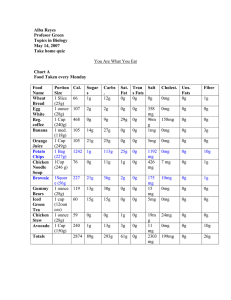

Milk Powder: 5g - Department of Chemistry

advertisement

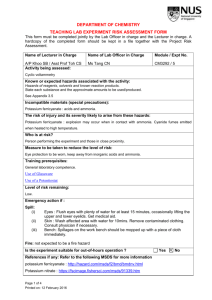

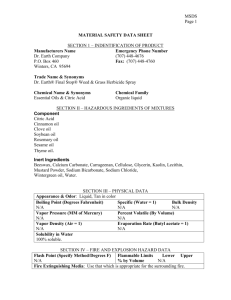

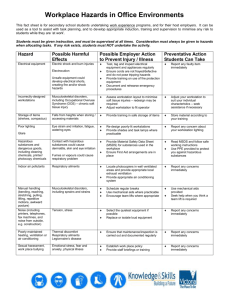

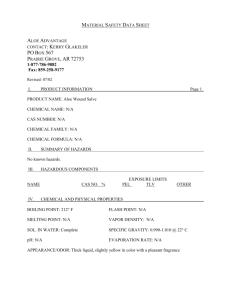

DEPARTMENT OF CHEMISTRY TEACHING LAB EXPERIMENT RISK ASSESSMENT FORM This form must be completed jointly by the Lab Officer in charge and the Lecturer in charge. A hardcopy of the completed form should be kept in a file together with the Project Risk Assessment. Name of Lecturer in Charge Name of Lab Officer in Charge Module / Expt No. A/P Jaenicke Stephan Activity being assessed: Toh Soh Lian CM 2166/Expt 1B Use of ion-selective electrodes for the determination of Sodium and Potassium in Baby Milk powder. Known or expected hazards associated with the activity: Hazards of reagents, solvents and known reaction products. State each substance and the approximate amounts to be used/produced. List of activities involved in this experiment which inevitably entail risks. The following are the activities being use: 1) Glass Apparatus. Refer to prepared risk assessment on Use of Glassware. 2) Hot Plate/Magnetic Stirrer, Oven. Refer to prepared risk assessment on Use of Laboratory Heating Equipment . 3) Electricity. Potentiometer meter. Refer to prepared risk assessment on Use of Standard Electrical Equipment . 1.0mg Na+/ml standard solution: 10ml No hazardous product. ISAB (Sodium): 100ml Causes respiratory tract, eye and skin irritation. May be harmful if swallowed. Routes of entry: Absorbed through skin. Eye contact. Inhalation. Ingestion. * No MSDS available for this reagent. Above information is based on MSDS for Triethanolamine used for preparation. 1.0mg K+/ml standard solution: 10ml No hazardous product. ISAB (Potassium): 100ml May cause allergic skin reaction. Hygroscopic. *No MSDS available for this reagent. Above information is based on MSDS for Triethanolamine used for preparation. Milk Powder: 5g No hazardous product. Page 1 of 6 Printed on: 13 February 2016 * Above amount stated are computed for the whole experiment. Incompatible materials (special precautions): 1.0mg Na+/ml standard solution: Not available. ISAB (Sodium): Reactive with oxidizing agents, acids. 1.0mg K+/ml standard solution: Not indicated. ISAB (Potassium): Strong oxidizing agents. Milk Powder: Not available. The risk of injury and its severity likely to arise from these hazards: 1.0mg Na+/ml standard solution: Eye Contact: May cause irritation. Ingestion of large amounts: May cause nausea, vomiting, spasms. No toxic effects are to be expected when handled properly. ISAB (Sodium): Eye Contact: Hazardous in case of eye contact (irritant). Inflammation of the eye is characterized by redness, watering, and itching. Skin Contact: Hazardous in case of skin contact (irritant). Skin inflammation is characterized by itching, scaling, reddening, or, occasionally, blistering. Inhalation: Hazardous in case of inhalation (lung irritant). Ingestion: May be hazardous in case of ingestion. 1.0mg K+/ml standard solution: No harmful effects indicated from available information. ISAB (Potassium): Skin Contact: Irritates Eye Contact: Severe irritation Inhalation: Irritates Ingestion: May be harmful. Page 2 of 6 Printed on: 13 February 2016 Milk Powder: Naturally occurring substance. No toxic effects are to be expected when the product is handled appropriately. Who is at risk? Persons handling the chemicals as well as those in the vicinity. Measure to be taken to reduce the level of risk: Proper laboratory attire and safety measures must always be used in order to reduce the level or risk. Wash thoroughly after handling. Do not take internally. Eye wash and safety equipment should be readily available. Eye protection: Chemical safety goggles. Hand protection: Gloves. Please refer to PSSO Safety Information Centre website on safety measures: http://www.chemistry.nus.edu.sg/PSSO/Safety.htm. Training prerequisites: This assessment should be read by everyone who will be using the above mentioned chemicals. Please refer to Completed Risk Assessment on Common Activities: http://www.chemistry.nus.edu.sg/PSSO/Safety/Risk/risk.htm#Common. Level of risk remaining: The level of risk is low although constant vigilance is necessary to avoid injury. Emergency action if : Spill: 1.0mg Na+/ml standard solution: Mop up with plenty of water and run to waste, diluting greatly with running water. ISAB (Sodium): Small Spill: Dilute with water and mop up, or absorb with an inert dry material and place in an appropriate waste disposal container. Large Spill: Absorb with an inert material and put the spilled material in an appropriate waste disposal. 