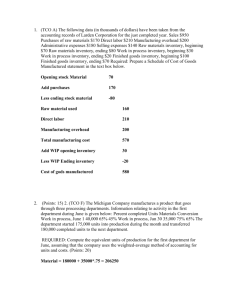

Managerial Accounting

advertisement

Managerial Accounting Tenth Canadian Edition Connect What You Really Need To Know Chapter 6: Systems Design: Process Costing and Service Department Overhead A. Process costing is used in industries that produce homogeneous products such as bricks, flour, and cement. It is also used in some assembly-type operations, as well as in utilities producing gas, water, and electricity. B. Process costing is similar to job-order costing in three ways: 1. Both systems have the same basic purposes, which are to assign material, labour, and overhead costs to products and to provide a mechanism for computing unit costs. 2. Both systems use the same basic manufacturing accounts: Manufacturing Overhead, Raw Materials, Work in Process, and Finished Goods. 3. Costs flow through these accounts in basically the same way in both systems. C. Process costing differs from job order costing in the following ways: 1. A single product is produced on a continuous basis, and each unit is essentially identical. 2. Costs are accumulated by department, rather than by job. 3. The department production report (rather than the job cost sheet) is the key document showing the accumulation and disposition of cost. 4. Unit costs are computed by department (rather than by job). This computation is made on the department production report. D. A processing department is any work center where work is performed on a product and where materials, labour, or overhead costs are added. Processing departments in a process costing system have two common features. First, the activity carried out in the department is performed uniformly on all units passing through it. Second, the output of the department is basically homogeneous. E. Less effort is usually required to use a process costing system than a job-order costing system; costs only need to be traced to a few processing departments, rather than to many individual jobs. F. Exhibit 6-3 provides a T-account model of cost flows in a process costing system. A separate work in process account is maintained for each processing department. Materials, labour, and overhead costs are entered directly into each processing department’s work in process account. G. Separate computations are made within each processing department for each cost category. The cost categories may include: 1. Costs of prior departments associated with units transferred into the department. 2. Materials costs added in the department. 3. Direct labour costs added in the department. 4. Manufacturing overhead costs applied in the department. In process costing, direct labour costs and manufacturing overhead costs are often combined into one cost category called conversion costs. H. Once the costs in each category have been totalled for a department, the department’s output must be determined so that unit costs can be computed. Units that have only been partially completed pose a problem. A unit that is only 10% complete should not count as much as a unit that has been completed and transferred on to the next department. This is where the concept of equivalent units comes in. 1. Equivalent units are the number of whole, complete units one could obtain from the materials and effort contained in partially completed units. Equivalent units are computed using the following formula: Equivalent units = Number of partially completed units × Percentage completion 2. Equivalent units of production is used to compute the cost per equivalent unit. Study Exhibit 6-5 carefully to develop an understanding of the equivalent unit concept. Under the weighted-average method, the equivalent units of production are determined as follows: + = Units transferred out to the next department or to finished goods ....... Equivalent units in ending work in process inventory.............................. Equivalent units of production ............. XXX XXX XXX 3. The equivalent units of production are computed separately for each cost category. I. Note the following points concerning process costing. 1. The equivalent units of production and the cost per equivalent unit must be computed separately for each cost category. 2. Units transferred out of the department to the next department—or, in the case of the last department, to finished goods—are always considered to be 100% complete with respect to the work done by the transferring department. 3. The first processing department will not have a cost category for the costs of units transferred in, but subsequent departments will have such a cost category. Units in process in a department are considered to be 100% complete with respect to the costs of the prior department. J. After the equivalent units of production are computed for each cost category, the next step is to compute the cost per equivalent unit for each cost category. Under the weighted-average method, the formula is: Cost of beginning Cost added work in process + during Cost per inventory the period equivalent = Equivalent units of production unit K. The final step is to compute the costs of the units transferred out during the period and the ending work in process inventory. These costs are determined as follows: 1. Units completed and transferred out. These units are presumed to be 100% complete. (If they were not complete with respect to the work done in the department, they would not be transferred out.) The costs of units transferred out are determined for each cost category within a department as follows: × = Units transferred to the next department . Cost per equivalent unit .......................... Cost of units transferred out .................... XXX XXX XXX This computation is made for each cost category in the department. The results are summed to determine the overall cost of units transferred out of the department. 