Creating Patient-Pleasing Eyewear - by Palmer R

advertisement

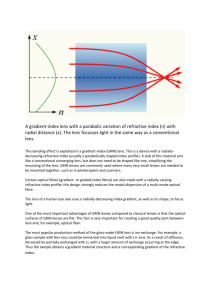

Reproduced with permission of Lenses & Technology, Jobson Publishing LLC, copyright 1999. Creating Patient-Pleasing Eyewear - by Palmer R. Cook, OD Whether you know it or not, if you start with a lens prescription and a patient, and place an order for finished eyewear, you are not just an “ophthalmic pharmacist,” you are an eyewear designer! Successful eyewear designers- you included- strive to convert the ‘scrip the doc has written into eyewear that meets four important needs for your patients. It allows them to see well, it makes them look good, it’s comfortable, and the value perceived by the patient is equal to or greater than the cost of the new eyewear. Fortunately we have lots of great ophthalmic technology which can yield all of these intended patient pleasing benefits. There’s More To It Than TechnologyIn designing eyewear you should consider more than just Rx, eyesize, bridge size, pd, and the many technological options available today. It’s also important to consider Pupil Size, Previous Eyewear History, and Patient Expectations. These areas are often overlooked, yet they can yield very helpful information. +Larger pupil size means a relatively decreased depth of field and possibly less tolerance to marginal astigmatism and peripheral power gain. Lean toward a smaller eyesize, in trifocals to deeper intermediate, and, in PAL’s, a harder lens design. +Knowing the patient’s previous experience with eyewear is often helpful. “Have you ever had a pair of glasses you couldn’t wear?” can be a wonderfully revealing question. A patient with a history of not being satisfied with his or her last one, two, or three sets of spectacles is an odds on favorite for having problems with yet another set. Perhaps medication, a physical problem such as a fluctuating blood sugar level, or an unequal half pd, has been overlooked. This important pre-design question can alert you to the presence of an easy-to-miss complicating factor and help you avoid tons of trouble for everyone. +Knowing the size, lens material, and other particulars of the previous eyewear will help you predict what changes will be apparent when the new eyewear is dispensed. Patients generally don’t appreciate paying for “new and improved” unless the thickness, weight, appearance, or lens performance is perceptibly different from their previous eyewear. +Not all eyewear options can be combined with success so look before you leap, and think before you speak or you may generate patient expectations that cannot be met. A good example could be the new atoric lenses which decrease peripheral aberrations in both major meridians. These lenses improve ‘away from center’ vision for patients with astigmatism, but they are not yet available in every lens material or style. Your patient’s confidence may suffer if you have to call with a “Well, we just can’t quite have your glasses made the way we had decided” statement. +Patients naturally have expectations about the eyewear they have ordered. It is advisable to demonstrate options such as tints, antireflection treatment, and aspheric curvature at the time of ordering the new eyewear and again at the dispensing. For example, the patient’s new aspheric lenses may be a lot flatter, optically speaking, but, especially in a small eyewire, the difference may not be easily perceived unless the difference is demonstrated with a lens clock at the dispensing table. There are no absolute guidelines as to when to use some of the new technology options except in the more extreme situations. In borderline situations, it is best to have an idea of what the patient expects, is sensitive to, and can comfortably tolerate. For example, switching to a high index, low specific gravity material for a mid-range Rx in a small eyewire may not save enough weight to be significant. On the other hand, if your patient is highly sensitive, with a pencil thin nose and paper thin skin, even fractions of an ounce in weight reduction can be important and greatly appreciated. Never Overlook Key FactorsThere are five key factors which should be considered when deciding which options to include in a patient’s new eyewear. As an eyewear designer, you need to be sensitive to all of these factors. If you aren’t, you can bet your patients and their families and friends will be sensitive to them, especially and unfortunately, after the eyewear has been dispensed. These factors are: APPEARANCE In the minds of the public, “strong” lenses mean weak eyes and call attention to a perceived physical deficiency. For hyperopes “strong” means thick lenses that bulge forward from the spectacle frame causing the eyes to be magnified and glassy in appearance. For myopes, “strong” means beady, minified eyes trapped in concentric bulls eye rings of internally reflected light. These strong minus lenses also have thick edges that occasion sideways glances from friends, relatives, and casual passersby. Thickness- Excessive thickness is the primary cause for an undeservedly “strong” appearance. Five ways of decreasing thickness for both myopes and hyperopes are: +Achieve “O” decentration (i.e. the frame p.d. equals the patient’s pd). The frame pd is determined by adding the eyesize to the bridge size. A 48-20 frame fit on a patient with a 68 pd eliminates the need to add to lens thickness to compensate for decentration. +Decrease the eyesize. This decreases the edge thickness for myopes and the center thickness for hyperopes. Caution: If you decrease the eyesize and finish a plus lens from a large, finished blank, you will end