Intro to Drafting Design

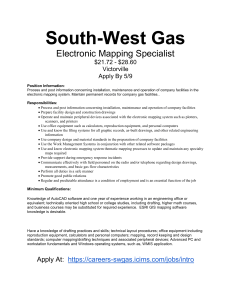

advertisement

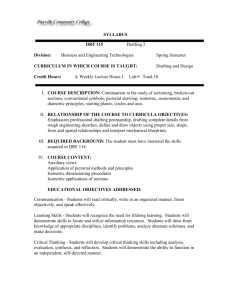

Course Syllabus 2012-2013 Program Name: Drafting and Design Technology Course Title: Intermediate Drafting Design Instructor: Mark Wellander Prerequisite: Intro to Drafting Design Course Description: Intermediate Drafting Design is a one-credit course designed to further the development of students’ knowledge regarding the use of drafting design practices and procedures. Students expand their ability to illustrate more complex objects using the Computer-Aided Drafting (CAD) system. Topics include sectioning, auxiliary views, threads and fasteners, pictorials, and the continuation of conventional dimensioning practices. Upon successful completion of the course students are able to develop section views, primary auxiliary views, thread representations and pictorial views, and apply dimensions properly on a drawing. Leadership activities, cocurricular opportunities, and employability skills are emphasized in appropriate career and technical education organization affiliations. Instructional Philosophy: Students will be expected to meet all course goals listed below, and demonstrate their understanding of the underlying concepts. The instruction will be heavily field/laboratory and application based, with a minimum of lecture and classroom work. The course requires extensive laboratory practices and demonstrations. Students will work independently as well as in teams to complete several projects that enable them to learn how to work independently to plan, construct, and trouble-shoot a variety of assignments. The community will be involved in evaluating, planning, and implementing the technical program and projects, by means of the Technical Advisory Committee. Students will be evaluated on classroom participation, exams, projects, and assignments. Students are required to pass all safety exams that is administered with a 100% mastery. Program Goals The goal of the Technical Education curriculum is to provide students access to a flexible system of rigorous school- and work-based learning planned collaboratively by students, parents, educators, and employers. This system will result in graduates having preparation for advanced study or employment. The course of study is designed to provide content that is studentcentered, allowing career pathways that include academic and Career/Technical Education courses specifically directed to students’ key interests and required skills. Upon graduation, students are prepared for postsecondary education, apprenticeship programs, employment; as well as individual, family, employer, and community success. 1 Course Goals: The students will learn how to: 1. Describe the purpose of a sectional view. 2. Select the appropriate type of sectional view to show the hidden features. 3. Show ribs, webs, fasteners, and similar features in section. 4. Rotate selected features into the cutting plane. 5. Describe and use conventional breaks and symbols. 6. Prepare a drawing with sectional views using both board drafting techniques and CAD. 7. Demonstrate the proper use of sectional view concepts. Cutting Planes Section lining and/or hatching Full Section Half Section Broken-out Section Offset section Revolved Section Removed section 8. Determine when a full auxiliary view is required. 9. Determine when a partial auxiliary view is required. 10. Develop a primary auxiliary view using board drafting or CAD techniques. 11. Develop revolutions using board drafting or CAD techniques. 12. Use the concept of revolutions to determine the true size and shape of an inclined surface. 13. Identify and describe various types of fasteners. 14. Define common screw-thread terms. 15. Specify threads and fasteners on a technical drawing 16. Draw detailed, schematic, and simplified thread representations. 17. Name and describe common thread series. 18. Describe and specify classes of thread fits. 19. Draw various types of thread fasteners using board drafting and CAD techniques. 20. List various uses of pictorial drawings. 21. Select and draw the most practical type of pictorial for a specific purpose. 22. Create isometric drawings with the isometric axes in normal and reversed positions. 23. Explain the basic differences in the three types of axonometric projection. 24. Apply measurements, notes, and symbols to a technical drawing. 25. Use ANSI and ISO standards for dimensions and notes. 26. Differentiate between size dimensions and location dimensions. 27. Specify geometric tolerances using symbols and notes. 28. Designate appropriate surface finishes. 29. Use board drafting techniques to add dimensions, notes, and geometric tolerances to a technical drawing. 30. Use a CAD system to add dimensions, notes, and tolerances to a technical drawing. Essential Question(s): 1. 2. 3. 4. 5. Why are section views necessary on technical drawings? Why are auxiliary views necessary on technical drawings? What is the relevance of representing threads and fasteners? What are the benefits to representing an object through an isometric drawing? Why is the implementation of proper dimensioning techniques vital for the field of Manufacturing and Construction? Course Outline 1. Demonstrate the proper use of sectional view concepts to create a full section, half section, broken-out section, offset section, revolved section, and a removed section. 2 2. 3. 4. 5. Create drawings of inclined surfaces. Create drawings illustrating detailed, schematic, and simplified thread representations. Utilize pictorial concepts to produce an isometric drawing. Apply dimensions, notes, and other relative information to a drafting design project. Examples: dimensions-angular, linear, tolerances Culminating Product(s): Successful completion of industry based written and performance testing Student Portfolio submission Instructional Delivery 1. 2. 3. 4. 5. Lectures Group and Individual Activities Resource Persons Demonstrations Media Presentations Assessment Plan: Grading Scale A= 100-90 B= 89-80 C= 79-70 D= 69-60 F= 59-below Evaluation: Students will be evaluated based on the quality, promptness and correctness of materials listed in the requirements. Attention will be given to practical applications of the course materials to student situations. Approximately 90% of the final grade will be determined by objective criteria, such as, tests, projects, class assignments, and portfolios. Other consideration will be given to outside assignments and subjective evaluations such as attendance, interest, participation, etc. Criteria: Method of Evaluation Percent Classroom Performance Attendance, Classroom Behavior, Safety , staying on task 10 Drawing Practice Drafting techniques and CAD 20 Projects Portfolios, Written and Oral Presentations, Completion of Drawing Assignments Accuracy of finished assignments 40 Tests Unit tests on related technical/academics 30 Grand Total 3 100% Career and Technical Student Organization (CTSO) Skills USA Available Industry Credentials: Postsecondary Degree Other Requirements Students are required to pay a student organization fee of $15.00 for the year The fee of $15.00 is due within the first two weeks from the beginning of school 4