Application of lixiviation-cum-solvent extraction

advertisement

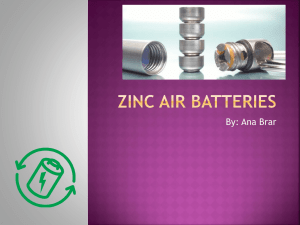

APPLICATION OF LIXIVIATION-CUM-SOLVENT EXTRACTION TO THE BENEFICIATION OF SPENT ZINC-CARBON BATTERIES. Assoc. Prof. Folahan A. ADEKOLA(+) and Dr. Alafara A. BABA (+) Department of Chemistry, P.M.B. 1515, University of Ilorin, Ilorin – Nigeria. (+) Corresponding Authors: E-mail: fadekola@unilorin.edu.ng (F. A. Adekola) alafara@unilorin.edu.ng (A. A. Baba) Tel: +2348067332320, +2348035010302 Abstract The techniques of chemical leaching and solvent extraction using Cyanex®272 have been applied to the recovery of valuable zinc (II) from spent zinc-carbon batteries in hydrochloric acid. The experimental data for the dissolution process have been analyzed and were found to follow the shrinking core model for mixed control reaction with surface chemical reaction as the rate controlling step. About 90.3%, dissolution was achieved with 4m HCl solution at 800C with 0.050 – 0.06 3mm particle size within 120 minutes at 360rpm. Activation energy value of 22.78kJ/mol and a reaction order of 0.74 with respect to H= ion concentration were obtained for the dissolution process. An extraction yield of 94.23% zinc (II) by 0.032M Cyanex®272 in kerosene was obtained from initial 10g/L spent battery leach liquor at 25±20C and at optimal stirring time of 25 minutes Iron has been effectively separated by precipitation prior to extraction by ammoniacal solution at pH 3.5, while lead and other trace elements were firstly separated from zinc (II) and total iron by cementation prior to iron removal and zinc (II) extraction. Finally, the stripping study showed that 0.1M HCl led to the stripping of about 95% of zinc (II) from the organic phase. Key words: Lixiviation, Solvent extraction, Zn(II) recovery, Zinc-carbon batteries. Introduction: The world demand for metals is progressively increasing, while primary resources are being depleted. With the constraints raised by law and related legislation assigned to protect the environment from hazardous wastes in the world, it becomes more and more important to partly satisfy such world demand through recovery of metals of concern from secondary sources including Zinc-Carbon batteries (Li et al, 2009; Rabah et al, 2008). Disposal of spent batteries is of major concern to the environment in terms of heavy metals content contained therein. According to the battery market evolution in 2003, the total portable battery weight in the East and West Europe was estimated to be 164, 000 tons, of which Zinc-carbon and alkaline batteries constituted 30.5% and 60.3%, respectively (Baba, et al, 2010). 1 Zinc batteries could therefore be considered as a valuable one of the secondary raw materials for the recovery of zinc. To this end, a world shortage of 432, 000 tons of zinc concentrates has been reported in 2005 and the zinc price attained a record value of about & 2500/tons (Ferella, et al, 2006) At present, there are basically two main methods employed world wide in metal production from secondary sources. The most important one is the conventional pyrometallurgical method, which may not be popular in a developing economy due to high-energy requirement (Baba, et al, 2009; Rotuska and Chmielewski, 2008). The hydrometallurgical processes are more environmentally suitable and economical to treat even low zinc containing materials on small scale. It consists of crushing, leaching (non-oxidative leaching, atmospheric leaching and pressure leaching), solvent extraction and electrowinning (Rotuska and Chmielewski, 2008). In recent years, the acid leaching of batteries are amenable due to the availability of materials for construction with improved resistance to chloride attack and substantially faster dissolution rates and relative cheap in terms of cost are among other reasons why HCl is preferred to other acids such as H2SO4 and HNO3 for leaching purposes (Zuo-mei, et al, 1984). In the publicly available literature, there is a substantial amount of data on the extraction of Zn(II) from acidic leachates using organophosphorus extractants (Alguacil, et al, 1992; Regel-Rosocka, et al, 2003). Therefore, the present study is developed to carry out a complete investigation involving both acid leaching and solvent extraction of Zinc(II) from the spent Zinc-carbon batteries that have constituted a major portion of the hazardous wastes in sub-saharan Africa (Tetsopgang, et al, 2007) by Cyanex®272. Experimental. Spent Zinc-Carbon batteries, the cheapest and the most popular brand (Tiger Head typemanufactured in China) in the Nigerian market were collected and used for this study. The sample dismantling, chemical leaching and Zinc(II) recovery procedure from the leach liquor are detailed elsewhere (Baba, et al, 2009). The Zinc(II) recovery was done by solvent extraction technique with Cyanex®272. After equilibration and phase separation, the concentration of Zn left in the aqueous phase was analysed. The concentration of the metal ion