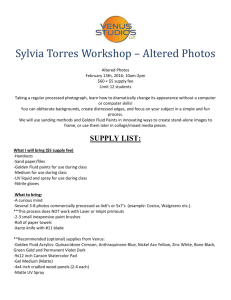

Anc Com sum 130406

advertisement

Accumulators Performance The accumulator is initially charged to a pressure P0 that is set at a level lower than the minimum operating pressure P1. The pressure of the gas will vary with changes in the volume, but the relationship between these parameters will depend on the amount of heat transferred to the surroundings. It is usual to assume a polytropic expansion index for the gas the value of which depends on the operating times and the duty cycle. Gas P,V Separator Accumulator pressure Referring to Figure 2, the gas states are defined as: Pre-charge: Minimum operating: Maximum operating: pressure P0 and volume V0. pressure P1 and volume V1. pressure P2 and volume V2. For a gas having a mass 'm', an absolute temperature 'T' and a polytropic index 'n', the universal gas laws for a perfect gas give: PV n cons tan t (1) PV mRT (2) R = Universal gas constant The accumulator is connected to an appropriate point in the hydraulic system such that when the pressure falls the gas will expand and deliver a volume of fluid V into the hydraulic system thus maintaining its pressure. The maximum volume is given by: V V1 V2 (3) Using a polytropic index, n1, for compression from V0 to V2, for the period when the fluid pressure increases to its maximum value, equation (1) gives: P0V0n1 P2V2n1 Thus P V2 0 P2 1 n1 V0 (4) Also, for the gas expansion from V2 to V1 with a polytropic index of n2: P V1 2 P1 1 n2 V2 (5) Equations 4 and 5 with equation 3 give: P V V0 0 P2 1 n1 P2 P1 1 n2 1 (6) The values of the polytropic indices cannot be accurately predicted and it is usual to take the value of n1 as 1 (isothermal) and n2 as for the gas, where this value is obtained for the expected operating temperature and pressure. Thus equation 6 produces: V0 P2 P 0 P2 P1 1 1 V (7) This equation gives a conservative value for most applications. In certain cases, e.g. high or low temperatures, it may be necessary to apply a correction factor and, in those situations, information should be obtained from the manufacturer. The value for can be obtained from Figure 3 that applies to real gases and should be used in accumulator sizing calculations. -430C Adiabatic Index 00C 470C 1070C 0 50 100 150 200 Pressure bar 250 300 350 Variation in adiabatic index with pressure and temperature for nitrogen Contamination control Filters Differential pressure device Mounting face Sampling port Seal Bypass valve Element support Removable bowl Filter element High-pressure filter (Pall) The main features of a replaceable element high-pressure filter are shown in Figure 6. As the fluid passes radially inward through the element contaminant is trapped in the material. With time the pressure drop across the filter will increase at a rate that is dependent on the fluid condition and eventually this will cause the bypass valve to open thus passing contaminated fluid directly into the system. However, the pressure drop can be monitored either mechanically or by electronic methods and this aspect is an important feature in a properly maintained system. The performance of a filter is based on its ability to trap particles which is defined by its beta ratio, , that is obtained from appropriate test methods. The beta ratio is defined as: x No . of particles particle size' x' upstream No . of particles particle size' x' downstream The beta ratio is defined for particle sizes above the given level because the number of trapped particles varies with the size, which is referred to as a distribution. Filters are selected on the basis of achieving the desired contamination levels and having sufficient contaminant holding capacity to maintain the required contamination levels under the worst envisaged circumstances. Various selection methods are available from different filter manufacturers, the majority of which are based on an absolute filter rating at a given ratio. Figure 7 contains an example showing the performance of different elements with a x = 200 rating where x is the minimum particle size for a beta ratio of 200. Contaminant ingression R Q,ND System Q,NU NU ND Generally it is not feasible to analyse systems in respect of the generation of contaminant particles and ingression from the environment. However a simple model such as that in Figure 8 can be used to show that: R and Q 1 R Q( 1 ) NU ND For beta ratios in the region of 10 and above, ND reduces as the inverse proportion of the beta ratio, which is represented by the chart. ISO 4406 standard code for contamination levels. Coolers Thermodynamic aspects C P T as dm QP dt P dm Q , then T dt C P Where dm = Mass flow rate dt kg s-1 Cp = Specific heat T = Temperature 2.1 kJ kg-1 K-1 (typical value) K = Density P = Pressure loss 870 kg m-3 (typical value) N m-2 m3s-1 Q = Flow Therefore, for a system with a 100 bar pressure loss, the temperature rise will be: T The input power, W0 QP P C p 5.5 C T Wo C pQ where Wo is the power input given in Watts. Cooler characteristics Heat dissipation (kW) 4.3 Oil flow (L/min) Cooler Performance Characteristics The cooling characteristics are usually presented in the form shown in Figure 11, which will apply for a particular value of inlet temperature difference. For different values a correction factor is applied to suit the application. Reservoirs If possible, the reservoir design should be such that any entrained air is released before the fluid is passed to the system inlet. A baffle can be used to increase the flow circulation and hence improve the air release. It also reduces the fluid movement due to motion of the reservoir itself. Passing the return flow through a diffuser in the reservoir reduces the fluid velocity and, by directing the fluid away from the bottom of the reservoir, reduces the re-entrainment of solid contaminant and water from the bottom of the reservoir. Transient changes in the fluid level and the release of air require the fitment of a breather. This must contain a filter that is sized to the minimum requirements of the system. It is preferable that the fluid is filtered during topping-up or replenishing.