CEDARPRIME – Technical-Planning Supervisor Profile

advertisement

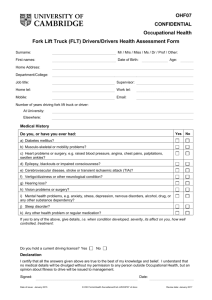

February 16, 2010 DRAFT Southcoast Millwork Forklift Operator Job Description . Responsibilities Maximizing the machine line(s) operating uptime Safety performance – “safety is a prerequisite to work” Maintain the highest quality control standards Monitors the sawdust and chip bin volumes and communicates with supervisor Tasks by Responsibility Maximize machine line(s) operating uptime First priority to ensuring machine line(s) are never out of wood or backed up due to finished loads not being removed promptly Follow an efficient yard & dry storage layout for all inventory Receive and follow run instructions from the supervisor and forklift coordinator Ensure work order wood is on the machine in feed prior to the start of every shift/order Ensure accuracy of inbound fibre volumes consistent with customer shipping documents Assist machine line(s) to debag/destaple, sort, package, wrap and strap loads as per run instructions Assist fork lift coordinator in the preparation of van loads Assist in the receiving, unloading and proper storage of lumber and other products Perform all other duties as assigned by the supervisor Safety Performance Perform pre shift inspection of fork lift and report deficiencies Wear proper protective equipment including a seat belt Ensure load is properly centered and balanced Handle loads only within the rated capacity Watch the swing when handling long loads Carry the load as low as possible with mast tilted back Maintaining a safe ground clearance Do not turn on an incline Make yourself aware of overhead wires, pipes, etc. Correct unsafe conditions and practices Immediate response and reporting of all forklift accident/incident Communicate any safety issues/concerns to the production supervisor Be involved in any forklift accident/incident investigation Maintain the highest quality control standards Use and placement of all blocking and dunnage All transportation/storage of products in the yard to minimizes handling/damage Package loads for shipment have the proper protection and identification Accuracy of package grade and tally consistent with order and documentation Monitors the sawdust and chip bin volumes and communicates with fork lift coordinator or supervisor Track production plan and resulting variations in sawdust and chip volumes Advise coordinator or supervisor of need to service sawdust and shavings bunkers Qualifications Knowledge Specific knowledge of grades, values and manufacturing processes Specialized knowledge of LISA inventory management system Safe operation of fork lifts Experience Minimum of 3 years experience effectively operating fork lift with wood products 3 years of large fork lift operation experience Skills A sense of urgency through enthusiasm, encouragement and a strong work ethic Strong interpersonal managing skills - effectively communicates what is required, holding people accountable for specific results, coaching for continuous improvement, listening and managing issues/differences that limit progress Demonstrated fork lift operation skills A problem solver - creative “out of the box” thinker, able to effectively assess and manage risk while developing innovative solutions to workplace issues Ordering and responding to different priorities Attributes/Qualities Approachable - enjoys people, will be open, tactful and sensitive while possessing the ability to lead people to achieve objectives, fair but firm. Demonstrates confidence High integrity - exceptional level of personal integrity, open and honest in dealing with others, able to make tough decisions Hands on - understands the value of being directly involved in the action. 2 Accountabilities Timely & effective delivery and removal of work order requirements to machine line(s) Daily inspection, reporting deficiencies and safe operation of fork lift Minimum handling and correct storage and documentation of all work order products Maximum uptime and cost effective operation and maintenance of the fork lift Contributes to the orderly yard inventory or all unprocessed, semi processed and processed stock 3