UniMasr.com_fb3c58c2db60b2fe30fea16c704e558c

advertisement

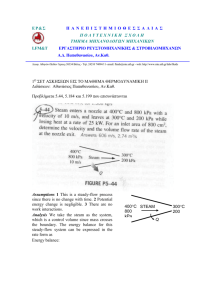

Gas Power Cycles Air-Standard Assumptions In our study of gas power cycles, we assume that the working fluid is air, and the air undergoes a thermodynamic cycle even though the working fluid in the actual power system does not undergo a cycle. To simplify the analysis, we approximate the cycles with the following assumptions: The air continuously circulates in a closed loop and always behaves as an ideal gas. All the processes that make up the cycle are internally reversible. The combustion process is replaced by a heat-addition process from an external source. A heat rejection process that restores the working fluid to its initial state replaces the exhaust process. The cold-air-standard assumptions apply when the working fluid is air and has constant specific heat evaluated at room temperature (25oC or 77oF). Terminology for Reciprocating Devices The following is some terminology we need to understand for reciprocating engines—typically piston-cylinder devices. Let’s look at the following figures for the definitions of top dead center (TDC), bottom dead center (BDC), stroke, bore, intake valve, exhaust valve, clearance volume, displacement volume, compression ratio, and mean effective pressure. The compression ratio r of an engine is the ratio of the maximum volume to the minimum volume formed in the cylinder. 1 The mean effective pressure (MEP) is a fictitious pressure that, if it operated on the piston during the entire power stroke, would produce the same mount of net work as that produced during the actual cycle. Otto Cycle: The Ideal Cycle for Spark-Ignition Engines Consider the automotive sparkignition power cycle with the following processes: - Intake stroke - Compression stroke - Power (expansion) stroke - Exhaust stroke Often the ignition and combustion process begins before the completion of the compression stroke. The number of crank angle degrees before the piston reaches TDC on the number one piston at which the spark occurs is called the engine timing. What are the compression ratio and timing of your engine in your car, truck, or motorcycle? 2 The air-standard Otto cycle is the ideal cycle that approximates the spark ignition combustion engine with the following processes: 1-2 Isentropic compression 2-3 Constant volume heat addition 3-4 Isentropic expansion 4-1 Constant volume heat rejection --------------------------------------------------------------------------------------------------------------------------------------------- Otto, Diesel, and Dual Cycles Although most gas turbines are also internal combustion engines, the name is usually reserved to reciprocating internal combustion engines of the type commonly used in automobiles, trucks, and buses. Two principal types of reciprocating internal combustion engines are the sparkignition engine and the compression-ignition engine. In a spark- ignition engine a mixture of fuel and air is ignited by a spark plug. In a compression ignition engine air is compressed to a high-enough pressure and temperature that combustion occurs spontaneously when fuel is injected. In a four-stroke internal combustion engine, a piston executes four distinct strokes within a cylinder for every two revolutions of the crankshaft. Figure 12.7 gives a pressure-displacement diagram as it might be displayed electronically. With the intake valve open, the piston makes an intake stroke to draw a fresh charge into the cylinder. Next, with both valves closed, the piston undergoes a compression stroke raising the temperature and pressure of the charge. A combustion process is then initiated, resulting in a high pressure, hightemperature gas mixture. A power stroke follows the compression stroke, during which the gas mixture expands and work is done on the piston. The piston then 3 executes an exhaust stroke in which the burned gases are purged from the cylinder through the open exhaust valve. Smaller engines operate on two-stroke cycles. In two-stroke engines, the intake, compression, expansion, and exhaust operations are accomplished in one revolution of the crankshaft. Although internal combustion engines undergo mechanical cycles, the cylinder contents do not execute a thermodynamic cycle, since matter is introduced with one composition and is later discharged at a different composition. A parameter used to describe the performance of reciprocating piston engines is the mean effective pressure, or mep. The mean effective pressure is the theoretical constant pressure that, if it acted on the piston during the power stroke, would produce the same net work as actually developed in one cycle. That is, where the displacement volume is the volume swept out by the piston as it moves from the top dead center to the bottom dead center. For two engines of equal displacement volume, the one with a higher mean effective pressure would produce the greater net work and, if the engines run at the same speed, greater power. Detailed studies of the performance of reciprocating internal combustion engines may take into account many features, including the combustion process occurring within the cylinder and the effects of irreversibilities associated with friction and with pressure and temperature gradients. Heat transfer between the gases in the cylinder and the cylinder walls and the work required to charge the cylinder and exhaust the products of combustion also might be considered. Owing to these complexities, accurate modeling of reciprocating internal combustion engines normally involves computer simulation. To conduct elementary thermodynamic analyses of internal combustion engines, considerable simplification is required. A procedure that allows engines to be studied qualitatively is to employ an air standard analysis having the following elements: (1) a fixed amount of air modeled as an ideal gas is the system; (2) the combustion process is replaced by a heat transfer from an external source and represented in terms of elementary thermodynamic processes; (3) there are no exhaust and intake processes as in an actual