BIP_21353_sm_suppinfo

advertisement

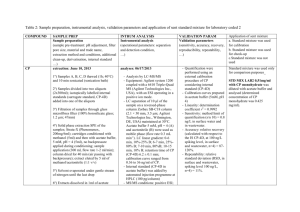

Supporting information Experimental details and protocols General procedures HPLC RP-HPLC analysis was performed on a Agilent 1100 system using either Agilent Zorbax or Vydac C18 silica column (typically 4.6mm x 50mm, 5m, 300 Å). Detection was by UV at 214 nm and 280 nm. Elution was performed using a suitable gradient of standard water/0.1% TFA (A) and acetonitrile/TFA (B) buffers . Preparative RP-HPLC was performed on a Waters system (2545 gradient pump and 2489 detector) using a gradient similar to the analytical system and either a 2 or 5 cm C18 column. LC-MS of substrates and small molecules LC-MS analysis was performed on a PE-Sciex API 150 mass spectrometer equipped with two Perkin Elmer Series 200 Micro pumps, a Perkin Elmer Series 200 auto sampler, a Applied Biosystems 785A UV detector. A Waters Xterra 3.0 mm x 50 mm 5 C-18 silica column was eluted at 1.5 ml/min at room temperature using the same buffers as for the HPLC system. It was equilibrated with 5 % B-buffer, eluted for 1.0 min with 5% B-buffer and then with a linear gradient from 5 to 90% B-buffer over 7 min. Detection was by UV detection at 214 nm and total ion current. A fraction of the column eluate was introduced into the ion spray interface of a PE-Sciex API 100 mass spectrometer. The mass range 100-800 amu was scanned every 2 seconds during the run. ESI TOF MS of protein derivatives MS spectra of protein derivatives were acquired on an Agilent LC/MSD TOF model G1669A, connected to an Agilent 1200 HPLC system. Samples were loaded to a Zorbax C3 column (4.6x50 mm, 5m, 300 Å) and eluted with a gradient from 25% to 90% Bbuffer. Protein purification Protein chromatography was performed on an Äkta Explorer chromatographic system and columns from GE Health Care. Anion exchange chromatography (AIEX) of hGH derivatives was carried out using a Q-Sepharose HP 26/10 column. Starting buffer was 20 mM triethanolamine buffer pH 8.5 and eluting buffer was starting buffer + 0.2 M NaCl. The compounds were typically eluted with a gradient of 0-75% eluting buffer over 15 column volumes. De-salting and buffer exchange was performed using a HiPrep 26/10 column. SDS-PAGE SDS poly-acrylamide gel electrophoresis was performed using NuPAGE 4%-12 % Bis-Tris gels (Invitrogen). The gels were Coomassie stained (Invitrogen LC6065) and where relevant also stained for PEG with barium iodide as described by M. M. Kurfurst in Anal.Biochem. 200(2):244-248, 1992. Capillary electrophoresis Capillary electrophoresis was carried out using an Agilent Technologies 3DCE system (Agilent Technologies). The capillary was a 64.5 cm (56.0 cm efficient length) 50 µm i.d. “Extended Light Path Capillary” from Agilent. UV detection was performed at 200 nm (16 nm Bw, reference 380 nm and 50 nm Bw). The running electrolyte was phosphate buffer 50 mM pH 7, except for separations of hGH-BAP conjugates where phosphate buffer 50 mM pH 2.5 was used. The capillary was conditioned with 0.1 M NaOH for 3min, then with Milli-Q water for 2 min and with the electrolyte for 3min. After each run, the capillary was flushed with Milli-Q water for 2 min, then with phosphoric acid for 2 min, and with Milli-Q water for 2 min. The hydrodynamic injection was done at 50 mbar for 4.0 s. The voltage was +25 kV. The capillary temperature was 30 C and the runtime was 10-15 min. NMR Spectra were acquired on a Bruker 