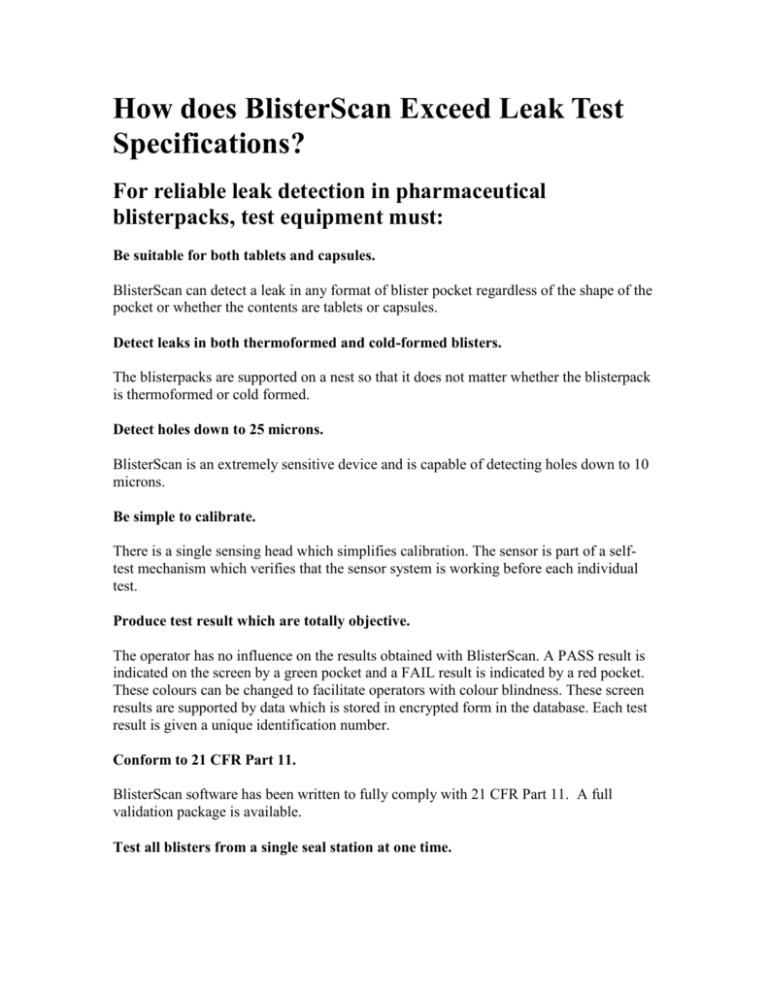

How does BlisterScan Exceed Leak Test Specifications

advertisement

How does BlisterScan Exceed Leak Test Specifications? For reliable leak detection in pharmaceutical blisterpacks, test equipment must: Be suitable for both tablets and capsules. BlisterScan can detect a leak in any format of blister pocket regardless of the shape of the pocket or whether the contents are tablets or capsules. Detect leaks in both thermoformed and cold-formed blisters. The blisterpacks are supported on a nest so that it does not matter whether the blisterpack is thermoformed or cold formed. Detect holes down to 25 microns. BlisterScan is an extremely sensitive device and is capable of detecting holes down to 10 microns. Be simple to calibrate. There is a single sensing head which simplifies calibration. The sensor is part of a selftest mechanism which verifies that the sensor system is working before each individual test. Produce test result which are totally objective. The operator has no influence on the results obtained with BlisterScan. A PASS result is indicated on the screen by a green pocket and a FAIL result is indicated by a red pocket. These colours can be changed to facilitate operators with colour blindness. These screen results are supported by data which is stored in encrypted form in the database. Each test result is given a unique identification number. Conform to 21 CFR Part 11. BlisterScan software has been written to fully comply with 21 CFR Part 11. A full validation package is available. Test all blisters from a single seal station at one time. The large format size of the BlisterScan allows a complete web width to be tested at one time. This can be custom designed to suit a particular web formation where the standard device is not suitable. Suitable for production or laboratory environments. The exterior surfaces of the BlisterScan are stainless steel and comply with GMP requirements. Be reliable and simple to use. The Blisterscan test is controlled from a user-friendly touch screen. Be non-destructive to blisters so all the product can be re-used. During the test there is no contact with any contaminating substance. Packs which pass can be added to the production batch. The product from failed packs can be deblistered and repackaged. Be possible to print out the results. The BlisterScan can be connected to a parallel printer port. There are also connection ports for storage devices such as floppy disc, CD Rom, etc. Be simple to set up and changeover from one pack to another. Set up: Batch details are entered on the screen and can be verified before the test is run. A database of the user's blister configurations is installed n the system before delivery to allow fast set-up. Before running the test, the BlisterScan displays a picture of the blisterpack from its database so that the operator can confirm that the correct blister is being tested. Changeover: The only change parts required are 2 product nests. These can be fitted in less than 1 minute. The nests are provided with a unique identification code which is identified by the scanner and confirmed on-screen. The identification number is also the trigger for the blister test information to be recalled from the database. Be bench-mounted for laboratory use or mobile for production use. The BlisterScan is available both as a bench-mounted or a mobile unit. Conclusion The BlisterScan outperforms the requirements for a production or laboratory leak tester in terms of quality, performance and flexibility. It is simple to operate and conveniently mobile.

![First Aid Training : Bronze [Power Point]](http://s2.studylib.net/store/data/005424634_1-e0b0e5e602f7c1666ebc2e9ff3f4a1b5-300x300.png)