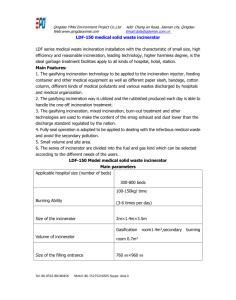

5.1 Waste Management Practices

advertisement