engine: the cycle is completed by a constant-volume heat rejection process; (4) all processes are internally reversible. The processes employed in air-standard analyses of internal combustion engines are selected to represent the events taking place within the engine simply and mimic the appearance of observed pressure-displacement diagrams. In addition to the constant volume heat rejection noted previously, the compression stroke and at least a portion of the power stroke are conventionally taken as isentropic. The 4 heat addition is normally considered to occur at constant volume, at constant pressure, or at constant volume followed by a constant pressure process, yielding, respectively, the Otto, Diesel, and Dual cycles shown in Table 12.7. Reducing the closed system energy balance, gives the following expressions for work and heat applicable in each case shown in Table 12.7: (12.32) Table 12.7 provides additional expressions for work, heat transfer, and thermal efficiency identified with each case individually. All expressions for work and heat adhere to the respective sign conventions of Eq. (12.7b). Equations (1) to (6) of Table 12.4 apply generally to air-standard analyses. In a cold air standard analysis the specific heat ratio k for air is taken as constant. Equations (1′) to (6′) of Table 12.4 apply to cold air-standard analyses, as does Eq. (4′) of Table 12.5, with n = k for the isentropic processes of these cycles. Referring to Table 12.7, the ratio of specific volumes v1/v2 is the compression ratio, r. For the Diesel cycle, the ratio v3/v2 is the cutoff ratio, rc. Figure 12.8 shows the variation of the thermal efficiency with compression ratio for an Otto cycle and Diesel cycles having cutoff ratios of 2 and 3. The curves are determined on a cold air-standard basis with k = 1.4 using the following expression: (12.33) where the Otto cycle corresponds to rc = 1. 5 As all processes are internally reversible, areas on the p-v and T-s diagrams of Table 12.7 can be interpreted, respectively, as work and heat transfer. Invoking Eq. (12.23) and referring to the p-v diagrams, the areas under process 3-4 of the Otto cycle, process 2-3-4 of the Diesel cycle, and process x-3-4 of the Dual cycle represent the work done by the gas during the power stroke, per unit of mass. For 6 each cycle, the area under the isentropic process 1-2 represents the work done on the gas during the compression stroke, per unit of mass. The enclosed area of each cycle represents the net work done per unit mass. With Eq. (12.25) and referring to the T-s diagrams, the areas under process 2-3 of the Otto and Diesel cycles and under process 2-x-3 of the Dual cycle represent the heat added per unit of mass. For each cycle, the area under the process 4-1 represents the heat rejected per unit of mass. The enclosed area of each cycle represents the net heat added, which equals the net work done, each per unit of mass. ---------------------------------------------------------------------------------------------Thermal Efficiency of the Otto cycle: Apply first law closed system to process 2-3, V = constant. Thus, for constant specific heats, Apply first law closed system to process 4-1, V = constant. Thus, for constant specific heats, The thermal efficiency becomes 7 Recall processes 1-2 and 3-4 are isentropic, so Since V3 = V2 and V4 = V1, we see that Is this the same as the Carnot cycle efficiency? Since process 1-2 is isentropic, where the compression ratio is r = V1/V2 and We see that increasing the compression ratio increases the thermal efficiency. However, there is a limit on r depending upon the fuel. Fuels under high temperature resulting from high compression ratios will prematurely ignite, causing knock. Example 8-1 An Otto cycle having a compression ratio of 9:1 uses air as the working fluid. Initially P1 = 95 kPa, T1 = 17oC, and V1 = 3.8 liters. During the heat addition process, 7.5 kJ of heat are added. Determine all T's, P's, th, the back work ratio, and the mean effective pressure. 8 Process Diagrams: Review the P-v and T-s diagrams given above for the Otto cycle. Assume constant specific heats with C v = 0.718 kJ/kg K, k = 1.4. (Use the 300 K data from Table A-2) Process 1-2 is isentropic; therefore, recalling that r = V1/V2 = 9, The first law closed system for process 2-3 was shown to reduce to (your homework solutions must be complete; that is, develop your equations from the application of the first law for each process as we did in obtaining the Otto cycle efficiency equation) Then, 9 Using the combined gas law Process 3-4 is isentropic; therefore, Process 4-1 is constant volume. So the first law for the closed system gives, on a mass basis, For the cycle, u = 0, and the first law gives 10 The thermal efficiency is The mean effective pressure is The back work ratio is (can you show that this is true?) Air-Standard Diesel Cycle The air-standard Diesel cycle is the ideal cycle that approximates the Diesel combustion engine 11 Process Description 1-2 Isentropic compression 2-3 Constant pressure heat addition 3-4 Isentropic expansion 4-1 Constant volume heat rejection The P-v and T-s diagrams are: Thermal efficiency of the Diesel cycle Now to find Qin and Qout. Apply the first law closed system to process 2-3, P = constant. Thus, for constant specific heats Apply the first law closed system to process 4-1, V = constant (just like the Otto cycle) Thus, for constant specific heats 12 The thermal efficiency becomes where rc is called the cutoff ratio, defined as V3 /V2, and is a measure of the duration of the heat addition at constant pressure. Since the fuel is injected directly into the cylinder, the cutoff ratio can be related to the number of degrees that the crank rotated during the fuel injection into the cylinder. Recall processes 1-2 and 3-4 are isentropic, so Since V4 = V1 and P3 = P2, we divide the second equation by the first equation and obtain 13 Therefore, What happens as rc goes to 1? Sketch the P-v diagram for the Diesel cycle and show rc approaching1 in the limit. 