2. Units in ending work in process inventory. The costs of the units in ending work in process inventory are determined for each cost category within a department as follows: × = Equivalent units of production in ending work in process inventory ...... Cost per equivalent unit ......................... Cost of ending work in process inventory ............................................ XXX XXX XXX This computation is made for each cost category in the department. The results are summed to determine the overall cost of ending work in process inventory. L. Note that the weighted-average method combines costs from the beginning inventory with costs from the current period. It is called the weighted-average method because it averages together costs from the prior period with costs of the current period. M. Operation costing is a hybrid system containing elements of both job-order and process costing. It is most commonly used when products use different materials but follow the same basic processing steps. For example, a factory that assembles personal computers might make many different models that use different components. However, all of the models go through the assembly department, testing department, and packing and shipping department. 1. In operation costing, products are handled in batches and each batch is charged with its own specific materials. In this sense, operation costing is similar to job-order costing. 2. Labour and overhead costs are accumulated by department and these costs are assigned to the batches on an average per unit basis as in process costing. N. Flexible manufacturing systems (FMS) have made it possible for companies to switch from the more costly job-order costing system to the less costly process or operation costing system. 1. This switch is made possible because FMS is proving to be highly efficient in reducing the setup time required between products and jobs. 2. Because setup time is reduced to insignificant amounts, companies are able to move between products and jobs with about the same speed as if they were working in a process-type environment. Appendix 6A: FIFO Method A. The FIFO method is more complex than the weighted average method, but is considered to be more accurate. The FIFO method keeps units and costs from the prior period separate from the units and costs of the current period. B. The production report under the FIFO method is similar to the production report under the weighted average method. There are, however, important differences in the reports that are easy to overlook. Refer to the Appendix A exhibits as you read the explanations that follow below. C. Under the FIFO method, the equivalent units of production are determined as follows: + + = Equivalent units to complete the beginning work in process inventory .. Units started and completed this period .. Equivalent units in ending work in process inventory................................. Equivalent units of production ................ XXX XXX XXX XXX Note that the weighted-average method includes the equivalent units in beginning inventory whereas the FIFO method does not. This is most easily seen from the following alternative method of computing the equivalent units of production under the FIFO method: – + = Units completed this period .................... Equivalent units in beginning inventory ............................................. Equivalent units in ending inventory ...... Equivalent units of production ................ XXX XXX XXX XXX D. Under the FIFO method, the cost per equivalent unit is computed using only costs added during the current period. Cost per = Cost added during the period equivalent unit Equivalent units of production E. The computation of the cost of ending work in process inventory is handled identically under the FIFO and weighted-average cost methods, although the costs per equivalent unit will usually be different. In computing the cost of units transferred out under the FIFO method, the units in beginning work in process inventory are kept separate from the units started and completed during the current period as follows: Computing the cost of units transferred out: Cost of beginning work in process inventory ......................................... × = × = Equivalent units of production required to complete the units in beginning work in process inventory ......................................... Cost per equivalent unit ...................... Cost to complete the units in beginning work in process inventory ......................................... Units started and completed this period .............................................. Cost per equivalent unit ...................... Cost of units started and completed this period ....................................... $XXX XXX $XXX $XXX XXX $XXX $XXX For each cost category within the department, the above three costs—the cost of beginning work in process inventory, the cost to complete the units in beginning work in process inventory, and the cost of units started and completed during the period—are summed to determine the cost of the units transferred out during the period. These costs are then summed across cost categories within the department to determine the overall cost of the units transferred out of the department during the period. F. When comparing the weighted-average and FIFO methods, two points should be noted: 1. From the standpoint of cost control, the FIFO method is superior to the weighted-average method because it separates the costs of the prior period from the costs of the current period. 