CMA029-9

advertisement

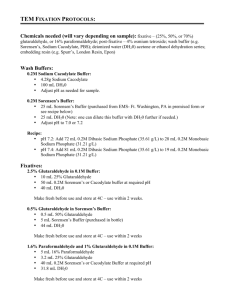

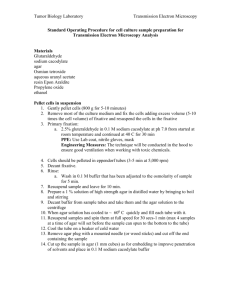

CMA029/9 Centre for Microscopy and Analysis (CMA) TCD FIXATION AND EMBEDDING PROCEDURE WARNING: Most chemicals used in Electron Microscopy are toxic and should be treated with extreme caution. ALL procedures should be carried out in a fume-cupboard and disposable gloves and appropriate protective gear worn. The fume-cupboard should be kept clean at all times and the user should sign the appropriate white board and fill in details of their work and any special hazards. Stock Solutions (stored in the fridge) 1. 0.2M Potassium dihydrogen phosphate (KH2PO4). 2. 0.2M Dipotassium hydrogen phosphate (K2HPO4). 3. 0.2M Sodium Cacodylate. 4. 25% Glutaraldehyde in water. 5. 4% Osmium tetroxide in water. WARNING Osmium tetroxide (OsO4) must only be used in a fume-cupboard as it is extremely toxic and volatile. Waste OsO4 should be disposed of in the waste bottle provided in the fume-cupboard. Solutions required to be made up at the start 1. 0.2M Phosphate Buffer (pH 6.8) Add 51 mls. of stock 0.2M KH2PO4 to 49 mls. of 0.2M K 2HPO4. 2. 0.05M Phosphate Buffer (pH 6.8) Dilute 25 mls. of 0.2M phosphate buffer with distilled water to make 100 mls. 3. 0.1M Sodium Cacodylate (pH 7.2) Dilute 50 mls. 0.2M Sodium Cacodylate with 50 mls. distilled water. CMA029/9 FIXATION Note: Glutaraldehyde / Phosphate buffer combination (pH 6.8) is normally used for general purpose and botanical fixation. Glutaraldehyde / Cacodylate buffer combination (pH 7.2) is normally used for animal tissue fixation. Seek advice from the CMA staff as the most applicable route to process your samples. Primary Fixative solutions (approx.) 3% Glutaraldehyde in 0.05M Potassium Phosphate buffer (pH 6.8) Mix (a) 15 mls. distilled water (b) 6 mls. 0.2M Phosphate buffer (c) 3 mls. 25% Glutaraldehyde Or (approx.) 3% Glutaraldehyde in 0.1M Sodium Cacodylate buffer (pH 7.2) Mix (a) (b) 9.5 mls. distilled water 12.5 mls. 0.2M Cacodylate buffer (c) 3 mls. 25% Glutaraldehyde Adjust to pH 7.2 with the dropwise addition of 1N Sodium Hydroxide. Primary Fixation Procedure Cut tissue into small blocks (1mm. cube max.) in some primary glutaraldehyde fixative on a piece of dental wax. Transfer to corked vials and fix for 1 to 1.5 hours at room temperature while agitating the solutions on a rotator. CMA029/9 Washing Procedure Wash 6 times for 1 hour with either 0.05M Phosphate or 0.1M Cacodylate buffer to remove any unreacted Glutaraldehyde from the samples before post fixation. Leave the samples in the vial and change the wash solutions using a pipette. Secondary fixative Solutions 2% Osmium Tetroxide in 0.05M Potassium Phosphate buffer (pH 6.8) Mix (a) 2mls. 4% OsO4 in water (VERY TOXIC). (b) 1 ml. 0.2M Phosphate buffer. (c) 1 ml. distilled water. 2% Osmium Tetroxide in 0.1M Sodium Cacodylate buffer (pH 7.2) Mix (a) (b) 2 mls. OsO4 in water (VERY TOXIC). 2 mls. 0.2M Cacodylate buffer. Secondary fixation Procedure Fix for 30 minutes at room temperature in suitable buffered 2% Osmium tetroxide in vials and using the rotator for agitation. CMA029/9 PLEASE NOTE 1. Do not use OsO4 on an open bench as the fumes are extremely dangerous. 2. Dispose of waste OsO4 in the bottle provided in the fume cupboard, NOT DOWN THE DRAIN. 3. OsO4 is very expensive (approx. €200 per gram.) Use only sufficient to cover your specimens. DEHYDRATION Dehydration Series An acetone dehydration series is normally used for botanical samples. An alcohol dehydration series is normally used for animal tissue (at room temperature R.T.). either / or 1. 10% acetone / alcohol in water 10 mins. at R.T. 2. 30% acetone / alcohol in water 10 mins. at R.T. 3. 50% acetone / alcohol in water 10 mins. at R.T. 4. 70% acetone / alcohol in water 10 mins. at R.T. 5. 95% acetone / alcohol in water 10 mins. at R.T. 6. 100% acetone / alcohol 15 mins. at R.T. 7. 100% acetone / alcohol 15 mins. at R.T. 8. 100% acetone / alcohol 30 mins. at R.T. CMA029/9 Transition to Resin Propylene Oxide is used as a transitional fluid as it is miscible with acetone / alcohol and also the resin. This chemical is very toxic and should not be allowed into contact with your skin. 1. 2. 