Apple Juice - Taunton Deane Borough Council

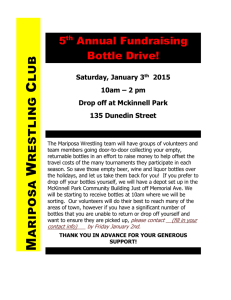

advertisement

GENERAL GUIDANCE FOR APPLE JUICE & CIDER PRODUCERS SECTION A Apple Juice 1) Pre-packed for Third Party Sales The Food Labelling Regulations 1996 lays down the labelling requirements for pre-packed foods, such as apple juice. The requirements are:a) Name of the food This must be sufficiently precise to inform the purchaser of the true nature of the food – i.e. Apple Juice Please note that if the juice has been pasteurised and described as ‘Fresh’ ,(either in the name or ingredients list) then the name of the food must also indicate this treatment eg, Fresh Apple Juice (Pasteurised). b) Ingredients list. A list is only required when additional ingredients are added to the juice, for example – ascorbic acid. Where this is the case the ingredients must be headed “Ingredients” and given in descending order of weight and the additive must be given in the prescribed manner. The manner in which an additive must be given is by category name followed by the additive’s specific name or its E number. For example: Antioxidant: Ascorbic acid OR Antioxidant: E300. Please note that Vitamin C is not sufficient, although it may be given voluntarily – for example Antioxidant: Ascorbic acid (Vitamin C). In light of the above, an example of an ingredients list would be: Ingredients: Apple juice, Antioxidant (Ascorbic Acid). c) Durability indication This should consist of either a ‘Best Before’ date or a ‘Use by’ date. The most appropriate durability indication must be chosen by the producer. d) Any Special storage conditions or conditions of use For example: A special storage condition would be: ‘Keep Refrigerated’ for unpasteurised juices with a ‘use by’ date. This condition should appear next to the durability indication. A condition of use might be: Once opened, keep refrigerated and consume within 3 days. e) Name and Address of manufacturer, packer or seller in EC. This must be sufficiently precise to ensure that correspondence can be delivered by the postal service. Quantity marking See the leaflet titled ‘Weights and Measures Act 1985’ and Section C below. Field of Vision requirement The following details must be given in the same field of vision:* name of the food * durability indication * Quantity marking 2) Pre-packed for direct sale Should you only sell Apple juice from the same premises from which you pack the product the labelling requirements are simplified to the following:a) The true name of the food b) Category of additive should the juice contain an additive with the following function: antioxidant, colour, flavouring, flavour enhancer, preservative, or sweetener. c) A quantity marking Points a) & b) can appear on a label attached to the food or on a notice displayed in close proximity to the bottles. SECTION B Cider & Perry Pre-packed For Third Party Sales In general, for alcoholic beverages over 1.2% the labelling requirements are:a) Name of the food b) Allergen labelling Should sulphur dioxide be added to the beverage and is present at concentrations at 10mg/Litre, or more, this should be indicated on the label. For example: Contains Sulphur Dioxide or Contains: Sulphites. There is a requirement to give an indication ‘with sweetener(s)’ if this applies. This should accompany the name of the food. c) Durability indication This is required for drinks with an alcoholic strength, by volume of under 10%. However, an indication is not required if it is sold in a container containing more than 5 Litres and is intended for supply to catering establishments. d) Indication of alcoholic strength This indication must take the format of: X% vol OR alcohol X % vol OR alc. X % vol. e) Name and Address of manufacturer, packer or seller in EC. This must be sufficiently precise to ensure that correspondence can be delivered by the postal service. 2) Quantity marking See the leaflet entitled ‘Weights and Measures Act 1985’ and Section C below. 3) Field of Vision requirement The following details must be given in the same field of vision: * name of the food * durability indication * Quantity marking * An indication of alcoholic strength 2 Pre-packed for direct sale and loose sales Should you only sell cider/perry from the same premises from which you pack the product the labelling requirements are simplified to the following:a) Name of the food (on label or on notice in close proximity to the food) b) Quantity marking Loose Sales (non-pre-packed sales/sales from barrel) a) Name of the food (on the barrel) b) Indication of the quantity the cider is sold in – ie. 2 Litres N.B. Should your cider contain an allergen, eg Sulphur Dioxide, it is good practice to indicate this on a notice. SECTION C Weights & Measures Requirements for Apple Juice & Cider/Perry Most producers who bottle their