OAC 252:515 - the Oklahoma Department of Environmental Quality

advertisement

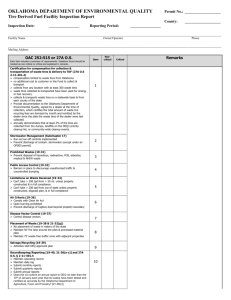

OKLAHOMA DEPARTMENT OF ENVIRONMENTAL QUALITY Permit No.: ___________________ Waste Tire Facility Inspection Report County: Inspection Date: ________________ Reporting Period: ___________________ ________________ _________________________________________________________________________________________________________________ Facility Name Owner/Operator Phone _________________________________________________________________________________________________________________ Mailing Address OAC 252:515 or 27A O.S. Each item includes a summary of requirements. Violations found should be marked as non-critical or critical and explained in remarks. Certification of compensation for waste tire processing [27A O.S. 2-11-401.4(C)(1)(a-c)] Facilities that process waste tires by altering the form of the waste tires but do not produce crumb rubber shall not receive compensation until the facility documents the sale & movement of the processed tire material off-site to a third party. Facilities shall report & certify tire processing activity in terms of weight Facility shall not have accumulated more processed material than the amount for which the facility has provided financial assurance under its solid waste permit or the amount accumulated from 3 years of operation , whichever is less. Certification of compensation for collection & transportation of waste tires & delivery to waste tire facility or TDF [27A O.S. 2-11-401.4] Compensation limited to waste tires from Oklahoma No additional cost to customer or the Fund to collect & transport Waste tires have been actually processed according to the solid waste permit Demonstrate that the facility is regularly engaged in the collection, transportation, & delivery of waste tires to a waste tire facility or to a TDF facility, on a statewide basis, & from each county of the State. Provide documentation to the Oklahoma Department of Environmental Quality, signed by a dealer at the time of collection, which certifies the total amount of waste tire recycling fees are itemized by month and remitted by the dealer since the date the waste tires of the dealer were last collected Annually demonstrate that at least 2% of the tires were collected from tire dumps or landfills on the Department’s priority cleanup list or community-wide cleanup events approved by the Department Stormwater Management (Subchapter 17) Run-on/run-off controls implemented Prevent discharge of contam. stormwater (except under an OPDES permit) Prohibited Wastes (19-31 & 21-32(b)) Prevent disposal of hazardous, radioactive, PCB, asbestos, medical & NHIW waste Only accept waste tires Public Access Control (19-32) Barriers in place to discourage unauthorized traffic & uncontrolled dumping Limitations on Waste Received (19-34) Can’t take > 200 tpd from > 50 mi. unless properly constructed & in full compliance Can’t take > 200 tpd from out of state unless properly constructed, disposal plan, & in full compliance Air Criteria (19-36) Comply with Clean Air Act Open burning prohibited Prevent discharge of fugitive dust beyond property boundary Disease Vector Control (19-37) Control disease vectors Placement of Waste (19-38 & 21-32(g)) No placement of waste in waters of the state Maintain 50’ fire lane around tire piles & processed material piles Maintain 75’ waste-free buffer zone with adjacent properties Salvage/Recycling (19-39) Activities IAW DEQ approved plan Recordkeeping/Reporting (19-40, 21-36(a-c)) Maintain operating record Submit monthly reports Submit quarterly reports Submit annual reports Item 1 2 3 4 5 6 7 8 9 10 11 Noncritical Critical Remarks Does the o/o submit an annual report to DEQ no later than the 10th of January each year that its scales have been tested and certified as accurate by the Oklahoma Department of Agriculture, Food, and Forestry? [21-36(c)] Special Collection Efforts (21-5) Collect tires prior to end of qtr if county hasn’t been served, or prior to end of the following qtr if county already served Maximum Storage (21-32(c)) Store <= 250,000 tires, or max. number allowed by permit Store <= 3 years processed tire material, or amount provided by financial assurance Tires Awaiting Processing (21-32(d)) Tire pile base <= 200’ x 150’ Tire pile height <= 7’ Tire pile slopes <= 2:1 Processed Material Storage (21-32(e)) Processed material pile base <= 200’ x 150’ Processed material pile height <= 20’ Processed material pile slopes are stable Tire Dumps [27A O.S. 2-11-401.4(C)(2)(d)(3)] 2% of tires collected annually from PCL dumps, landfills on the Department’s priority cleanup list, or community-wide cleanups Weighing Processed Material (21-32(h)) Weigh processed tire material on certified scales Weigh each truck/trailer full & empty Imprint gross & tare weights on same ticket Do not use stored tare weights Automotive Dismantler Tires (21-33) Verified statement attached to manifest Mobile Operations (21-34) Mobile equipment described in the permit Waste tires processed directly into truck/trailer Processed tires transported daily to waste tire facility Waste Tire Manifests (21-51) Use of Waste Tire Compensation Manifest Signature of generator, transporters, & tire facility present Manifest returned to generator within 30 days Manifests maintained for 5 years Closure (Subchapter 25, Part 3) Approved closure plan Closed IAW plan & rules Closure certification (includes PE certification for > 5000 population or population equivalent) County land records notice Cost Estimates & Financial Assurance (Subchapter 27) Cost estimates approved by DEQ Cost estimates adjusted annually Trust fund/escrow: properly funded based on 15-yr pay-in or economic life of site, whichever is shorter Corporate test submitted w/i 90 days of end of corporate fiscal year Municipal test submitted w/i 180 days of end of municipal fiscal year Other mechanisms funding equal to approved cost estimates Waste Exclusion (29-3) Notify DEQ of rejected waste Miscellaneous In compliance with permit conditions, requirements of DEQ NOVs/Orders not identified, other requirements of OAC 252:515, other DEQ rules 12 13 14 15 16 17 18 19 20 21 22 23 24 Purpose of Visit Operating Status Action [] Routine Inspection (circle item numbers inspected) [] Active [] None [] Full Compliance Inspection (all inspection items were inspected) [ ] Closed (date entered PC _____________) [] Notice to comply [] Other (identify _____________________) _____________________________________________________________________________________________________________________________ _____ LPD Inspector Date __________________________________________________________________________________________________________________________________ Facility Representative Date OAC 252:515 rules adopted June 2003; 1st revision January 21, 2005 due to statutory change; 2nd revision October 21, 2005 due to statutory change; 3rd revision June 2006 due to statutory change; 4th revision October 10, 2007 due to statutory change DEQ Form # 515-840T