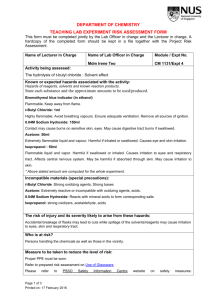

DEPARTMENT OF CHEMISTRY TEACHING LAB EXPERIMENT

advertisement

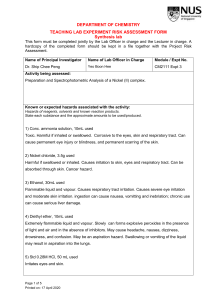

DEPARTMENT OF CHEMISTRY TEACHING LAB EXPERIMENT RISK ASSESSMENT FORM This form must be completed jointly by the Lab Officer in charge and the Lecturer in charge. A hardcopy of the completed form should be kept in a file together with the Project Risk Assessment. Name of Lecturer in Charge Name of Lab Officer in Charge Module / Expt No. A/P Khoo SB / Asst Prof Toh CS Activity being assessed: Ms Tang CN CM3292 / 5 Cyclic voltammetry Known or expected hazards associated with the activity: Hazards of reagents, solvents and known reaction products. State each substance and the approximate amounts to be used/produced. See Appendix 3.5 Incompatible materials (special precautions): Potassium ferricyanate : acids and ammonia. The risk of injury and its severity likely to arise from these hazards: Potassium ferricyanate : explosion may occur when in contact with ammonia. Cyanide fumes emitted when heated to high temperature. Who is at risk? Person performing the experiment and those in close proximity. Measure to be taken to reduce the level of risk: Eye protection to be worn, keep away from inorganic acids and ammonia. Training prerequisites: General laboratory competence. Use of Glassware Use of a Potentiostat Level of risk remaining: Low. Emergency action if : Spill: (i) (ii) (iii) Eyes : Flush eyes with plenty of water for at least 15 minutes, occasionally lifting the upper and lower eyelids. Get medical aid. Skin : Wash affected area with water for 10mins. Remove contaminated clothing. Consult physician if necessary. Bench: Spillages on the work bench should be mopped up with a piece of cloth immediately. Fire: not expected to be a fire hazard Is the experiment suitable for out-of-hours operation ? References if any: Refer to the following MSDS for more information potassium ferricyanate : http://hazard.com/msds/f2/bmd/bmdnv.html Potassium nitrate : https://fscimage.fishersci.com/msds/91339.htm Page 1 of 4 Printed on: 12 February 2016 Yes No Signature of Lab Officer in Charge:……………………………………………………………….. Date:………………………… Signature of Lecturer in Charge:………… …………………………………….. Date:… …………………….. Prepared Risks Assessments for standard equipment and operation are with the kind permission of Dr. Ken MacNeil, School of Chemistry, University of Bristol. Page 2 of 4 Printed on: 12 February 2016 Activity being assessed: Note any activity to be used which entail risk (e.g. use of glass vacuum apparatus, high pressures, high voltage, radiation, high temperatures). Give reference to any special protocols to be followed, and if appropriate attach copies to the risk assessment form. State any additional precautions taken to minimise risk. Known or expected hazards associated with the activity: FOR EACH CHEMICAL, read the MSDS and note:a) Particular hazards (e.g. highly toxic, carcinogenic, corrosive, flammable, pyrophoric, explosive, volatile, dust hazard). Note any dangerous combinations of properties (e.g. volatile and toxic). b) Requirements for safe handling (e.g. fume cupboard, inert atmosphere, low temperature). c) How to dispose of residuals Dispose to drain, with water dilution Neutralise, then to drain with suitable dilution To flammable liquid waste receptacle To non-flammable liquid waste receptacle Keep for recovery/recycling Keep for special disposal later (e.g. heavy metals) Double bag and dispose to dry waste Special procedure (specify) Incompatible materials (special precautions) Note any dangerously incompatible materials and hazards arising from contact of any reagents and substances used with common materials such as paper, benches, hoses, etc. Measures to be taken to reduce the level of risk Include hazards of previously unknown products. Location of work – laboratory, open bench, fume cupboard Level of risk remaining: Likelihood and consequences of any accident or unforeseen events whilst carrying out the activity. When this has been done, choose the appropriate procedure:a) Close supervision and/or attendance of trained first-aider needed. b) Specific approval of supervisor needed. c) Training is needed prior-to or during the operations specified. d) Training is complete and only general laboratory competence required. e) No risk perceived. Emergency action: a) Any special requirements to deal with accidental spillage or leakage. b) What to do in the event of accidental exposure (skin contact, inhalation, etc.). Page 3 of 4 Printed on: 12 February 2016 Appendix 3.5 Reagent Amount used/produced Expected hazards 30mL May cause irritation to eyes and skin. K3Fe(CN)6 Concentration 50ppm in 0.1M KNO3 K3Fe(CN)6 4mM in 0.1M KCl 50mL “ KNO3 0.1M 250mL May cause irritation to eyes and skin. Page 4 of 4 Printed on: 12 February 2016