14 Brayton Cycle The Brayton cycle is the air-standard ideal cycle approximation for the gasturbine engine. This cycle differs from the Otto and Diesel cycles in that the processes making the cycle occur in open systems or control volumes. Therefore, an open system, steady-flow analysis is used to determine the heat transfer and work for the cycle. We assume the working fluid is air and the specific heats are constant and will consider both open and closed gas-turbine cycles. The closed cycle gas-turbine engine Process Description 1-2 Isentropic compression (in a compressor) 2-3 Constant pressure heat addition 3-4 Isentropic expansion (in a turbine) 4-1 Constant pressure heat rejection The T-s and P-v diagrams are Thermal efficiency of the Brayton cycle 15 Now to find Qin and Qout. Apply the conservation of energy to process 2-3 for P = constant (no work), steady-flow, and neglect changes in kinetic and potential energies. For constant specific heats, the heat added per unit mass flow is The conservation of energy for process 4-1 yields for constant specific heats (let’s take a minute for you to get the following result) The thermal efficiency becomes Recall processes 1-2 and 3-4 are isentropic, so 16 Since P3 = P2 and P4 = P1, we see that The Brayton cycle efficiency becomes Is this the same as the Carnot cycle efficiency? Since process 1-2 is isentropic, where the pressure ratio is rp = P2/P1 and 17 Extra Assignment Evaluate the Brayton cycle efficiency by determining the net work directly from the turbine work and the compressor work. Compare your result with the above expression. Note that this approach does not require the closed cycle assumption. Example 8-2 The ideal air-standard Brayton cycle operates with air entering the compressor at 95 kPa, 22oC. The pressure ratio r p is 6:1 and the air leaves the heat addition process at 1100 K. Determine the compressor work and the turbine work per unit mass flow, the cycle efficiency, the back work ratio, and compare the compressor exit temperature to the turbine exit temperature. Assume constant properties. Apply the conservation of energy for steady-flow and neglect changes in kinetic and potential energies to process 1-2 for the compressor. Note that the compressor is isentropic. The conservation of mass gives For constant specific heats, the compressor work per unit mass flow is Since the compressor is isentropic 18 The conservation of energy for the turbine, process 3-4, yields for constant specific heats (let’s take a minute for you to get the following result) Since process 3-4 is isentropic We have already shown the heat supplied to the cycle per unit mass flow in process 2-3 is 19 The cycle efficiency becomes The back work ratio is defined as Note that T4 = 659.1 K > T2 = 492.5 K, or the turbine outlet temperature is greater than the compressor exit temperature. Can this result be used to improve the cycle efficiency? What happens to th, win /wout, and wnet as the pressure ratio r p is increased? 20 Let's take a closer look at the effect of the pressure ratio on the net work done. Note that the net work is zero when For fixed T3 and T1, the pressure ratio that makes the work a maximum is obtained from: This is easier to do if we let X = r p (k-1)/k Solving for X Then, the r p that makes the work a maximum for the constant property case and fixed T3 and T1 is 21 For the ideal Brayton cycle, show that the following results are true. When rp = rp, max work, T4 = T2 When rp < rp, max work, T4 > T2 When rp > rp, max work, T4 < T2 Regenerative Brayton Cycle For the Brayton cycle, the turbine exhaust temperature is greater than the compressor exit temperature. Therefore, a heat exchanger can be placed between the hot gases leaving the turbine and the cooler gases leaving the compressor. This heat exchanger is called a regenerator or recuperator. The sketch of the regenerative Brayton cycle is shown below. We define the regenerator effectiveness regen as the ratio of the heat transferred to the compressor gases in the regenerator to the maximum possible heat transfer to the compressor gases. For ideal gases using the cold-air-standard assumption with constant specific heats, the regenerator effectiveness becomes 22 Using the closed cycle analysis and treating the heat addition and heat rejection as steady-flow processes, the regenerative cycle thermal efficiency is Notice that the heat transfer occurring within the regenerator is not included in the efficiency calculation because this energy is not a heat transfer across the cycle boundary. Assuming an ideal regenerator regen = 1 and constant specific heats, the thermal efficiency becomes (take the time to show this on your own) When does the efficiency of the air-standard Brayton cycle equal the efficiency of the air-standard regenerative Brayton cycle? If we set th, Brayton = th, regen then Recall that this is the pressure ratio that maximizes the net work for the simple Brayton cycle and makes T4 = T2. What happens if the regenerative Brayton cycle operates at a pressure ratio larger than this value? For fixed T3 and T1, pressure ratios greater than this value cause T4 to be less than T2, and the regenerator is not effective. What happens to the net work when a regenerator is added? What happens to the heat supplied when a regenerator is added? The following shows a plot of the regenerative Brayton cycle efficiency as a function of the pressure ratio and minimum to maximum temperature ratio, T1/T3. 