300 MHz instrument. Spectra were referenced to the solvent residual peak (=2.50 ppm in DMSO-d6) Peptide mapping protocol Peptide mapping was performed using Asp-N digestion of the reduced and alkylated hGH protein by standard protocols. Briefly, the protein was first treated with DTT (dithiothreitol) and iodoacetamide. The alkylated product was purified by reversed phase HPLC using a C4 column and standard TFA/acetonitrile buffer system on a Agilent HP1100 instrument. Subsequently the alkylated purified product was digested overnight with endoprotease Asp-N (Boehringer) at an enzyme:substrate ratio of 1:100. The digest was separated by standard reversed phase HPLC (C18). The resulting peptide map was compared to that of un-derivatized hGH and fractions with different retention times were collected and further analyzed using MALDI-TOF mass spectrometry with cyanocinnamic acid matrix on a Bruker Microflex instrument. Modification of hGH via 1,3-bisaminoxy propane (preparative PEGylation): compounds 1 and 2. The following solutions were prepared: a) hGH (internal Novo Nordisk batch, 100 mg, 4.5 mol) was dissolved in Na-phosphate buffer (50 mM, pH 6.0, ca. 9 ml). Subsequently, pH was adjusted to 6 and the volume was adjusted to 10 ml using Na-phosphate buffer (50 mM, pH 6.0). a) 1,3-bisaminoxypropane∙2HCl1 (2.00 g, 11 mmol) was dissolved in Naphosphate buffer (50 mM, pH 6.0, ca. 5 ml), followed by adjustment of pH and volume as for solution a. c) Microbial transglutaminase (Activa WM, Ajinomoto, 30 mg, 0.3 mg enzyme, 7.5 nmol) was dissolved in Na-phosphate buffer (50 mM, pH 6.0, ca. 9 ml), followed by adjustment of pH and volume as for solution a. Solutions a, b, and c were mixed in that order, filtered through a 0.45 m syringe filter and allowed to react at r.t. for a period of 2.5 h. At this point, CE (low pH method) and ESI TOF MS spectroscopy showed approximately 50% conversion of hGH, with approximately 80 % of the product being the desired hGH-derivative 1. Analytical data is provided in Figure 3. To the reaction mixture was added 30 ml of 2 mM aqueous N-ethylmaleimide (NEM). Subsequently, pH was adjusted to 8.0 and the solution was washed 6 times by ultra filtration (Amicon Ultracel 10K, 3600 RCF, r.t., reduce volume to 1/10) using a 1:1 mixture of aqueous NEM 2mM and phosphate buffer (50 mM, pH 8.0). After the last wash, pH was adjusted to 6.0. PEG-aldehyde 40kDa (NOF, 180 mg, 4.5 mol) in buffer (10 ml) was added to the reaction mixture. The reaction was complete within a period of 3 h. RP-HPLC and SDS-page showed high conversion of the hGH-derivative 1 to the PEGylated hGH 2. The solution of crude compound 2 was diluted with triethanolamine buffer (20 mM, pH 8.5, 10ml) and 1 M aqueous NaOH was added drop wise until pH reached 8.4 (ca. 4 drops). The solution was buffer-exchanged to triethanolamine buffer (20 mM, pH 8.5) by ultra filtration (Amicon, Ultracel 10K, 3600 RCF, r.t.) until the conductivity is was below 0.6 mS/cm-1. The final volume was 5 ml which was purified by AIEX using triethanolamine buffer (20mM, pH 8.5 (A-buffer)) and triethanolamine buffer (20mM, pH 8.5 + 0.5 M NaCl (B-buffer)). Pure fractions containing mono-PEGylated material eluted at ca. 50% B-buffer and were buffer exchanged on a HiPrep column to NH4HCO3 buffer (10 mM, pH 8.5), and freeze dried to give compound 2. Yield:33 mg. SDS-PAGE and peptide mapping analysis showed confirmed the structure of compound 