up with excessive edge and center thickness. The solution is to have your lab surface the lenses so that you have a minimal finished edge thickness. +Use and aspheric design. Flatter peripheral curves tend to reduce edge thickness. +Increase the index. Higher index lenses have more light bending muscle and therefore don’t have to be curved as much to achieve the needed prescription. There’s no doubt about it, flatter curves do mean thinner lenses. +Use polycarbonate, which permits safe, ultrathin centers. Reducing the center thickness of a lens from 2.0 to 1.5 millimeters means that every point on the lens, including the edge, will be a half millimeter thinner – affording both an improvement in appearance and a savings in weight. Part of the art of achieving a good lens design lies in the way you mix these five ways of thinning. The patient’s facial characteristics, prescription, and vocation and avocations are the primary factors which determine which of these factors can be used to good and safe effect. Facial Inset- High myopes have a facial inset problem that optically indents the portion of their head that is seen through their glasses. This facial inset problem is a minification issue that will not change with index changes or asphericity. Using a smaller “A” measurement and a frame with wider eyewires makes facial inset less noticeable. Savvy dispensers often use frames with turnback endpieces to allow a smaller eyewire to look wide enough in these situations. Turnback endpieces extend laterally from the eyewire before turning back toward the ear. Anti-Reflective Lenses- Patients who wear low power lenses are prone to problems with ghost images. The lower the power, the worse the problem. Patients under one diopter of power are the most affected. The single most effective approach for this problem is to use antireflective lenses, and you should be proactive, specifying the antireflective lenses initially, rather than waiting for the patient to complain. The most troubled patient with this will be the presbyope with a low distance Rx having their first experience with spectacles. Watch out! Antireflection coating should always be considered when using higher index lenses. Reflections detract from appearance, and reflections may be as much as 30% or more intense when high index material is used. This is because more light “splashes back” from high index lenses due to their greater power to slow light compared to a lower index lens. For hard resin, at index 1.49, the reflectance is about 4%. Polycarbonate, at index 1.58, reflects about 5.15% of incident light, or about 28% more than hard resin. Using antireflection coating not only improves lens performance and increases light transmission for the patient, it also improves appearance by making the light reflected from the lenses less bright! ABERRATIONS All ophthalmic lenses perform well when the line of sight passes only through the optical center, but when the line of sight deviates, passing through the peripheral portion of the lens the effective power of the lens changes and unwanted astigmatic power changes occur – even in spherical lenses. These effects and other unwanted optical distortions are called aberrations. If only we had but one eye, immobile and fixed firmly in the center of our face, and two noses to support the weight of eyewear! Alas, the basic human design incorporates two eyes that are constantly roving about. (Just visit your local singles bar on a Friday or Saturday night if you doubt it.) Since it is difficult to train patients to use only their neck muscles as they change their direction of gaze and since the neck muscles are unrelated to convergence or divergence, we must design lenses that give the best possible performance away from the center – reduced aberration lenses. Corrected Curve & Aspheric- Some peripheral aberrations, particularly marginal astigmatism and curvature of field, are reduced in ophthalmic lenses through “corrected curve” or more recently developed aspheric designs. Aspheric lenses not only decrease peripheral aberrations, their flatter curves give a less strong appearance, especially in larger eyesizes. Manufacturers of high index materials recommend the aspheric lens curvatures that minimize peripheral lens aberrations. Increasing these curvatures beyond manufacturers’ recommendations for better lash relief, or decreasing them for a “less bulgy” appearance is not a good idea. Chromatic Aberration & Abbe- Chromatic aberration, or color dispersion, is the other aberration over which you have some control. Abbe numbers are used to indicate how much chromatic aberration is present in the various lens materials. These numbers range from about 32 to 60, with the higher numbers indicating less chromatic aberration. Patients in the mid-range prescriptions are probably more sensitive to chromatic aberration than either low or high Rx patients. Low power lenses just don’t separate the colors far enough for chromatic aberration to be a problem. Patients wearing high power lenses tend to stay near their lens centers simply because they see better if they do. As a result they may be less annoyed by chromatic aberration since it is always less bothersome when looking through the optical center. Many high Rx patients have also learned the virtue of tolerance by experience with their high power lenses. This tolerance helps them ignore increased chromatic aberration, especially if their new eyewear has offsetting virtues such as lighter weight or increased break resistance. Prism Prescriptions- Patients with prism prescriptions in all power ranges will be less tolerant of increased