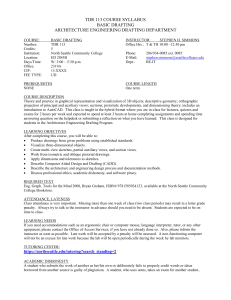

Engineering 2 Curriculum Guide

advertisement