2 with modification on Gln141 (see Figure 5). Synthesis of modified glutamine substrates 3-18 The substrates were prepared by standard Fmoc solid phase synthesis protocols (vide infra), except for compounds 6 and 9, which were commercially available, and compounds 5, 15, 16, and 17 which were fully or partially prepared in solution. Compound 5: Z-Gln-OSu (510 mg, 1.4 mmol) was suspended in THF (15 ml and 25% aqueous ammonia (5 ml) was added. After stirring for 5 min, the solution was clear and after another 5 min, precipitation occurred. Further stirring for a period of 30 min, filtration, washing with ether and drying in vacuo afforded Z-Gln-NH2 (5) as a white solid. Yield 390 mg (100 %). The sample contained THF and N-hydroxysuccinimide. LCMS showed m/z 280 ([M+H]+) and 302 ([M+Na]+). 1H-NMR (300MHz, DMSO-d6): Shift ppm 1.71 (m, -H, 1H), 1.78 (m, -H, 1H), 2.10 (m, -H, 2H), 3.90 (m, -H, 1H),5.02 (s, benzyl, 2H), 6.76 (br s, amide, 1H), 7.02 (br s, amide , 1H), 7.28-7.37 (m, benzyl, amide and and carbamate, 8H). Compound 16 (15 was prepared analogously): 1,2-diaminoethan trityl resin (NovaBiochem, 2 g, 3 mmol) was swelled in NMP and drained. To the resin was added a solution of Z-GlnGly-OH (Bachem, 1.52 g, 4.5 mmol) and hydroxybenzotriazole (HOBt, 0.61 g, 4.5 mmol) in NMP followed by diisopropylcarbodiimide (DIC) (700 µl, 4.5 mmol). The reaction mixture was allowed to react for a period of 3 h, after which the resin was drained and washed with NMP (6 x 30 ml), then with DCM (6 x 30 ml), and finally drained. It then was treated with a mixture of trifluoroacetic acid (TFA, 6.3 ml), water (0.3 ml), DCM (2.9 ml) and triisopropylsilane (0.4 ml). After reaction for 1 h, the resin was filtered slowly into diethyl ether (100 ml) while stirring. The resulting precipitate was oily and was separated from the ether by decantation. The oil was re-dissolved in neat TFA (5 ml) and added to drop wise ether (100 ml). Again, the product precipitated as an oil. The oil was in a mixture of 5% aqueous ammonia (10 ml), water (5 ml) and acetonitrile (5 ml) and purified by preparative HPLC, giving the Z-GlnGly-NHCH2CH2NH2 compound. Yield 320 mg. LCMS analysis showed m/z 380 ([M+H]+). Boc-4-aminobenzoic acid (200 mg, 0.85 mmol) was dissolved in 4 ml DMF and triethylamine (117ul, 0.84 mmol) was added. The mixture was cooled in dry-ice/i-PrOH to ca. -20°C and isobutyl chloroformate (118 l, 0.89 mmol) dissolved in DMF (2 ml) was added drop wise in 1 min. The reaction mixture was stirred at ca. -20°C for a period of 30 min. The Z-GlnGly-NHCH2CH2NH2 compound from above was dissolved in a mixture of DMF (4 ml) triethylamine (117 l, 0.84 mmol), and added drop wise to the crude mixed anhydride while stirring. After 30 min after the mixture was warmed to r.t and after 3 hours the mixture was concentrated to dryness. The crude product contained the desired adduct as well as several by-products. The residue was dissolved in a mixture of 5% aqueous ammonia (16 ml) and acetonitrile (4 ml) and purified by preparative HPLC in two portions. Relevant fractions were identified by LCMS and freeze dried giving the ZGlnGly-NHCH2CH2NH-CO-C6H4-NHBoc compound. Yield 75 mg. LCMS analysis showed m/z 599 ([M+H]+) and 621 ([M+Na]+). The purified Z-GlnGly-NHCH2CH2NH-CO-C6H4-NHBoc compound was dissolved in a mixture of TFA (2 ml) and DCM (2 ml) and stirred at r.t. for a period of 30 min. It was concentrated to dryness, stripped with acetonitrile (2 x 4 ml), re-dissolved in water:acetonitrile 1:1 (5 ml) and freeze dried, leaving the pure compound 16 as a white solid. Yield 62 mg. LCMS showed m/z 499 ([M+H]+). 