extracted into the organic phase was caculated by difference. (Baba, et al, 2009). Prior to extraction of Zn and in order to avoid interference, iron has been previously removed by precipitation in ammoniacal solution at pH 3.5 with conc. NH3 solution after moderate stirring (Daoud, et al, 2006). Lead and other trace elements from the leach liquor were successfully separated from Zinc by cementation with pure Zinc metal (Baba, et al, 2004). Finally, the stripping of Zinc from organic phase was done by 0.1M HCl (Baba, 2008). Results, Discussion and conclusions: The results of the quantitative leaching of the powdered Zinc-Carbon batteries by hydrochloric acid showed that the dissolution rates are significantly influenced by system temperature and concentration of the acid solutions. The experimental data for the dissolution rates have been analysed and were found to 2 follow the shrinking core model for mixed control reaction with surface chemical reaction as the controlling step. Finally, a hydrometallurgical scheme for Zinc and lead recovery from spent Zinc-carbon batteries by hydrochloric acid leaching consisting of 594.3mg/L Zn, 70.4mg/L Pb and 98.74mg/L Fe as major constituents by Cyanex®272 is summarized in Fig. 1. 3 Spent zinc-carbon battery collection and sample preparation (crushing, sorting, pulverizing) Leaching in HCl media 4M HCl at 360rpm; 3.0; 80oC Composition: Zn: 594.3mg/L; Pb: 70.40mg/L; Fe: 98.74mg/L Other elements: Ag, Mn, Cu are present in traces. Leachate Zn metal granules; 25±2oC Cementation Composition: Zn: 622.59mg/L; Pb: <2mg/L; Fe: 95.66mg/L Efficiency of cementation = 98% Ammoniacal solution, pH 3.5; 25±2oC Re-use, n≤3 Iron separation Composition: Zn: 604.27mg/L; Fe: <1mg/L Iron removal efficiency = 98% 0.032M Cyanex®272; pH 3.0; Stirring rate = 25min; 25±2oC Solvent extraction of Zinc(II) Cyanex®272 regenerated Zn-Cyanex®272: 569.38mg/L; Extraction efficiency = 94.23% 0.1M HCl; 25oC Zinc(II) stripping Zn-aqueous: 507.41mg/L; Recovery efficiency = 95.48% Zn(II) in 0.1M HCl Fig. 1 Hydrometallurgical scheme for zinc and lead recovery from spent zinc-carbon batteries in Hydrochloric acid4medium by Cyanex®272.. Acknowledgements: The authors are grateful to Dr. Oliver Rouher and Mrs. Christine Salomon of Cytec Industries, Rungis Cedex, France for providing the Cyanex®272 used for this study. A. A. Baba also appreciates the University of Ilorin, Ilorin-Nigeria for the 2005/2006 Staff Development Award. References: Alguacil, F.J., Cobo, A., and Caravaca, C. Study of the extraction of Zinc(II) In aqueous chloride media by Cyanex 302. Hydrometallurgy, 31, 163174, 1992. Baba, A. A., Adekola, F. A. and Bale, R. B. Development of a combined pyro- and hydro-metallurgical route to treat spent zinc-carbon batteries. Journal of Hazardous Materials, 171, 838-844, 2009. Baba, A.A., Adekola, F. A. and Ewuloye, G.D. Leaching of lead from spent motorcycle battery in hydrochloric acid part 1: Dissolution kinetics. Acta Metallurgical Slovaca, 16(4), 88-93, 2010. Baba, A.A., Adekola, F.A. and Mesubi, M.A. Solvent extraction of Zinc with Triphenylphosphite from a Nigerian sphalerite in hydrochloric acid. J. Sci., Isl. Rep., Iran. 14(1), 33-37, 2004. Baba, A.A. Recovery of zinc and lead from sphalerite, galena and waste materials by hydrometallurgical treatment. Ph.D. Thesis, Chemistry Department, University of Ilorin, Ilorin-Nigeria, 675pp., 2008. Daoud, J.A., Ali, A.M.I. and Ahmad, J. A. CYANEX 272 for the extraction and recovery of Zinc from aqueous waste solution using a mixer-settler unit. Sep. & Purification Technol., 47, 135-140, 2006. Ferella, F., Michelis, I.D., Pagnanelli, F., Beokhini, F., Furlani, G., Navarra, M., Vegilio, F. and Tovo, L. Recovery of Zinc and manganese from spent batteries by different leaching systems. Acta Metallurgical Slovaca, 12, 95-104, 2006. Li, J., Li, X., Lu, Q., Wang, Z., Zheng, J., Wu, L. and Zhang, L. Study of extraction and purification of Ni, Co and Mn From spent battery material. Hydrometallurgy, HDROM-03021, 6pp. 2009. Rabah, M.A., Farghaly, F.E. and Abd-El-Motaleb, M.A. Recovery of nickel, cobalt and some salts from spent Ni-MH batteries. Waste Management, 28(7), 1159-1167, 2008. Regel-Rosocka, M., Miesiac, R., Cierpiszewski, I., Mishowov, K., Alejski, A. and Symanowski, J. Recovery of Zinc(II) from spent hydrochloric acid solutions from Zinc hot-dip galvanizing plants. A Proceeding Hydrometallurgy 2003 Mineral Soc. Am. Short Course Notes, 1577-1591, 2003. Rotuska, K. and Chmielewski, T. Growing role of solvent extraction in 5 copper ores processing, Physiocochemical Problems of Min. Processing, 42, 29-36, 2008. Tetsopgang, S. and Kuepono, G. Quantification and Characterization of discarded batteries in Yaounde from the perspective of health, safety and environment protection. Resources, Conserv. Recycling, 52(8-9), 1077-1081, 2007. Zno-mei, G., Warren, W. and Henein, H. Reaction kinetics of the ferric chloride leaching of sphalerite- an experimental study. Met. Trans. B., 15B, 5-12, 1984. 6