chromatic aberration than patients with non-prism Rx’s in the same power ranges. Lower their Abbe with caution. Patients with low refractive corrections who require prism prescriptions, usually pediatric patients, will have more problems with reflections and “ghost images.” They should have antireflective lenses. It is important not to decenter aspheric lenses to achieve a prismatic correction. Patients who require both a prismatic correction and an aspheric design must have ground in rather than decentered prism. Decentering an aspheric lens to achieve a prism effect will cause a prescription power error for the patient. ADAPTION The human body is marvelously adaptable. Witness the lips stretched with metal plates, necks elongated with brass rings, and other body parts permanently and successfully deformed in other cultures, and the spinal misalignments of women in our own culture who regularly wear high heels. Since I have no experience adapting to high heels, much less lip plates and neck stretching rings, I can’t make a first hand comparison, but it is almost axiomatic that ophthalmic lenses of the correct power and of any reasonable design will be adapted to within 7 to 10 days of constant wear. Unfortunately, it is a rare dispenser who cannot tell at least a few grim and painful tales of “adaptation” problems. The root cause of many of these horror stories lies in the patient’s fear that one, the problem will persist, and two, there is no ultimate benefit associated with adapting to the new lens design or material. True adaptation problems related to using new ophthalmic technology of index are generally only mild to moderate. If a high index material or an aspheric is used for better comfrot and appearance, patients should be motivated, without unduly suggesting problems, to wait out any initial optical adaptation period. WEIGHT Weight is a function of the volume of space that a lens occupies and the specific gravity of the material of which it is made. A strong lens can be made significantly lighter by using a material with more light bending muscle, even if that material has a higher specific gravity, provided that the lens volume is sufficiently decreased. The kicker in this is: What is “significantly lighter?” How much more light bending muscle is enough? AND, what does “sufficiently decreased volume” mean? From a practical standpoint the lens designer must artfully mix the ingredients of light bending muscle, eyesize and bridge size, cost, and patient tolerance considerations to achieve an acceptable weight factor. Use the rule of 8’s & 2’s (below) to get an idea of how much weight will change with eyesize changes. In the days of large eyesizes, a drop of 16% or 20% in lens weight was more likely to be significant than the same percentage drop in today’s smaller eyesizes, so advice should be tempered in this area. COST/VALUE Patients must perceive a value that is equal to or greater than the cost or they will experience that disturbing phenomenon – buyer’s remorse. They must accurately perceive high value at the time they order their eyewear, and that perception must persist as they receive and wear their new eyewear. When patients are asked to pay more for options and improvements they, rightfully, expect to receive a perceptible benefit that justifies the cost. On the other hand, not using an option when it is needed can also result in perceived value and buyer’s remorse problems. The trick is knowing when to use those options. Consider All Your Options- Using a higher index alone, without trying for “no decentration,” reduced eyesize, and other design options may not get a “Wow!” reaction from the patient, and can lead to buyer’s remorse problems- even though the higher index helps. The rule is: Consider all available options. Patients invariably compare the new eyewear to the old. If they are paying a premium for special options they will always have the expectation of receiving a significant and perceptible benefit. Select carefully from all your lens design options to exceed your patient’s expectations and achieve a patient-acceptable balance between benefits and cost. Dr. Cook is director of the Practice Support Division of Diversified Ophthalmics, Inc. in Cincinnati, Ohio. He has served as a clinical instructor at both Ohio State University and University of Houston College of Optometry, and has lectured extensively in the areas of mechanical and ophthalmic optics. The RULE of 8’s & 2’s: 1.) When you increase the size of the eyewire by one step (i.e. 2mm) the weight of the lens will increase by about 8% if the lens is plano. 2.) If the lens has optical power (either plus or minus) you will have another 2% increase in weight for every diopter when you increase the eyesize one step. For example, a patient with a –8.00 Rx who jumps from a 50 to a 52 eyesize will have an increase of about 24% in weight. There is an 8% increase (think of every lens as having a plano carrier that increases 8% when the eyesize goes up 2mm) plus another 2% per diopter (2% x 8 = 16%). Adding the carrier’s 8% to the power’s 16% gives a 24% total increase in lens weight. The Rule of 8’s and 2’s is an approximation that works for all lens materials as long as you compare apples to apples. In other words a –8.00 that increases by 2mm in diameter will be about 24% heavier whether it is made of crown, hard resin, or even high index. The Rule of 8’s and 2’s doesn’t work in comparing lenses fabricated from different materials, but using it helps educate patients to the need for a different material. Reproduced with permission of Lenses & Technology, Jobson Publishing LLC, copyright 1999.