1H-NMR (300MHz, DMSO-d6): Shift ppm 1.74 (m, -H, 1H), 1.85 (m, -H, 1H), 2.13 (m, -H, 2H), 3.23 (m, ethyldiamine, 2H), 3.69 (d, -H Gly, 2H), 3.99 (m, -H Gln, 1H), 5.03 (m, benzyl, 2H), 6.68 (d, aminobenzoyl, 2H), 6.77 (br s, prim. amide, 1H), 7.27-7.37 (m, benzyl and prim. amide, 6H), 7.55 (d, carbamate, 1H), 7.62 (d, aminobenzoyl, 2H), 7.91 (br t, amide, 1H), 8.15 (m, amide, 2H). Compound 17: Z-GlnGly-OH (Bachem, 1 g, 3.0 mmol) was dissolved in 20 ml DMF and triethylamine (441 l, 3.0 mmol) was added. The mixture was cooled in dry-ice/i-PrOH to ca. -20°C and isobutyl chloroformate (407 l, 3.1 mmol) dissolved in DMF (4 ml) was added drop wise in 3 min. The reaction mixture was stirred at ca. -20°C for a period of 50 min. (R)-3-amino-1,2-propanediol (Fluka, 270 mg, 3.0 mmol) was dissolved in a mixture of DMF (2 ml) triethylamine (407 l, 3.0 mmol), and added drop wise to the mixed anhydride while stirring. The cold bath was removed and the mixture was warmed to r.t and stirred overnight. The mixture was concentrated to dryness. The crude product (1.9 g) was dissolved in a mixture of water and acetonitrile and purified by preparative HPLC in two rounds (the first column did not provide pure fractions). Relevant fraction were concentrated on rotary evaporator to remove the bulk acetonitrile and the residual solvent was removed by freeze drying. Yield 344 mg. LCMS showed m/z 411 ([M+H] +). 1 H-NMR (300MHz, DMSO-d6): Shift ppm 1.74 (m, -H, 1H), 1.88 (m, -H, 1H), 2.13 (m, -H, 2H), 3.02 (m, -NH-CH2-CHOH-, 1H), 3.25 (m, -NH-CH2-CHOH-, 1H), 3.29 (d, HOCH2-CHOH-, 2H), 3.50 (m, -NH-CH2-CHOH-, 1H), 3.70 (d, -H Gly, 2H), 3.98 (m, -H Gln, 1H), 5.03 (m, benzyl, 2H), 6.78 (br s, prim. amide, 1H), 7.27-7.37 (m, benzyl and prim. amide, 6H), 7.56 (d, carbamate, 1H), 7.74 (br tr, amide, 1H), 8.16 (br t, amide, 1H) Solid phase synthesis of substrates is exemplified by the synthesis of compound 14: Coupling of the first residue: To a 2-chlorotrityl chloride resin (Pepchem, 2 g, 1.5 mmol/g) was added Fmoc-(4-Boc-amino-Phe)-OH (Fluka, 2.26 g, 4.5 mmol) dissolved in a mixture of DCM (16 ml) and diisopropylethyl amine (780 µl). The slurry was stirred for 5 min followed by addition of diisopropylethyl amine (1540 µl). Stirring was continued for a period of 1 h after which methanol (5 ml) was added, and stirring was continued for an additional 15 min. The resin was drained and washed with DCM (6 x 30 ml) followed by NMP (6 x 30 ml). Removal of the Fmoc group: A mixture of 20% piperidine in NMP (20 ml) was added to the resin and left reacting for 15 min. The resin was drained and again treated with 20% piperidine in NMP (20 ml) for 1 h. The resin was drained and washed with NMP (6 x 30 ml). Coupling Z-GlnGly-OH: A solution of Z-Gln-Gly-OH (Bachem, 1.52 g, 4.5 mmol) and hydroxybenzotriazole (HOBt, 0.61 g, 4.5 mmol) in NMP was added to the resin followed by diisopropylcarbodiimide (DIC) (700 µl, 4.5 mmol). After reaction overnight, the resin was drained and washed with NMP (6 x 30 ml), then with DCM (6 x 30 ml). Cleavage from the solid support: The resin was drained to remove bulk DCM. It was treated with a mixture of trifluoroacetic acid (TFA, 12.6 ml), water (0.6 ml), DCM (5.8 ml) and triisopropylsilane (0.8 ml). After reaction for 1 h, the resin was filtered slowly within 15 min into diethyl ether (100 ml) which was stirred for an additional 30 min. The resulting precipitate was recovered by centrifugation and washed 3 times with diethyl ether. The product was dried overnight in vacuo leaving compound 14 as a white solid. Yield: 380 mg (25%). LCMS showed m/z 500 ([M+H]+). 