23 Example 8-3: Regenerative Brayton Cycle Air enters the compressor of a regenerative gas-turbine engine at 100 kPa and 300 K and is compressed to 800 kPa. The regenerator has an effectiveness of 65 percent, and the air enters the turbine at 1200 K. For a compressor efficiency of 75 percent and a turbine efficiency of 86 percent, determine (a) The heat transfer in the regenerator. (b) The back work ratio. (c) The cycle thermal efficiency. Compare the results for the above cycle with the ones listed below that have the same common data as required. (a) The actual cycle with no regeneration, = 0. (b) The actual cycle with ideal regeneration, = 1.0. (b) The ideal cycle with regeneration, = 0.65. (d) The ideal cycle with no regeneration, = 0. (e) The ideal cycle with ideal regeneration, = 1.0. We assume air is an ideal gas with constant specific heats, that is, we use the cold-air-standard assumption. Summary of Results 24 Compressor analysis The isentropic temperature at compressor exit is To find the actual temperature at compressor exit, T2a, we apply the compressor efficiency Since the compressor is adiabatic and has steady-flow Turbine analysis The conservation of energy for the turbine, process 3-4, yields for constant specific heats (let’s take a minute for you to get the following result) 25 Since P3 = P2 and P4 = P1, we can find the isentropic temperature at the turbine exit. To find the actual temperature at turbine exit, T4a, we apply the turbine efficiency. The turbine work becomes The back work ratio is defined as 26 Regenerator analysis To find T5, we apply the regenerator effectiveness. To find the heat transferred from the turbine exhaust gas to the compressor exit gas, apply the steady-flow conservation of energy to the compressor gas side of the regenerator. Using qregen, we can determine the turbine exhaust gas temperature at the regenerator exit. 27 Heat supplied to cycle Apply the steady-flow conservation of energy to the heat exchanger for process 5-3. We obtain a result similar to that for the simple Brayton cycle. Cycle thermal efficiency The net work done by the cycle is The cycle efficiency becomes You are encouraged to complete the calculations for the other values found in the summary table. 28 Other Ways to Improve Brayton Cycle Performance Intercooling and reheating are two important ways to improve the performance of the Brayton cycle with regeneration. Intercooling When using multistage compression, cooling the working fluid between the stages will reduce the amount of compressor work required. The compressor work is reduced because cooling the working fluid reduces the average specific volume of the fluid and thus reduces the amount of work on the fluid to achieve the given pressure rise. To determine the intermediate pressure at which intercooling should take place to minimize the compressor work, we follow the standard approach. For the adiabatic, steady-flow compression process, the work input to the compressor per unit mass is 29 Can you obtain this relation another way? Hint: apply the first law to processes 14. For two-stage compression, let’s assume that intercooling takes place at constant pressure and the gases can be cooled to the inlet temperature for the compressor, such that P3 = P2 and T3 = T1. The total work supplied to the compressor becomes ] To find the unknown pressure P2 that gives the minimum work input for fixed compressor inlet conditions T1, P1, and exit pressure P4, we get 30 or, the pressure ratios across the two compressors are equal. Intercooling is almost always used with regeneration. During intercooling the compressor exit temperature is reduced; therefore, more heat must be supplied in the heat addition process. Regeneration can make up part of the required heat transfer. To supply only compressed air, using intercooling requires less work input. The next time you go to a home supply store where air compressors are sold, check the larger air compressors to see if intercooling is used. For the larger air compressors, the compressors are made of two piston-cylinder chambers. The intercooling heat exchanger may be only a pipe with a few attached fins that connects the large piston-cylinder chamber with the smaller pistoncylinder chamber. Extra Assignment Obtain the expression for the compressor total work by applying conservation of energy directly to the low- and high-pressure compressors. Reheating When using multistage expansion through two or more turbines, reheating between stages will increase the net work done (it also increases the required heat input). The regenerative Brayton cycle with reheating is shown above. The optimum intermediate pressure for reheating is the one that maximizes the turbine work. Following the development given above for intercooling and assuming reheating to the high-pressure turbine inlet temperature in a constant pressure steady-flow process, we can show the optimum reheat pressure to be or the pressure ratios across the two turbines are equal. 31 Refrigeration Cycles The vapor compression refrigeration cycle is a common method for transferring heat from a low temperature to a high temperature. The figure shows the objectives of refrigerators and heat pumps. The purpose of a refrigerator is the removal of heat, called the cooling load, from a low-temperature medium. The purpose of a heat pump is the transfer of heat to a high-temperature medium, called the heating load. When we are interested in the heat energy removed from a lowtemperature space, the device is called a refrigerator. When we are interested in the heat energy supplied to the high-temperature space, the device is called a heat pump. In general, the term heat pump is used to describe the cycle as heat energy is removed from the low-temperature space and rejected to the high temperature space. The performance of refrigerators and heat pumps is expressed in terms of coefficient of performance (COP), defined as Both COPR and COPHP can be larger than 1. Under the same operating conditions, the COPs are related by Refrigerators, air conditioners, and heat pumps are rated with a SEER number or seasonal adjusted energy efficiency ratio. The SEER is defined as the Btu/hr of heat transferred per watt of work energy input. The Btu is the British thermal unit and is equivalent to 778 ft-lbf of work (1 W = 3.4122 Btu/hr). An EER of 10 yields a COP of 2.9. Refrigeration systems are also rated in terms of tons of refrigeration. One ton of refrigeration is equivalent to 12,000 Btu/hr or 211 kJ/min. How did the term “ton of cooling” originate? 