1.0mg K+/ml standard solution: Evacuate the area of all unnecessary personnel. Wear suitable protective clothing. Eliminate any ignition sources until the area is determined to be free from explosion or fire hazards. Contain the release and eliminate its source, if this can be done without risk. Page 3 of 6 Printed on: 13 February 2016 ISAB (Potassium): Before dealing with spillages take necessary protective measures, inform others to keep at a safe distance and, for flammable materials, shut off all possible sources of ignition. Transfer carefully into container and arrange removal by disposal. Wash site of spillage thoroughly with water and detergent. Milk Powder: Take up dry. Forward for disposal. Rinse away remainder with water. Fire: 1.0mg Na+/ml standard solution: None. ISAB (Sodium): Small Fire: Use DRY chemical powder. Large Fire: Use water spray, fog or foam. Do not use water jet. 1.0mg K+/ml standard solution: Use any suitable for adjacent material. ISAB (Potassium): Use water, dry powder or carbon dioxide. Milk Powder: In adaption to materials stored in the immediate neighbourhood. Is the experiment suitable for out-of-hours operation ? Yes No References if any: http://www.hannainst.com/downloads/msds/7080.pdf http://www.emdchemicals.com/analytics/doc/msds/msds-display.asp?materialid=px1413 http://www.emdchemicals.com/analytics/doc/msds/msds-display.asp?materialid=NX0416 http://www.emdchemicals.com/analytics/doc/msds/msds-display.asp?materialid=M822148 http://www.jtbaker.com/msds/englishhtml/T1054.htm http://www.chemdat.de/cdrl/catalog/standard/en/ (Cat. No: 115363) Page 4 of 6 Printed on: 13 February 2016 Signature of Lab Officer in Charge:……………………………………………………………….. Date:………………………… Signature of Lecturer in Charge:………… …………………………………….. Date:… …………………….. Prepared Risks Assessments for standard equipment and operation are with the kind permission of Dr. Ken MacNeil, School of Chemistry, University of Bristol. Page 5 of 6 Printed on: 13 February 2016 Activity being assessed: Note any activity to be used which entail risk (e.g. use of glass vacuum apparatus, high pressures, high voltage, radiation, high temperatures). Give reference to any special protocols to be followed, and if appropriate attach copies to the risk assessment form. State any additional precautions taken to minimise risk. Known or expected hazards associated with the activity: FOR EACH CHEMICAL, read the MSDS and note:a) Particular hazards (e.g. highly toxic, carcinogenic, corrosive, flammable, pyrophoric, explosive, volatile, dust hazard). Note any dangerous combinations of properties (e.g. volatile and toxic). b) Requirements for safe handling (e.g. fume cupboard, inert atmosphere, low temperature). c) How to dispose of residuals Dispose to drain, with water dilution Neutralise, then to drain with suitable dilution To flammable liquid waste receptacle To non-flammable liquid waste receptacle Keep for recovery/recycling Keep for special disposal later (e.g. heavy metals) Double bag and dispose to dry waste Special procedure (specify) Incompatible materials (special precautions) Note any dangerously incompatible materials and hazards arising from contact of any reagents and substances used with common materials such as paper, benches, hoses, etc. Measures to be taken to reduce the level of risk Include hazards of previously unknown products. Location of work – laboratory, open bench, fume cupboard Level of risk remaining: Likelihood and consequences of any accident or unforeseen events whilst carrying out the activity. When this has been done, choose the appropriate procedure:a) Close supervision and/or attendance of trained first-aider needed. b) Specific approval of supervisor needed. c) Training is needed prior-to or during the operations specified. d) Training is complete and only general laboratory competence required. e) No risk perceived. Emergency action: a) Any special requirements to deal with accidental spillage or leakage. b) What to do in the event of accidental exposure (skin contact, inhalation, etc.). Page 6 of 6 Printed on: 13 February 2016