1H-NMR (300MHz, DMSO-d6): Shift ppm 1.71 (m, -H Gln, 1H), 1.87 (m, -H Gln, 1H), 2.12 (m, -H, 2H), 2.82 (m, -H amino-Phe, 1H), 3.01 (dd, -H amino-Phe, 1H), 3.69 (d, -H Gly, 2H), 3.97 (m, -H Gln, 1H), 4.39 (m, -H amino-Phe, 1H), 5.02 (m, benzyl, 2H), 6.78 (br s, prim. amide, 1H), 6.97 (d, aromatic amino-Phe, 2H), 7.17 (d, aromatic amino-Phe, 2H), 7.30-7.37 (m, benzyl and prim. amide, 6H), 7.52 (d, carbamate, 1H), 8.13 (m, amide, 2H) Modification of hGH via modified glutamine substrates, general procedure hGH (internal Novo Nordisk batch, typically 10 mg) was dissolved in 0.15 mM), Glnsubstrate (300 mM) and mTGase (0.75 M) were incubated @ r.t. Products and conversion in the right column of table 1 refers to overnight incubation. In some instances, addition of N-methylpyrrolidone (up to 20% V/V) was necessary for substrate solubilisation. Preparative PEGylation using compound 14: Three solutions are prepared: a) hGH (40 mg, 1.8 µmol) dissolved in triethanolamine buffer (20 mM, pH 8.5, 1 ml). b) compound 14 (202 mg, 412 µmol) dissolved in triethanolamine buffer (20 mM, pH 8.5, 2 ml). The pH adjusted to 8.15 using 10 % aqueous triethanolamine (2.4 ml). c) Microbial transglutaminase (Activa WM, Ajinomoto, 36 mg, 0.36 mg enzyme, 9.0 nmol) was dissolved in triethanolamine buffer (20 mM, pH 8.5, 1 ml). Solutions a and b were mixed, and solution c (111 µl) was added. After 48 h reaction at r.t., analysis by CE (neutral pH method) showed the presence of a new product with an increased migration time and about 50% conversion to the transamidated product. To the reaction mixture was added aqueous N-ethylmaleimide (10 mM, 300 µl) and it was stored at 5 °C overnight. The mixture was buffer exchanged on a HiPrep column to triethanolamine buffer (20 mM, pH 8.5) to remove low molecular weight substances. Relevant fractions were pooled and the protein recovery 37 mg (UV A280). To the solution of transamidated hGH was added a mixture of glacial acetic acid (1 ml) and water (1 ml). pH was adjusted to 3.3 using 1 M NaOH (1 ml). To this solution was added PEG-aldehyde 40 kDa (NOF, 120 mg, 3 µmol) dissolved in a mixture of triethanolamine buffer (20 mM, pH 8.5, 1.2 ml) and water (1.2 ml). It was allowed to react for a period of 1 h, after which a solution of NaCNBH3 in water (7.1 mg/ml, 70 µl, 0.5 mg, 8 µmol) was added. The reaction was continued overnight. Analysis by reduced SDS PAGE showed the presence of a product with the expected molecular weight. The mixture was desalted on a HiPrep column. The relevant fractions (20 ml) were diluted with 20 ml water. This mixture was purified by AIEX using triethanolamine buffer (20mM, pH 8.5 (A-buffer)) and triethanolamine buffer (20mM, pH 8.5, 0.2 M NaCl (B-buffer)). Pure fractions containing mono-PEGylated material eluted at ca. 50% B-buffer and were buffer exchanged on a HiPrep column to NH4HCO3 buffer (10 mM, pH 8.5), and freeze dried to give compound 20. Yield 8 mg. SDS-PAGE and peptide mapping analysis confirmed the structure of compound 20 with modification on Lys145 (not shown). References 1 A. Shirayev, et al., Synthesis 1997, 38-40.