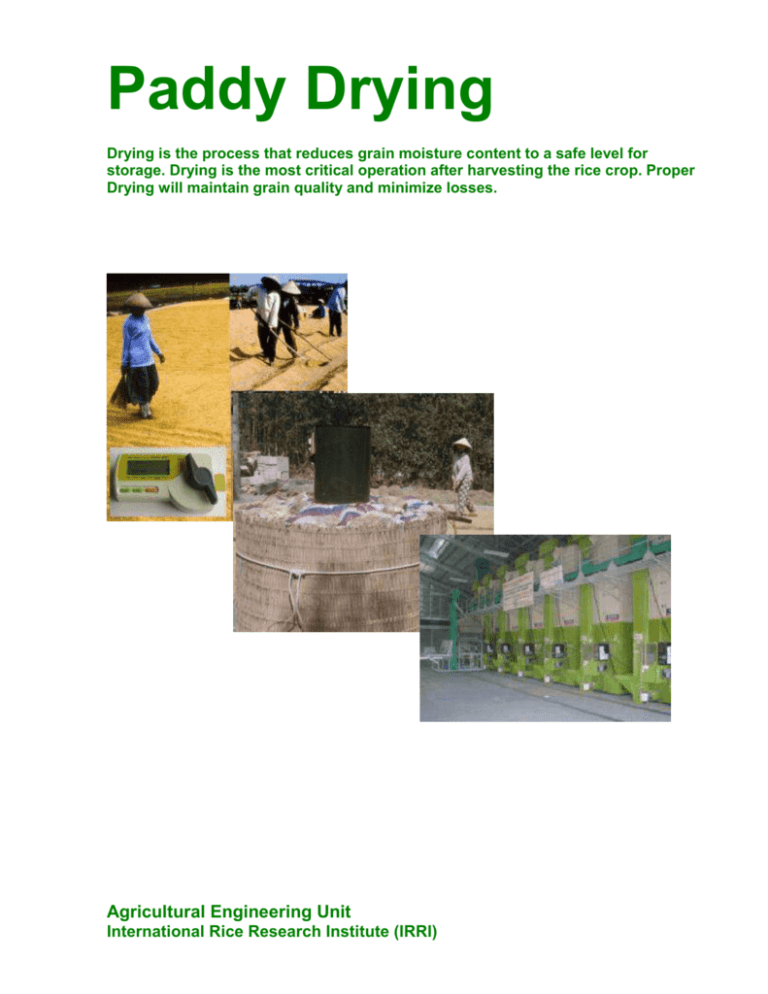

Paddy drying manual - Rice Knowledge Bank

advertisement