product in advance of a consumer order, will pack in ‘predetermined constant quantities’, for example: 75cl. When this is the case, it is important that steps are taken to comply with the Weights & Measures (Packaged Goods) Regulations 2006. The enclosed leaflets entitled ‘The Average System of Weights and Measures’ and ‘Weight & Measuring Equipment for Trade & Commercial Use’ will assist you. Measuring Container Bottles & Templates/Templets Most producers use a filling machine and Measuring Container Bottles (MCBs). MCBs are marked with information usually on or near the base indicating the quantity it holds when it is filled to a certain point. For example 250ml 33mm Э163 The above means that the bottle will contain 250ml when filled to a level 33mm from the top rim. The 163 represents the mould number. To ensure the bottles are filled correctly a template/templets should be used to check a sample of filled bottles. -These checks should be recorded. Templates should be specific for the bottles being used. Your bottle supplier should be able to assist in obtaining templates, although there are other companies who produce such templates. The templates will need to be marked with: a reference number or mark identifying the pattern or design of the MCB for which it is intended to be used; the operational temperature of the liquid and, if it is other than 20 degrees centigrade, a description of the liquid and coefficient of cubical expansion; the manufacturer's name or trade mark; an identification number. In addition the template should indicate whether it should be used with or without the lid (often called crown) on the bottle. The templates can be graduated in millimetres or millilitres, but if in millimetres you will need to use them with a conversion chart. The graduations need to be such that when the bottles are checked you can establish if the volume is within tolerance. To ensure the accuracy of the template, it would need to be certified by a Trading Standard Officer or approved laboratory and the certificate of test kept. 3 Filling or Checking by Volume It may be appropriate to fill your bottles using a calibrated volumetric flask. These are available from glassware suppliers, who can be found in Yellow pages. If you are filling bottles in this manner it is essential you purchase glassware that is marked with ‘Ex’ and this means it measures the stated quantity when the liquid is poured out of the flask. You may however choose to do sample checks on bottles already filled. This is a destructive test and therefore may not be appropriate for your system. The glassware in this case would have to be marked with ‘IN’ as it has been calibrated to measure the quantity pour into the flask. Filling or Checking by Weight In order to use these methods the density of the product would need to be established. If you already work out the Specific gravity figure for your product this figure can be used as the density to calculate the weight required to ensure the volume is correct. The following equation will assist: Mass = Density x Volume. You may choose to place each individual empty bottle on the scale and fill to the corresponding weight or only do this for a number of bottles and ensure that the fill heights on the other bottles in the batch are the same or very close. Alternatively, you may choose to do weight checks on the filled bottles. If this is the case it is important that the bottles from each batch are a constant tare. (Please note that weights of glass bottles can vary considerably and therefore a constant tare may not be achievable). For these methods a UK stamped or EC verified scale must be used – please see the enclosed leaflet on weighing and measuring trade equipment. Please note that should you pack cider in 20 Litre bags (ie. ‘bag in a box’), carrying out quantity checks by weight using the density of cider has been found by this Service to be the most efficient, particularly as it has not been possible to identify a source of calibrated volumetric flasks of this capacity. Plastic bottle checks Where you only sell your cider or juice from your own premises in bottles at the request of the customer (i.e. straight from the barrel), it is important that checks are carried out on each new batch of empty bottles to ensure they are capable of containing the quantity stated and that when filling the bottles you ensure that the declared quantity is filled on each occasion. This could be done by using one of the above methods. The advice given in this leaflet supersedes any previous advice given. It has been prepared for the guidance of Traders by Somerset County Council and is NOT an authoritative document on the law. Manufacturers will need to seek further guidance to meet their obligations. Last Updated 09.10.2012 Issued by Somerset Trading Standards Service 4