27_SWP_Making 30_ Low Bis Acrylamide

advertisement

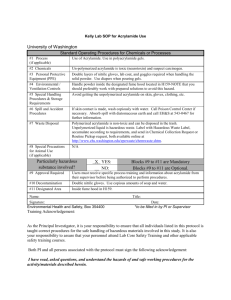

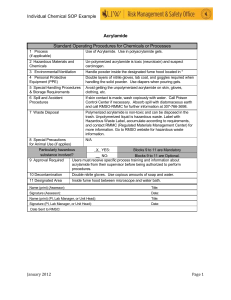

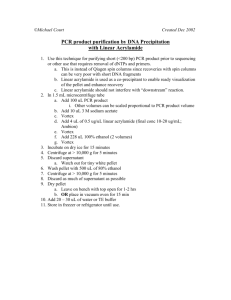

OHS026 Safe Work Procedure Faculty/Division Medicine Document number Initial Issue date 23rd June 2009 SOMS.CGM.SWP027 School/ Divisional Unit School of Medical Sciences, Oncology Research Unit/Neuromuscular and Regenerative Medicine Unit Current version Current Version Next review date 1 23rd June 2012 Issue date 23rd June 2009 The Writing Safe Work Procedures Guideline (OHS027) should be consulted to assist in the completion of this form. Safe Work Procedure Title and basic description Title: Low Bis Acrylamide solution Description: Making a 30% solution of low-bis acrylamide Associated risk assessment title and location: 27_RA_Making 30% Low0Bis Acrylamide Solution_SW Describe the activity or process IMPORTANT NOTE. Acrylamide and N,N’ -Methylene bis-acrylamide are both known carcinogens and suspected neurotoxin. Fine dust generated from the powdered forms of these two compounds can enter the body via mucosal surfaces with entry occurring mainly by either inhalation and/or ingestion. Weighing of acrylamide powder should always be carried out in a fume hood whilst wearing appropriate PPE including gloves, face mask and safety goggles. THE FOLLOWING PROCEDURE MUST BE CARRIED OUT IN A FUME HOOD. Procedure for preparing 30% low-bis acrylamide stock In a fume hood weight out the appropriate amounts N,N’ methylene-bis-acrylamide and acrylamide and make up appropriate volume with MilliQ water in a conical flask. The volumes and weights 30% low-bis acrylamide (92:1) are as follows: Acrylamide Bis Acrylamide 100 ml 29.73g 0.27g 200 ml 59.46g 0.54g 500 ml 148.65g 1.35g Stir solution with gentle swirling until acrylamide is dissolved. Filter solution through Whatman filter paper into an appropriate sized Schott bottle wrapped in aluminum foil. Store at 4oC. List all resources required including plant, chemicals, personal protective clothing and equipment, etc Fume Hood Acrylamide N,N’ Methylene-bis-Acrylamide MilliQ water Conical Flask Schott bottle Whatman Filter Paper Weighing Balance Weigh Boats Disposable Face Mask ___________________________________________________________________________________________________________ ___________ Page 1 of 3 Safe Work Procedure Date Effective: 01/01/2007 Uncontrolled document when printed Current Version: 1.2, 15/08/2007 Gloves Safety Glasses Lab Coat/Gown List potential hazards and risk controls including specific precautions required Potential Hazards Symptoms Of Overexposure (For Each Potential Route Of Exposure): Inhaled: Material should be handled in a fume hood. Airborne acrylamide is readily absorbed through the lung and overexposure will produce signs and symptoms similar to those described in "Swallowed". Contact With Skin Or Eyes: Can produce conjunctival eye irritation and can lead to systemic exposure if contact is prolonged and/or repeated. May cause peeling and redness of skin. Absorbed Through Skin: Readily absorbed through unbroken skin. Signs and symptoms as in " Swallowed " but proceeded by peeling and redness of skin of fingers and hands. Swallowed: Neurotoxicity can result after a single ingestion but is more likely to occur after ingestion of small amounts over a period of several day or weeks. Signs and symptoms include increased sweating of hands and feet, numbness, tingling and weakness in extremities, unsteady gait, and decreased reflexes. Health Effects Or Risks From Exposure Acute: Increased sweating of hands and feet, numbness, drowsiness, tingling and weakness in extremities, unsteady gait, and decreased reflexes. Chronic: Suspected Human Carcinogen (ACGIH). Repeated skin contact, inhalation, or swallowing may cause nervous system disturbances. An early sign of overexposure is peeling of this skin of the fingertips. Patients should be monitored for at least 2-3 weeks and observed for signs of delayed neurotoxicity. Acute and chronic exposure may lead to weak or absent reflexes, positive Romberg's sign, loss of vibration and position senses, and numbness and tingling of the limbs. Risk Controls and Precautions Ventilation And Engineering Controls: A closed system should be employed such as a fume hood. Where this is not possible utilize enclosures and local exhaust ventilation to prevent and/or control skin contact, dust generation, and vapor release. After acrylamide is in solution, exposure to liquid and mist must be controlled. Respiratory Controls: Wear disposable face masks Eye Protection: Chemical safety goggles and/or full face shield and head covering should be worn as necessary to prevent eye and scalp contact. Maintain eye wash fountain and quick-drench facilities in work area. Gloves: Wear clean impervious rubber or plastic gloves. Other Clothing And Equipment: Rubber shoes and long sleeved coveralls or suitable lab coat should be provided daily. Other Handling and Requirements: -ventilated place away from incompatible ___________________________________________________________________________________________________________ ___________ Page 2 of 3 Safe Work Procedure Date Effective: 01/01/2007 Uncontrolled document when printed Current Version: 1.2, 15/08/2007 materials. Protective Measures During Maintenance Of Contaminated Equipment: Wear protective clothing and appropriate respiratory protection. Do not cut, grind, weld, or drill on or near container. List emergency shutdown instructions In the event of inhalation or ingestion the first aid officer should be consulted immediately. First Aid Officer: Renee Szokoli ext 58497 List clean up and waste disposal requirements Weigh boats use for weighing powder and KimWipes used for cleaning spatulas should be disposed of in the designated cytotoxic waste containers. List legislation, standards and codes of practice used in the development of the SWP NSW OHS Act 2000 NSW OHS Regulation 2001 Australia Dangerous Goods Code Code of Practice for the Labelling of Workplace Substances AS/NZS 2243.2:2006. Safety in laboratories. Part 2: Chemical aspects AS/NZS 2161.1:2000 Occupational Protective Gloves – Selection, Use and Maintenance AS/NZS 1336:1997 Recommended Practices for Occupational Eye Protection UNSW Hazardous Waste Disposal Procedure Supervisory approval, training, and review Supervisor: Peter Gunning Signature: Plant custodian: Signature List competency required – qualifications, certificates, licencing, training - eg course or instruction: Training as per Training Needs Analysis, Induction to Lab, Training in this SWP ___________________________________________________________________________________________________________ ___________ Page 3 of 3 Safe Work Procedure Date Effective: 01/01/2007 Uncontrolled document when printed Current Version: 1.2, 15/08/2007