2. If there are no beginning inventories, there will be no difference in costs reported using the FIFO and weighted-average methods. Because lean production reduces inventories to a minimum, adopting lean production will reduce the differences in costs computed under the two methods. What To Watch Out For (Hints, Tips and Traps) Although a process costing system may seem complex, a brief overview of process costing in its simplest form (weighted-average method) follows: A. In process costing, costs are accumulated in processing departments. B. A separate departmental production report is compiled for each processing department. This report provides the details of how costs are assigned to units that pass through the department. C. Costs to be accounted for in each processing department consist of: 1. Costs of the beginning work in process inventory in the department. 2. Costs added during the period. a. Costs of units transferred in from a preceding department. b. Costs added in the department itself (materials + labour + overhead). D. Costs are accounted for by assigning them to: 1. Ending work in process inventory in the department. 2. Units transferred out to the next department (or to finished goods). E. In process costing, each unit is assigned the average cost of units processed through the department. F. Two things must be known to compute the average cost per unit in a department: 1. The total cost. 2. The total number of units processed. G. Partially completed units are converted to equivalent (whole) units. For example, 200 units in ending inventory are 25% complete with respect to conversion costs. H. The two common methods of computing average costs per unit are the weighted-average method and the FIFO method. The FIFO method is discussed in Appendix 6A. A key aspects of applying the concepts of this chapter in practice deals with a concept known as equivalent units of production (pay particular attention to the computations in Exhibit 6-5) and preparing a production report, using either the weighted-average method or the FIFO method. The production report is complex and you will need to devote time to learning how it is constructed. Exhibit 6-7 provides a detailed example of a production report using the weighted-average method. (A production report prepared using the FIFO method follows the same concepts presented for the weighted-average method; however you must use the FIFO calculation illustrated in Appendix A.) A. The purpose of the production report is to summarize all of the activity that takes place in a department’s work in process account for a period. A production report has three parts: 1. A quantity schedule, which shows the flow of units through the department, and the computation of equivalent units for each cost category for the period. 2. A statement showing computation of the cost per equivalent unit for each cost category for the period. 3. A reconciliation of all cost flows into and out of the department during the period. Refer to Exhibit 6-7 as you go through the explanation of the production report below. B. The purpose of the quantity schedule on the production report is to show the flow of units through a department. The schedule shows the number of units to be accounted for in a department and it shows how those units have been accounted for. 1. The format of the quantity schedule under the weighted-average method is: Units to be accounted for: Work in process, beginning ........................... XXX Started into production .................................. XXX Total units ...................................................... XXX Units accounted for as follows: Transferred out to the next department or to finished goods ............... XXX Work in process, ending ................................. XXX Total units ...................................................... XXX 2. The equivalent units for the units transferred out and for the ending work in process inventory are listed next to the quantity schedule on the production report. C. The second step in preparing a production report is to compute the cost per equivalent unit for each cost category. Under the weighted-average method, this involves adding the costs from the beginning inventory to any costs added during the period to arrive at total cost. This figure is then divided by the equivalent units of production (from the quantity schedule) for the cost category to determine the cost per equivalent unit. D. The final step in a production report is to prepare a reconciliation of all costs. Costs are accounted for as either transferred out during the period or assigned to the ending work in process inventory. Costs are determined as follows: 1. Units transferred out. These units are presumed to be 100% complete. (If they were not complete with respect to the work done in the department, they would not be transferred out.) The costs of units transferred out are computed by multiplying the number of units transferred out by the cost per equivalent unit for each cost category. These costs are then summed. To simplify, a total equivalent cost per unit is usually calculated by summing the individual amounts for each cost category. This total is then multiplied by the number of units transferred out. 2. Units in ending work in process inventory. Within each cost category, the number of equivalent units is multiplied by the cost per equivalent unit for that cost category. These costs are then summed. E. Study Exhibit 6-7 carefully; it shows how the weighted average method works. Note that this method combines costs from the beginning inventory with costs from the current period. It is called the weighted average method because it averages together costs from the prior period with costs of the current period.