SOP for Working with Acrylamide

advertisement

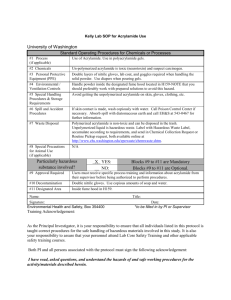

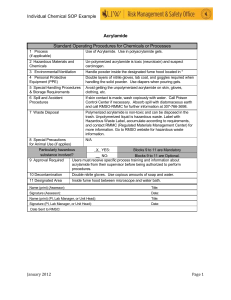

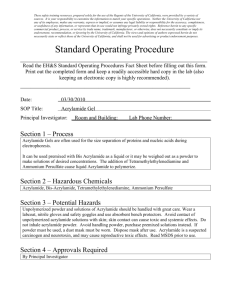

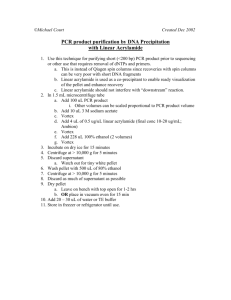

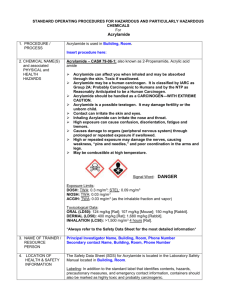

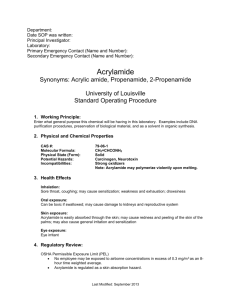

DOHS SOP#______________ Date DOHS Received_______ Departmental Approval _________________________ DOHS Approval _________________________ _ STANDARD OPERATING PROCEDURE FOR CARCINOGENS AND HIGHLY TOXIC MATERIALS Principal Investigator(s):___________________________________________ Location(s):_____________________________________________________ Chemical(s): ACRYLAMIDE 1. Purchasing: All purchases of this material must have approval from the Principal Investigator before ordering. The user is responsible to ensure that a current Material Safety Data Sheet (MSDS) is obtained unless a current one is already available within the laboratory. Quantities of this material will be limited to the smallest amount necessary to complete the experiment. 2. Use Use of Acrylamide in powder/dry form for making electrophoresis gels. Although gels are less hazardous from an inhalation route of exposure, these procedures can also be followed to protect against hazards from the gel. 3. Storage: Powder easily becomes airborne and may result in personal exposure and area contamination. Use care to avoid dispersing dust. Keep container tightly closed to prevent acrylamide from subliming and entering the atmosphere. Store in cool place. Keep from contact with oxidizing materials, reducing agents, acids, bases, metal and contaminants. Materials will be stored according to compatibility and label recommendations in a designated area: Storage areas will be regularly inspected by________________________ to ensure safety. Periodic inventory reductions will be scheduled. 4. Authorized personnel: Use of this material requires prior written approval from Title:N/A.(see Chemical Hygiene Plan for approval level requirements). Use will be limited to the following personnel (check all that apply): Principal Investigator _X_ Graduate students____ Technical staff __X_ Post doctoral employees____ Undergraduates ____ Other (describe) _________________________ 5. Training requirements: The user must demonstrate competency and familiarity regarding the safe handling and use of this material prior to purchase. Training should include the following: Review of current MSDS Review of the OSHA Lab Standard Review of the Chemical Hygiene Plan Special training provided by the department/supervisor(Right to Know) Review of the departmental safety manual Safety meetings and seminars 6. Use location: Materials shall be used only in the following designated areas in room Use process enclosures, local exhaust ventilation or other engineering controls such a fume hood or weighing hood to reduce dust concentrations as low as reasonably achievable. Engineering controls should be used whenever feasible to maintain airborne acrylamide concentrations at the lowest achievable levels. Check all that apply: demarcated area in lab (describe) laboratory fume hood ONLY no open bench work fume hood __X__ glove box __X___ other (describe) _______________________ 7. Personal protective equipment: All personnel are required to wear the following personal protective equipment whenever handling this material(check all that apply): Chemical safety goggles X Face shield _____ Gloves (type) Nitrile, Viton , PVC or Butyl Rubber Respirator (type)______________ Rubber apron_____ Lab coat __X__ Tyvek clothing _____ Other (describe) ______________ Gloves should be used when potential for skin contact exists. Disposable nitrile, viton, PVC, or butyl rubber gloves should be worn. Safety glasses with side shields, or goggles should be worn. A laboratory coat should be worn when working with chemicals. 