32 Reversed Carnot Refrigerator and Heat Pump Shown below are the cyclic refrigeration device operating between two constant temperature reservoirs and the T-s diagram for the working fluid when the reversed Carnot cycle is used. Recall that in the Carnot cycle heat transfers take place at constant temperature. If our interest is the cooling load, the cycle is called the Carnot refrigerator. If our interest is the heat load, the cycle is called the Carnot heat pump. The standard of comparison for refrigeration cycles is the reversed Carnot cycle. A refrigerator or heat pump that operates on the reversed Carnot cycle is called a Carnot refrigerator or a Carnot heat pump, and their COPs are Notice that a turbine is used for the expansion process between the high and lowtemperatures. While the work interactions for the cycle are not indicated on the figure, the work produced by the turbine helps supply some of the work required by the compressor from external sources. Why not use the reversed Carnot refrigeration cycle? Easier to compress vapor only and not liquid-vapor mixture. Cheaper to have irreversible expansion through an expansion valve. What problems result from using the turbine? 33 The Vapor-Compression Refrigeration Cycle The vapor-compression refrigeration cycle has four components: evaporator, compressor, condenser, and expansion (or throttle) valve. The most widely used refrigeration cycle is the vapor-compression refrigeration cycle. In an ideal vapor-compression refrigeration cycle, the refrigerant enters the compressor as a saturated vapor and is cooled to the saturated liquid state in the condenser. It is then throttled to the evaporator pressure and vaporizes as it absorbs heat from the refrigerated space. The ideal vapor-compression cycle consists of four processes. Ideal Vapor-Compression Refrigeration Cycle 1-2 Isentropic compression 2-3 Constant pressure heat rejection in the condenser 3-4 Throttling in an expansion valve 4-1 Constant pressure heat addition in the evaporator The P-h diagram The ordinary household refrigerator is a good example of the application of this cycle. 34 Example 10-1 Refrigerant-134a is the working fluid in an ideal compression refrigeration cycle. The refrigerant leaves the evaporator at -20oC and has a condenser pressure of 0.9 MPa. The mass flow rate is 3 kg/min. Find COPR and COPR, Carnot for the same Tmax and Tmin , and the tons of refrigeration. Using the Refrigerant-134a Tables, we have The tons of refrigeration, often called the cooling load or refrigeration effect, are Another measure of the effectiveness of the refrigeration cycle is how much input power to the compressor, in horsepower, is required for each ton of cooling. The unit conversion is 4.715 hp per ton of cooling. 35 Actual Vapor-Compression Refrigeration Cycle Gas Refrigeration Systems The power cycles can be used as refrigeration cycles by simply reversing them. Of these, the reversed Brayton cycle, which is also known as the gas refrigeration cycle, is used to cool aircraft and to obtain very low (cryogenic) temperatures after it is modified with regeneration. The work output of the turbine can be used to reduce the work input requirements to the compressor. Thus, the COP of a gas refrigeration cycle is 36 Vapor and Combined Power Cycles We consider power cycles where the working fluid undergoes a phase change. The best example of this cycle is the steam power cycle where water (steam) is the working fluid. The heat engine may be composed of the following components. Steam Power Cycle The working fluid, steam (water), undergoes a thermodynamic cycle from 1-2-34-1. The cycle is shown on the following T-s diagram. Carnot Vapor Cycle Using Steam The thermal efficiency of this cycle is given as Note the effect of TH and TL on th, Carnot. : The larger the TH the larger the th, Carnot and the smaller the TL the larger the th, Carnot To increase the thermal efficiency in any power cycle, we try to increase the maximum temperature at which heat is added. Reasons why the Carnot cycle is not used: Pumping process 1-2 requires the pumping of a mixture of saturated liquid and saturated vapor at state 1 and the delivery of a saturated liquid at state 2. To superheat the steam to take advantage of a higher temperature, elaborate controls are required to keep TH constant while the steam expands and does work. To resolve the difficulties associated with the Carnot cycle, the Rankine cycle was devised. 37 Rankine Cycle The simple Rankine cycle has the same component layout as the Carnot cycle shown above. The simple Rankine cycle continues the condensation process 4-1 until the saturated liquid line is reached. Ideal Rankine Cycle Processes Process Description 1-2 Isentropic compression in pump 2-3 Constant pressure heat addition in boiler 3-4 Isentropic expansion in turbine 4-1 Constant pressure heat rejection in condenser The T-s diagram for the Rankine cycle is given below. Locate the processes for heat transfer and work on the diagram. Example 9-1 Compute the thermal efficiency of an ideal Rankine cycle for which steam leaves the boiler as superheated vapor at 6 MPa, 350oC, and is condensed at 10 kPa. We use the power system and T-s diagram shown above. P2 = P3 = 6 MPa = 6000 kPa T3 = 350oC P1 = P4 = 10 kPa Pump The pump work is obtained from the conservation of mass and energy for steadyflow but neglecting potential and kinetic energy changes and assuming the pump is adiabatic and reversible. Since the pumping process involves an incompressible liquid, state 2 is in the compressed liquid region, we use a second method to find the pump work or the h across the pump. Recall the property relation: 38 Since the ideal pumping process 1-2 is isentropic, ds = 0. The incompressible liquid assumption allows The pump work is calculated from Using the steam tables Now, h2 is found from 39 Boiler To find the heat supplied in the boiler, we apply the steady-flow conservation of mass and energy to the boiler. If we neglect the potential and kinetic energies, and note that no work is done on the steam in the boiler, then We find the properties at state 3 from the superheated tables as The heat transfer per unit mass is Turbine The turbine work is obtained from the application of the conservation of mass and energy for steady flow. We assume the process is adiabatic and reversible and neglect changes in kinetic and potential energies. We find the properties at state 4 from the steam tables by noting s4 = s3 and asking three questions. 