I. Overview of H-Bridge Motor Controller

advertisement

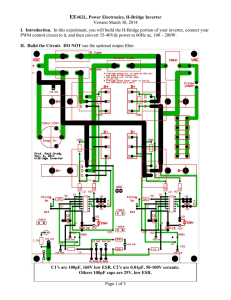

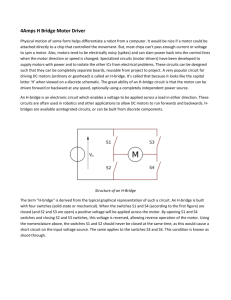

I. Overview of H-Bridge Motor Controller: The H-Bridge is basically a motor reversing circuit that is able to be switched very rapidly. The ability for the circuit to be switched on and off very rapidly allows the use of a pulse width modulation, or PWM signal to control the circuit. As the PWM signal is applied to various transistors within the HBridge, the result is an average voltage applied to the motor, or load varies with the duty cycle of the PWM signal. At 100% duty cycle, the load will have 100% of the source voltage applied across it. At 50% duty cycle, the load will experience an average voltage of ½ that of the source voltage. Varying the average voltage applied to a motor will ultimately affect its speed of rotation, and torque output. Being able to control the angular velocity of the motor will allow the platform to move at various speeds. In addition to controlling speed of the motor, the H-Bridge also allows for motor reversing. Applying the same PWM signal to the opposite pair of transistors will have the same affect as before, except this time the polarity of applied voltage across the DC motor changes, resulting in rotation of the armature in the opposite direction. II. Proposed Concepts A. H-Bridge from P07021 The first candidate for the H-Bridge system is the one which was designed by a previous RIT Senior Design Team. 1. Pros: a) Already designed b) Simple design 2. Cons: a) Low power output b) Thermal problems B. H-Bridge Driver IC and a custom designed NMOS Bridge Figure 5.2.1: Schematic of HIP4081A H-Bridge Driver and NMOS Bridge The figure above shows how the Harris Semiconductor HIP4081A NMOS H-Bridge driver IC would be implemented with a NMOS Bridge. The HIP4081A allows the upper NMOS to be turned fully on as the IC has a pump circuit which allows the gate of the NMOS to be driven higher than the supply voltage, thus achieving a VGS which is much greater than the threshold voltage. For this reason, the H-Bridge can be constructed of all NMOS transistors, which have a much lower RON than their PMOS compliments. 1. Pros: a) Low resistance through bridge b) High power efficiency c) NMOS Bridge can be customized for application 2. Cons: a) Not completely open source b) Higher complexity C. Custom Complimentary MOSFET H-Bridge Design with built in Driver Figure 5.2.2: Schematic CMOS H-Bridge Logic Circuitry Figure 5.2.3: Schematic of CMOS H-Bridge The figures above show the Complementary MOSFET H-Bridge design. The way this design functions is that there is a direction and PWM signal from the main controller. The direction bit is used to turn on (continuously) one of the upper PMOS transistors. The NMOS transistor connected to the other side of the load is pulsed on and off by means of the PWM signal. This allows for just 1 transistor to be switched resulting in less dynamic power consumption. However, compared to other NMOS bridges, the on resistance will be slightly higher due to the use of PMOS transistors. As a benefit, there is no need for a pump circuit or driver, resulting in lower cost and reduced complexity. Figure 5.2.4 shows simulation results of the proposed circuit. In particular it shows the voltage applied to the load, PWM input, as well as current through the load. Figure 5.2.4: Simulation of CMOS H-Bridge 1. Pros: a) b) c) d) e) High power efficiency Has integrated E-Stop and brake Does not require NMOS driver pump circuit Inexpensive Open Source 2. Cons: a) Requires PCB layout and assembly b) Slightly higher RON due to PMOS D. Off Shelf H-Bridges Figure 5.2.5: Tecel Microcontrollers D200 Model H-Bridge Figure 5.2.6: Robot Power Simple-H Figures 5.2.4 and 5.2.5 are two examples of off the shelf, assembled H-Bride solutions. These are similar to the circuits mentions previously, except here all the design, building and testing have already been performed. In addition to these perks, some of the available off the shelf board have additional functionality than the circuits previously mentioned. Some are available in multiple channel models and may come with LED indicators or cooling fans. Some also incorporate dynamic motor braking depending upon certain inputs to the module. Data for these particular boards can be seen in table 5.2.1. 1. Pros: a) High power efficiency b) May have braking functions c) Ready to use 2. Cons: a) Expensive b) Not open source c) May not be optimized for application III. Selection Criteria Model P07201 Imax Icont 5A Vpower 24V Vlogic 5V Input Form PWM Frequency RON Static Power Loss 2A Draw 10A Draw Price w/o E-Stop HIP4081A CMOS D200 Simple-H 75A 30A 15 to 30V 5V PWM 0 to 10kHz 0.008 Ω 50A 36A 5 to 40V 3 to 5V PWM 0 to 10Khz 0.018 Ω 45A 10A 55V 5V PWM - 45A 20A to 25A 24V 3 to 5V PWM 0 to 20kHz 0.016 Ω 60 mW 1.6 W 140 mW 3.6 W ~$24 + PCB ~$15 + PCB 130 mW 3.2 W $35.00 $79.99 Table 5.2.1: Option Specifications H-Bridge Manufacturability Cost Efficiency Modularity Open Source Robust Size Durability Total P07021 0 0 0 0 0 0 0 0 0 MOSFET Design + 0 + + + + + 3 Table 5.2.1: Pugh's Matrix for Motor Driver Systems Off Shelf 0 0 + 0 + 0 + 2 H-Bridge Manufacturability Cost Efficiency Modularity Open Source Robust Size Durability Total Weight 20.0% 20.0% 12.5% 12.5% 10.0% 10.0% 10.0% 5.0% 100% Rating 5 2 3 3 2 2 4 2 23 P07021 Weighted Score 1 0.4 0.375 0.375 0.2 0.2 0.4 0.1 3.05 MOSFET Design Rating Weighted Score 2 0.4 5 1 4 0.5 5 0.625 5 0.5 3 0.3 3 0.3 4 0.2 31 3.825 Rating 3 1 4 3 1 4 1 4 21 Off Shelf Weighted Score 0.6 0.2 0.5 0.375 0.1 0.4 0.1 0.2 2.475 Table 5.2.3: Weighted Pugh's Matrix for Motor Driver Systems Both the weighted and non weighted Pugh’s matrixes in Table 3.1.2 and Table 3.1.3 show that the Custom MOSFET design has the highest ratings. The team decided that ease in manufacturing, cost, modularity and power efficiency were among the most important aspects to rate the different designs. IV. Conclusion The in-house CMOS design was chosen by the platform team as the best overall design for this project. Being completely designed and built in house, the design is completely open source. It also allows the team to design the unit to custom fit the rest of the system both electronically as well as mechanically. These custom boards can be designed to be stackable so that they can easily be added or removed as needed, making for a very modular system.