100% Propylene Oxide 100% Propylene Oxide 15 mins. at R.T. 30 mins. at R.T. EMBEDDING SCHEDULE AGAR 100 RESIN (medium mix) Weigh out the components on the top pan balance. Use the correct plastic disposable containers and wearing disposable gloves and appropriate protective equipment. Agar 100 Epoxy resin DDSA Hardener MNA Hardener BDMA Accelerator 24.0 g. 16.0 g. 10.0 g. 1.5 g. Mix all components well to ensure an evenly polymerized resin. Embedding Procedure 1. Replace the final propylene oxide solution with a 50% Resin solution, (10 ml. Resin + 10 ml. Propylene Oxide), for 2- 3 hours. 2. Change to a 100% Resin solution, (re-mix Resin thoroughly before use), for 2- 3 hours. 3. Transfer samples to pans / capsules containing fresh 100% Resin. (re-mix Resin thoroughly before use) Note: Remove samples from the glass vials, using an applicator stick, and place on a piece of filter paper to remove as much excess old resin as possible. Then transfer the samples to the pans / capsules containing fresh Resin. 4. The pans / capsules, containing the samples, are then placed under vacuum to remove air bubbles from the Resin. CMA029/9 (a) Place pans in vacuum oven and screw the door shut. (b) Plug in rotary pump and connect the vacuum line to the top valve on the oven (check valve is open) and switch on the rotary pump. (c) When the required vacuum has been reached, close the top valve on the oven, switch off the rotary pump and DISCONNECT the vacuum line. (Note: - failure to disconnect the vacuum line will cause suck back of the rotary pump oil.) (d) After approx. 10 minutes, open the top oven valve slowly and return the oven to ambient pressure. (e) Ensure the oven is plugged in and turned on (it is pre-set at 60º C) and leave the samples at 60 0C for 24 hours. 5. (a) All surplus resin from vials etc. should be poured into the plastic resin beaker and polymerized at the same time as the samples. (b) All glass pipettes should be placed in the CinBin provided in the fume cupboard. (c) All applicator sticks, plastic pipettes, vials and paper that have been contaminated with resin should be placed in a plastic bag and sealed. Please avoid getting resin on to the outside of this bag. (d) Clean down the fume-cupboard and equipment with a little alcohol and paper from the blue roll. NOTE: - Failure to clean and tidy the fume-cupboard and lab may result in refusal of entry to the facilities. Remember RESIN IS TOXIC SUMMARY Day 1 3% glutaraldehyde Washes / Buffer 1 to 1.5 hours 1 hour Total: 2.5 to 3 hrs. 2% Osmium Tetroxide 10% Alcohol / Acetone 30% Alcohol / Acetone 50% Alcohol / Acetone 70% Alcohol / Acetone 95% Alcohol / Acetone 100% Alcohol / Acetone 100% Alcohol / Acetone 30 minutes 10 minutes 10 minutes 10 minutes 10 minutes 10 minutes 15 minutes 15 minutes Total: 1 hr. 50 mins. 100% Alcohol / Acetone 30 minutes or overnight in fridge. CMA029/9 Day 2 100% Propylene Oxide 100% Propylene Oxide 15 minutes 30 minutes 50% P.O. / 50% Resin 100% Resin 100% Resin 2 to 3 hours 2 to 3 hours Oven 24 hours Total: 45 mins. Total: 4 to 6 hrs. POST-STAINING OF THIN SECTIONS ON GRIDS Solutions:- (Staining stock solutions) (a) 0.5% aqueous Uranyl Acetate. (b) Reynold’s Lead Citrate. Procedure: (1) Place one drop of Uranyl Acetate stain per grid on parafilm in a petri dish. Use the specially cleaned pipettes for dispensing stains to minimize the chance of contamination of the sections. (2) Pick up a grid with cleaned forceps and place the grid on the drop of stain with the section-side down. (3) Leave for 10-30 minutes depending on the staining ability of the specimen. (4) Use filtered distilled water for washing grids. Dip the grid repeatedly into a beaker of distilled water for about 30 seconds, shake and dip into a second beaker of distilled water for another 30 seconds. (5) Dry the grid with a wedge of Whatman No. 50 filter paper. CMA029/9 (6) Place one drop of Reynold’s Lead Citrate stain per grid on parafilm in a petri dish. (7) Place the grid on the drop of stain with the section-side down. (8) Leave for 5- 10 minutes depending on the staining ability of the specimen. (9) Wash the grid as in (4) above. (10) Dry the grid with a wedge of filter paper and place in a petri dish on a clean piece of labelled filter paper. (11) Examine the grid in the transmission electron microscope as soon as possible after staining. (12) Clean away all used glass pipettes (CinBin), used staining solutions etc.