40 The turbine work per unit mass is The net work done by the cycle is The thermal efficiency is 41 Ways to improve the simple Rankine cycle efficiency: Superheat the vapor Average temperature is higher during heat addition. Moisture is reduced at turbine exit (we want x4 in the above example > 85 percent). Increase boiler pressure (for fixed maximum temperature) Availability of steam is higher at higher pressures. Moisture is increased at turbine exit. Lower condenser pressure Less energy is lost to surroundings. Moisture is increased at turbine exit. Extra Assignment For the above example, find the heat rejected by the cycle and evaluate the thermal efficiency from 42 Reheat Cycle As the boiler pressure is increased in the simple Rankine cycle, not only does the thermal efficiency increase, but also the turbine exit moisture increases. The reheat cycle allows the use of higher boiler pressures and provides a means to keep the turbine exit moisture (x > 0.85 to 0.90) at an acceptable level. The thermal efficiency is given by Example 9-2 Compare the thermal efficiency and turbine-exit quality at the condenser pressure for a simple Rankine cycle and the reheat cycle when the boiler pressure is 4 MPa, the boiler exit temperature is 400 oC, and the condenser pressure is 10 kPa. The reheat takes place at 0.4 MPa and the steam leaves the reheater at 400oC. 43 Regenerative Cycle To improve the cycle thermal efficiency, the average temperature at which heat is added must be increased. One way to do this is to allow the steam leaving the boiler to expand the steam in the turbine to an intermediate pressure. A portion of the steam is extracted from the turbine and sent to a regenerative heater to preheat the condensate before entering the boiler. This approach increases the average temperature at which heat is added in the boiler. However, this reduces the mass of steam expanding in the lower- pressure stages of the turbine, and, thus, the total work done by the turbine. The work that is done is done more efficiently. The preheating of the condensate is done in a combination of open and closed heaters. In the open feedwater heater, the extracted steam and the condensate are physically mixed. In the closed feedwater heater, the extracted steam and the condensate are not mixed. Cycle with an open feedwater heater Rankine Steam Power Cycle with an Open Feedwater Heater Rankine Steam Power Cycle with an Open Feedwater Heater Cycle with a closed feedwater heater with steam trap to condenser Rankine Steam Power Cycle with a Closed Feedwater Heater 44 Cycle with a closed feedwater heater with pump to boiler pressure Consider the regenerative cycle with the open feedwater heater. To find the fraction of mass to be extracted from the turbine, apply the first law to the feedwater heater and assume, in the ideal case, that the water leaves the feedwater heater as a saturated liquid. (In the case of the closed feedwater heater, the feedwater leaves the heater at a temperature equal to the saturation temperature at the extraction pressure.) Conservation of mass for the open feedwater heater: Let y m m ! / ! 6 5 be the fraction of mass extracted from the turbine for the feedwater heater. Conservation of energy for the open feedwater heater: 45 Example 9-3 An ideal regenerative steam power cycle operates so that steam enters the turbine at 3 MPa, 500oC, and exhausts at 10 kPa. A single open feedwater heater is used and operates at 0.5 MPa. Compute the cycle thermal efficiency. Using the software package the following data are obtained. The work for pump 1 is calculated from Now, h2 is found from The fraction of mass extracted from the turbine for the open feedwater heater is obtained from the energy balance on the open feedwater heater, as shown above. 46 This means that for each kg of steam entering the turbine, 0.163 kg extracted for the feedwater heater. The work for pump 2 is calculated from Now, h4 is found from the energy balance for the pump. Apply the steady-flow conservation of energy to the isentropic turbine. The net work done by the cycle is 47 Apply the steady-flow conservation of mass and energy to the boiler. The heat transfer per unit mass entering the turbine at the high pressure, state 5, is The thermal efficiency is If these data were used for a Rankine cycle with no regeneration, then th = 35.6 percent. Thus, the one open feedwater heater operating at 0.5 MPa increased the thermal efficiency by 5.3 percent. However, note that the mass flowing through 48 the lower-pressure stages has been reduced by the amount extracted for the feedwater and the net work output for the regenerative cycle is about 10 percent lower than the standard Rankine cycle. Below is a plot of cycle thermal efficiency versus the open feedwater heater pressure. The feedwater heater pressure that makes the cycle thermal efficiency a maximum is about 400 kPa. Below is a plot of cycle net work per unit mass flow at state 5 and the fraction of mass y extracted for the feedwater heater versus the open feedwater heater pressure. Clearly the net cycle work decreases and the fraction of mass extracted increases with increasing extraction pressure. Why does the fraction of mass extracted increase with increasing extraction pressure? Placement of Feedwater Heaters The extraction pressures for multiple feedwater heaters are chosen to maximize the cycle efficiency. As a rule of thumb, the extraction pressures for the feedwater heaters are chosen such that the saturation temperature difference between each component is about the same. 49 Example 9-4 An ideal regenerative steam power cycle operates so that steam enters the turbine at 3 MPa, 500oC, and exhausts at 10 kPa. Two closed feedwater heaters are to be used. Select starting values for the feedwater heater extraction pressures. Deviation from Actual Cycles Piping losses--frictional effects reduce the available energy content of the steam. Turbine losses--turbine isentropic (or adiabatic) efficiency. The actual enthalpy at the turbine exit (needed for the energy analysis of the next component) is Pump losses--pump isentropic (or adiabatic) efficiency. 