8. Waste disposal: The authorized person using this material is responsible for the safe collection, preparation and proper disposal of waste unless otherwise stated below. Waste shall be disposed of as soon as possible and in accordance with all laboratory and University procedures. Specific instructions: Liquid waste will be placed inside a Nalgene waste container. The nalgene container will have a safety waste funnel attached to it. The safety funnel has a hinged cover to keep emissions contained and spills to a minimum. This container also has a built in vent to minimize overflow. This material should be appropriately labeled with the name and the quantity. Solid waste that is unable to go into a nalgene container should be placed into a 6 mil poly bag or triple bagged into the normal trash bags. The bagged material should then be appropriately labeled with a hazardous waste label and set aside for pick up by the Department of Occupational Health & Safety. Reagent dry acrylamide as well as solutions or gel should be labeled with a hazardous waste label. Dispose of waste through Occupational Health & Safety. 9. Decontamination: Periodically treat area where unpolymerized acrylamide is used with 1.6% potassium persulfate, then with 1.6 % Sodium metabisulfite. Let stand for 30 minutes, then wash with plenty of water. 10 Exposures: Emergency procedures to be followed (from MSDS): Acrylamide is a suspect human carcinogen and neurotoxin Skin/eye contact--symptoms: The acute toxicity of acrylamide is moderate by ingestion or skin contact. Skin exposure leads to redness and peeling of the skin of the palms. Inthe event of skin contact, immediately wash with soap and water and remove contaminated clothing. Repeated exposure to low levels of dust has resulted in neurotoxicity in humans. The primary route of occupational exposure is skin absorption, but inhalation and ingestion can contribute significantly to the overall exposure. The appearance of symptoms may be delayed up to 2 months, with low level exposures. Symptoms may include: tiredness, weakness in hands and feet, tremor, dizziness, muscular incoordination (ataxia), sleepiness, poor memory, confusion, slurred speech, abnormal behavior, vision changes, and urinary system changes, and weight loss. Recovery from these toxic effects is usually good, but may take months to years, depending on severity and duration of exposure. PEL(OSHA) 0.3 mg/m3 -skin TLV-TWA(ACGIH) 0.03 mg/m3- skin LD50 skin(rat) 400mg/kg Ingestion-- symptoms: The acute toxicity of acrylamide is moderate by ingestion or skin contact. If acrylamide is ingested, obtain medical attention immediately. LD50 Oral(rat) 124 mg/kg Inhalation--symptoms: Dusts can probably cause irritation of the nose and throat. High concentrations of dust may cause coughing and sneezing. It appears unlikely that a serious occupational poisoning could result from short-term inhalation alone since skin absorption is a major route of occupational exposure. However, inhalation exposure can contribute to the total exposure. If large quantities of acrylamide dust are inhaled, move the person to fresh air and seek medical attention at once. 11 Spills: Spill cleanup materials to be used, location of materials, PPE to be used, disposal of cleanup materials, etc. Please be as complete as possible: Wear appropriate protective clothing. If potential respiratory hazard exists call OHS (ext. 8475). Collect spills into appropriate waste container. Avoid creation of airborne dust. Small liquid spill: Absorb with sand or other non-combustible absorbent materials and place into containers for later disposal. Treat site with 1.6% potassium persulfate, then with 1.6 % sodium metabisulfite. Let stand for 30 minutes, then wash with plenty of water. Small dry spill: Scrape material into clean, dry containers and cover. Do not create airborne dust. Treat site with 1.6% potassium persulfate, then with 1.6 % sodium metabisulfite. Let stand for 30 minutes, then wash with plenty of water. Large spill: Notify others in room of spill. Evacuate room/immediate area. Call OHS for cleanup (ext. 8475). Post room with warning notifying others of spill. Prevent unnecessary entry into area until arrival of OHS response team. Provide assistance and information to spill responders. Treat any spilled material as hazardous waste and dispose of through OHS. 12. Emergency Phone Numbers: Campus Police 9-911 Occupational Health & Safety X8475 13. Other Special precautions: