1 - Environmental Health and Safety

advertisement

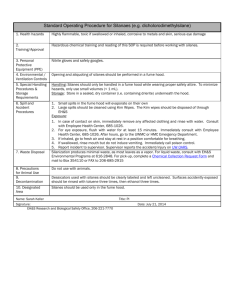

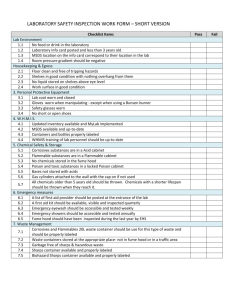

The University of Connecticut Department of Environmental Health and Safety POLICIES AND PROCEDURES Subject: Approved: Safety Procedures for Rooftop Exhaust Fan Operation and Maintenance A. Date: March 10, 1999 Teresa M. Dominguez, Occupational Health and Safety Manager General This policy has been developed to protect employees from health and safety hazards while performing operation and maintenance work on rooftop exhaust fans and related systems. Supervisors must ensure that this policy is made available to their employees and that the required procedures are carried out. Employees must be sure to familiarize themselves with the policy and comply with the requirements. Please contact Environmental Health & Safety (X3613 or X-0981) with any questions related to this policy. B. Safety Procedures 1. General Safety Procedures--All Exhaust Fans Prior to working on any rooftop exhaust system/fan, workers must: (1) Notify affected room or area representatives. (2) Ensure that the occupants have closed, sealed, or removed all hazardous materials from the fume hood and have shut down any experiments. (3) Shut down, lock and tag out the system/fan and place a sign (use sign on page 4 of this policy—copy onto gold-colored paper) on fume hood cabinets to notify room occupants. (4) Wear appropriate Personal Protective Equipment (PPE)—refer to section C of this policy. 2. Biosafety Cabinet Exhaust Fans All biosafety cabinets are HEPA-filtered at the cabinet. Very few biosafety cabinets are ducted to the outside. Those that are ducted to the outside do not pose a biological hazard beyond the HEPA-filtered cabinet. However, if work will be performed inside a biosafety cabinet, it must first be assessed by Biological Health and Safety (X-2436). EH&S 3/99 1 3. Chemical Fume Hood Exhaust Fans All fume hood exhaust internal components have potential chemical hazards. Therefore, workers should wear chemical resistant gloves (e.g., nitrile or neoprene) in addition to any standard PPE (see section C). Disposable coveralls should be considered depending on the nature of the work. Perchloric acid hoods—there is one fume hood on campus at the Young building (room 104) that is used for perchloric acid digestions. The exhaust fan is labeled at the rooftop. There is a potential explosive hazard when working on this exhaust system. Prior to working on this system, it must be flushed and tested by Chemical Health and Safety (X-3115 or X-1110). Bronwell (Engineering III)—The roof of Bronwell is restricted due to a potential for toxic gases (arsine and hydrogen selenide) to be produced in the MOCVD lab (room 113). Access to the roof will only be granted to authorized individuals who must follow specific lockout/tagout procedures (see page 5 of this policy). Contact Occupational Health and Safety (X-0981) for further information. 4. Radiological Hood Exhaust Fans C. There are four hoods on campus where volatile (airborne) radioactive material is used (Pharmacy, rm. 282; BioB#4, rm. 44; HazardousWaste Facility; and EH&S Radiation Safety Lab). These exhaust fans are labeled at the rooftops. Workers should not open or perform maintenance on the ventilation systems for these specialized hoods without prior approval from Radiation Safety (x-3613). Within some laboratories on campus there are fume hoods labeled for radioactive material use. The ventilation systems (exhaust fans and ducts) of these fume hoods present no radiation hazards to workers. However, if work will be performed inside a fume hood, it must first be assessed by Radiation Safety (X-3613). Personal Protective Equipment Personal Protective Equipment (PPE) is required for all work that presents health or physical hazards to workers. Some form of PPE may be required for any work involving exhaust fan operation and maintenance. Therefore, a hazard assessment must be made prior to the work to determine the appropriate PPE for the job. In addition, basic hygiene practices, such as washing up with soap and water after any work, should always be used. The minimum level of PPE to be used will be work gloves and safety glasses or goggles. For further information refer to the University’s Personal Protective Equipment policy or contact Occupational Health and Safety at X-3613 or X-0981. D. Flow Chart of Safety Procedures To assist workers in determining the proper safety procedures to follow, the following flow chart has been developed: EH&S 3/99 2 EXHAUST FAN Operation & Maintenance Flow Chart of Safety Procedures INTERIOR WORK (parts in airstream) Biological Chemical Perchloric Bronwell Roof (Young, rm 104) (Rm. 113) Flush, then call EH&S to test Authorized and trained personnel only EXTERIOR WORK (parts outside airstream) Radiation Other fume hood exhaust fans Use chemicalresistant PPE General (HVAC) Perchloric (Young, rm. 104) All others (Pharm, rm 282) (BioB#4, rm 44) (Haz.Waste Fac.) (EH&SRad Lab) Call EH&S to test Flush, then call EH&S to test Follow General Safety Procedures (see B.1. in policy) EH&S 3/99 3 WARNING WORKERS ON ROOF DO NOT USE FUME HOOD EH&S 3/99 **Copy onto GOLD colored paper** 4 Lockout/Tagout Procedures for Roof Work at Bronwell Building (Eng’g III) 1. Prepare for Shutdown --Notify researchers in the MOCVD lab (Room 113) that maintenance work will be performed on the roof that will require the MOCVD reactor (and fume hoods, if applicable) to be shut down and locked out. 2. Shutdown and Isolate --Verify through the lab researchers that the MOCVD reactor is not running. --Cover the MOCVD computer keyboard with the enclosure made for lockout/tagout. --If maintenance work will be on or near fume hood exhausts: Verify that the fume hoods are not being used and place a sign across the face of each fume hood. The sign should read: Do Not Use Fume Hood--Workers on Roof. 3. Lockout/Tagout --Apply your assigned locks and tags to the hasp of the computer keyboard cover. --(Apply lock/tag to the fume hood switch(es), if applicable) Note: Each worker on the roof must apply their own lock and tag. 4. Verify Isolation --Make sure that all operating controls have been successfully isolated. (Check the integrity of the cover and check with the researcher again to ensure the MOCVD is not running.) You may now perform work on the roof Removal of Locks and Tags 1. Check the equipment and surrounding area on the roof to ensure that all work has been completed, guards replaced and tools have been picked up. 2. Verify that no one is left on the roof and that you have the key to the roof hatch lock. 3. Go to the MOCVD lab and remove your locks and tags from the computer keyboard cover. 4. Notify researchers in the lab that your roof work is complete and that locks and tags have been removed. EH&S 3/99 5