50 The actual enthalpy at the pump exit (needed for the energy analysis of the next component) is Condenser losses--relatively small losses that result from cooling the condensate below the saturation temperature in the condenser. 51 Thermodynamics II Problems on power cycles ----------------------------------------------------------------------------------------1. An ideal Otto cycle has a compression ratio of 8 . At the beginning of the compression process, air is at 95 kPa and 27 oC, and 750 kJ / kg of heat is transferred to air during the constant volume heat addition process. Determine (a) the pressure and temperature at the end of the heat addition process, (b) the net work output, (c) the thermal efficiency, and (d) the mean effective pressure for the cycle. Answers: (a) 3898, 1 kPa, 1538 K, (b) 392 kJ/kg, (c) 52%, (d) 495 kPa 2. A four – cylinder spark – ignition engine has a compression ratio of 8, and each cylinder has a maximum volume of 0.6 L. At the beginning of the compression process, the air is at 98 kPa and 17 oC, and the maximum temperature in the cycle is 1800 K. Assuming the engine to operate on the ideal Otto cycle, determine (a) the amount of heat supplied per cylinder, (b) the thermal efficiency, and 9 (c) the number of revolutions per minute required for a net power output of 80 kW. 3. The compression ratio of an air – standard Otto cycle is 9.5. Prior to the isentropic compression process, the air is at 100 kPa, 17 oC, and 600 cm3. The temperature at the end of the isentropic expansion process is 800 K Determine (a) the highest temperature and pressure in the cycle, (b) the amount of heat added in kJ, (c) the thermal efficiency, and (d) the mean effective pressure. Answers: (a) 1987 K, 649 kPa, (b) 0.65 kJ/kg, (c) 59%, (d) 719 kPa 4. An air – standard Diesel cycle has a compression ratio of 18 .2 Air is at 27 oC and 0.1 MPa at the beginning of the compression process and at 2000 K at the end of the heat addition process. Accounting for the variation of specific heats with temperature, determine (a) the cutoff ratio (b)the heat rejection per unit mass, and (c) the thermal efficiency. 5. An ideal diesel engine has a compression ratio of 20 and uses air as the working fluid. The state of air at the beginning of the compression process is 95 kPa and 20 oC. If the maximum temperature in the cycle is not to exceed 2200 K, determine (a) the thermal efficiency and (b) the mean effective pressure. Assume constant heats for air at room temperature. Answers: (a) 63.5 percent (b) 933 kPa. 6. An ideal dual cycle has a compression ratio of 12 and uses air as the working fluid. At the beginning of the compression process, air is 100 kPa and 30 oC 52 and occupies a volume of 1.2 L. During the heat addition process, 0.3 kJ of heat is transferred to air at constant volume and 1.1 kJ at constant pressure. Determine the thermal efficiency of the cycle. 7. The compression ratio of an ideal dual cycle is 14. Air is at 100 kPa and 300 K at the beginning of the compression process and at 2200 K at the end of the heat addition process. Heat transfer to air takes place partly at constant volume and partly at constant pressure, and it amounts to 1520.4 kJ/kg. Determine (a) the fraction of heat transferred at constant volume and (b) the thermal efficiency of the cycle. 8. A simple Brayton cycle using air as the working fluid has a pressure ratio of 8. The minimum and maximum temperatures in the cycle are 310 and 1160 K. Assuming an adiabatic efficiency of 75 percent for the compressor and 82 percent for the turbine , determine (a) the air temperature at the turbine exit, (b) the net work output, and (c) the thermal efficiency. 9. Air enters the compressor of a gas–turbine engine at 300 K and 100 kPa, where it is compressed to 700 kPa and 580 K. Heat is transferred to air in the amount of 950 kJ/kg before it enters the turbine. For a turbine to efficiency of 86 percent, determine (a) the fraction of the turbine work output used to drive the compressor and (b) the thermal efficiency. Answers: (a) 64.7 percent, (b) 16.4 percent. 10. A gas turbine power plant operates on the simple Brayton cycle with air as the working fluid and delivers 15 MW of power. The minimum and maximum temperatures in the cycle are 310 and 900 K and the pressure of air at the compressor exit is 8 times the value at the compressor inlet. Assuming an adiabatic efficiency of 80 percent for the compressor and 86 percent for the turbine, determine the mass flow rate of air through the cycle. 11. A Brayton cycle with regeneration using air as the working fluid has a pressure ratio of 8. The minimum and maximum temperatures in the cycle are 310 and 1150 K. Assuming an adiabatic efficiency of 75 percent for the compressor and 82 percent for the turbine and an effectiveness of 65 percent for the regenerator; determine (a) the air temperature at the turbine exit, (b) the net work output, and (c) the thermal efficiency. Answers: (a) 763.07 kg/kg (b) 101.64 kg/kg, (c) 21.0 percent. 12. Air enters the compressor of a regenerative gas – turbine engine at 300 k and 100 kPa where it is compressed to 800 kPa and 580 K The regenerator has an 53 effectiveness of 65 percent, and the air enters the turbine at 1200 K For a turbine efficiency of 86 percent, determine (a) the amount of heat transfer in the regenerator and (b) the thermal efficiency. Answers: (a) 137.7 kJ/kg (b) 35.0 percent. 