average Bulk soil density for Northern Ireland from the within the UK Soil and Herbage Pollutants Survey 2007 ranges between 390 kg/m3 and 1333 kg/m3 (dry basis). The average value of 750kg/m3 was used. No removal of PCCD/F takes place from the soil over the 25 year period. Calculations are based on the point at which the maximum ground level concentration occur assuming operation of 8760 hours per year for 25 years. The addition of IMP6.9 to confirm that the actual environmental impact is in line with that predicted by the modelling. The Scientific Committee for Food established a tolerable weekly intake of 14pg/kg TEQ/kg of body weight a week for dioxins. The Committee on the Toxicity of Chemicals in Food, Consumer Products and the Environment recommend a Page 9 of 11 Decision Document Part A Q57/15 Version 0 tolerable daily intake of 2 picograms WHO-TEQ/kg body weight/day. This is based on the most sensitive effect of TCDD in laboratory animals, namely adverse effects on the developing foetus resulting from exposure in utero. This 2 picogram WHOTEQ/kg body weight/day value has been used in the screening tool put forward by the operator. Using the screening method derived by SNIFFER the proposed facility will at worst case contribute to 7% of the tolerable daily intake. This 7% of daily intake is for the hypothetical most exposed individual whose entire diet is presumed to derive from the point of maximum ground level pollutant concentration. The SNIFFER method was also applied to emission of heavy metals emitted at emission limit values. The predicted daily intakes were found to be acceptable on an individual basis with no further assessment required. Annex VI of IED groups together certain pollutants i.e. Cd & Th; Sb, As, Pb, Cr, Cu, Co, Mn, Ni, V therefore the impact of the %TDI will be greatly reduced. Page 10 of 11 Annual emission (g/yr) Ground level conc (ug/m3) Daily intake Pollutant Effective Annual stack Emission height (m) (tonnes/yr) (mg/kg/day) TDI (mg/kg/day) Source of TDI Intake as % of TDI Further assessment required? Antimony 40 0 0.00E+00 0.00E+00 4.00E-04 IRIS 0% No Arsenic 40 0.5 500000 1.76E-02 2.30E-04 2.00E-03 WHO 11% No Cadmium 40 0.05 50000 1.76E-03 2.93E-04 1.00E-03 WHO 29% No Chromium VI 40 0.5 500000 1.76E-02 2.79E-04 3.00E-03 IRIS 9% No Lead 40 0.5 500000 1.76E-02 1.79E-04 6.00E-03 WHO 3% No Manganese 40 0.5 500000 1.76E-02 2.49E-04 1.40E-01 IRIS 0% No Mercury 40 0.05 50000 1.76E-03 6.10E-06 7.00E-04 WHO 1% No Nickel 40 0.5 500000 1.76E-02 2.51E-04 1.10E-02 WHO 2% No Thallium 40 0.05 50000 1.76E-03 2.41E-05 8.00E-05 IRIS 30% No Vanadium 40 0.5 500000 1.76E-02 1.10E-04 9.00E-03 IRIS 1% No Dioxin/furan 40 0.1 3.52E-09 1.46E-10 2.00E-09 WHO 7% No Decision Document Part A Q57/15 Version 0 Noise: The conclusion of modelling exercise was that noise limits are predicted to be below those presented in BS4142 and WHO guidance and the site will be operating to BAT. The Operator is required to validate the re accesses the actual impact of noise emissions one the plant has been commissioned. This is required under Section 6 of the permit. Draft Permit Discussion with Operator Draft permit shared with Operator via email on the 15th Jan 2013. Comments received on the 06th March 2013 with no concerns raised to the content of the permit or improvement programmes. Public Participation Directive Draft determination was posted on website and public registers on the 07 March 2013. No comments were received in relation to the draft determination. Completed by …………………………. Keith Bradley Date: 09/04/2013 Page 11 of 11