13. Consider an ideal gas turbine cycle with two stages of compression and two stages of expansion. The pressure ratio across each stage of compressor and turbine is 3. The air enters each stage of the compressor at 300 K and each stage of the turbine at 1200 K. Determine the back work ratio and the thermal efficiency of the cycle, assuming (a) no regenerator is used and (b) a regenerator with 75 percent effectiveness is used. 14. Consider a regenerative gas – turbine power plant with two stages of compression and two stages of expansion. The overall pressure ratio of the cycle is 9. The air enters each stage of the compressor at 300 K and each stage of the turbine at 1200 K. Determine the minimum mass flow rate of air needed to develop a net power output of 50 MW. Answer: 113.4 kg/s. 15. A steady-flow Carnot refrigeration cycle uses refrigerant-134a as the working fluid. The refrigerant changes from saturated vapor to saturated liquid at 30°C in the condenser as it rejects heat. The evaporator pressure is 160 kPa. Show the cycle on a T-s diagram relative to saturation lines, and determine (a) the coefficient of performance, (b) the amount of heat absorbed from the refrigerated space, and (c) the net work input. Answers: (a) 5.64, (b) 147 kJ/kg, (c) 26.1 kJ/kg 16. A refrigerator uses refrigerant-134a as the working fluid and operates on an ideal vapor-compression refrigeration cycle between 0.12 and 0.7 MPa. The mass flow rate of the refrigerant is 0.05 kg/s. Show the cycle on a T-s diagram with respect to saturation lines. Determine (a) the rate of heat removal from the refrigerated space and the power input to the compressor, (b) the rate of heat rejection to the environment, and (c) the coefficient of performance. Answers: (a) 7.41 kW, 1.83 kW, (b) 9.23 kW, (c) 4.06 17. Refrigerant-134a enters the compressor of a refrigerator as superheated vapor at 0.14 MPa and _10°C at a rate of 0.12 kg/s, and it leaves at 0.7 MPa and 50°C. The refrigerant is cooled in the condenser to 24°C and 0.65 MPa, and it is throttled to 0.15 MPa. Disregarding any heat transfer and pressure drops in the connecting lines between the components, show the cycle on a T-s diagram with respect to saturation lines, and determine (a) the rate of heat removal from the refrigerated space and the power input to the compressor, 54 (b) the isentropic efficiency of the compressor, and (c) the COP of the refrigerator. Answers: (a) 19.4 kW, 5.06 kW, (b) 82.5 percent, (c) 3.83 18. A gas refrigeration system using air as the working fluid has a pressure ratio of 4. Air enters the compressor at _7°C. The high-pressure air is cooled to 27°C by rejecting heat to the surroundings. It is further cooled to _15°C by regenerative cooling before it enters the turbine. Assuming both the turbine and the compressor to be isentropic and using constant specific heats at room temperature, determine (a) the lowest temperature that can be obtained by this cycle, (b) the coefficient of performance of the cycle, and (c) the mass flow rate of air for a refrigeration rate of 12 kW. Answers: (a) _99.4°C, (b) 1.12, (c) 0.237 kg/s 19. A steam power plant operates on a simple ideal Rankine cycle between the pressure limits of 3 MPa and 50 kPa. The temperature of the steam at the turbine inlet is 400 oC, and the mass flow rate of steam through the cycle is 40 kg/s. Show the cycle on a T– s diagram with respect to saturation lines, and determine (a) the thermal efficiency of the cycle and (b) the net power output of the power plant. 20. Steam enters the turbine of a steam power plant which operates on a simple ideal Rankine cycle at a pressure of 6 MPa, and it leaves as a saturated vapor at 7.5 kPa. Heat is transferred to the steam in the boiler at a rate of 10 5 kJ/s. Steam is cooled in the condenser by the cooling water from a nearby river which enters the condenser at 18 oC. Show the cycle on a T-s diagram with respect to saturation lines, and determine (a) the turbine inlet temperature (b) the net power output and the thermal efficiency and (c) the minimum mass flow rate of the cooling water required. 21. A steam power plant operates on a simple ideal Rankine cycle between the pressure limits of 9 MPa and 10 kPa. The mass flow rate of steam through the cycle is 25 kg/s. The moisture content of the steam at the turbine exit is not to exceed 10 percent. Show the cycle on a T-s diagram with respect to saturation lines, and determine (a) the minimum turbine inlet temperature, (b) the rate of heat input in the boiler (c) the thermal efficiency of the cycle. 22. A steam power plant operates on the ideal reheat Rankine cycle. Steam enters the high pressure turbine at 8 MPa and 500 oC and leaves at 3 MPa. Steam is then reheated at constant pressure to 500 oC before it expands to 20 kPa in the low pressure turbine. Determine the turbine work output, in kJ/kg, and the 55 thermal efficiency of the cycle. Also show the cycle on a T-s diagram with respect to saturation lines. 23. Steam enters the high – pressure turbine of a steam power plant which operates on the ideal reheat Rankine cycle at 6 MPa and 450 oC and leaves as saturated vapor. Steam is then reheated to 400 oC before it expands to a pressure of 7.5 kPa. Heat is transferred to the steam in the boiler at a rate of 10 kJ/s. Steam is cooled in the condenser by the cooling water from a nearby river, which enters the condenser at 18 oC. Show the cycle on T-s diagram with respect to saturation lines and determine (a) the pressure at which reheating takes place (b) the net power output and thermal efficiency and (c) the minimum mass flow rate of the cooling water required. 24. A steam power plant operates on an ideal regenerative Rankine cycle. Steam enters the turbine at 6 MPa and 450 oC and is condensed in the condenser at 20 kPa. Steam is extracted from the turbine at 0.4 MPa to heat the feed water in an open feed water heater. Water leaves the feed water heater as a saturated liquid. Show the cycle on a T-s diagram and determine (a) the net work output per kilogram of steam flowing through the boiler and (b) the thermal efficiency of the cycle. Answers: (a) 1016 kJ/kg (b) 37.8 percent. 25. A steam power plant operates on an ideal reheat regenerative Rankine cycle and has a net power output of 80 MW. Steam enters the high pressure turbine at 10 MPa and 550 oC and leaves at 0.8 MPa. Some steam is extracted at this pressure to heat the feed water in an open feed water heater. The rest of the steam is reheated to 500 oC and is expanded in the low pressure turbine to the condenser pressure of 10 kPa. Show the cycle on a T-s diagram with respect to saturation lines, and determine (a) the mass flow rate of steam through the boiler and (b) the thermal efficiency of the cycle. Answers: (a) 54.56 kg / s (b) 44.4 percent. 56